Stainless Steel Bevel Gears Ratio 2:1 Straight-Tooth System

The stainless steel bevel gears ratio 2:1 straight-tooth system refers to a mechanical gear assembly designed for transmitting rotational motion between two shafts positioned at an angle, typically 90 degrees. Bevel gears feature cone-shaped teeth that are arranged to mesh at the intersection of the shafts. In a straight-tooth system, the teeth are cut radially along the pitch cone, resulting in a simpler design compared to spiral bevel gears.

The stainless steel bevel gears ratio 2:1 straight-tooth system refers to a mechanical gear assembly designed for transmitting rotational motion between two shafts positioned at an angle, typically 90 degrees. Bevel gears feature cone-shaped teeth that are arranged to mesh at the intersection of the shafts. In a straight-tooth system, the teeth are cut radially along the pitch cone, resulting in a simpler design compared to spiral bevel gears.

The 2:1 gear ratio means that for every two rotations of the driver gear, the driven gear completes one rotation, effectively reducing speed while increasing torque proportionally. Made of stainless steel, these gears are highly durable, corrosion-resistant, and ideal for demanding environments, including industrial machinery, automotive systems, and marine equipment. This system offers efficient power transfer, precision, and reliability in applications requiring robust performance.

Stainless Steel Bevel Gear Ratio 2:1

|  |

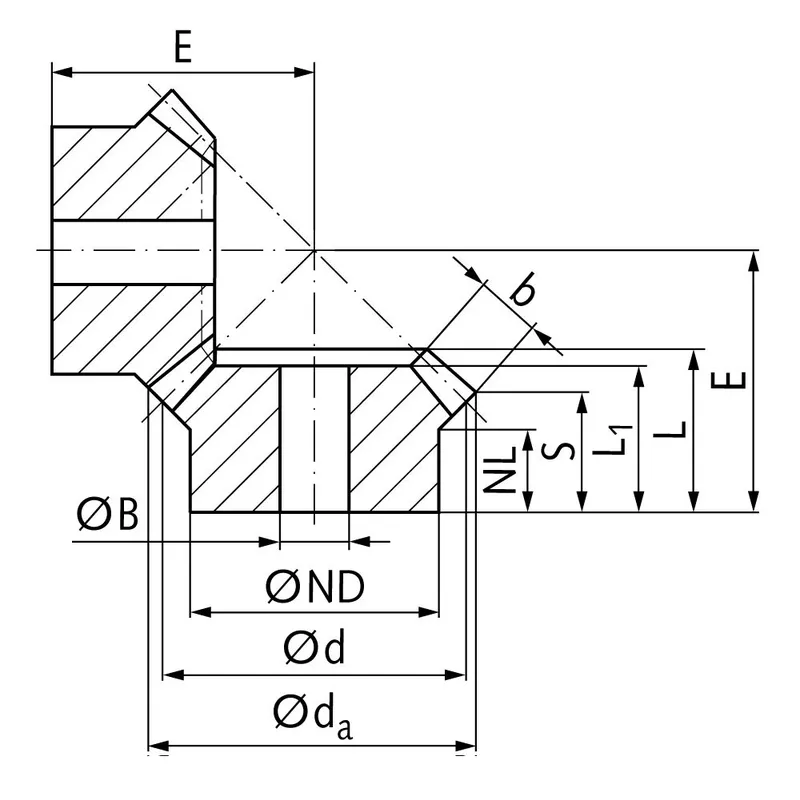

| Module | Number of teeth | da | d | ND | NL | L1 | L | S | b | BH7 | E | Torque* | Weight |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | Ncm | g | ||

| 1 | 15 | 17,4 | 15 | 13 | 6,5 | 11 | 11,9 | 7,6 | 5,0 | 5 | 22 | 0,08 | 10 |

| 1 | 30 | 30,6 | 30 | 20 | 9,0 | 13 | 15,1 | 13,1 | 5,0 | 5 | 20 | 0,16 | 40 |

| 1,5 | 15 | 26,1 | 22,5 | 18 | 6,5 | 13 | 14,8 | 8,4 | 7,6 | 8 | 30 | 0,27 | 26 |

| 1,5 | 30 | 45,9 | 45 | 30 | 12,0 | 18 | 20,7 | 17,6 | 7,6 | 10 | 28 | 0,54 | 124 |

| 2 | 15 | 33,7 | 30 | 20 | 7,5 | 22 | 23,0 | 10,9 | 14 | 10 | 40 | 0,78 | 58 |

| 2 | 30 | 61,8 | 60 | 40 | 12,0 | 24 | 27,2 | 21,9 | 14 | 15 | 35 | 1,56 | 312 |

| 2,5 | 15 | 42,2 | 37,5 | 30 | 15,6 | 31 | 33,3 | 18,6 | 17 | 10 | 55 | 1,6 | 160 |

| 2,5 | 30 | 77,3 | 75 | 50 | 10,0 | 24 | 28,1 | 21,6 | 17 | 15 | 38 | 3,2 | 530 |

| 3 | 15 | 50,6 | 45 | 30 | 11,5 | 33 | 35,4 | 16,4 | 22 | 10 | 60 | 2,8 | 270 |

| 3 | 30 | 92,8 | 90 | 50 | 10,0 | 26 | 30,7 | 22,3 | 22 | 20 | 42 | 5,6 | 750 |

| 4 | 15 | 67,5 | 60 | 40 | 10,0 | 38 | 41,0 | 16,9 | 28 | 20 | 75 | 6,0 | 410 |

| 4 | 30 | 123,8 | 120 | 60 | 15,0 | 33 | 39,4 | 28,8 | 28 | 25 | 55 | 12,0 | 1600 |

Stainless Steel Straight Bevel Gear Features

- Corrosion Resistance

Stainless steel straight bevel gears, often made from grades like 1.4305 or AISI 303, resist rust and chemical degradation. This makes them ideal for harsh environments such as food processing, marine applications, or chemical plants where durability is critical. - Straight-Tooth Design

These stainless steel gears feature linear teeth cut parallel to the pitch cone. This design simplifies manufacturing, reducing costs compared to spiral bevel gears. It ensures efficient power transmission at lower speeds, though it may generate more noise during operation. - High Strength and Durability

Stainless steel provides excellent mechanical strength, allowing these gears to withstand high loads and stresses. Their robust construction ensures long service life, even in demanding applications, minimizing maintenance and replacement costs over time. - 90-Degree Power Transmission

Straight bevel gears are designed to transfer motion between shafts intersecting at a 90-degree angle. This configuration is essential for applications requiring angular power transmission, such as in machinery for automotive or industrial systems. - Precision Machining

These bevel gears are precisely machined to ensure accurate tooth profiles and smooth engagement. High-quality machining reduces wear and enhances efficiency, making it suitable for applications requiring consistent performance, like conveyor systems or robotic mechanisms. - Versatile Ratio Options

Available in various gear ratios, such as 2:1, these straight bevel gears allow for tailored speed reduction or torque amplification. This flexibility supports diverse applications, from heavy machinery to precision instruments, optimizing performance for specific operational needs.

Straight Bevel Gear Material Options

1. Carbon Steel

Carbon steel is a popular material for straight bevel gears due to its affordability and high strength. It offers excellent wear resistance and can be heat-treated to enhance its hardness. Carbon steel gears are commonly used in industrial machinery and heavy-duty applications where strength and durability are essential. However, they may require surface coatings or lubrication to prevent rust in environments exposed to moisture.

2. Alloy Steel

Alloy steel straight bevel gears are designed for higher performance and durability than standard carbon steel. By incorporating elements like chromium, nickel, or molybdenum, alloy steel offers improved toughness, wear resistance, and fatigue strength. These gears are ideal for demanding applications, such as automotive transmissions or heavy machinery, where extreme forces and stresses are present. Their ability to withstand high temperatures also makes them suitable for high-speed operations.

3. Stainless Steel

Stainless steel gears are highly valued for their corrosion resistance and durability in environments prone to moisture or chemicals. They are ideal for marine applications, food processing equipment, and medical devices where hygiene and resistance to rust are critical. While stainless steel gears are more expensive than other materials, their long lifespan and low maintenance requirements make them a cost-effective choice for harsh or sensitive conditions.

4. Plastic

Plastic straight bevel gears are lightweight, corrosion-resistant, and cost-effective. They are commonly used in low-load applications, such as consumer electronics, toys, and small machinery. Plastic gears operate quietly and do not require lubrication, making them suitable for environments where noise reduction is important. However, they lack the strength and wear resistance of metal gears, limiting their use in high-stress or high-temperature applications.

5. Brass

Brass bevel gears are known for their excellent machinability, corrosion resistance, and aesthetic appeal. They are often used in precision instruments, clocks, and decorative mechanisms. Brass gears provide smooth operation with minimal noise and are resistant to tarnish. While they are not as strong as steel gears, their self-lubricating properties and ability to resist corrosion make them ideal for low-load applications or systems requiring smooth, reliable performance.

|  |

|  |

Applications of Stainless Steel Bevel Gear

- Marine and Offshore Equipment

Stainless steel bevel gears are widely used in marine and offshore applications due to their exceptional corrosion resistance. They are found in ship propulsion systems, winches, and anchor-handling equipment, where exposure to saltwater and extreme weather conditions demands durable and reliable components. - Food and Beverage Processing Machinery

In food and beverage industries, stainless steel bevel gears are essential for machinery like mixers, conveyors, and packaging equipment. Their non-corrosive and hygienic properties ensure compliance with strict sanitation standards, making them safe for use in environments requiring regular cleaning and exposure to food-grade chemicals. - Pharmaceutical and Medical Equipment

Stainless steel bevel gears are crucial in pharmaceutical and medical devices where cleanliness and precision are paramount. They are used in surgical instruments, diagnostic machinery, and automated production lines. Their resistance to rust and sterilization processes ensures long-lasting and contamination-free performance. - Chemical Processing Plants

Chemical processing plants use stainless steel bevel gears in pumps, mixers, and agitators because they withstand exposure to corrosive chemicals and extreme temperatures. Their robust construction ensures reliable operation and longevity, making them ideal for environments involving aggressive substances and continuous processes. - Aerospace and Defense Applications

In aerospace and defense, stainless steel bevel gears are used in actuators, landing gear systems, and control mechanisms. Their strength, resistance to harsh conditions, and ability to perform under high loads and extreme temperatures make them indispensable for mission-critical applications. - Robotics and Automation

Stainless steel bevel gears are integral to robotic arms, automated systems, and precision machinery in manufacturing. Their durability and ability to transmit torque smoothly ensure accurate positioning and reliable operation in automated processes where precision and consistent performance are crucial.

|  |

| Bevel Gear for Marine Industry | Bevel Gear for Medical Industry |

|  |

| Bevel Gear for Food Industry | Bevel Gear for Robotics Industry |

Additional information

| Edited by | Yjx |

|---|