Polyketone Resin Plastic Bevel Gears Ratio 1:1 – 5:1

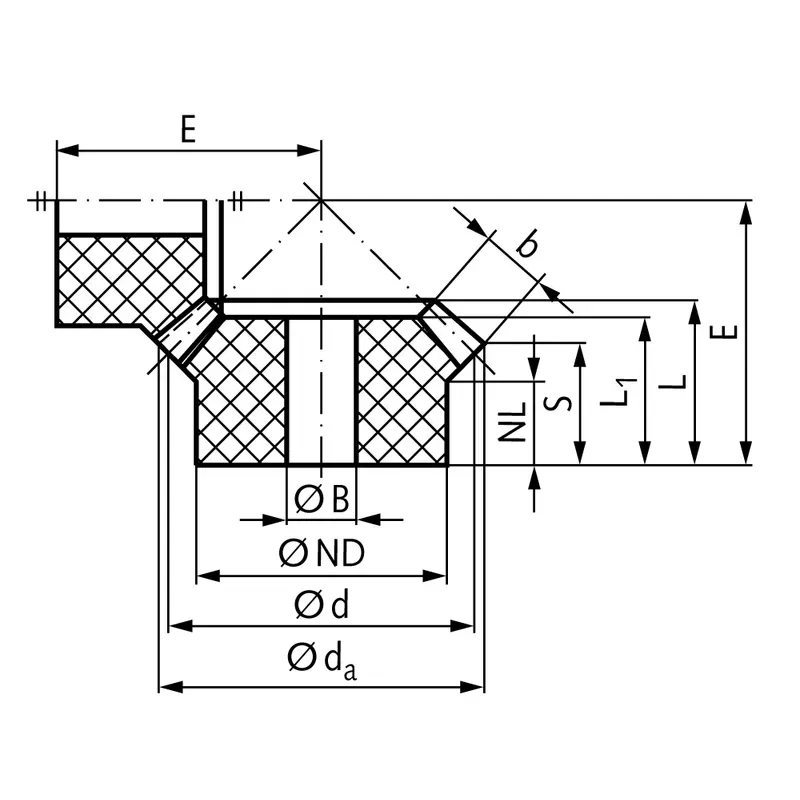

Polyketone resin plastic bevel gears with ratios from 1:1 to 5:1 are precision-engineered components designed for transmitting motion at a 90-degree shaft angle. Made from aliphatic polyketone (PK), a high-performance thermoplastic, these gears offer superior wear resistance, low friction, and excellent dimensional stability due to low moisture absorption compared to polyamide (nylon) or polyacetal (POM). They are injection-molded with straight teeth, typically featuring an engagement angle of 20°, and are available in modules ranging from 0.5 to 3.

Polyketone resin plastic bevel gears with ratios from 1:1 to 5:1 are precision-engineered components designed for transmitting motion at a 90-degree shaft angle. Made from aliphatic polyketone (PK), a high-performance thermoplastic, these gears offer superior wear resistance, low friction, and excellent dimensional stability due to low moisture absorption compared to polyamide (nylon) or polyacetal (POM). They are injection-molded with straight teeth, typically featuring an engagement angle of 20°, and are available in modules ranging from 0.5 to 3.

Their ivory-colored, die-cast construction ensures durability, with a temperature range of -40°C to +140°C, making them suitable for diverse applications, including food-contact environments due to their chemical resistance. These gears are sold individually, requiring two matching gears of the same module and ratio for a pair, with 1:1 needing identical teeth counts and uneven ratios requiring different teeth counts.

Polyketone Resin Plastic Bevel Gear Ratio 1:1

|  |

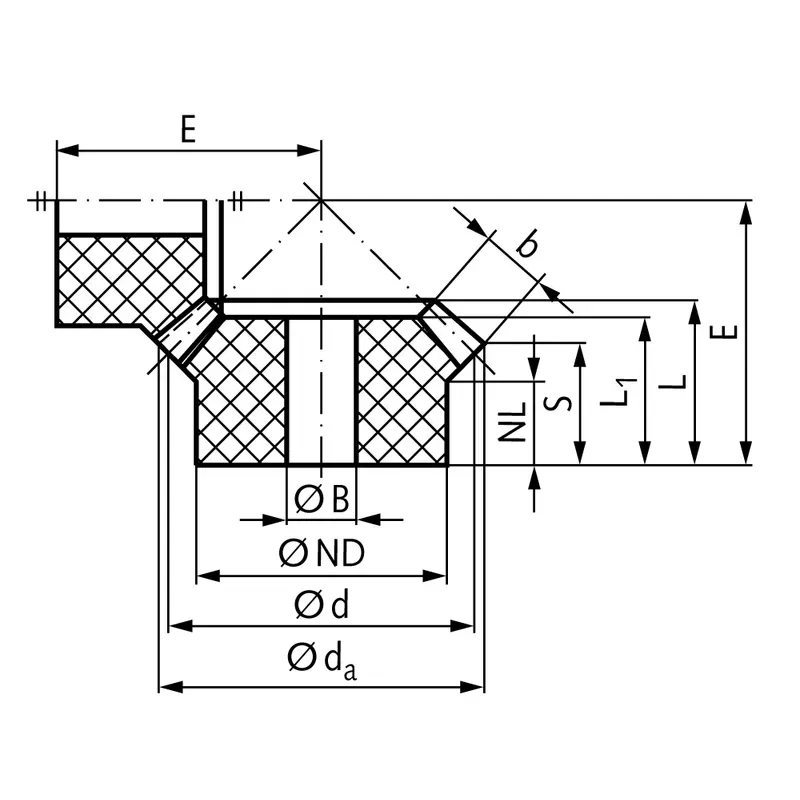

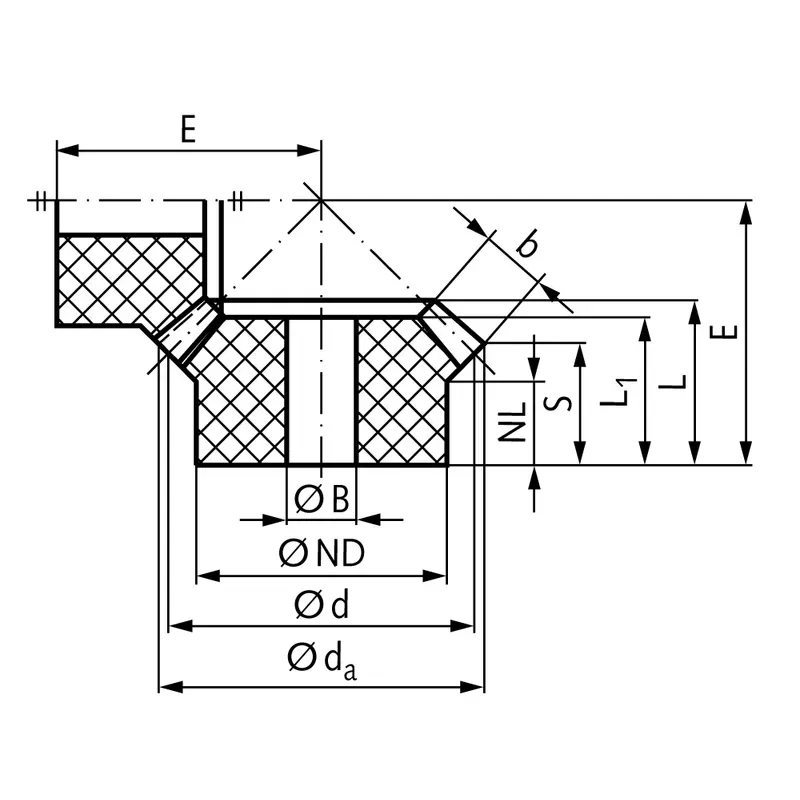

| Module | Number of teeth | da | d | ND | NL | L1 | L | S | b | B | E | Torque* | Weight |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | Ncm | g | ||

| 0,5 | 16 | 8,7 | 8 | 7 | 6 | 8 | 8 | 6,6 | 2 | 3 | 10,5 | 0,95 | 0,27 |

| 1 | 16 | 17,6 | 16 | 12 | 8 | 13,6 | 13,6 | 10,6 | 4,7 | 5 | 18,4 | 8,7 | 1,8 |

| 1 | 30 | 31,4 | 30 | 15 | 7,4 | 12,9 | 15,3 | 10,8 | 7,4 | 6 | 24,8 | 61 | 5,4 |

| 1,5 | 16 | 26,4 | 24 | 18,5 | 10 | 16,2 | 18,4 | 14,4 | 7 | 8 | 25,8 | 31 | 5,4 |

| 2 | 16 | 34,9 | 32 | 21,9 | 9,6 | 18,3 | 21,2 | 14,9 | 10 | 10 | 30,4 | 77 | 9,7 |

| 2,5 | 16 | 43,5 | 40 | 25,2 | 11,5 | 22,9 | 25,5 | 18,2 | 12,3 | 12 | 37 | 152 | 17,9 |

| 3 | 16 | 52,3 | 48 | 28,8 | 13,2 | 25,8 | 29,2 | 20,6 | 13,8 | 14 | 43 | 263 | 27,8 |

| 3,5 | 16 | 61,4 | 56 | 33,3 | 14,4 | 28,1 | 33,1 | 22,8 | 15,8 | 18 | 49,5 | 462 | 42,2 |

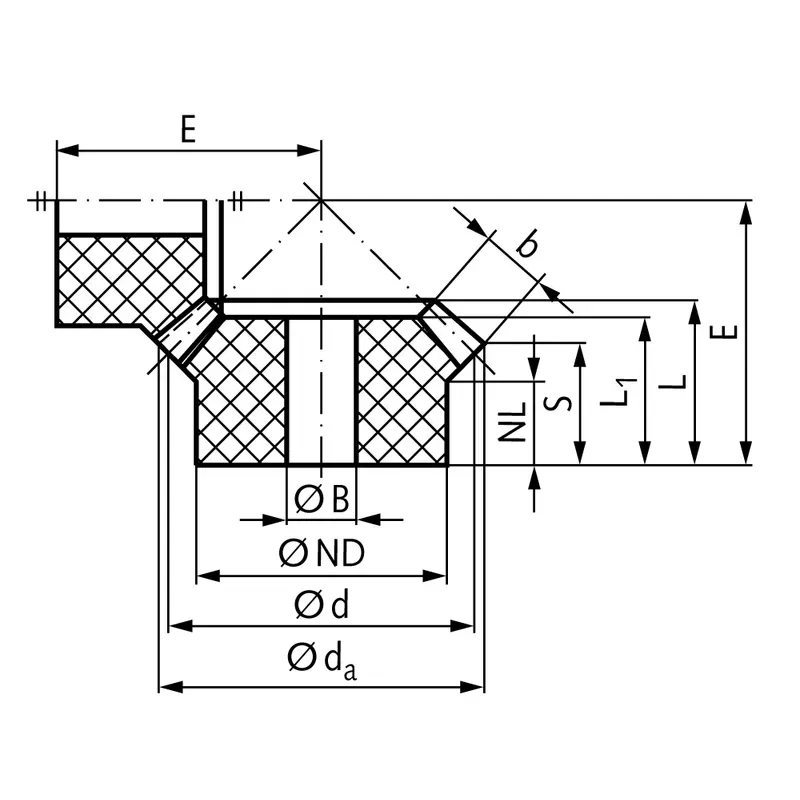

Polyketone Resin Plastic Bevel Gear Ratio 1.5:1

|  |

| Module | Number of teeth | da | d | ND | NL | L1 | L | S | b | B | E | Torque* | Weight |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | Ncm | g | ||

| 1,5 | 16 | 26 | 24 | 20 | 10,8 | 17,8 | 18,8 | 12,5 | 8 | 8 | 30 | 38 | 6,5 |

| 1,5 | 24 | 37 | 36 | 24 | 11,3 | 18 | 19,5 | 15,0 | 8 | 10 | 26,6 | 57 | 10,4 |

Polyketone Resin Plastic Bevel Gear Ratio 2:1

|  |

| Module | Number of teeth | da | d | ND | NL | L1 | L | S | b | B | E | Torque* | Weight |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | Ncm | g | ||

| 1 | 15 | 16,8 | 15 | 12,2 | 10,6 | 17 | 17 | 11,5 | 6,6 | 5 | 26,4 | 12,6 | 2,2 |

| 1 | 30 | 31,1 | 30 | 18 | 9,1 | 14,8 | 16,2 | 13,6 | 6,6 | 8 | 20,9 | 25 | 6,3 |

| 1,5 | 15 | 25,4 | 22,5 | 17 | 11,5 | 22,8 | 22,8 | 13,8 | 10,5 | 8 | 35,8 | 45 | 6,7 |

| 1,5 | 30 | 46,4 | 45 | 23,4 | 9,6 | 17,5 | 19,5 | 15,0 | 10,5 | 10 | 26,2 | 90 | 16,2 |

| 2 | 15 | 33,6 | 30 | 22,5 | 11,8 | 26 | 27 | 14,5 | 14,6 | 10 | 44,2 | 112 | 11,9 |

| 2 | 30 | 62,2 | 60 | 30,2 | 11,8 | 22,6 | 24,2 | 18,5 | 14,6 | 12 | 32,6 | 225 | 37,7 |

| 2,5 | 15 | 42 | 37,5 | 26,5 | 13 | 29,6 | 31,2 | 16,4 | 17,3 | 12 | 53,3 | 220 | 21,2 |

| 2,5 | 30 | 77,3 | 75 | 36,1 | 15 | 27,5 | 29,5 | 22,8 | 17,3 | 16 | 40,5 | 439 | 69,1 |

| 3 | 15 | 50,3 | 45 | 31,2 | 14,8 | 35 | 36,3 | 19,0 | 20,5 | 14 | 63,3 | 389 | 34,1 |

| 3 | 30 | 93 | 90 | 45 | 19 | 34,2 | 37 | 29,2 | 20,5 | 18 | 49,5 | 777 | 122,0 |

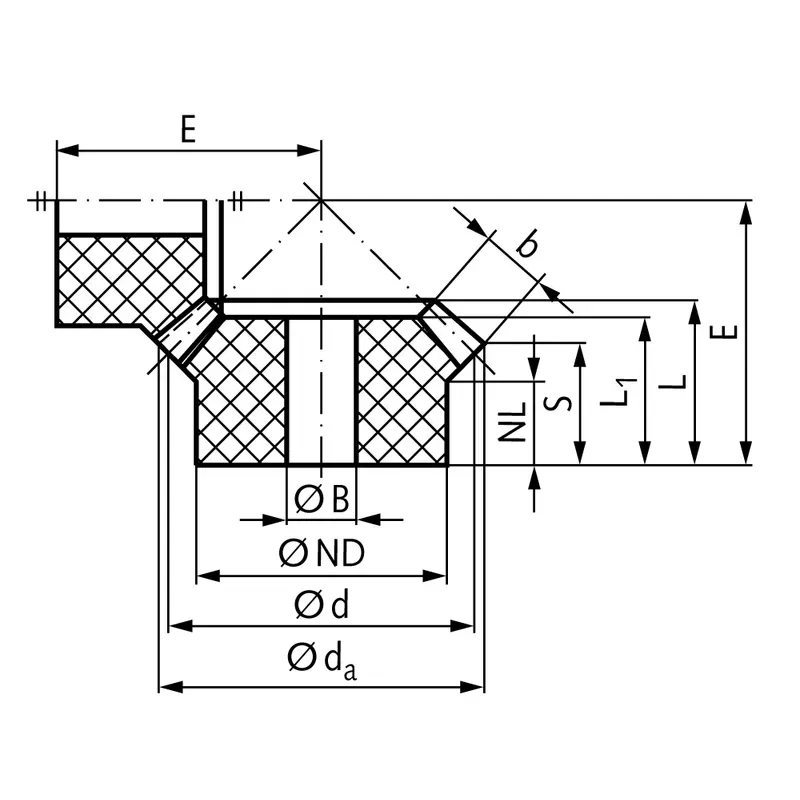

Polyketone Resin Plastic Bevel Gear Ratio 3:1

|  |

| Module | Number of teeth | da | d | ND | NL | L1 | L | S | b | B | E | Torque* | Weight |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | Ncm | g | ||

| 1 | 15 | 16,6 | 15 | 12,3 | 11 | 20,4 | 20,4 | 12,1 | 9,2 | 5 | 34,3 | 16,8 | 2,5 |

| 1 | 45 | 46,1 | 45 | 23,4 | 9,6 | 16,5 | 18,2 | 15,7 | 9,2 | 10 | 22,7 | 50 | 15,7 |

| 1,5 | 15 | 25,1 | 22,5 | 17,2 | 12,5 | 26,8 | 26,8 | 13,5 | 14 | 8 | 47,9 | 67 | 6,8 |

| 1,5 | 45 | 68,8 | 67,5 | 30,4 | 11,5 | 21,5 | 23 | 19,2 | 14 | 12 | 29,4 | 202 | 45,3 |

| 2 | 10 | 24,0 | 20 | 15,6 | 12 | 25,0 | 25 | 13,2 | 12,5 | 6 | 43,7 | 32 | 5,4 |

| 2 | 30 | 61,7 | 60 | 30,3 | 11,5 | 20,2 | 22,5 | 19,0 | 12,5 | 12 | 28 | 95 | 34,1 |

| 2,5 | 10 | 29,7 | 25 | 18,8 | 13 | 28,8 | 28,8 | 14,1 | 15,7 | 8 | 52,4 | 63 | 9,2 |

| 2,5 | 30 | 77,2 | 75 | 36,1 | 15,5 | 25,2 | 29 | 24,1 | 15,7 | 18 | 35,7 | 189 | 60,6 |

Polyketone Resin Plastic Bevel Gear Ratio 4:1

|  |

| Module | Number of teeth | da | d | ND | NL | L1 | L | S | b | B | E | Torque* | Weight |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | Ncm | g | ||

| 1 | 10 | 12 | 10 | 7,8 | 9,3 | 17,7 | 17,7 | 10,1 | 8,2 | 4 | 30,1 | 4,7 | 0,8 |

| 1 | 40 | 40,8 | 40 | 23,4 | 10,8 | 15,7 | 17 | 15,1 | 8,2 | 10 | 20,1 | 19 | 11,3 |

| 1,5 | 10 | 18 | 15 | 11,3 | 10,9 | 23,5 | 23,5 | 11,7 | 12,3 | 5 | 41,7 | 18 | 2,7 |

| 1,5 | 40 | 61,2 | 60 | 30,4 | 12,8 | 20 | 21,7 | 18,6 | 12,3 | 12 | 26,2 | 71 | 28,7 |

| 2 | 10 | 23,8 | 20 | 14,3 | 12,8 | 28,9 | 28,9 | 13,2 | 16,3 | 6 | 54 | 42 | 5,6 |

| 2 | 40 | 81,5 | 80 | 36 | 16,6 | 24,7 | 27 | 23,1 | 16,3 | 18 | 32,5 | 168 | 55,6 |

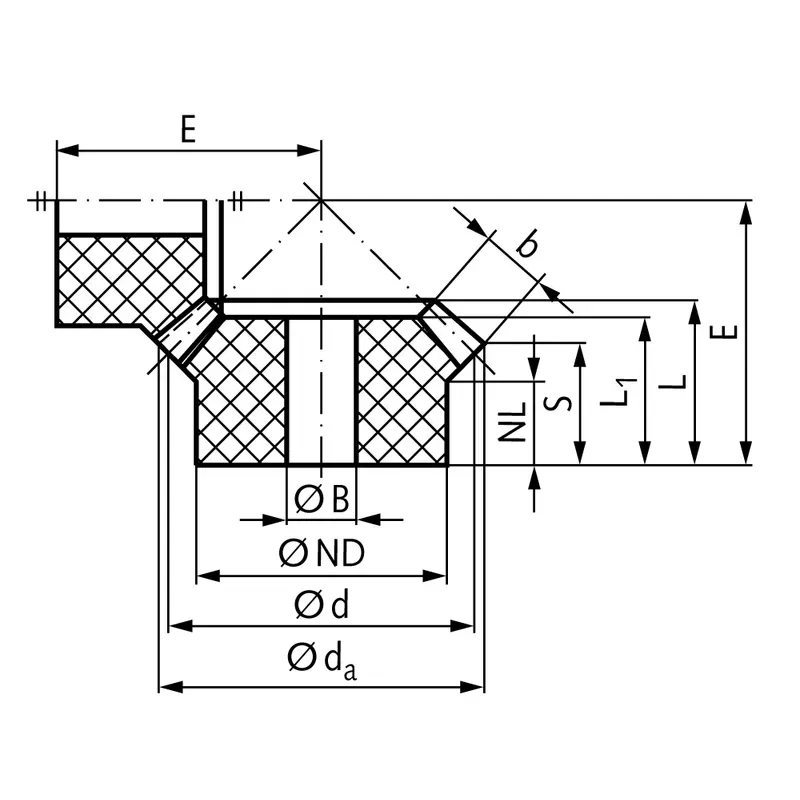

Polyketone Resin Plastic Bevel Gear Ratio 5:1

|  |

| Module | Number of teeth | da | d | ND | NL | L1 | L | S | b | B | E | Torque* | Weight |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | Ncm | g | ||

| 1 | 12 | 13,7 | 12 | 9,5 | 10 | 20,3 | 20,3 | 10,5 | 9,5 | 4 | 40,5 | 12,6 | 1,4 |

| 1 | 60 | 60,4 | 60 | 20,5 | 11 | 15,5 | 17,4 | 15,4 | 9,5 | 10 | 21 | 63 | 17,9 |

Polyketone Resin Plastic Bevel Gear Features

1. High Wear Resistance and Durability

Polyketone resin plastic bevel gears exhibit exceptional wear resistance due to their aliphatic polyketone (PK) composition. This material outperforms traditional plastics like nylon and POM, ensuring long-lasting performance in demanding applications, including continuous motion systems, with minimal degradation over time.

2. Low Friction and Smooth Operation

These bevel gears feature a low coefficient of friction, enabling smooth and efficient power transmission. The straight-tooth design with a 20° engagement angle minimizes energy loss, making them ideal for applications requiring precise motion transfer, such as robotics or small machinery.

3. Excellent Dimensional Stability

Polyketone’s low moisture absorption ensures consistent gear dimensions even in humid environments. Unlike nylon, which can swell, these gears maintain tight tolerances, reducing backlash and ensuring reliable performance in precision-driven applications like automation or medical equipment.

4. Wide Temperature Range

These bevel gears operate effectively from -40°C to +140°C, accommodating extreme environmental conditions. This broad temperature tolerance makes them suitable for industries ranging from automotive to food processing, where thermal stability is critical for consistent gear performance.

5. Chemical and Food-Safe Properties

Polyketone resin offers excellent resistance to chemicals, oils, and solvents, making these gears suitable for food-contact applications. Compliant with stringent safety standards, they are ideal for use in food processing equipment, ensuring hygiene without compromising mechanical strength.

6. Injection-Molded Precision

Manufactured through injection molding, these polyketone resin bevel gears achieve high precision and uniformity. Available in modules from 0.5 to 3, their ivory-colored, die-cast construction ensures consistent quality, enabling reliable 90-degree motion transmission in compact, lightweight assemblies for various engineering applications.

Plastic Bevel Gear Material Options

1. Polyoxymethylene (POM)

Polyoxymethylene (POM), commonly known as acetal, is a highly durable engineering plastic renowned for its excellent mechanical properties. It offers high stiffness, low friction, and excellent dimensional stability, making it an ideal choice for small plastic bevel gears that require precision and strength. POM gears exhibit superior wear resistance and are well-suited for applications where smooth operation and long-lasting performance are critical.

2. Nylon

Nylon is a versatile and widely used engineering plastic known for its outstanding toughness and abrasion resistance. It provides excellent tensile strength and impact resistance, making it a reliable material for small plastic bevel gears that need to withstand heavy loads and harsh conditions. Nylon’s ability to absorb vibrations and reduce noise further enhances its suitability for various applications, ensuring smooth and quiet gear operation.

3. Other Engineering Plastics

We also offer a range of other high-performance engineering plastics tailored to specific application needs. These materials include, but are not limited to, advanced composites that provide enhanced heat resistance, chemical stability, and lightweight properties. Whether it's for extreme environments or specialized applications, our selection of engineering plastics ensures that we can deliver custom small plastic bevel gears that meet the most demanding requirements.

Polyketone Resin Plastic Bevel Gear Examples

Robotics and Automation

In robotics, these polyketone resin bevel gears enable precise motion control and power transmission between angled shafts. Their low friction and smooth operation ensure accurate and efficient movement, making them essential in robotic arms, conveyor systems, and automated machinery requiring high precision.

Food Processing Equipment

These plastic bevel gears are ideal for food-contact machinery due to their chemical resistance and compliance with safety standards. Their low moisture absorption and durability make them suitable for conveyors and mixers, ensuring reliable performance in hygienic, high-humidity food production environments.

Medical Equipment

Polyketone bevel gears are used in medical devices such as imaging equipment, surgical robots, and diagnostic tools. Their smooth and quiet operation, along with their ability to work in sterile environments, makes them highly suitable for sensitive healthcare applications.

Automotive Industry

Polyketone resin plastic bevel gears are widely used in automotive systems such as steering mechanisms, transmission components, and fuel pumps. Their durability, chemical resistance, and lightweight nature make them ideal for withstanding harsh conditions and ensuring smooth, reliable performance in vehicles.

Consumer Electronics

These bevel gears are employed in devices like printers and cameras for compact motion control. Their injection-molded precision and low noise output ensure smooth functionality in small, high-precision mechanisms, meeting the demands of modern, space-constrained electronic designs.

Agricultural Equipment

In farming machinery like seeders, harvesters, and irrigation systems, polyketone bevel gears provide reliable performance. Their resistance to wear, environmental factors, and chemicals like fertilizers ensures they perform effectively in rugged outdoor and agricultural environments.

|  |

| Bevel Gear for Robotics | Bevel Gear for Automotive Industry |

|  |

| Bevel Gear for Medical Equipment | Bevel Gear for Food Industry |

Additional information

| Edited by | Yjx |

|---|