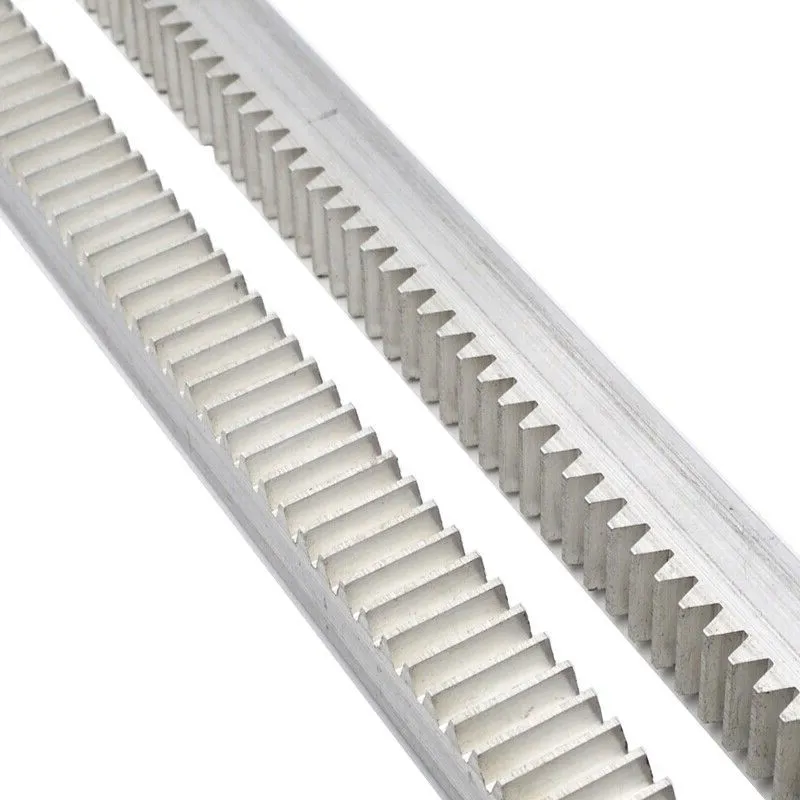

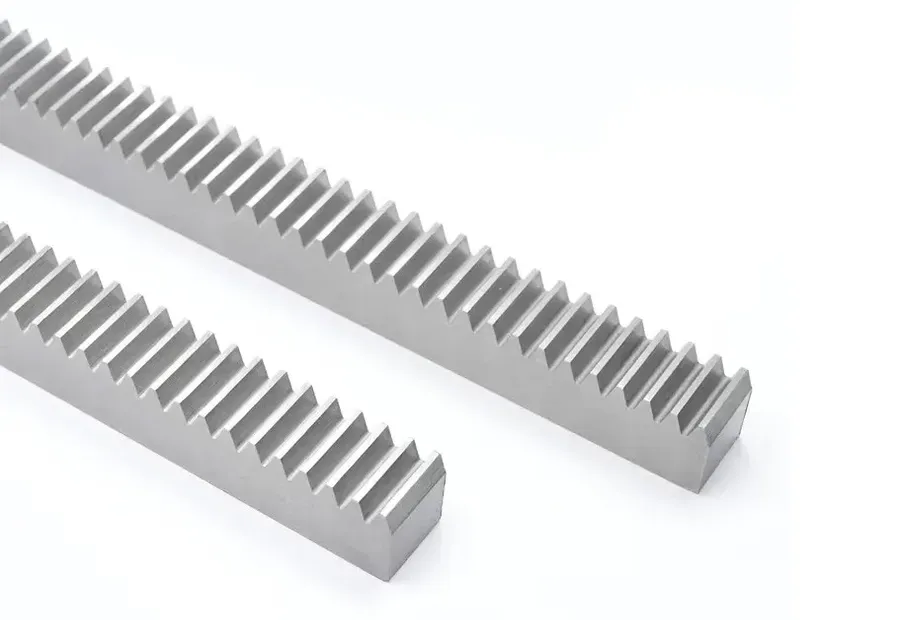

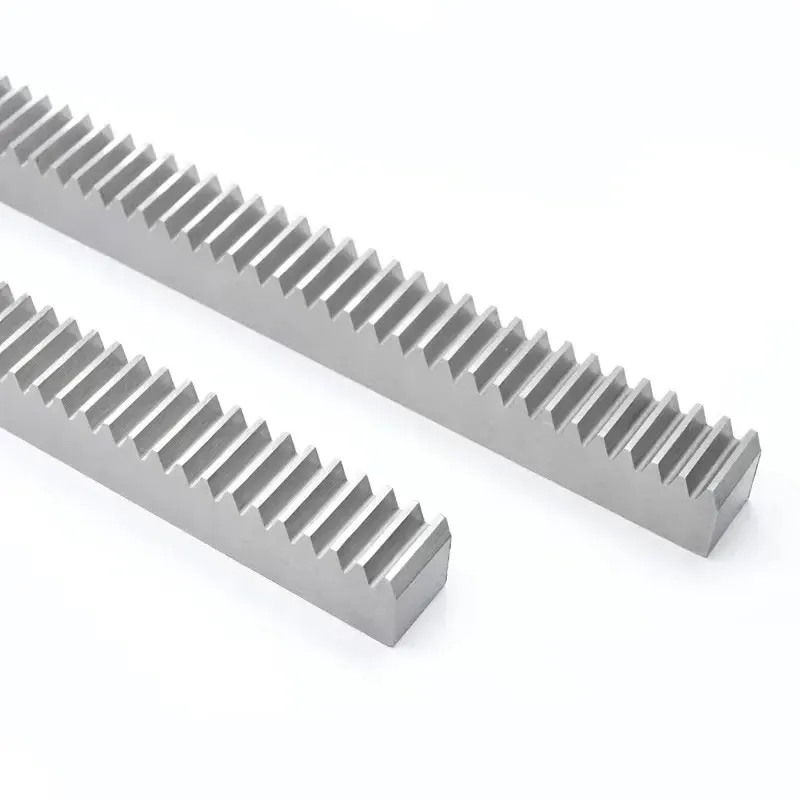

Stainless Steel Gear Racks

Stainless steel gear racks are manufactured from high-quality AISI 303 grade stainless steel (1.4305) and can operate in harsh, corrosive, abrasive, and food-grade environments. Our stainless steel gear racks are precisely manufactured per DIN 687/ 3972 standards with a 20° pressure angle straight tooth design. Percicley straightened, these gear racks provide optimal performance and longevity. We standardly supply these from Modules 1 – 4 in lengths ranging from 250mm to 2,000mm, but alternate lengths and pitches are available upon request. We also supply a range of stainless steel spur gears.

Stainless steel gear racks are manufactured from high-quality AISI 303 grade stainless steel (1.4305) and can operate in harsh, corrosive, abrasive, and food-grade environments. Our stainless steel gear racks are precisely manufactured per DIN 687/ 3972 standards with a 20° pressure angle straight tooth design. Percicley straightened, these gear racks provide optimal performance and longevity. We standardly supply these from Modules 1 - 4 in lengths ranging from 250mm to 2,000mm, but alternate lengths and pitches are available upon request. We also supply a range of stainless steel spur gears.

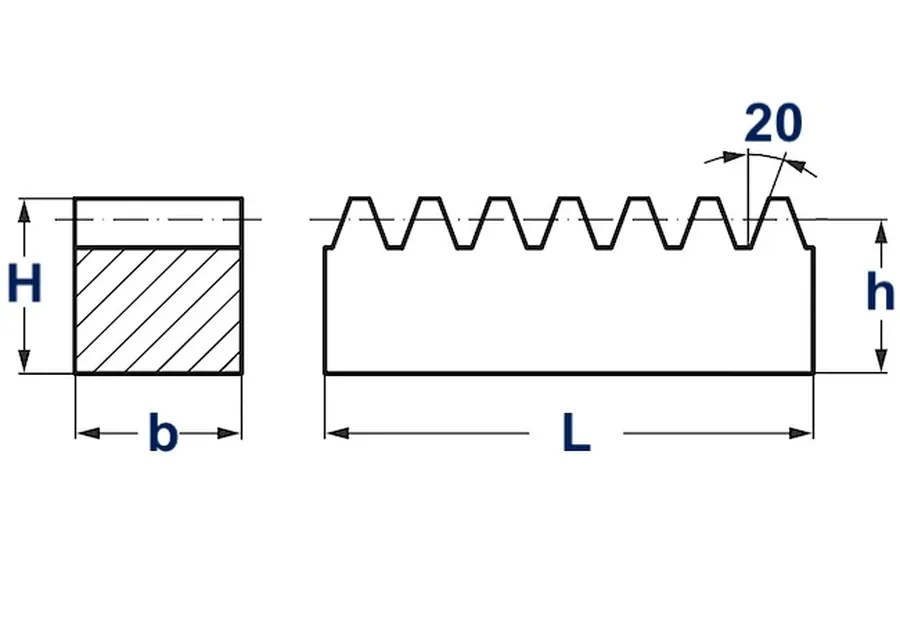

Stainless Steel Gear Rack Dimensions

|  |

| Part # | Module | Dimension (b) | Dimension (H) | Dimension (h) | Nominal Length (L) | Effective Length | Weight |

|---|---|---|---|---|---|---|---|

| 22499603 | 1 | 10mm | 10mm | 9.0mm | 250mm | -- | 0.17Kg |

| 22499605 | 1 | 10mm | 10mm | 9.0mm | 500mm | -- | 0.34Kg |

| 22499608 | 1 | 10mm | 10mm | 9.0mm | 1000mm | -- | 0.68Kg |

| 22499609 | 1 | 15mm | 15mm | 14.0mm | 250mm | -- | 0.41Kg |

| 22499610 | 1 | 15mm | 15mm | 14.0mm | 500mm | -- | 0.81Kg |

| 22499612 | 1 | 15mm | 15mm | 14.0mm | 1000mm | -- | 1.61Kg |

| 22899602 | 1.5 | 15mm | 15mm | 13.5mm | 250mm | -- | 0.39Kg |

| 22899603 | 1.5 | 15mm | 15mm | 13.5mm | 500mm | -- | 0.77Kg |

| 22899605 | 1.5 | 15mm | 15mm | 13.5mm | 1000mm | -- | 1.55Kg |

| 22899607 | 1.5 | 15mm | 15mm | 13.5mm | 1500mm | -- | 2.33Kg |

| 24199602 | 2 | 20mm | 20mm | 18.0mm | 250mm | -- | 0.69Kg |

| 24199603 | 2 | 20mm | 20mm | 18.0mm | 500mm | -- | 1.38Kg |

| 24199605 | 2 | 20mm | 20mm | 18.0mm | 1000mm | 1005,0-1 | 2.77Kg |

| 24199607 | 2 | 20mm | 20mm | 18.0mm | 1500mm | 1501,0-1 | 4.12Kg |

| 24199609 | 2 | 20mm | 20mm | 18.0mm | 2000mm | 2004,0-1,5 | 5.50Kg |

| 24299602 | 2.5 | 25mm | 25mm | 22.5mm | 250mm | -- | 1.09Kg |

| 24299603 | 2.5 | 25mm | 25mm | 22.5mm | 500mm | -- | 2.17Kg |

| 24299605 | 2.5 | 25mm | 25mm | 22.5mm | 1000mm | 1005,1-1 | 4.31Kg |

| 24299607 | 2.5 | 25mm | 25mm | 22.5mm | 1500mm | 1507,5-1 | 6.46Kg |

| 24299609 | 2.5 | 25mm | 25mm | 22.5mm | 2000mm | 2002,5-1,5 | 8.61Kg |

| 24299603 | 3 | 30mm | 30mm | 27.0mm | 500mm | -- | 3.17Kg |

| 24399605 | 3 | 30mm | 30mm | 27.0mm | 1000mm | 1008,0-1,5 | 6.27Kg |

| 24399607 | 3 | 30mm | 30mm | 27.0mm | 1500mm | 1507,5, -1,5 | 9.33Kg |

| 24399609 | 3 | 30mm | 30mm | 27.0mm | 2000mm | 2007,0-1,5 | 12.43Kg |

| 24499603 | 4 | 40mm | 40mm | 36.0mm | 500mm | -- | 5.55Kg |

| 24499605 | 4 | 40mm | 40mm | 36.0mm | 1000mm | 1005,0-1,5 | 11.14Kg |

| 24499607 | 4 | 40mm | 40mm | 36.0mm | 1500mm | 1507,5-1 | 16.50Kg |

| 24499609 | 4 | 40mm | 40mm | 36.0mm | 2000mm | 2010,0-1,5 | 22.50Kg |

Notes:

Production tolerances for dimensions h and H are -0.2mm for modules 1 - 2.

Production tolerances for dimensions h and H are -0.3mm for modules 2.5 - 4.

Stainless Steel Gear Rack Advantages

- Corrosion Resistance

Stainless steel gear racks are highly resistant to corrosion, making them ideal for use in harsh environments, such as marine, chemical, and food-grade applications. Their AISI 303 stainless steel construction prevents rust and degradation, ensuring long-term reliability and performance. - Durability and Longevity

These gear racks are manufactured with precise straightening and high-quality materials, which provide exceptional strength and durability. Their robust design allows them to withstand heavy loads and repeated usage without deformation, ensuring extended operational life in demanding applications. - Smooth and Efficient Operation

With a 20° pressure angle straight tooth design, stainless steel gear racks deliver smooth and efficient power transmission. This precise tooth geometry minimizes backlash and ensures optimal performance, even under high-speed or high-torque conditions, for consistent and reliable operation. - Versatility in Applications

Stainless steel gear racks are suitable for a wide range of applications, including those in corrosive, abrasive, and hygienic environments. From food processing equipment to industrial machinery, their adaptability makes them a versatile component for various industries and environments. - Customizable Options

These gear racks are available in standard modules and lengths, ranging from 250mm to 2,000mm. However, they can also be customized to meet specific requirements, including alternate lengths and pitches, enabling tailored solutions for unique applications or specialized machinery.

Stainless Steel Gear Rack Applications

- Food and Beverage Industry

Stainless steel gear racks are widely used in food processing and beverage manufacturing equipment due to their resistance to corrosion and ability to withstand hygienic cleaning processes. Their compliance with food-grade standards ensures safe and reliable operation in sanitary environments. - Marine and Offshore Applications

In marine environments, stainless steel gear racks are essential for equipment like winches, hoists, and positioning systems. Their ability to resist corrosion from saltwater and harsh weather conditions makes them reliable components for long-term use in offshore industries. - Chemical and Pharmaceutical Industries

These gear rack and pinions are ideal for chemical and pharmaceutical equipment, where exposure to corrosive substances is common. Their resistance to chemicals and durability under abrasive conditions ensure smooth and safe operation in environments requiring stringent cleanliness and material integrity. - Industrial Automation and Robotics

Stainless steel gear racks are critical for precision motion control in industrial automation and robotics. Their accurate tooth geometry enables smooth linear movement, making them suitable for applications like conveyor systems, robotic arms, and other automated machinery requiring precise positioning. - Aerospace and Defense Systems

In aerospace and defense applications, stainless steel gear racks are used in systems requiring high precision and durability. Their ability to function in extreme conditions, including high temperatures and corrosive environments, makes them a reliable choice for critical aerospace mechanisms. - Medical Equipment

Stainless steel gear racks are often used in medical devices and equipment, such as imaging systems and surgical instruments. Their corrosion resistance and hygienic properties make them suitable for sterile environments, ensuring reliable performance and compliance with medical-grade standards.

|  |

| Gear Rack for Medical Equipment | Gear Rack for Marine and Offshore |

|  |

| Gear Rack for Food and Beverage Industry | Gear Rack for Aerospace and Defense Systems |

Stainless Steel Gear Rack Maintenance and Lubrication

- Regular Cleaning

Stainless steel gear racks should be cleaned regularly to remove dust, debris, and contaminants. This prevents buildup that could hinder smooth operation. Use non-abrasive cleaning agents to protect the stainless steel surface and ensure optimal performance and longevity in demanding environments. - Inspection for Wear and Damage

Routine inspections are essential to identify wear, damage, or misalignment in the gear teeth. Early detection of issues such as pitting or deformation prevents further damage and ensures the gear rack maintains efficient and reliable operation over its lifespan. - Proper Lubrication

Apply a suitable lubricant regularly to reduce friction and wear between the gear rack and mating gear. Food-grade lubricants are recommended for hygienic applications, while high-performance lubricants are ideal for heavy-duty or harsh environments, ensuring smooth and efficient operation. - Avoid Overloading

To maintain the integrity of the stainless steel gear rack, it is crucial to avoid overloading the system. Excessive loads can cause deformation or damage to the gear teeth, leading to premature failure and inefficient performance. Operate within the specified load capacity. - Corrosion Prevention

Although stainless steel is corrosion-resistant, exposure to extreme environments can still cause surface degradation over time. Regular application of protective coatings or appropriate lubricants can enhance corrosion resistance, especially in marine, chemical, or high-moisture environments, to prolong the rack’s life. - Alignment and Adjustment

Ensure that the gear rack and pinion gear are precisely aligned to prevent uneven wear and improve performance. Periodic realignment and adjustments, if necessary, help maintain consistent gear meshing, reduce stress on the components, and enhance overall operational efficiency.

Additional information

| Edited by | Yjx |

|---|