Polyacetal Resin Plastic Bevel Gear Ratio 2:1 Straight Tooth System

The polyacetal resin plastic bevel gear ratio 2:1 straight tooth system is a mechanical gear assembly designed for efficient power transmission between intersecting shafts, typically positioned at a 90-degree angle. Made from polyacetal resin, a high-performance thermoplastic known for its durability, low friction, and excellent wear resistance, plastic straight bevel gears are commonly used in robotics, automotive systems, and machinery.

The polyacetal resin plastic bevel gear ratio 2:1 straight tooth system is a mechanical gear assembly designed for efficient power transmission between intersecting shafts, typically positioned at a 90-degree angle. Made from polyacetal resin, a high-performance thermoplastic known for its durability, low friction, and excellent wear resistance, this straight bevel gear system is lightweight, corrosion-resistant, and suitable for high-precision applications.

The 2:1 gear ratio indicates that the driving gear completes two revolutions for every one revolution of the driven gear, effectively doubling the torque or halving the speed, depending on the application. The straight tooth design ensures smooth engagement, making it ideal for low- to medium-speed operations. Commonly used in robotics, automotive systems, and machinery, this gear system offers reliability and longevity in demanding environments.

Polyacetal Resin Plastic Bevel Gear Ratio 2:1

|  |

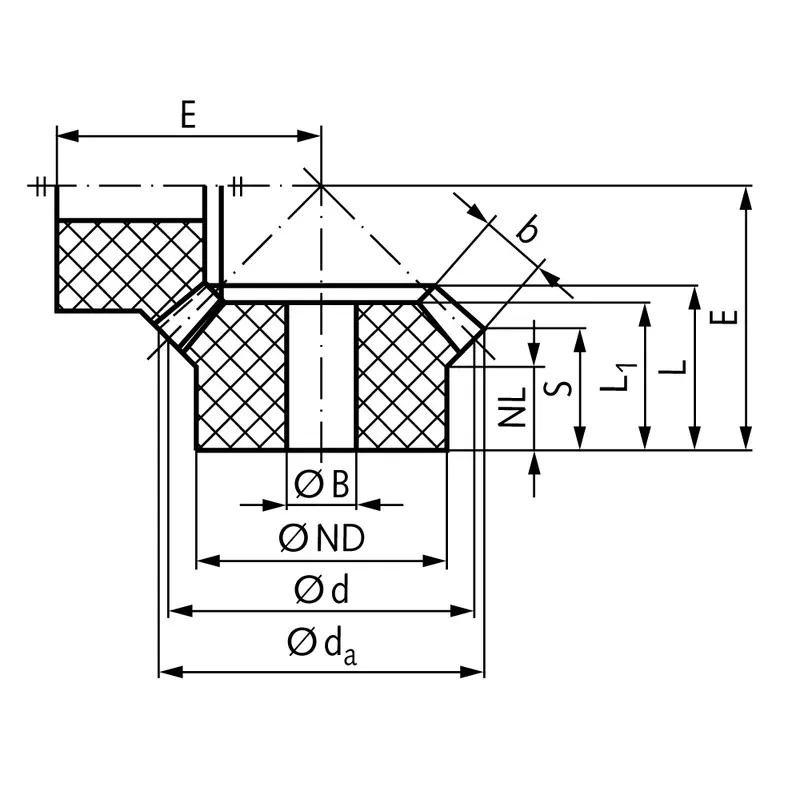

| Module | Number of teeth | da | d | ND | NL | L1 | L | S | b | B | E | Torque* | Weight |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | Ncm | g | ||

| 1 | 15 | 16,8 | 15 | 12,2 | 10,6 | 17 | 17 | 11,5 | 6,6 | 5 | 26,4 | 12 | 2,4 |

| 1 | 30 | 31,1 | 30 | 18 | 9,1 | 14,8 | 16,2 | 13,6 | 6,6 | 8 | 20,9 | 24 | 7,0 |

| 1,5 | 15 | 25,4 | 22,5 | 17 | 11,5 | 22,8 | 22,8 | 13,8 | 10,5 | 8 | 35,8 | 43 | 7,5 |

| 1,5 | 30 | 46,4 | 45 | 23,4 | 9,6 | 17,5 | 19,5 | 15,0 | 10,5 | 10 | 26,2 | 86 | 18,0 |

| 2 | 15 | 33,6 | 30 | 22,5 | 11,8 | 26 | 27 | 14,5 | 14,6 | 10 | 44,2 | 107 | 13,3 |

| 2 | 30 | 62,2 | 60 | 30,2 | 11,8 | 22,6 | 24,2 | 18,5 | 14,6 | 12 | 32,6 | 214 | 42,0 |

| 2,5 | 15 | 42 | 37,5 | 26,5 | 13 | 29,6 | 31,2 | 16,4 | 17,3 | 12 | 53,3 | 209 | 23,6 |

| 2,5 | 30 | 77,3 | 75 | 36,1 | 15 | 27,5 | 29,5 | 22,8 | 17,3 | 16 | 40,5 | 418 | 77,0 |

| 3 | 15 | 50,3 | 45 | 31,2 | 14,8 | 35 | 36,3 | 19,0 | 20,5 | 14 | 63,3 | 370 | 38,0 |

| 3 | 30 | 93 | 90 | 45 | 19 | 34,2 | 37 | 29,2 | 20,5 | 18 | 49,5 | 740 | 136,0 |

Plastic Straight Tooth Bevel Gear Features

- High Strength and Durability

Polyacetal resin plastic bevel gears are engineered for exceptional strength and long-term durability. They can withstand high mechanical stresses and maintain their structural integrity, making them ideal for applications requiring consistent performance over extended periods, even under heavy loads. - Low Friction and Smooth Operation

These plastic bevel gears feature a low coefficient of friction, allowing for smooth and efficient power transmission. The reduced friction minimizes wear and tear on the gear teeth, ensuring quieter operation and prolonging the life of the gear under various operating conditions. - Lightweight and Corrosion-Resistant

Polyacetal resin is a lightweight material that significantly reduces the overall weight of mechanical systems. Additionally, its excellent resistance to moisture, chemicals, and corrosion makes it suitable for use in environments prone to exposure to harsh elements. - Precision Tooth Alignment

The straight bevel gear design ensures precise tooth alignment, enabling accurate power transfer between shafts. This precision is crucial in applications requiring high operational accuracy, such as robotics, automotive systems, and industrial machinery, where gear misalignment could lead to inefficiencies. - Temperature and Chemical Resistance

Polyacetal resin gears exhibit excellent resistance to a wide range of temperatures and chemicals. This property allows them to maintain performance in high-temperature environments and resist degradation when exposed to oils, fuels, and cleaning agents. - Cost-Effective and Versatile

These gears offer a cost-effective solution for high-performance applications due to their manufacturability and material efficiency. Their versatility allows them to be used in various industries, including automotive, aerospace, and consumer appliances, supporting diverse mechanical and automation needs.

Plastic Bevel Gears Transmission Uses

- Automotive Systems

Plastic bevel gears are widely used in automotive systems, such as steering assemblies, windshield wipers, and power window mechanisms. Their lightweight construction reduces the overall vehicle weight while maintaining reliable performance, making them essential for efficient power transmission in various car components. - Robotics and Automation

In robotics, plastic straight bevel gears are essential for transmitting motion between intersecting axes, such as robotic arms or joint mechanisms. Their precision and smooth operation allow robots to perform complex movements accurately, ensuring efficiency and reliability in automated systems and industrial robotics. - Consumer Electronics and Appliances

These gears are commonly used in consumer devices like printers, coffee machines, and blenders. Their low noise levels, lightweight properties, and smooth operation make them suitable for compact, quiet, and efficient designs in home appliances and everyday electronic devices. - Medical Devices and Equipment

Plastic bevel gears play a critical role in medical equipment like surgical robots, imaging systems, and infusion pumps. Their corrosion resistance and precision ensure reliable and safe performance, making them ideal for delicate applications where accuracy and hygiene are vital. - Aerospace Industry

In aircraft systems, plastic straight bevel gears are used in auxiliary mechanisms, such as seat adjustments and control panel operations. Their lightweight nature reduces the load on the aircraft, while their resistance to wear ensures long-lasting performance in demanding aerospace environments. - Industrial Machinery

Plastic bevel gears are frequently employed in industrial machinery for tasks like conveyor belt drives, packaging equipment, and assembly lines. Their durability and efficiency in transferring power across intersecting axes make them a reliable choice for heavy-duty and continuous operations.

|  |

| Bevel Gear for Automotive Systems | Bevel Gear for Industrial Equipments |

|  |

| Bevel Gear for Consumer Electronics | Bevel Gear for Robotics and Automation |

Plastic Bevel Gear vs Steel Bevel Gear

Plastic bevel gears and steel bevel gears are designed for power transmission between intersecting shafts but differ significantly in their material properties, performance characteristics, and applications. Here are the key differences:

- Material Composition

Plastic bevel gears are typically made from high-performance thermoplastics like polyacetal (POM) or nylon, which offer lightweight and corrosion-resistant properties. Steel bevel gears, on the other hand, are made from hardened metals like carbon steel or stainless steel, known for their superior strength and durability. - Strength and Load Capacity

Steel bevel gears excel in handling heavy loads and high-torque applications due to their exceptional strength and wear resistance. Plastic bevel gears, while durable, are better suited for low- to medium-load applications as they cannot withstand the same mechanical stresses as steel gears. - Noise and Vibration

Plastic bevel gears operate more quietly and with reduced vibration compared to steel gears. This is because plastics have inherent damping properties, making them ideal for applications where noise reduction is critical, such as consumer appliances or medical devices. - Weight and Efficiency

Plastic bevel gears are significantly lighter than steel gears, reducing the overall weight of the mechanical system. This is especially useful in applications like robotics and aerospace, where minimizing weight is crucial. Steel gears, while heavier, offer superior efficiency in high-power transmission scenarios. - Corrosion Resistance

Plastic gears are naturally resistant to rust and corrosion, making them suitable for humid or chemically exposed environments. Steel gears, unless specially treated or coated, are prone to corrosion, especially in moist or corrosive conditions. - Cost and Manufacturing

Plastic bevel gears are generally more cost-effective to produce, especially for mass production using injection molding. Steel gears, while more expensive, are preferred for applications requiring maximum strength and durability over long periods.

|  |

| Plastic Bevel Gear | Steel Bevel Gear |

Additional information

| Edited by | Yjx |

|---|