Stainless Steel Bevel Gears Ratio 1:1 Straight-Tooth System

The stainless steel bevel gears ratio 1:1 straight-tooth system is a mechanical component designed for power transmission between intersecting shafts at a 90-degree angle. These gears are known for their straight-tooth configuration, meaning the teeth are cut radially, allowing for smooth and efficient torque transfer. The 1:1 gear ratio indicates that the input and output shafts rotate at the same speed, making it ideal for applications where speed consistency is required.

The stainless steel bevel gears ratio 1:1 straight-tooth system is a mechanical component designed for power transmission between intersecting shafts at a 90-degree angle. These gears are known for their straight-tooth configuration, meaning the teeth are cut radially, allowing for smooth and efficient torque transfer. The 1:1 gear ratio indicates that the input and output shafts rotate at the same speed, making it ideal for applications where speed consistency is required.

Made from stainless steel, these straight bevel gears offer excellent strength, durability, and resistance to corrosion, making them suitable for harsh environments, including marine, chemical, and food processing industries. The system is typically used in machinery where precision, reliability, and low maintenance are critical, such as conveyors, pumps, and robotics, ensuring robust and consistent performance.

Stainless Steel Bevel Gear Ratio 1:1

|  |

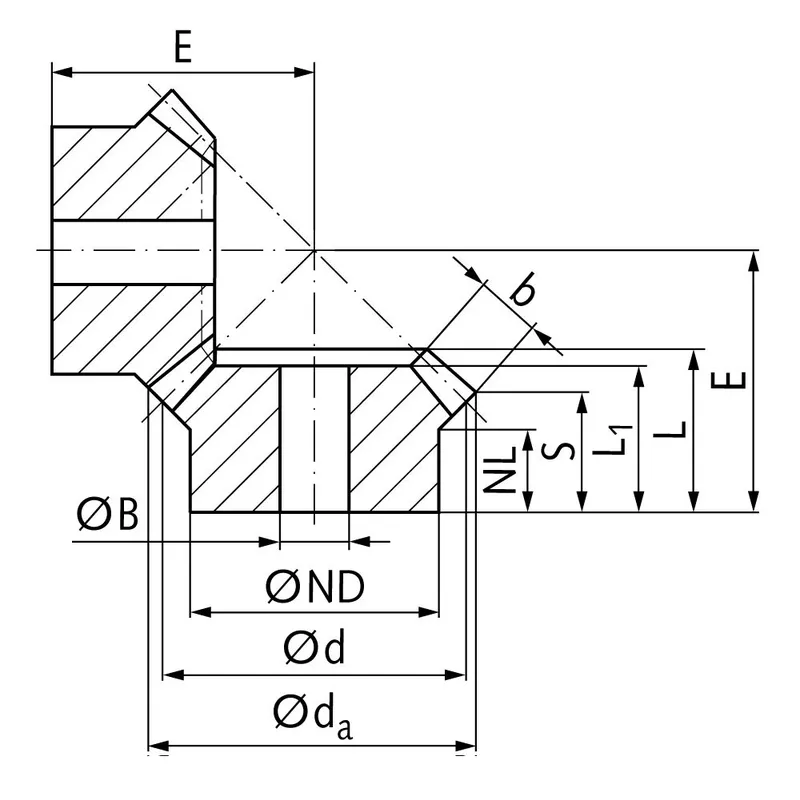

| Module | Number of teeth | da | d | ND | NL | L1 | L | S | b | BH7 | E | Torque* | Weight |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | Ncm | g | ||

| 1 | 16 | 17,4 | 16 | 14 | 7 | 10 | 11,2 | 8,7 | 4,0 | 5 | 16 | 0,06 | 9 |

| 1,5 | 16 | 26,1 | 24 | 20 | 11 | 15 | 17,3 | 14,1 | 5,1 | 8 | 25 | 0,19 | 32 |

| 2 | 16 | 34,8 | 32 | 25 | 11,5 | 18 | 20,7 | 16,4 | 6,8 | 10 | 31 | 0,46 | 66 |

| 2,5 | 16 | 43,7 | 40 | 30 | 10 | 21 | 23,8 | 16,8 | 11 | 10 | 35 | 1,1 | 120 |

| 3 | 16 | 52,4 | 48 | 40 | 12 | 24 | 27,7 | 18,2 | 15 | 10 | 40 | 2,0 | 240 |

| 4 | 16 | 70,0 | 64 | 50 | 11 | 29 | 32,9 | 21,0 | 19 | 20 | 50 | 4,8 | 420 |

Stainless Steel Straight Bevel Gear Advantages

- Corrosion Resistance

Stainless steel straight bevel gears are highly resistant to rust and corrosion due to their material composition, typically 303 or 304 stainless steel. This makes them ideal for harsh environments like marine, food processing, or chemical industries where exposure to moisture or corrosive substances is common. Their durability ensures long-term performance without frequent replacements. - High Strength and Durability

The robust nature of stainless steel provides exceptional strength, allowing these stainless steel gears to withstand significant mechanical stress and heavy loads. This durability ensures reliable operation in demanding applications, such as industrial machinery, where consistent torque transmission is critical, reducing maintenance costs over time. - Simple Design and Manufacture

Straight bevel gears feature teeth cut directly along the conical surface, making them easier and less costly to produce compared to spiral bevel gears. This straightforward design allows for quicker manufacturing and assembly, making them a cost-effective choice for applications requiring precise 90-degree motion transfer. - Effective for 1:1 Ratio Applications

With a 1:1 gear ratio, these gears transmit motion without altering speed or torque, ideal for miter gear setups. This ensures precise angular motion transfer between intersecting shafts, commonly used in machinery requiring consistent rotational output, such as conveyors or pumps. - Versatility Across Industries

The combination of corrosion resistance, strength, and reliable performance makes stainless steel bevel gears versatile for various sectors, including aerospace, automotive, and medical equipment. Their ability to function in extreme conditions, like high humidity or temperature, ensures adaptability to diverse operational requirements.

Stainless Steel Bevel Gear Application Industry

- Aerospace Industry

Stainless steel bevel gears are widely used in the aerospace sector for power transmission in landing gear systems, control mechanisms, and thrust reversers. Their high strength, precise torque transfer, and ability to withstand extreme temperatures ensure reliability during critical flight operations. - Automotive Industry

In the automotive sector, these gears are integral to drivetrain systems, steering mechanisms, and differential components. Their corrosion resistance, durability, and ability to handle high torque make them ideal for vehicles operating under varying load and environmental conditions. - Food Processing Industry

Stainless steel bevel gears are essential in food processing machinery, such as mixers, conveyors, and packaging equipment. Their corrosion resistance, hygienic properties, and compliance with strict sanitary standards make them a perfect choice for handling food-grade applications safely and efficiently. - Marine Industry

The marine sector relies on stainless steel bevel gears for propulsion systems, winches, and steering mechanisms. Their resistance to saltwater corrosion and ability to perform well in harsh marine environments ensure long-lasting and dependable operation in ships and boats. - Robotics and Automation

In robotics and automated systems, these gears enable precise movement and torque control. Their high precision and durability make them indispensable for applications requiring accurate positioning, such as robotic arms, CNC machines, and automated assembly lines. - Chemical and Pharmaceutical Industry

Stainless steel bevel gears are used in chemical and pharmaceutical equipment like pumps, mixers, and reactors. Their resistance to corrosive chemicals and ability to maintain performance in sterile environments make them invaluable for production processes requiring precision and cleanliness.

|  |

| Bevel Gear for Automotive Industry | Bevel Gear for Food Industry |

|  |

| Bevel Gear for Robotics Industry | Bevel Gear for Aerospace Industry |

Custom Stainless Steel Bevel Gear

- Tailored Design Specifications

Custom stainless steel bevel gears are engineered to meet specific application requirements, including precise gear ratios, tooth profiles, and dimensions. This customization ensures optimal performance in unique machinery, accommodating huntingtonshires precise motion transfer while meeting exact dimensional and functional needs. - Material Versatility

These gears can be crafted from various stainless steel grades, such as 303, 304, or 316, chosen based on application needs. This allows for tailored corrosion resistance, strength, or biocompatibility, ensuring the gears perform reliably in environments like marine, chemical, or medical settings. - Precision Manufacturing

Custom bevel gears are machined with high precision using advanced CNC milling or grinding techniques. This ensures accurate tooth geometry and smooth operation, critical for applications requiring exact 90-degree motion transfer, such as robotics or aerospace, where tolerances are extremely tight. - Enhanced Durability

By selecting specific stainless steel alloys and heat treatment processes, custom gears offer superior strength and wear resistance. This customization extends service life in high-load or harsh environments, reducing downtime and maintenance costs in industries like automotive or heavy machinery. - Application-Specific Features

Custom gears can include specialized features like keyways, splines, or mounting holes designed for specific machinery. These additions ensure seamless integration into complex systems, enhancing performance in applications such as food processing equipment or industrial conveyors requiring precise alignment. - Surface Finish Options

Custom stainless steel bevel gears can be finished with polishing, passivation, or coatings to enhance corrosion resistance or reduce friction. These treatments improve performance in demanding environments, such as chemical processing or marine applications, ensuring longevity and reliability under extreme conditions.

Additional information

| Edited by | Yjx |

|---|