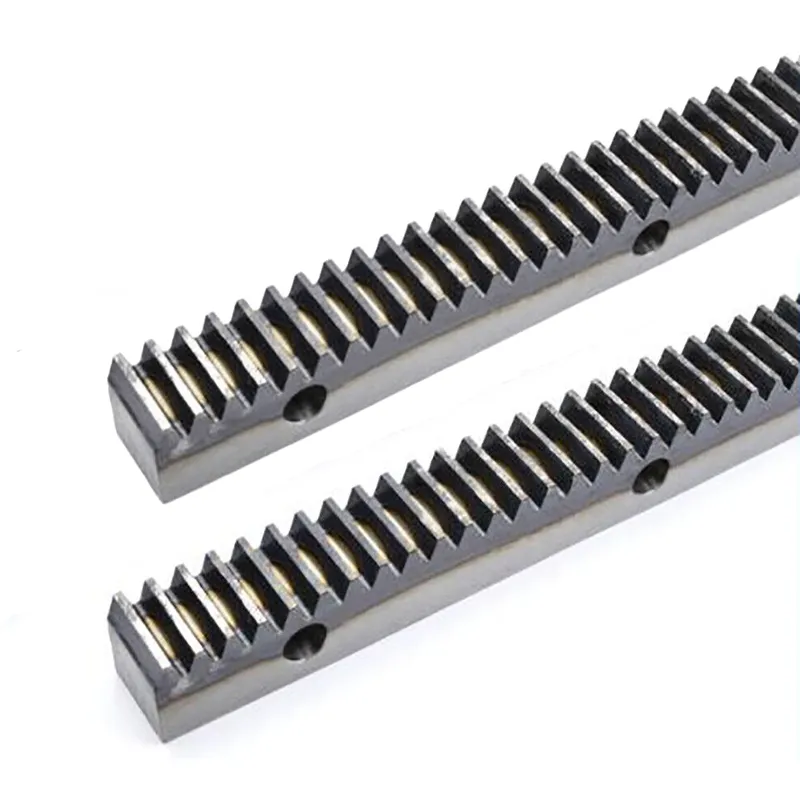

Steel Gear Racks

Steel gear racks are mechanical components used to convert rotational motion into linear motion or vice versa, forming an essential part of systems requiring precise movement. They consist of a straight or flat toothed bar designed to mesh with a round gear, known as a pinion. When the pinion rotates, it drives the gear rack to move linearly, enabling applications like lifting, sliding, or positioning in industrial and mechanical systems. Typically made from durable materials like Bright Steel C45K and Steel C45, these materials are known for their excellent machinability, high strength, wear resistance, and toughness.

Steel gear racks are mechanical components used to convert rotational motion into linear motion or vice versa, forming an essential part of systems requiring precise movement. They consist of a straight or flat toothed bar designed to mesh with a round gear, known as a pinion. When the pinion rotates, it drives the gear rack to move linearly, enabling applications like lifting, sliding, or positioning in industrial and mechanical systems.

Typically made from durable materials like Bright Steel C45K and Steel C45, these materials are known for their excellent machinability, high strength, wear resistance, and toughness. Bright Steel C45K is a cold-drawn variant of medium-carbon steel, providing improved dimensional accuracy and a smoother surface finish ideal for precision applications. Steel C45, a medium-carbon steel, balances strength and flexibility, making it versatile for heavy-load operations. Both materials can undergo heat treatment to further enhance their hardness and durability.

Steel gear racks are widely used in automation, robotics, machine tools, and heavy machinery, where reliable and efficient transmission of motion is critical. Their ability to handle high loads and offer precise movement makes them vital in numerous engineering and industrial systems.

Steel Gear Rack Dimensions

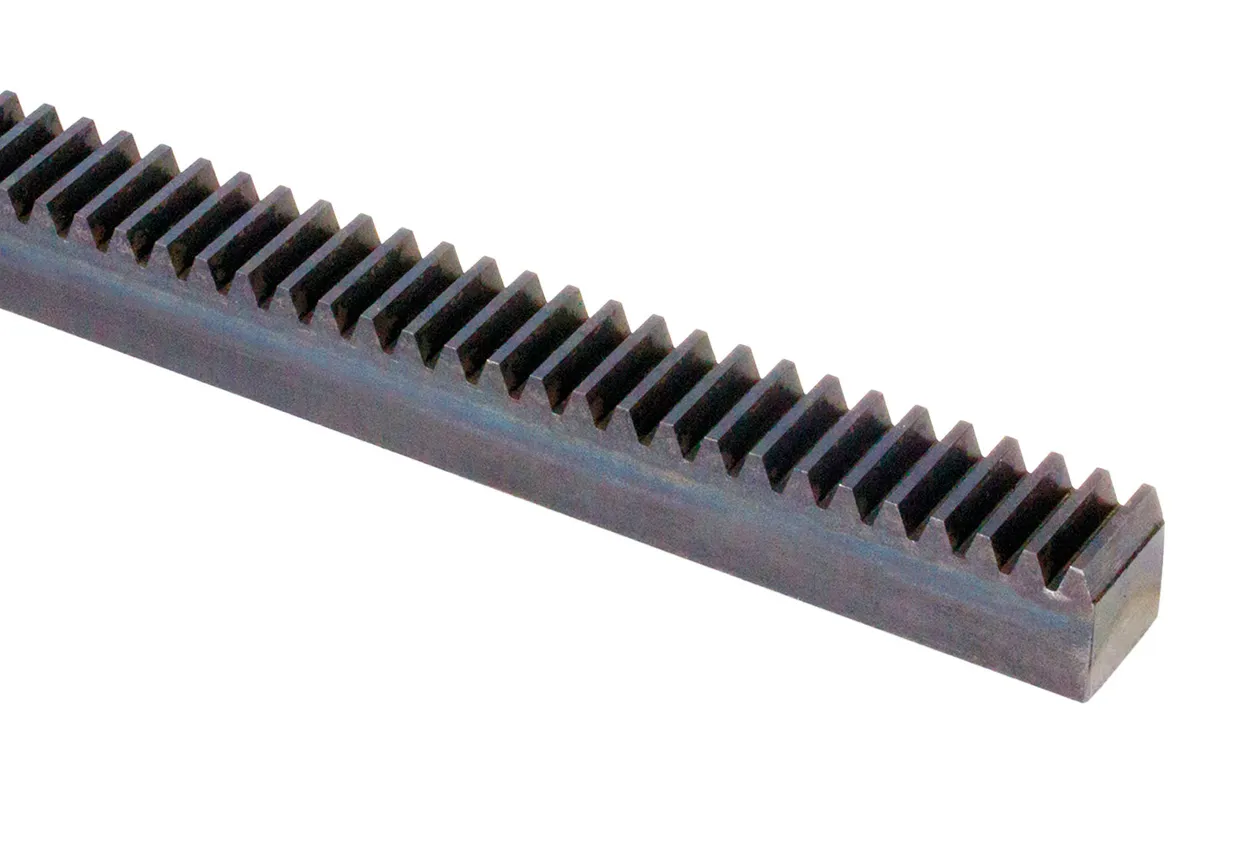

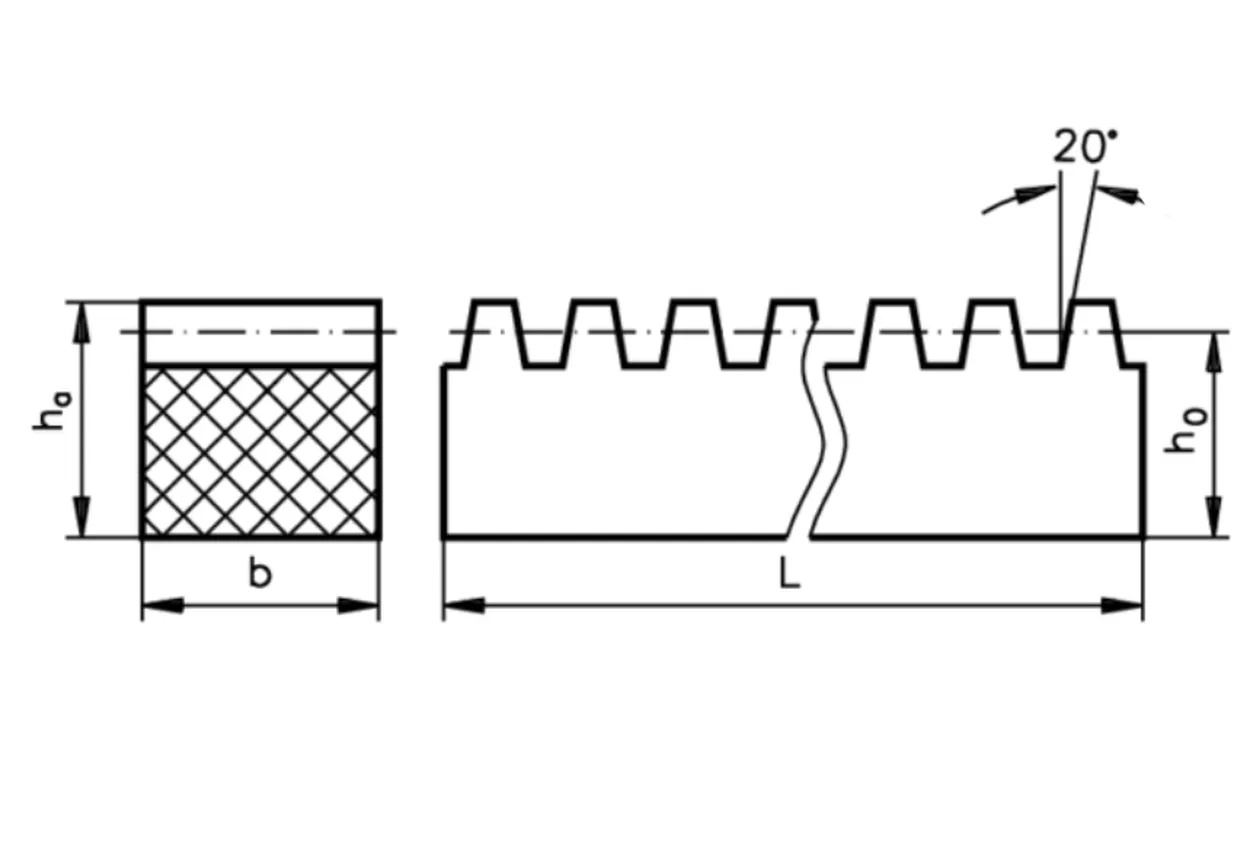

1. C45K Steel Gear Rack Dimensions

|  |

Material: Bright Steel C45K.

Reference profile 2 DIN 867 / DIN 3972. Pressure angle 20º. Milled in quality 8. Tooth area induction hardened, 54 + 4 HRC. The hardening sets the tooth quality to 10-11. Precisely straightened.

The gear racks are cut for continuous linking, with gap.

Production-related tolerances of dimensions ha and h0:

module 2: -0.2 mm

module 2.5 - 4: -0.3 mm

module 5 - 6: -0.4 mm

| Product No. | Module | b mm | ha mm | ho mm | Nom. Length L mm | Eff. Length mm | Weight kg |

| 241 886 05 | 2 | 20 | 20 | 18,0 | 1000 | 1005,0-1 | 2,77 |

| 241 886 09 | 2 | 20 | 20 | 18,0 | 2000 | 2004,0-1,5 | 5,5 |

| 242 886 05 | 2,5 | 25 | 25 | 22,5 | 1000 | 1005,0-1.5 | 4,31 |

| 242 886 09 | 2,5 | 25 | 25 | 22,5 | 2000 | 2002,5-1,5 | 8,61 |

| 243 886 05 | 3 | 30 | 30 | 27,0 | 1000 | 1008,0-1,5 | 6,27 |

| 243 886 09 | 3 | 30 | 30 | 27,0 | 2000 | 2007,0-1,5 | 12,43 |

| 244 886 05 | 4 | 40 | 40 | 36,0 | 1000 | 1005,0-1,5 | 11,14 |

| 244 886 09 | 4 | 40 | 40 | 36,0 | 2000 | 2010,0-1,5 | 22,5 |

| 245 886 05 | 5 | 50 | 50 | 45,0 | 1000 | 1005,0-1,5 | 17,5 |

| 245 886 09 | 5 | 50 | 50 | 45,0 | 2000 | 2010,0-1,5 | 35,0 |

| 246 886 05 | 6 | 60 | 60 | 54,0 | 1000 | 998,5-1,5 | 25,0 |

| 246 886 09 | 6 | 60 | 60 | 54,0 | 2000 | 1997,5-1,5 | 50,0 |

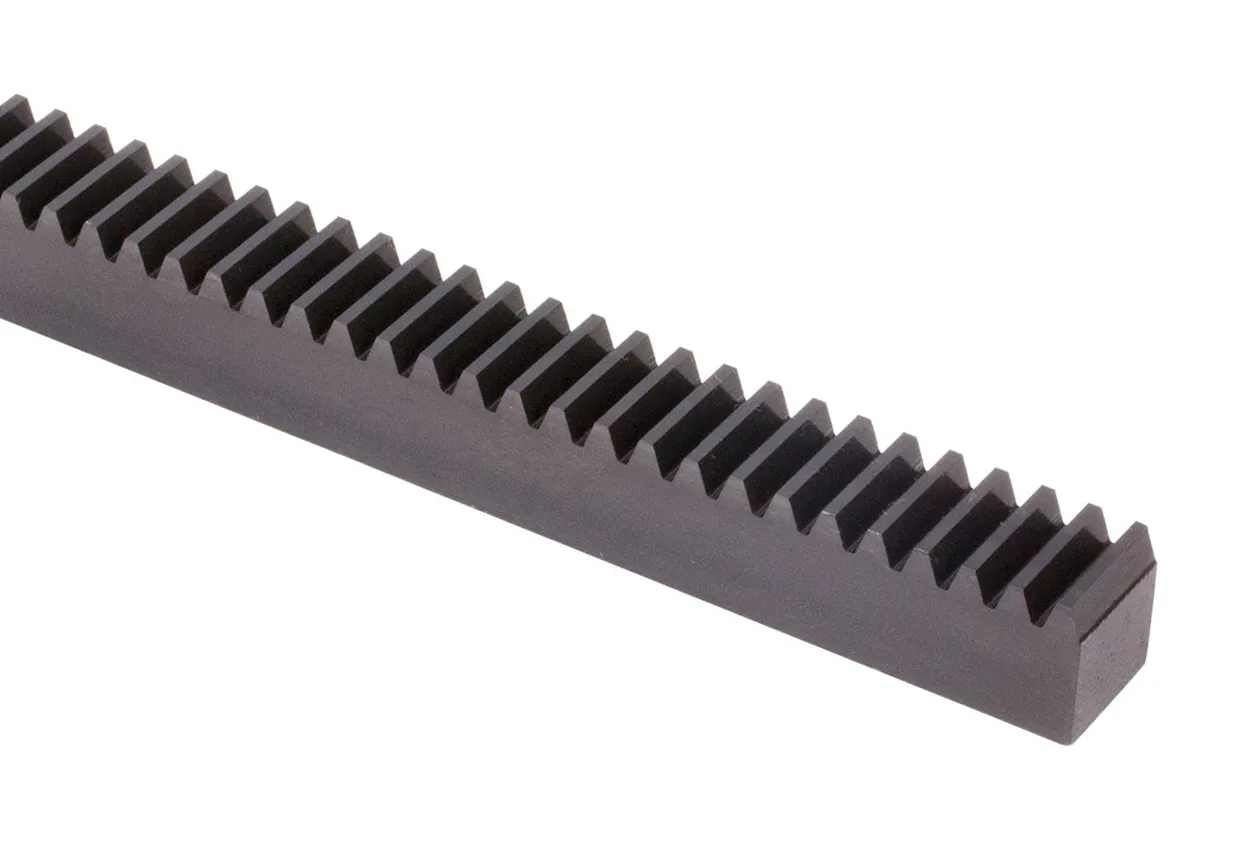

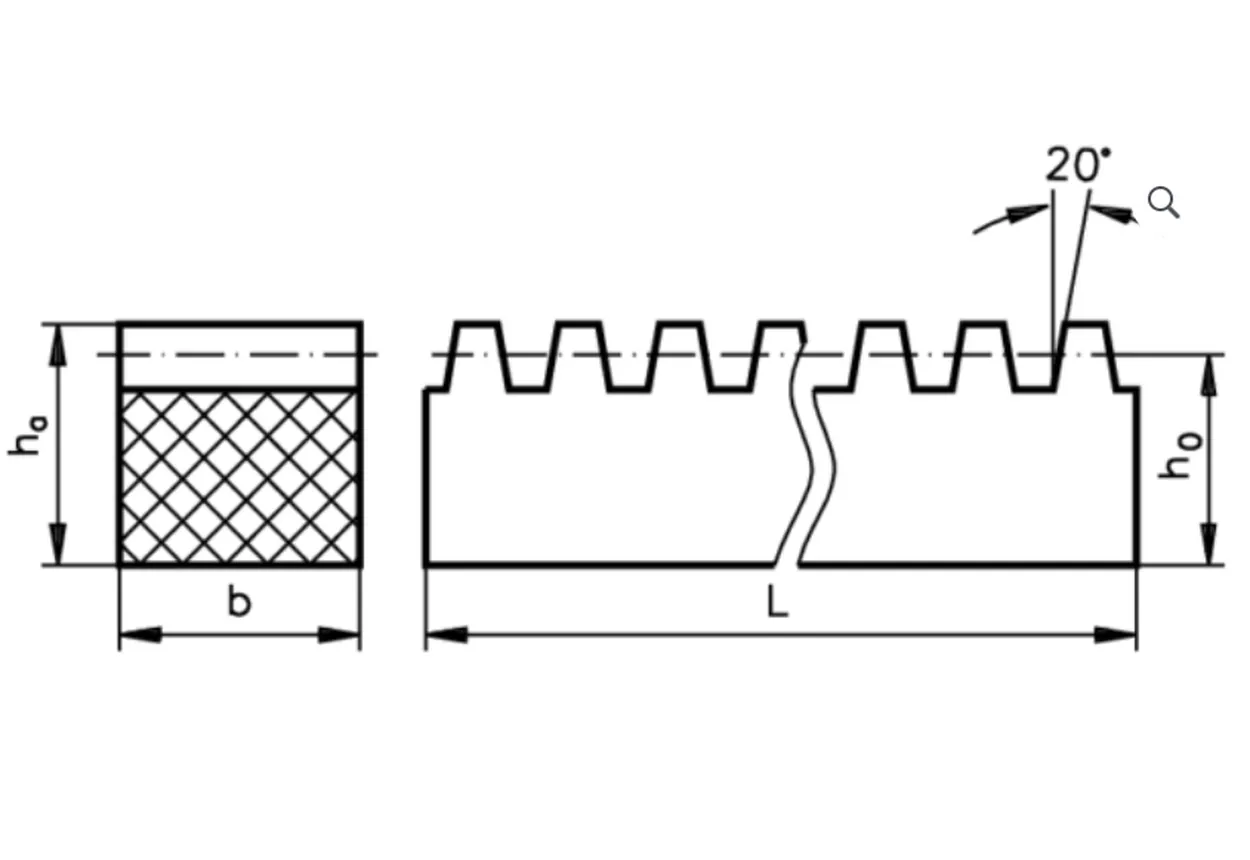

2. C45 Steel Gear Rack Dimensions

|  |

Material: Steel C45, black oxide finish.

Reference profile 2 DIN 867 / DIN 3972. Pressure angle 20º. Tooth quality 9 DIN 3967.

All gear racks from module 2,5 are cut of for continuous linking, with gap.

Production-related tolerances of dimensions ha and h0:

module 1 - 2: -0.2 mm

module 2.5 - 4: -0.3 mm

module 5 - 6: -0.4 mm

| Product No. | Module | b mm | ha mm | ho mm | Nom. Length L mm | Eff. Length mm | Weight kg |

| 224 116 08 | 1 | 10 | 10 | 9,0 | 1000 | 0,68 | |

| 224 116 09 | 1 | 10 | 10 | 9,0 | 2000 | 1,36 | |

| 224 116 12 | 1 | 15 | 15 | 14,0 | 1000 | 1,61 | |

| 224 116 19 | 1 | 15 | 15 | 14,0 | 2000 | 3,32 | |

| 228 116 05 | 1,5 | 15 | 15 | 13,5 | 1000 | 1,54 | |

| 228 116 09 | 1,5 | 15 | 15 | 13,5 | 2000 | 3,09 | |

| 228 116 12 | 1,5 | 17 | 17 | 15,5 | 1000 | 2,05 | |

| 228 116 19 | 1,5 | 17 | 17 | 15,5 | 2000 | 4,10 | |

| 241 116 05 | 2 | 20 | 20 | 18,0 | 1000 | 1005,0-1 | 2,77 |

| 241 116 09 | 2 | 20 | 20 | 18,0 | 2000 | 2004,0-1,5 | 5,54 |

| 242 116 05 | 2,5 | 25 | 25 | 22,5 | 1000 | 1005,0-1 | 4,35 |

| 242 116 09 | 2,5 | 25 | 25 | 22,5 | 2000 | 2002,5-1,5 | 8,70 |

| 243 116 05 | 3 | 30 | 30 | 27,0 | 1000 | 1008,0-1.5 | 6,27 |

| 243 116 09 | 3 | 30 | 30 | 27,0 | 2000 | 2007,0-1,5 | 12,54 |

| 244 116 05 | 4 | 40 | 40 | 36,0 | 1000 | 1005,0-1,5 | 11,10 |

| 244 116 09 | 4 | 40 | 40 | 36,0 | 2000 | 2010,0-1,5 | 22,20 |

| 245 116 05 | 5 | 50 | 50 | 45,0 | 1000 | 1005,0-1,5 | 17,50 |

| 245 116 09 | 5 | 50 | 50 | 45,0 | 2000 | 2010,0-1,5 | 35,00 |

| 246 116 05 | 6 | 60 | 60 | 54,0 | 1000 | 998,0-1,5 | 24,60 |

| 246 116 09 | 6 | 60 | 60 | 54,0 | 2000 | 1997,0-1,5 | 49,20 |

Advantages of Steel Gear Racks

- High Strength and Durability

Steel gear racks, especially those made from materials like Bright Steel C45K and Steel C45, offer exceptional strength and durability. Their robust construction ensures they can withstand heavy loads, high torque, and extended usage in demanding industrial environments without deformation or failure. - Superior Wear Resistance

The medium-carbon composition and ability to undergo heat treatment provide excellent wear resistance. This characteristic allows steel gear racks to maintain their performance and precision over time, even in applications involving continuous movement or exposure to abrasive forces. - High Precision and Accuracy

Steel gear racks are manufactured with tight tolerances and smooth finishes, especially in the case of Bright Steel C45K. This precision ensures smooth meshing with pinions and accurate motion control, which is essential for applications requiring exact positioning or linear motion. - Versatility Across Applications

Steel gear racks are suitable for a wide range of applications, including in automotive systems, industrial automation, robotics, and heavy machinery. Their ability to handle different loads and speeds makes them a versatile choice for diverse mechanical and engineering systems. - Enhanced Machinability

Materials like Steel C45 and Bright Steel C45K are known for their excellent machinability. This makes it easier to customize the gear racks to specific design requirements, such as unique tooth profiles or sizes, without compromising their structural integrity. - Cost-Effective Over Time

Although the initial investment in steel gear racks may be higher than some alternatives, their long lifespan, minimal maintenance requirements, and reliability make them a cost-effective solution. Their durability reduces the need for frequent replacements, lowering operational costs in the long run.

|  |

Steel Gear Rack Application Fields

- Industrial Automation and Robotics

Steel gear racks are widely used in industrial automation systems and robotics for precise linear motion. They enable accurate positioning in assembly lines, conveyor systems, and robotic arms, ensuring efficiency and reliability in automated processes that demand consistent and repeatable movement. - Machine Tools and Manufacturing Equipment

In machine tools such as lathes, milling machines, and CNC systems, steel gear racks facilitate controlled linear motion. They play a crucial role in guiding components, ensuring smooth operation, and achieving precise cuts or shaping of materials in manufacturing processes. - Automotive Steering Systems

Steel gear racks are integral to rack-and-pinion steering mechanisms in vehicles. They provide smooth and responsive steering control by converting the rotational motion of the steering wheel into linear motion, ensuring safe and efficient vehicle maneuvering under various driving conditions. - Heavy Machinery and Construction Equipment

Heavy-duty applications in construction equipment, cranes, and lifts rely on steel gear racks for lifting, positioning, or moving heavy loads. Their durability and ability to handle high loads make them essential components in environments that demand robust and reliable operation. - Elevators and Lifting Systems

In elevators, hoists, and other vertical lifting systems, steel gear racks are used to achieve precise and stable movement. Their high load-bearing capacity and wear resistance ensure the safety and reliability of these systems, even under continuous usage. - Renewable Energy Systems

Steel gear racks are utilized in renewable energy systems such as solar trackers and wind turbines. They enable the adjustment of solar panels or turbine blades, optimizing their alignment with the sun or wind to maximize energy efficiency and output in varying conditions.

|  |

| Gear Rack for Automation and Robotics | Gear Rack for CNC Machine Tool |

|  |

| Gear Rack for Construction Hoist Machinery | Gear Rack for Elevators and Lifts |

Steel Gear Rack vs. Stainless Steel Gear Rack

Steel gear racks, commonly made from materials like C45 Steel or Bright Steel C45K, are widely used in applications requiring high strength, durability, and wear resistance. These gear racks are designed to handle heavy loads and operate efficiently under demanding conditions. Steel gear racks can undergo heat treatment processes like hardening or tempering to enhance their hardness and lifespan. They are ideal for industrial automation, heavy machinery, and automotive steering systems due to their robust performance and cost-effectiveness.

Stainless steel gear racks, made from stainless steel grades such as 304 or 316, are specifically designed for environments where corrosion resistance is paramount. These gear racks are often used in industries like food processing, marine applications, and pharmaceuticals, where exposure to water, chemicals, or extreme conditions is common. Stainless steel gear racks are naturally resistant to rust, making them suitable for outdoor or high-humidity environments. While they offer excellent durability, their strength is generally lower compared to standard steel gear racks.

Differences Between Steel Gear Racks and Stainless Steel Gear Racks

- Corrosion Resistance

Stainless steel gear racks have superior corrosion resistance, making them ideal for wet, chemical, or outdoor applications. Steel gear racks, unless coated or treated, are more prone to corrosion in such environments. - Strength and Load Capacity

Steel gear racks offer higher strength and load-bearing capacity compared to stainless steel gear racks. This makes them better suited for heavy-duty industrial applications where high torque and force are required. - Cost

Steel gear racks are generally more cost-effective than stainless steel gear racks due to the lower material and manufacturing costs. Stainless steel gear racks are more expensive but essential in corrosive environments. - Applications

Steel gear racks are commonly used in industries like construction, machinery, and automotive. Stainless steel gear racks are preferred for food processing, marine, and medical applications where hygiene and corrosion resistance are critical. - Maintenance

Stainless steel gear racks require minimal maintenance due to their anti-corrosion properties. Steel gear racks need regular maintenance, including lubrication and protective coatings, especially in harsh environments. - Surface Finishing

Bright steel gear racks often have a smoother and more precise surface finish, while stainless steel gear racks focus more on corrosion resistance rather than extreme precision in machining.

|  |

| Steel Gear Rack | Stainless Steel Gear Rack |

Additional information

| Edited by | Yjx |

|---|