Round Gear Racks

Round gear racks function in the same linear action as square or rectangular gear racks but are cylindrical in shape. These gear racks are available in inch and metric pitch sizes and in C45K carbon steel, St50K carbon steel, and 303-grade stainless steel. Our precision round gear racks conform to DIN 867 / DIN 3972 for interchangeability and utilize a straight-toothed system with a 20-degree pressure angle. We standardly supply these in lengths ranging from 500mm to 2000mm, but custom lengths and configurations are available upon request.

Round gear racks function in the same linear action as square or rectangular gear racks but are cylindrical in shape. These gear racks are available in inch and metric pitch sizes and in C45K carbon steel, St50K carbon steel, and 303-grade stainless steel. Our precision round gear racks conform to DIN 867 / DIN 3972 for interchangeability and utilize a straight-toothed system with a 20-degree pressure angle. We standardly supply these in lengths ranging from 500mm to 2000mm, but custom lengths and configurations are available upon request.

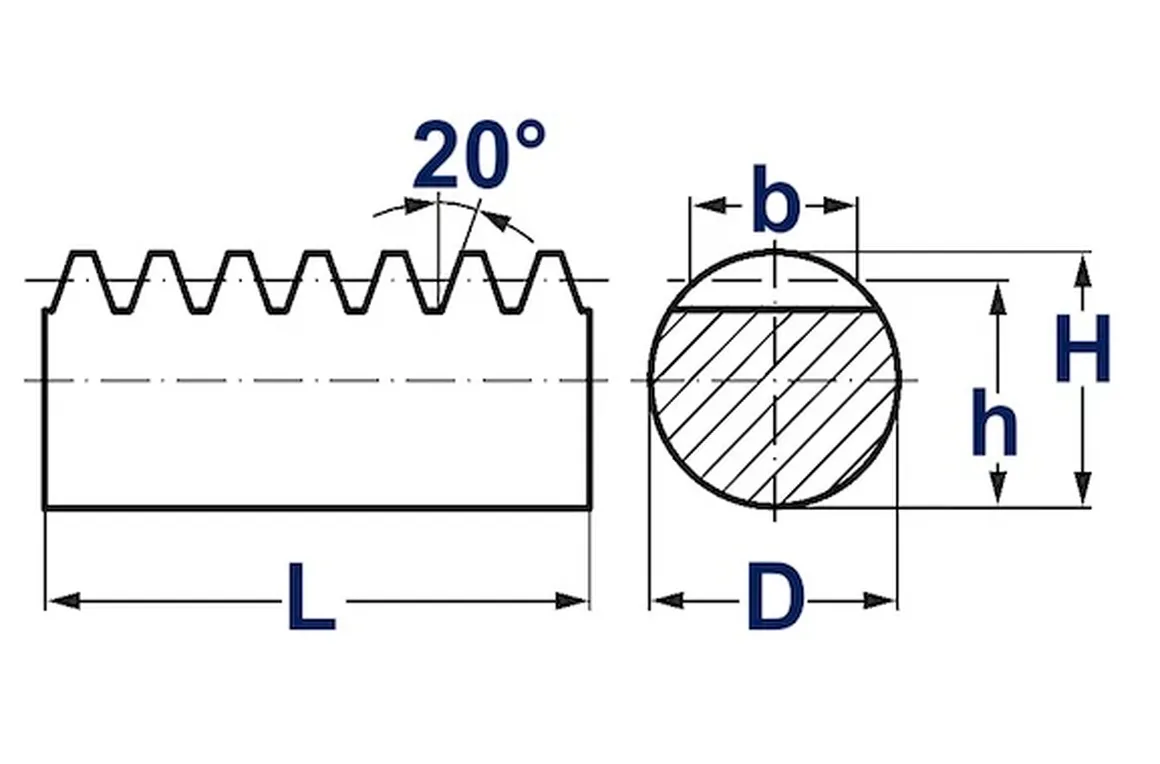

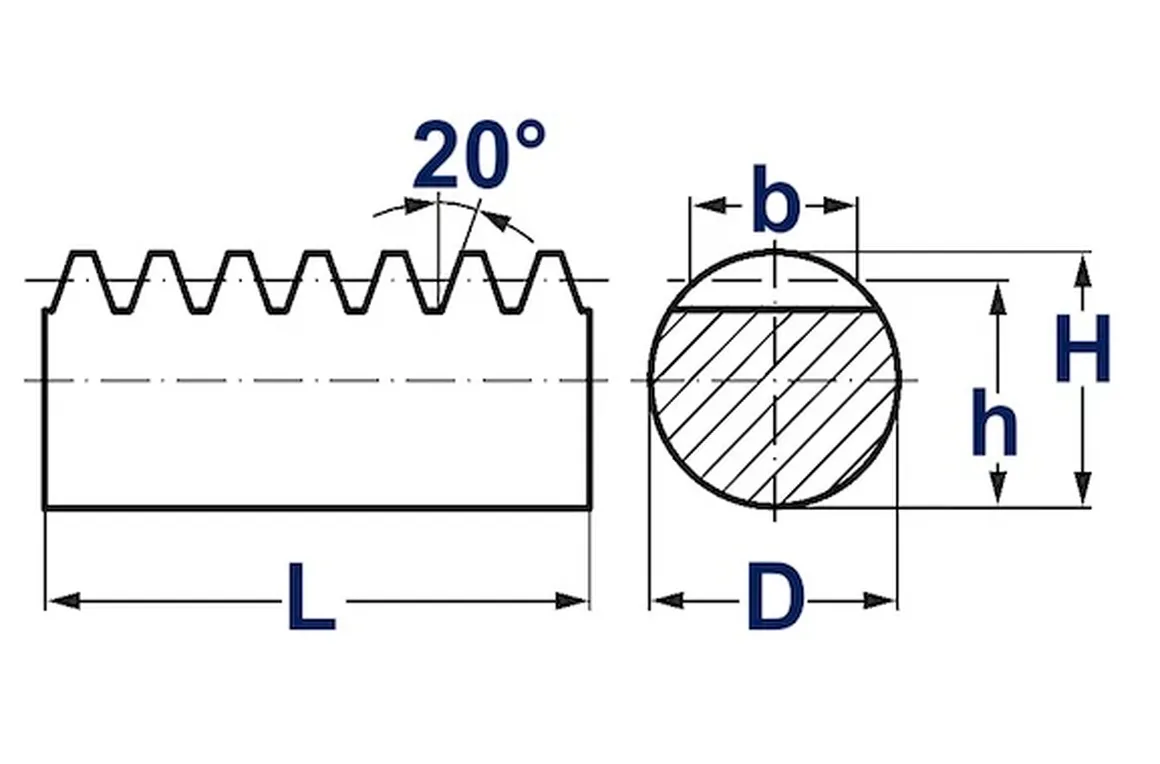

Round Gear Rack Dimensions

1. Metric Round Gear Rack Sizes

|  |

| Part # C45K Steel | Part # Stainless | Pitch | Module | Diameter (D) | Gearing Width (b) | Height (h) | Height (H) | Nomial Length (L) | Weight |

|---|---|---|---|---|---|---|---|---|---|

| 20563100 | 20599631 | 5mm | 1.59mm | 15mm | 9.4mm | 15mm | 13.4mm | 500mm | 0.64KG |

| 20563200 | 20599632 | 5mm | 1.59mm | 15mm | 9.4mm | 15mm | 13.4mm | 1000mm | 1.28KG |

| 20563400 | 20599634 | 5mm | 1.59mm | 15mm | 9.4mm | 15mm | 13.4mm | 2000mm | 2.56KG |

| 21063100 | 21099631 | 10mm | 3.18mm | 30mm | 18.8mm | 30mm | 26.8mm | 500mm | 2.59KG |

| 21063200 | 21099632 | 10mm | 3.18mm | 30mm | 18.8mm | 30mm | 26.8mm | 1000mm | 5.14KG |

| 21063400 | 21099634 | 10mm | 3.18mm | 30mm | 18.8mm | 30mm | 26.8mm | 2000mm | 10.28KG |

Notes:

Standard Steel is St50K carbon steel (2,000mm+ length is C45K)

5mm pitch production-related tolerances of dimensions h and H is -0.2mm

10mm pitch production-related tolerances of dimensions h and H is -0.3mm

Round Gear Rack Sizes

2. Round Gear Rack Sizes

|  |

| Part # Carbon Steel | Part # High-Strength Carbon Steel | Part # Stainless | Module | Diameter (D) | Gearing Width (b) | Height (h) | Height (H) | Nomial Length (L) | Weight |

|---|---|---|---|---|---|---|---|---|---|

| 22463000 | - | - | 1 | 10mm | 6.0mm | 10mm | 9.0mm | 250mm | 0.14KG |

| 22463100 | 22466631 | 22499631 | 1 | 10mm | 6.0mm | 10mm | 9.0mm | 500mm | 0.28KG |

| 22463200 | 22466632 | 22499632 | 1 | 10mm | 6.0mm | 10mm | 9.0mm | 1000mm | 0.56KG |

| 22563000 | - | - | 1 | 15mm | 7.5mm | 15mm | 14.0mm | 250mm | 0.33KG |

| 22563100 | 22566631 | - | 1 | 15mm | 7.5mm | 15mm | 14.0mm | 500mm | 0.66KG |

| 22563200 | 22566632 | - | 1 | 15mm | 7.5mm | 15mm | 14.0mm | 1000mm | 1.35KG |

| 22863000 | - | - | 1.5 | 15mm | 9.0mm | 15mm | 13.5mm | 250mm | 0.32KG |

| 22863100 | 22866631 | 22899631 | 1.5 | 15mm | 9.0mm | 15mm | 13.5mm | 500mm | 0.64KG |

| 22863200 | 22866632 | 22899632 | 1.5 | 15mm | 9.0mm | 15mm | 13.5mm | 1000mm | 1.28KG |

| 22963000 | - | - | 1.5 | 17mm | 9.6mm | 17mm | 15.5mm | 250mm | 0.42KG |

| 22963100 | - | - | 1.5 | 17mm | 9.6mm | 17mm | 15.5mm | 500mm | 0.84KG |

| 22963200 | - | - | 1.5 | 17mm | 9.6mm | 17mm | 15.5mm | 1000mm | 1.70KG |

| 24163000 | - | - | 2 | 20mm | 12mm | 20mm | 18.0mm | 250mm | 0.57KG |

| 24163100 | 24166631 | 24199631 | 2 | 20mm | 12mm | 20mm | 18.0mm | 500mm | 1.14KG |

| 24163200 | 24166632 | 24199632 | 2 | 20mm | 12mm | 20mm | 18.0mm | 1000mm | 2.28KG |

| 24163400 | 24166634 | 24199634 | 2 | 20mm | 12mm | 20mm | 18.0mm | 2000mm | 4.52KG |

| 24263000 | - | - | 2.5 | 25mm | 15mm | 25mm | 22.5mm | 250mm | 0.89KG |

| 24263100 | 24266631 | 24299631 | 2.5 | 25mm | 15mm | 25mm | 22.5mm | 500mm | 1.78KG |

| 24263200 | 24266632 | 24299632 | 2.5 | 25mm | 15mm | 25mm | 22.5mm | 1000mm | 3.56KG |

| 24263400 | 24266634 | 24299634 | 2.5 | 25mm | 15mm | 25mm | 22.5mm | 2000mm | 7.20KG |

| 24363000 | - | - | 3 | 30mm | 18mm | 30mm | 27mm | 250mm | 2.59KG |

| 24363100 | 24366631 | 24399631 | 3 | 30mm | 18mm | 30mm | 27mm | 500mm | 1.30KG |

| 24363200 | 24366632 | 24399632 | 3 | 30mm | 18mm | 30mm | 27mm | 1000mm | 5.14KG |

| 24363400 | 24366634 | 24399634 | 3 | 30mm | 18mm | 30mm | 27mm | 2000mm | 10.28KG |

| 24463000 | - | - | 4 | 40mm | 24mm | 40mm | 36mm | 250mm | 2.28KG |

| 24463100 | 24466631 | 24499631 | 4 | 40mm | 24mm | 40mm | 36mm | 500mm | 4.56KG |

| 24463200 | 24466632 | 24499632 | 4 | 40mm | 24mm | 40mm | 36mm | 1000mm | 9.12KG |

| 24463400 | 24466634 | 24499634 | 4 | 40mm | 24mm | 40mm | 36mm | 2000mm | 18.24KG |

| 24563000 | - | - | 5 | 50mm | 30mm | 50mm | 45mm | 250mm | 3.55KG |

| 24563100 | 24566631 | - | 5 | 50mm | 30mm | 50mm | 45mm | 500mm | 7.10KG |

| 24563200 | 24566632 | - | 5 | 50mm | 30mm | 50mm | 45mm | 1000mm | 14.20KG |

| 24563400 | 24566634 | - | 5 | 50mm | 30mm | 50mm | 45mm | 2000mm | 28.40KG |

| 24663100 | 24666631 | - | 6 | 60mm | 36mm | 60mm | 54mm | 500mm | 10.28KG |

| 24663200 | 24666632 | - | 6 | 60mm | 36mm | 60mm | 54mm | 1000mm | 20.56KG |

| 24663400 | 24666634 | - | 6 | 60mm | 36mm | 60mm | 54mm | 2000mm | 41.12KG |

Notes:

Standard Steel is St50K carbon steel (2,000mm+ length is C45K)

Modules 1 - 2 production-related tolerances of dimensions h and H is -0.2mm

Modules 2.5 - 4 production-related tolerances of dimensions h and H is -0.3mm

Modules 5 - 6 production-related tolerances of dimensions h and H is -0.4mm

Round Gear Rack Design Features

- Cylindrical Shape for Unique Applications

Unlike traditional square or rectangular gear racks, round gear racks feature a cylindrical design. This allows for specialized applications where space constraints or specific engineering requirements demand a more compact and versatile shape, ensuring efficient linear motion in tight or unique setups. - High-Quality Material Construction

Round gear racks are constructed from premium materials such as C45K carbon steel, St50K carbon steel, and 303-grade stainless steel. These materials provide excellent durability, corrosion resistance, and wear resistance, making the racks suitable for demanding industrial environments and ensuring a long operational lifespan. - Standardized Precision Engineering

Designed to conform to DIN 867 and DIN 3972 standards, round gear racks maintain high levels of precision and interchangeability. These standards ensure that the racks can be easily integrated into compatible systems while delivering consistent and reliable performance across a wide range of applications. - Straight-Toothed System with 20-Degree Pressure Angle

Featuring a straight-toothed configuration with a 20-degree pressure angle, round gear racks provide smooth and efficient motion transfer. This design reduces the risk of gear slippage while enhancing load distribution, ensuring accurate and reliable linear motion under varying operational conditions. - Customizable Lengths and Configurations

Standard lengths for round gear racks range from 500mm to 2000mm. However, they can be customized to meet specific requirements. This flexibility allows engineers to design systems tailored to unique challenges, ensuring optimal performance across diverse applications and industries. - Inch and Metric Pitch Size Availability

To accommodate global engineering standards, round gear racks are available in both inch and metric pitch sizes. This versatility ensures compatibility with various systems worldwide, reducing the need for additional conversions or adjustments during installation and improving overall efficiency.

Applications of Round Gear Racks

- Automation and Robotics

Round gear racks are extensively used in automation and robotics to achieve precise linear motion. Their cylindrical design allows for compact integration into robotic arms, conveyor systems, and pick-and-place mechanisms, ensuring smooth and accurate movement in high-precision industrial operations. - CNC Machines and Precision Equipment

In CNC machines and other high-precision equipment, round gear racks facilitate accurate positioning and controlled linear motion. Their conformity to DIN standards ensures seamless integration into these systems, supporting tasks like milling, cutting, and drilling with exceptional accuracy and reliability. - Elevators and Lifting Mechanisms

Round gear racks play a crucial role in elevators and lifting mechanisms, where linear motion is essential for vertical or horizontal movement. Their durable construction and smooth motion transfer make them ideal for supporting heavy loads in residential, commercial, and industrial applications. - Automotive and Transportation Systems

Round gear racks are used in automotive steering systems and automated transportation equipment. Their ability to deliver consistent and precise linear motion ensures reliable performance in critical applications like steering mechanisms, rail systems, and automated vehicle navigation systems. - Packaging and Material Handling Equipment

In packaging and material handling systems, round gear racks aid in linear positioning for conveyor belts, sorting systems, and pick-and-place units. Their customizable lengths and compatibility with different pitch sizes make them suitable for diverse industrial packaging solutions. - Medical Equipment and Devices

Round gear racks are commonly utilized in medical devices and equipment requiring precise linear motion, such as diagnostic machines and surgical robots. Their high precision, durability, and corrosion-resistant materials make them suitable for the stringent requirements of the healthcare industry.

|  |

| Gear Rack for Automation and Robotics | Gear Rack for Automotive Systems |

|  |

| Gear Rack for CNC Machine Tool | Gear Rack for Elevators and Lifts |

Round Gear Rack Material Optional

Round gear racks are available in various materials to suit different applications, each offering distinct benefits in terms of durability, performance, and environmental compatibility. The three main material options for round gear racks include steel, stainless steel, and plastic.

- Steel

Steel round gear racks are commonly made from materials like C45K carbon steel or St50K carbon steel, known for their exceptional strength and durability. These racks are ideal for heavy-duty applications, such as industrial machinery, automotive systems, and lifting mechanisms, where high load-bearing capacity and impact resistance are required. Steel gear racks are also cost-effective, making them a preferred choice for applications where material strength is prioritized over corrosion resistance. - Stainless Steel

Stainless steel round gear racks, often made from 303-grade stainless steel, are designed for applications requiring enhanced corrosion resistance and durability. They are particularly well-suited for environments exposed to moisture, chemicals, or extreme temperatures, such as marine, food processing, or medical industries. Stainless steel racks provide long-lasting performance and require minimal maintenance, making them a reliable option for equipment operating in harsh or regulated conditions. - Plastic

Plastic round gear racks are lightweight and ideal for low-load or sensitive applications where noise reduction and minimal wear are critical. Commonly made from high-performance polymers, these racks are used in medical devices, electronics, and lightweight automation systems. Plastic gear racks offer excellent resistance to corrosion and are cost-efficient for applications requiring low friction and reduced operational noise.

Additional information

| Edited by | Yjx |

|---|