Side Shift Hydraulic Cylinder for Small Tonnage Forklift

A side shift hydraulic cylinder for small-tonnage forklifts is a critical hydraulic component designed to facilitate lateral movement of the forklift’s carriage and forks without needing to reposition the entire vehicle. This cylinder is part of the forklift’s attachment system, enabling precise horizontal adjustments to improve load-handling efficiency and accuracy. It operates by converting hydraulic pressure into mechanical force, allowing the operator to shift loads left or right within a specified range.

A side shift hydraulic cylinder for small-tonnage forklifts is a critical hydraulic component designed to facilitate lateral movement of the forklift's carriage and forks without needing to reposition the entire vehicle. This cylinder is part of the forklift’s attachment system, enabling precise horizontal adjustments to improve load-handling efficiency and accuracy. It operates by converting hydraulic pressure into mechanical force, allowing the operator to shift loads left or right within a specified range.

Typically constructed from high-strength materials to withstand heavy loads and frequent use, the forklift side shift cylinder includes a piston, seals, and hydraulic ports for smooth, controlled motion. This feature is especially useful in confined spaces, such as warehouses, where precise alignment of loads onto shelves or pallets is required. It enhances operational efficiency, reduces manual adjustments, and minimizes wear on the forklift.

Forklift Side Shift Hydraulic Cylinder Dimensions

| Forklift Side Shift Cylinder |

|||||||

| drawing number | bore diameter (D) | rod diameter (d) | stroke (S) | Installation distance (L) | working pressure | Interface dimensions (M) | weight |

| 7B3-304000-00 | Φ70 | Φ30 | 300 | 536 | 18MPa | 2-M14*1.5 | 13.5kg |

| Product Name: | Side Shift Hydraulic Cylinder |

| Function: | Used to achieve the overall left and right movement of the fork. |

| Cylinder diameter: | 50mm |

| Rod diameter: | 25mm |

| Travel: | 200mm |

| Maximum pressure MPa: | 17.5MPa |

| Maximum thrust KN: | 34KN |

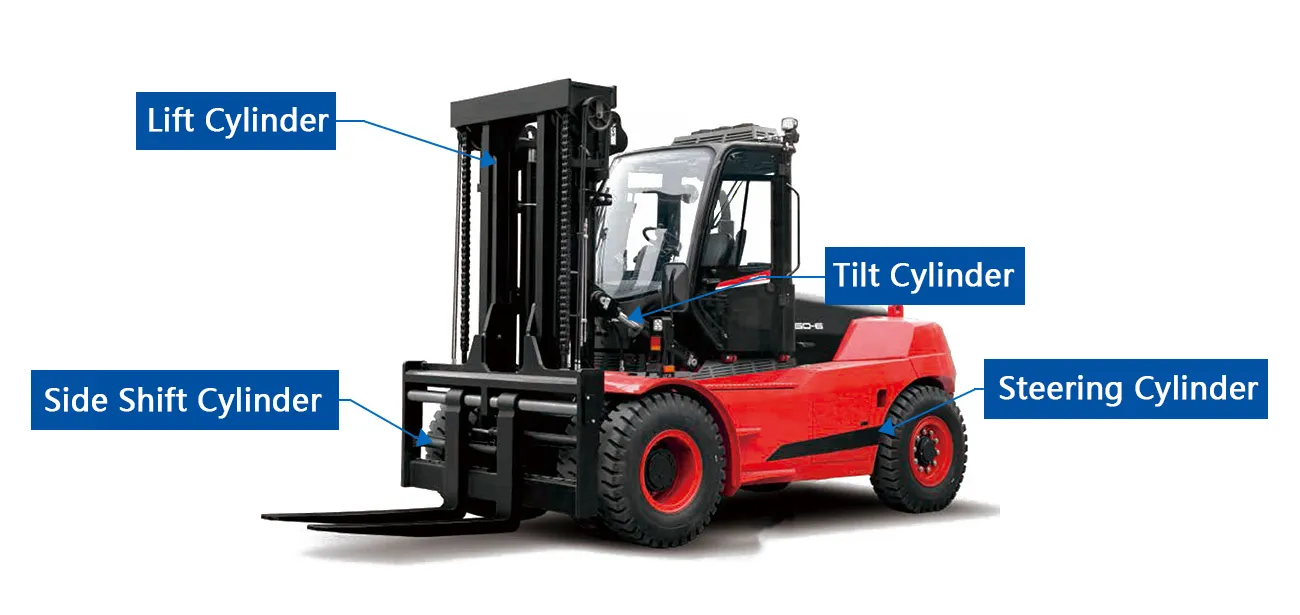

Small Tonnage Forklift Hydraulic Cylinder Types

- Hydraulic Tilt Cylinders

Hydraulic tilt cylinders are essential for controlling the forward and backward tilting of the forklift mast. They allow operators to adjust the angle of the forks for precise load positioning. These cylinders ensure stability during load handling by securely tilting the mast toward the forklift or away from it. Built with high-strength materials, they withstand significant pressure, making them durable for heavy-duty applications. - Hydraulic Lift Cylinders

Hydraulic lift cylinders are responsible for raising and lowering the forklift’s mast and forks. They convert hydraulic pressure into vertical motion, enabling the safe lifting of loads to various heights. These cylinders are designed for smooth operation, ensuring precise load control and stability. They are commonly used in warehouses and industrial settings, where lifting efficiency is crucial for productivity. - Hydraulic Steering Cylinders

Hydraulic steering cylinders assist in controlling the forklift’s steering system, ensuring smooth and responsive directional changes. They enable operators to maneuver the forklift with minimal effort, especially in tight spaces. These cylinders reduce steering resistance by converting hydraulic power into linear motion. Their robust construction ensures consistent performance and durability even under demanding operational conditions. - Hydraulic Side Shift Cylinders

Hydraulic side shift cylinders enable the lateral movement of the forklift’s carriage, allowing the forks to shift left or right without moving the vehicle. This functionality improves precision and efficiency in confined environments. It is particularly useful for aligning loads onto shelves or pallets. Designed for heavy-duty use, these cylinders ensure smooth and controlled motion while reducing operational strain on the forklift.

Forklift Hydraulic Side Shift Cylinder Benefits

- Enhanced Precision in Load Placement

The side shift cylinder allows operators to adjust the fork position laterally by up to 150 mm. This ensures precise alignment with pallets or racks. It reduces the need for vehicle repositioning. This is ideal for tight warehouse spaces. - Increased Operational Efficiency

By enabling quick lateral adjustments without moving the entire forklift, the forklift hydraulic side shift cylinder saves time during load handling. This boosts productivity in high-volume environments. Operators can handle more pallets per hour. It streamlines workflows in busy warehouses. - Improved Safety for Operators

Precise load alignment minimizes the risk of load instability or tipping. The forklift hydraulic cylinders reduce abrupt vehicle movements. This enhances operator safety. It also protects nearby workers and inventory. Stable loads prevent accidents in crowded work areas. - Reduced Wear on Forklift Components

Side shifting reduces the need for frequent vehicle maneuvering. This lowers stress on tires, axles, and steering systems. It extends the forklift’s service life. Maintenance costs are reduced. The side shift hydraulic cylinder promotes smoother, less abrasive operations. - Versatility in Confined Spaces

The cylinder enables forklifts to operate effectively in narrow aisles or cramped stockrooms. Lateral adjustments allow handling of loads in tight spaces. This is critical for small tonnage forklifts. It maximizes storage capacity in compact warehouses. - Enhanced Load Protection

Accurate positioning prevents load damage from misaligned forks or racks. The hydraulic side shift cylinder ensures gentle, controlled movements. This is vital for fragile or high-value goods. It reduces product loss. Customer satisfaction improves with intact deliveries.

Custom Forklift Hydraulic Side Shift Cylinders

- Bore Diameter

The bore diameter determines the cylinder's capacity to handle hydraulic pressure and generate force. Customizing this dimension ensures the forklift side shift cylinder provides the required power for side-shifting heavy or light loads effectively. - Rod Diameter

The rod diameter affects the cylinder's strength and resistance to bending. A properly customized rod diameter ensures durability and stability, allowing the hydraulic side shift cylinder to handle lateral stresses during repetitive side-shifting operations. - Stroke

The stroke defines the maximum distance the cylinder’s rod can extend or retract. Customizing the stroke length ensures that the side shift hydraulic cylinder provides the precise range of side-shift motion needed for specific forklift operations. - Installation Distance

The installation distance refers to the cylinder’s mounting dimensions. Customizing this ensures seamless integration with the forklift’s carriage and side-shift mechanism, enabling smooth operation and reducing unnecessary stress on components. - Working Pressure

The working pressure defines the hydraulic force that the forklift hydraulic cylinder can withstand. Customizing this parameter ensures the cylinder operates efficiently under the specific pressure requirements of the forklift’s hydraulic system. - Interface Dimensions

The interface dimensions determine compatibility with the forklift’s hydraulic connections. Customizing these dimensions ensures a proper fit, reducing the risk of leaks and ensuring reliable fluid flow for optimal forklift side shift hydraulic cylinder performance.

Additional information

| Edited by | Yjx |

|---|