Polyacetal Resin Plastic Bevel Gears Ratio 1:1 – 5:1

Polyacetal resin plastic bevel gears with ratios ranging from 1:1 to 5:1 are precision-engineered components designed for transmitting motion between intersecting shafts at a 90-degree angle. Made from polyacetal (POM), a semicrystalline thermoplastic, these plastic bevel gears offer high stiffness, low friction, and excellent dimensional stability, making them ideal for applications requiring reliable torque transfer, such as in automotive, appliances, and industrial machinery.

Polyacetal resin plastic bevel gears with ratios ranging from 1:1 to 5:1 are precision-engineered components designed for transmitting motion between intersecting shafts at a 90-degree angle. Made from polyacetal (POM), a semicrystalline thermoplastic, these plastic bevel gears offer high stiffness, low friction, and excellent dimensional stability, making them ideal for applications requiring reliable torque transfer, such as in automotive, appliances, and industrial machinery. The gear ratios indicate the speed and torque relationship between paired gears; for example, a 1:1 ratio means equal teeth counts for uniform speed, while a 5:1 ratio involves a larger gear driving a smaller one, amplifying torque.

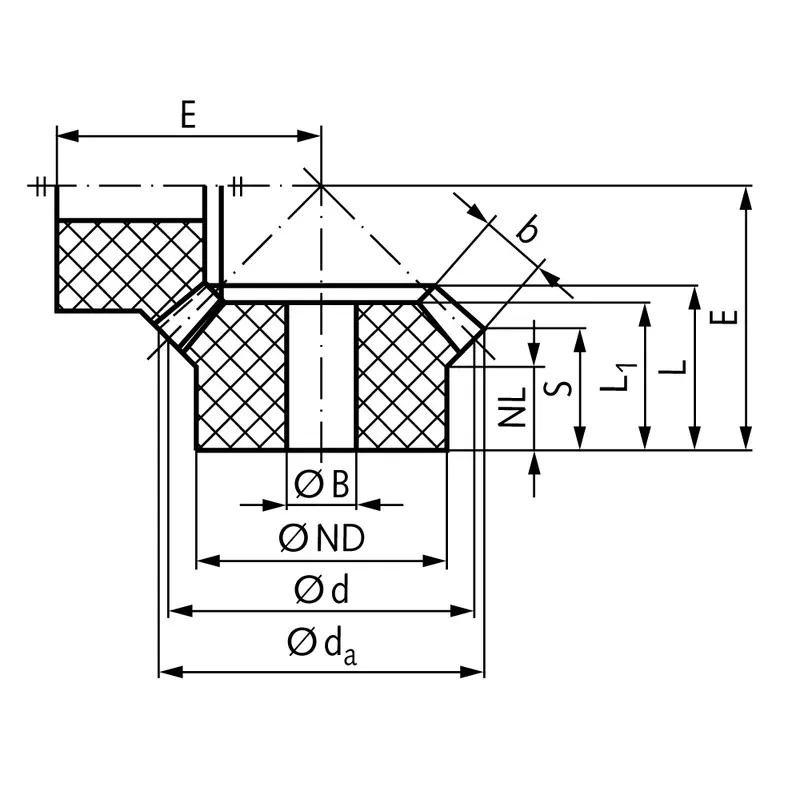

Polyacetal Resin Plastic Bevel Gear Ratio 1:1

|  |

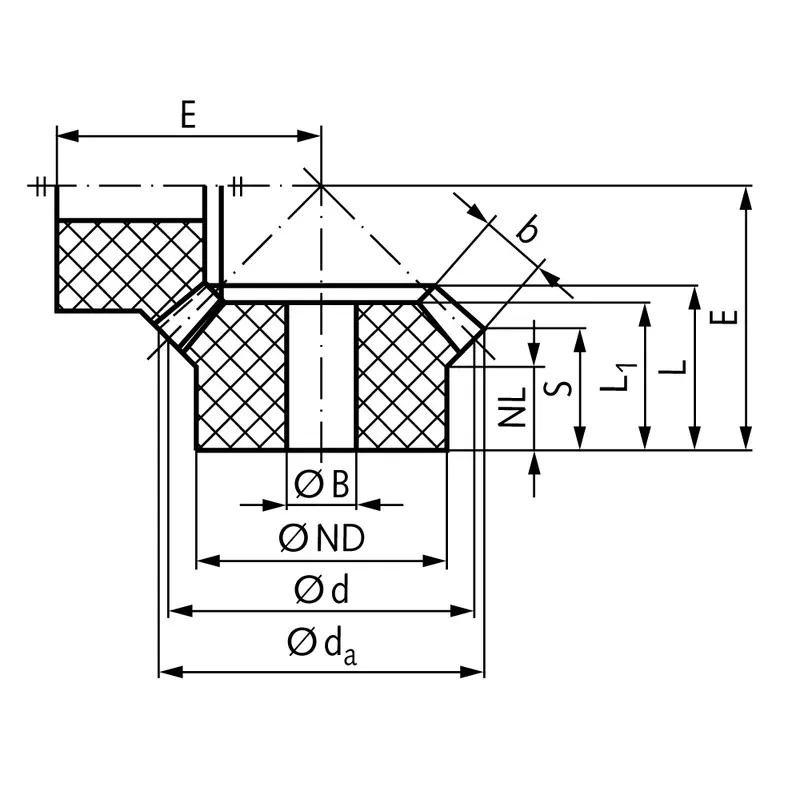

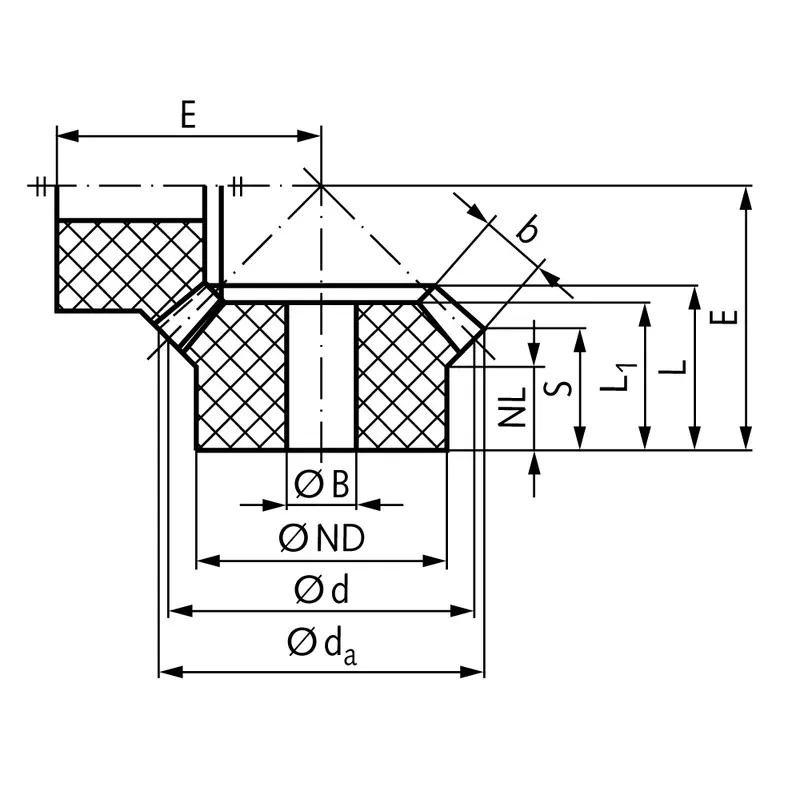

| Module | Number of teeth | da | d | ND | NL | L1 | L | S | b | B | E | Torque* | Weight |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | Ncm | g | ||

| 0,5 | 16 | 8,7 | 8 | 7 | 6 | 8 | 8 | 6,6 | 2 | 3 | 10,5 | 0,9 | 0,3 |

| 1 | 16 | 17,6 | 16 | 12 | 8 | 13,6 | 13,6 | 10,6 | 4,7 | 5 | 18,4 | 8,3 | 2,0 |

| 1 | 30 | 31,4 | 30 | 15 | 7,4 | 12,9 | 15,3 | 10,8 | 7,4 | 6 | 24,8 | 58 | 6,0 |

| 1,5 | 16 | 26,4 | 24 | 18,5 | 10 | 16,2 | 18,4 | 14,4 | 7 | 8 | 25,8 | 29 | 6,0 |

| 2 | 16 | 34,9 | 32 | 21,9 | 9,6 | 18,3 | 21,2 | 14,9 | 10 | 10 | 30,4 | 73 | 10,8 |

| 2,5 | 16 | 43,5 | 40 | 25,2 | 11,5 | 22,9 | 25,5 | 18,2 | 12,3 | 12 | 37 | 145 | 20,0 |

| 3 | 16 | 52,3 | 48 | 28,8 | 13,2 | 25,8 | 29,2 | 20,6 | 13,8 | 14 | 43 | 250 | 31,0 |

| 3,5 | 16 | 61,4 | 56 | 33,3 | 14,4 | 28,1 | 33,1 | 22,8 | 15,8 | 18 | 49,5 | 440 | 47,0 |

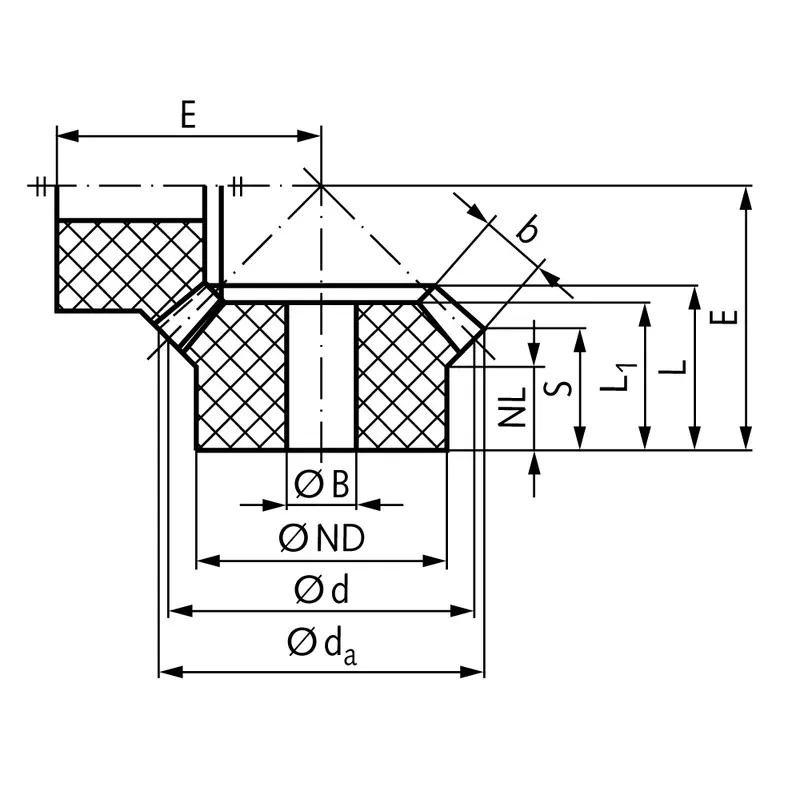

Polyacetal Resin Plastic Bevel Gear Ratio 1.5:1

|  |

| Module | Number of teeth | da | d | ND | NL | L1 | L | S | b | B | E | Torque* | Weight |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | Ncm | g | ||

| 1,5 | 16 | 26 | 24 | 20 | 10,8 | 17,8 | 18,8 | 12,5 | 8 | 8 | 30 | 36 | 6,6 |

| 1,5 | 24 | 37 | 36 | 24 | 11,3 | 18 | 19,5 | 15,0 | 8 | 10 | 26,6 | 54 | 11,6 |

Polyacetal Resin Plastic Bevel Gear Ratio 2:1

|  |

| Module | Number of teeth | da | d | ND | NL | L1 | L | S | b | B | E | Torque* | Weight |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | Ncm | g | ||

| 1 | 15 | 16,8 | 15 | 12,2 | 10,6 | 17 | 17 | 11,5 | 6,6 | 5 | 26,4 | 12 | 2,4 |

| 1 | 30 | 31,1 | 30 | 18 | 9,1 | 14,8 | 16,2 | 13,6 | 6,6 | 8 | 20,9 | 24 | 7,0 |

| 1,5 | 15 | 25,4 | 22,5 | 17 | 11,5 | 22,8 | 22,8 | 13,8 | 10,5 | 8 | 35,8 | 43 | 7,5 |

| 1,5 | 30 | 46,4 | 45 | 23,4 | 9,6 | 17,5 | 19,5 | 15,0 | 10,5 | 10 | 26,2 | 86 | 18,0 |

| 2 | 15 | 33,6 | 30 | 22,5 | 11,8 | 26 | 27 | 14,5 | 14,6 | 10 | 44,2 | 107 | 13,3 |

| 2 | 30 | 62,2 | 60 | 30,2 | 11,8 | 22,6 | 24,2 | 18,5 | 14,6 | 12 | 32,6 | 214 | 42,0 |

| 2,5 | 15 | 42 | 37,5 | 26,5 | 13 | 29,6 | 31,2 | 16,4 | 17,3 | 12 | 53,3 | 209 | 23,6 |

| 2,5 | 30 | 77,3 | 75 | 36,1 | 15 | 27,5 | 29,5 | 22,8 | 17,3 | 16 | 40,5 | 418 | 77,0 |

| 3 | 15 | 50,3 | 45 | 31,2 | 14,8 | 35 | 36,3 | 19,0 | 20,5 | 14 | 63,3 | 370 | 38,0 |

| 3 | 30 | 93 | 90 | 45 | 19 | 34,2 | 37 | 29,2 | 20,5 | 18 | 49,5 | 740 | 136,0 |

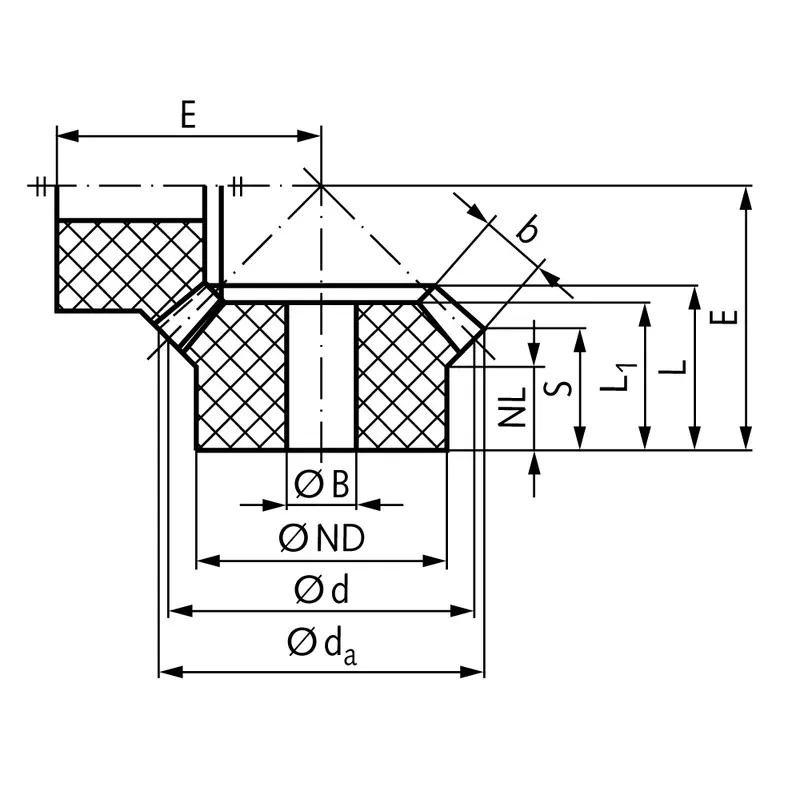

Polyacetal Resin Plastic Bevel Gear Ratio 3:1

|  |

| Module | Number of teeth | da | d | ND | NL | L1 | L | S | b | B | E | Torque* | Weight |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | Ncm | g | ||

| 1 | 15 | 16,6 | 15 | 12,3 | 11 | 20,4 | 20,4 | 12,1 | 9,2 | 5 | 34,3 | 16 | 2,8 |

| 1 | 45 | 46,1 | 45 | 23,4 | 9,6 | 16,5 | 18,2 | 15,7 | 9,2 | 10 | 22,7 | 48 | 17,5 |

| 1,5 | 15 | 25,1 | 22,5 | 17,2 | 12,5 | 26,8 | 26,8 | 13,5 | 14 | 8 | 47,9 | 64 | 7,6 |

| 1,5 | 45 | 68,8 | 67,5 | 30,4 | 11,5 | 21,5 | 23 | 19,2 | 14 | 12 | 29,4 | 192 | 50,5 |

| 2 | 10 | 24,0 | 20 | 15,6 | 12 | 25,0 | 25 | 13,2 | 12,5 | 6 | 43,7 | 30 | 6,0 |

| 2 | 30 | 61,7 | 60 | 30,3 | 11,5 | 20,2 | 22,5 | 19,0 | 12,5 | 12 | 28 | 90 | 38,0 |

| 2,5 | 10 | 29,7 | 25 | 18,8 | 13 | 28,8 | 28,8 | 14,1 | 15,7 | 8 | 52,4 | 60 | 10,2 |

| 2,5 | 30 | 77,2 | 75 | 36,1 | 15,5 | 25,2 | 29 | 24,1 | 15,7 | 18 | 35,7 | 180 | 67,5 |

Polyacetal Resin Plastic Bevel Gear Ratio 4:1

|  |

| Module | Number of teeth | da | d | ND | NL | L1 | L | S | b | B | E | Torque* | Weight |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | Ncm | g | ||

| 1 | 10 | 12 | 10 | 7,8 | 9,3 | 17,7 | 17,7 | 10,1 | 8,2 | 4 | 30,1 | 4,5 | 0,9 |

| 1 | 40 | 40,8 | 40 | 23,4 | 10,8 | 15,7 | 17 | 15,1 | 8,2 | 10 | 20,1 | 18 | 12,6 |

| 1,5 | 10 | 18 | 15 | 11,3 | 10,9 | 23,5 | 23,5 | 11,7 | 12,3 | 5 | 41,7 | 17 | 3,0 |

| 1,5 | 40 | 61,2 | 60 | 30,4 | 12,8 | 20 | 21,7 | 18,6 | 12,3 | 12 | 26,2 | 68 | 32,0 |

| 2 | 10 | 23,8 | 20 | 14,3 | 12,8 | 28,9 | 28,9 | 13,2 | 16,3 | 6 | 54 | 40 | 6,2 |

| 2 | 40 | 81,5 | 80 | 36 | 16,6 | 24,7 | 27 | 23,1 | 16,3 | 18 | 32,5 | 160 | 62,0 |

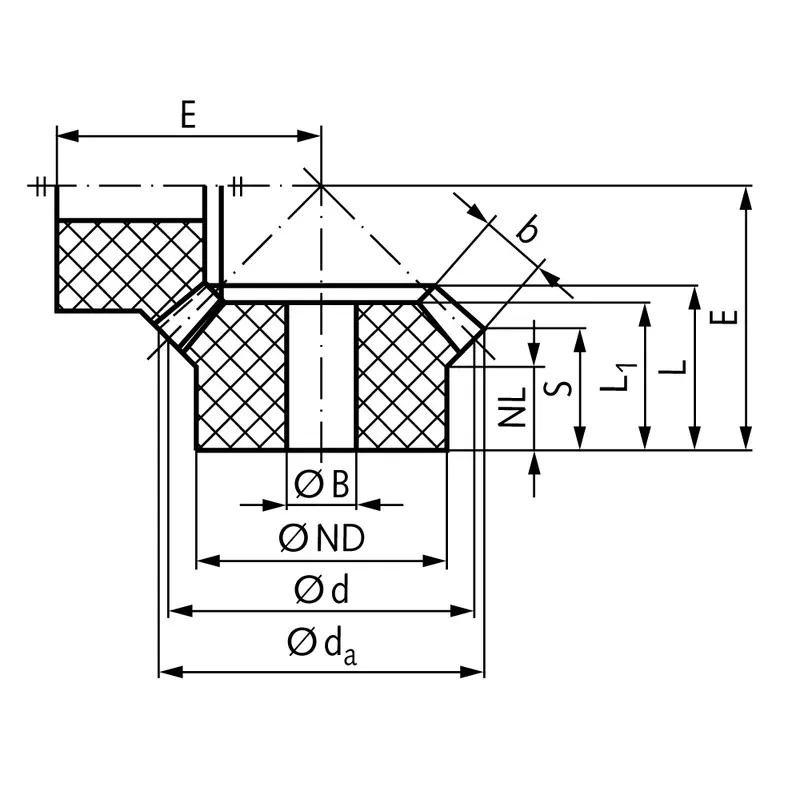

Polyacetal Resin Plastic Bevel Gear Ratio 5:1

|  |

| Module | Number of teeth | da | d | ND | NL | L1 | L | S | b | B | E | Torque* | Weight |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | Ncm | g | ||

| 1 | 12 | 13,7 | 12 | 9,5 | 10 | 20,3 | 20,3 | 10,5 | 9,5 | 4 | 40,5 | 12 | 1,6 |

| 1 | 60 | 60,4 | 60 | 20,5 | 11 | 15,5 | 17,4 | 15,4 | 9,5 | 10 | 21 | 60 | 20,0 |

Polyacetal Resin Plastic Bevel Gear Benefits

1. High Durability and Wear Resistance

Polyacetal resin offers exceptional durability and wear resistance, making these plastic bevel gears suitable for long-term use in demanding applications. This material reduces surface friction during operation, ensuring the gears maintain their structural integrity and performance even under continuous or heavy loads.

2. Lightweight with High Mechanical Strength

These polyacetal resin bevel gears are lightweight yet retain high mechanical strength, allowing for efficient power transmission without adding unnecessary weight to the system. This characteristic makes them ideal for applications like robotics, drones, and automotive systems, where weight reduction is critical for performance.

3. Excellent Dimensional Stability

Polyacetal resin resists deformation due to temperature changes and mechanical stress, ensuring the plastic bevel gears maintain precise dimensions. This stability is crucial for applications requiring high accuracy, as it prevents misalignment and ensures consistent gear performance over time.

4. Corrosion and Chemical Resistance

These gears are resistant to corrosion and many chemicals, making them suitable for use in harsh environments such as industrial machinery or outdoor applications. They can operate reliably in moist, humid, or chemically aggressive conditions without degradation in quality or performance.

5. Quiet and Smooth Operation

The low-friction properties of polyacetal resin contribute to quiet and smooth gear operation. This feature is particularly advantageous for applications in noise-sensitive environments like medical equipment or consumer electronics, where silent performance is a priority.

6. Cost-Effective and Easy to Manufacture

Polyacetal resin bevel gears are cost-effective due to their ease of manufacturing through injection molding. This process allows for large-scale production of gears with consistent quality and precision, reducing overall costs while meeting the demands of various industries.

Plastic Bevel Gear vs. Stainless Steel Bevel Gear

| Feature | Plastic Bevel Gear (Polyacetal Resin) | Stainless Steel Bevel Gear |

|---|---|---|

| Material | Made from polyacetal resin, a lightweight thermoplastic material. | Made from stainless steel, a durable and heavy metal. |

| Weight | Lightweight, ideal for weight-sensitive applications. | Heavier, increasing the overall system weight. |

| Strength | Moderate strength, suitable for light to medium loads. | High strength, capable of handling heavy loads effectively. |

| Durability | Durable but may wear faster under high loads or extreme conditions. | Extremely durable and resistant to wear over time. |

| Corrosion Resistance | Resistant to moisture and mild chemicals but less effective in harsh conditions. | Excellent corrosion resistance, especially in harsh environments. |

| Noise Levels | Operates quietly due to low friction and material properties. | Can produce louder noise during operation due to hardness. |

| Thermal Resistance | Limited temperature resistance; may deform at high temperatures. | High thermal resistance; suitable for high-temperature environments. |

| Cost | Cost-effective and cheaper to manufacture. | More expensive due to material and machining costs. |

| Manufacturing Process | Produced through injection molding, enabling mass production. | Manufactured primarily through machining processes. |

| Applications | Ideal for light-duty applications like robotics and consumer devices. | Preferred for heavy-duty applications like industrial machinery. |

| Maintenance | Requires careful maintenance to avoid damage under stress. | Low maintenance due to its durability and wear resistance. |

| Environmental Impact | Eco-friendlier as plastic can be recycled in some cases. | Higher environmental impact due to mining and processing. |

| Flexibility in Design | Easier to mold into complex designs and shapes. | Limited design flexibility due to machining constraints. |

| Surface Friction | Low friction, reducing power loss and wear. | Higher friction, which may require lubrication. |

| Impact Resistance | Can absorb minor shocks but may crack under significant impact. | Excellent shock resistance, less prone to cracking. |

|  |

| Plastic Bevel Gear | Stainless Steel Bevel Gear |

Polyacetal Resin Plastic Bevel Gear Applications

1. Robotics and Automation

Polyacetal resin bevel gears are widely used in robotics and automation systems due to their lightweight nature and smooth operation. They help reduce power consumption while ensuring precise motion control, which is essential for the accuracy and efficiency of robotic mechanisms.

2. Medical Equipment

These plastic bevel gears are ideal for use in medical devices such as imaging machines and surgical tools. Their quiet operation and low friction are critical in environments where noise reduction and smooth performance are necessary to maintain patient comfort and ensure device reliability.

3. Consumer Electronics

In products like printers, cameras, and home appliances, polyacetal resin bevel gears are used for power transmission. Their lightweight design and resistance to wear and tear make them perfect for small, high-performance devices requiring durable and compact components.

4. Automotive Industry

These gears are utilized in applications such as windshield wiper systems, seat adjustments, and small transmission mechanisms. Their corrosion resistance and ability to function quietly make them suitable for enhancing user comfort and reliability in automotive systems.

5. Aerospace and Drones

Polyacetal resin bevel gears are often employed in drones and lightweight aerospace applications. Their low weight and high dimensional stability ensure efficient power transmission without adding unnecessary mass, which is crucial for achieving optimal flight performance and fuel efficiency.

6. Industrial Machinery

In light-duty industrial equipment, these gears are used for precision power transmission. Their resistance to chemicals and moisture, combined with low maintenance requirements, makes them a reliable choice for machinery operating in controlled environments or handling light mechanical loads.

|  |

| Bevel Gear for Robotics | Bevel Gear for Automotive Industry |

|  |

| Bevel Gear for Medical Equipment | Bevel Gear for Aerospace Industry |

Additional information

| Edited by | Yjx |

|---|