Plastic Gear Racks

Our plastic gear racks are manufactured per DIN 867/ DIN 3967 dimensional standards and are available in plastic materials like Polyacetal, Polyketon, and POM. Our superior selection of plastic spur gear racks ranges from module 0.5 to module 3 and provides excellent resistance to corrosion and chemical and harsh environments. These racks are commonly found in medical, food, beverage, robotics, scientific, and more applications! See the charts below to discover our standard plastic gear racks. We also supply a range of plastic gears, custom plastic components upon request, and a gear rack mounting aid for ease of installation.

Our plastic gear racks are manufactured per DIN 867/ DIN 3967 dimensional standards and are available in plastic materials like Polyacetal, Polyketon, and POM. Our superior selection of plastic spur gear racks ranges from module 0.5 to module 3 and provides excellent resistance to corrosion and chemical and harsh environments. These racks are commonly found in medical, food, beverage, robotics, scientific, and more applications! See the charts below to discover our standard plastic gear racks. We also supply a range of plastic gears, custom plastic components upon request, and a gear rack mounting aid for ease of installation.

Plastic Gear Rack Types

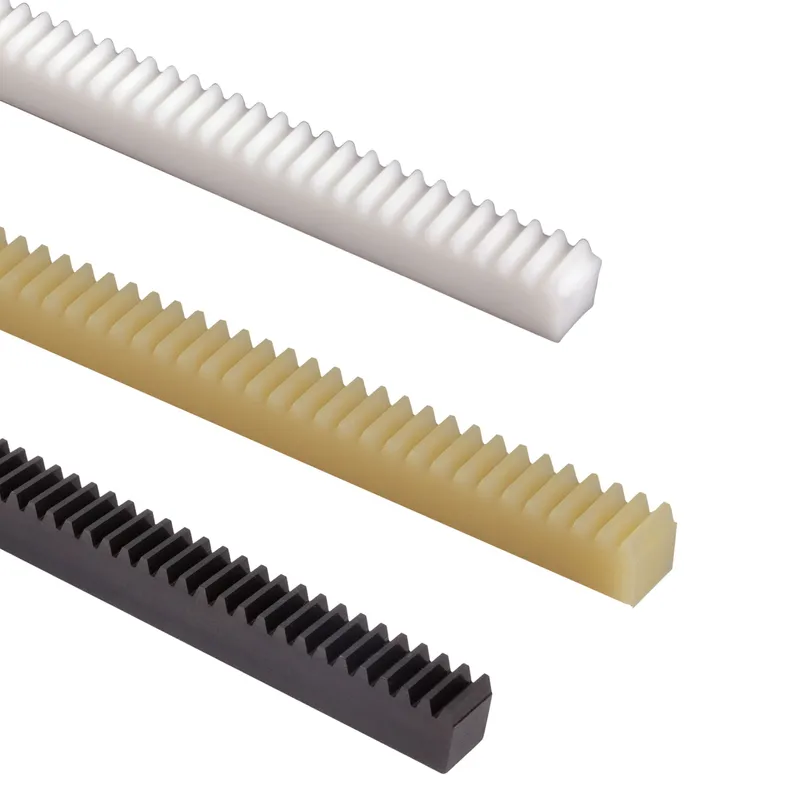

(1) Polyacetal and polyketone Plastic Gear Racks

These gear racks have an operating temperature range of -40°C to + 140°C, and both materials have their place in specific applications. Polyketone material has lower friction, extending its lifespan even without lubrication. This material has a much higher safety against tooth breakage and is ivory in color while slightly more expensive than polyacetal. In contrast, polyacetal is a standard-quality material with high hardness and white.

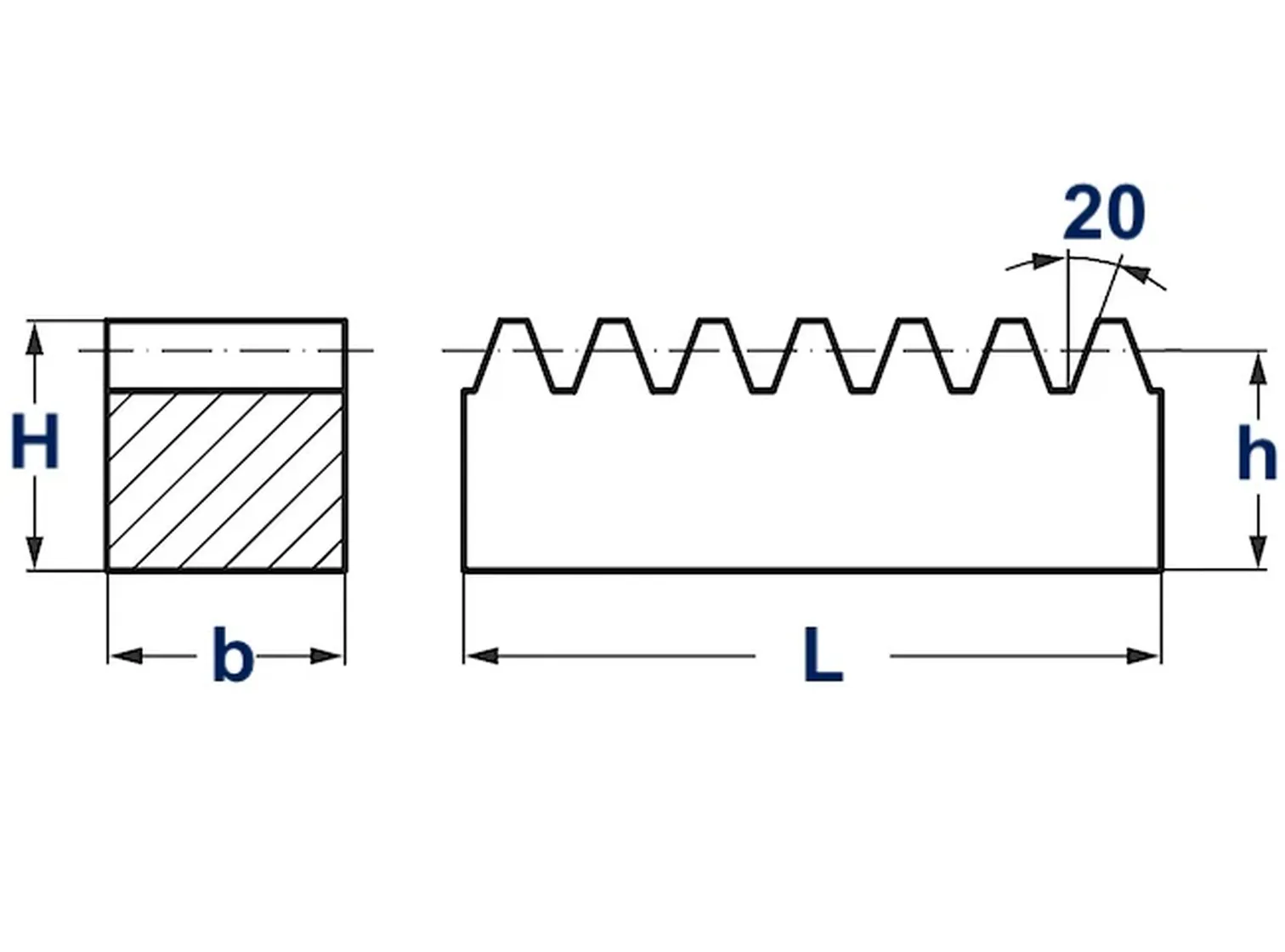

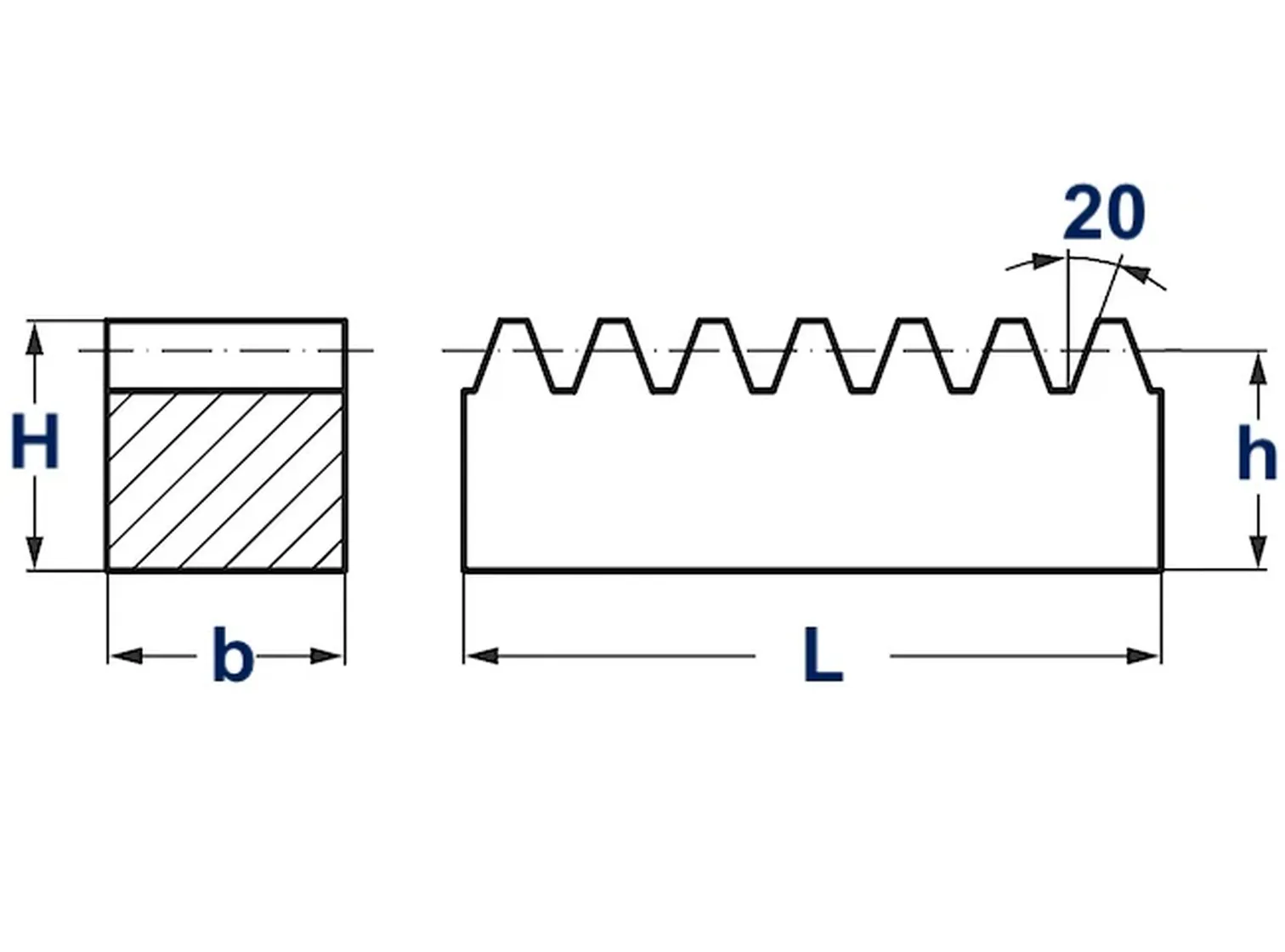

Polyacetal and polyketone Gear Rack Dimensions

|  |

| Part # (Polyacetal) | Part # (Polyketon) | Module | Dimension (b) | Dimension (H) | Dimension (h) | Length (L) | Weight (Polyacetal) | Weight (Polyketon) |

|---|---|---|---|---|---|---|---|---|

| 28160100 | 28160101 | 0.5 | 4mm | 4.5mm | 4.0mm | 250mm | 5.2 Grams | 4.6 Grams |

| 28160200 | 28160201 | 0.5 | 4mm | 6mm | 5.5mm | 250mm | 7.5 Grams | 6.8 Grams |

| 28260100 | 28260101 | 0.7 | 6mm | 6.7mm | 6.0mm | 250mm | 12 Grams | 10.6 Grams |

| 28360100 | 28360101 | 1 | 9mm | 9mm | 8mm | 250mm | 24.8 Grams | 21.8 Grams |

| 28460100 | 28460101 | 1.25 | 10mm | 11mm | 9.75mm | 250mm | 35 Grams | 30.8 Grams |

| 28560100 | 28560101 | 1.5 | 12mm | 12mm | 10.5mm | 250mm | 42.3 Grams | 37.2 Grams |

| 28660100 | 28660101 | 2 | 15.4mm | 11mm | 9mm | 250mm | 44.8 Grams | 39.3 Grams |

| 28760100 | 28760101 | 2.5 | 17mm | 13mm | 10.5mm | 250mm | 58.2 Grams | 51.1 Grams |

| 28860100 | 28860101 | 3 | 19.4mm | 15mm | 12mm | 250mm | 75.8 Grams | 66.6 Grams |

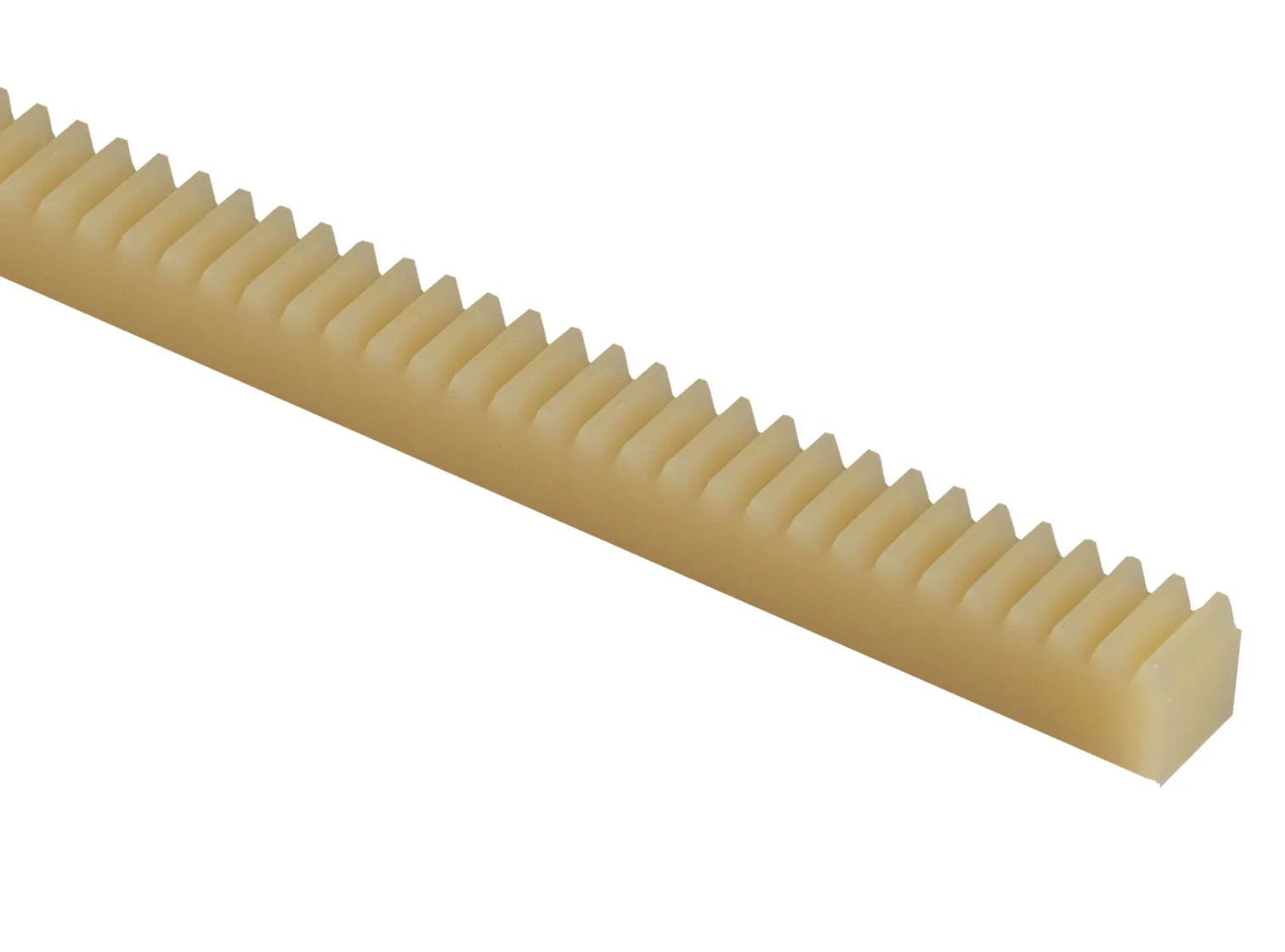

(2) Slim POM White Plastic Gear Racks

These gear racks are manufactured from natural POM material, which is white and has a slim profile. Additionally, these racks are manufactured per DIN 867/ DIN 3972 standards, except the 500mm nominal length racks cut for continuous linking with a gap. It is important to note that plastic gear racks are not straightened due to the material used. For additional information or to get a quote on racks or matching gears, contact our customer service team!

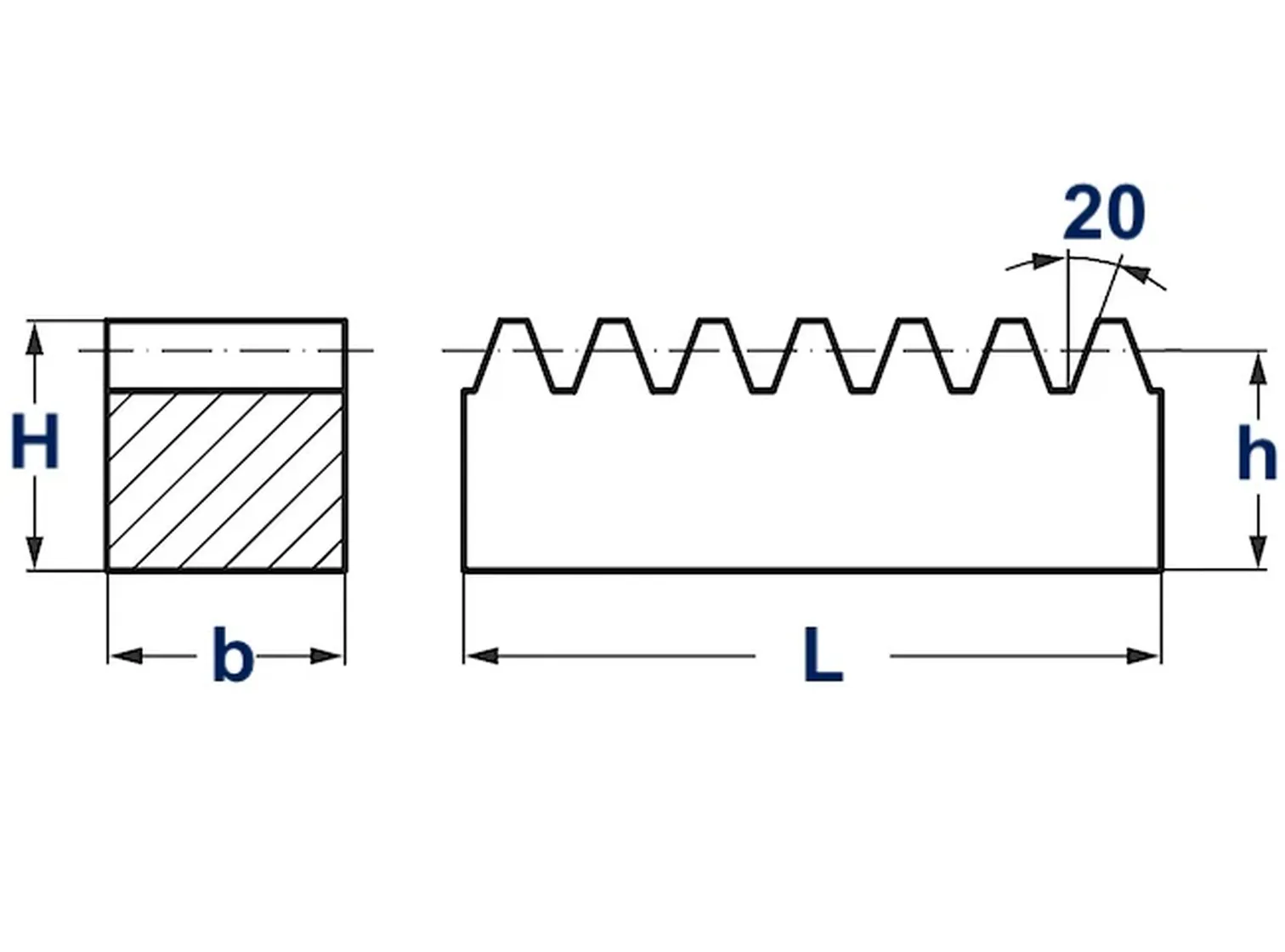

POM Slim Plastic Gear Rack Dimensions

|  |

| Part # | Module | Dimension (b) | Dimension (H) | Dimension (h) | Length (L) | Weight |

|---|---|---|---|---|---|---|

| 29160100 | 0.5 | 4mm | 6mm | 5.5mm | 250mm | 8 Grams |

| 29260100 | 0.7 | 5mm | 7mm | 6.3mm | 250mm | 11 Grams |

| 29360100 | 1 | 10mm | 10mm | 9.0mm | 250mm | 32 Grams |

| 29360300 | 1 | 10mm | 10mm | 9.0mm | 500mm | 63 Grams |

| 29460100 | 1.25 | 10mm | 10mm | 8.75mm | 250mm | 31 Grams |

| 29460300 | 1.25 | 10mm | 10mm | 8.75mm | 500mm | 61 Grams |

| 29560100 | 1.5 | 15mm | 15mm | 13.5mm | 250mm | 72 Grams |

| 29560300 | 1.5 | 15mm | 15mm | 13.5mm | 500mm | 140 Grams |

| 29560500 | 1.5 | 15mm | 15mm | 13.5mm | 1,000mm | 285 Grams |

| 29660300 | 2 | 16mm | 16mm | 14.0mm | 500mm | 157 Grams |

| 29660500 | 2 | 16mm | 16mm | 14.0mm | 1,000mm | 312 Grams |

| 29660700 | 2 | 16mm | 16mm | 14.0mm | 1,500mm | 466 Grams |

| 29760300 | 2.5 | 20mm | 20mm | 17.5mm | 500mm | 243 Grams |

| 29760500 | 2.5 | 20mm | 20mm | 17.5mm | 1,000mm | 489 Grams |

| 29760700 | 2.5 | 20mm | 20mm | 17.5mm | 1,500mm | 735 Grams |

| 29860300 | 3 | 25mm | 25mm | 22.0mm | 500mm | 385 Grams |

| 29860500 | 3 | 25mm | 25mm | 22.0mm | 1,000mm | 772 Grams |

| 29860700 | 3 | 25mm | 25mm | 22.0mm | 1,500mm | 1,146 Grams |

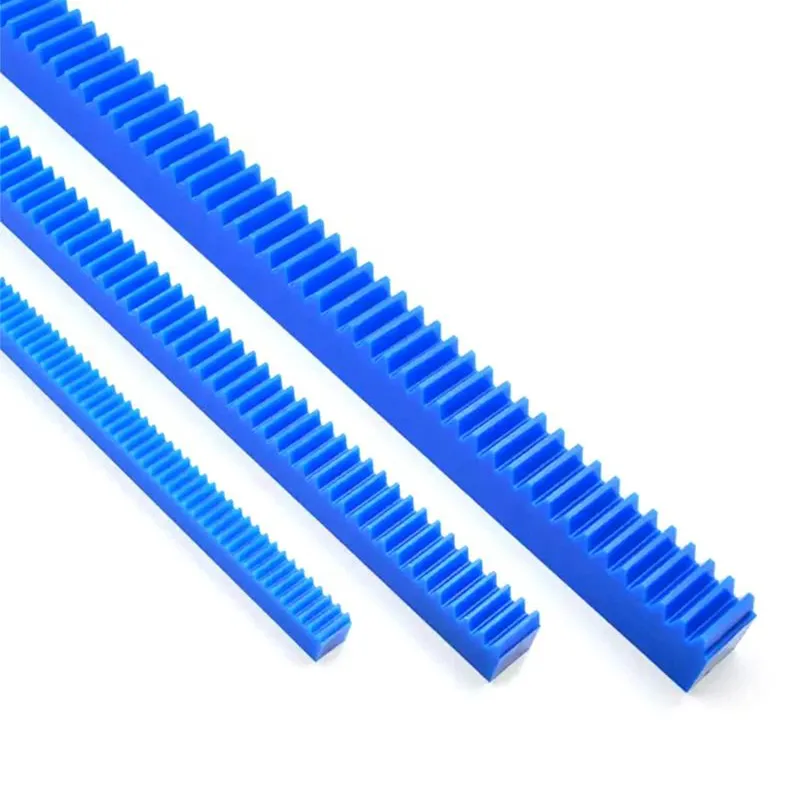

(3) POM Plastic Gear Racks

Our standard-width POM plastic gear racks are available in natural (white) color or REPRO (Black) color and are manufactured per DIN 867 / DIN3972 standards. We supply these racks from module 1 to module 3 pitch sizes and lengths from 250mm to 1,000mm as a standard. These gear racks utilize milled teeth in the straight tooth system. We also supply matching gear!

POM Plastic Gear Rack Dimensions

|  |

| Part # (White) | Part # (Black) | Module | Dimension (b) | Dimension (H) | Dimension (h) | Length (L) | Weight |

|---|---|---|---|---|---|---|---|

| 29311601 | 29311701 | 1 | 15mm | 15mm | 14.0mm | 250mm | 75 Grams |

| 29311603 | 29311703 | 1 | 15mm | 15mm | 14.0mm | 500mm | 149 Grams |

| 29311605 | 29311705 | 1 | 15mm | 15mm | 14,0mm | 1,000mm | 300 Grams |

| 29511601 | 29511701 | 1.5 | 17mm | 17mm | 15.5mm | 250mm | 92 Grams |

| 29511603 | 29511703 | 1.5 | 17mm | 17mm | 15.5mm | 500mm | 186 Grams |

| 29511605 | 29511705 | 1.5 | 17mm | 17mm | 15.5mm | 1,000mm | 400 Grams |

| 29611601 | 29611701 | 2 | 20mm | 20mm | 18.0mm | 250mm | 127 Grams |

| 29611603 | 29611703 | 2 | 20mm | 20mm | 18.0mm | 500mm | 254 Grams |

| 29611605 | 29611705 | 2 | 20mm | 20mm | 18.0mm | 1,000mm | 500 Grams |

| 29711601 | 29711701 | 2.5 | 25mm | 25mm | 22.5mm | 250mm | 198 Grams |

| 29711603 | 29711703 | 2.5 | 25mm | 25mm | 22.5mm | 500mm | 397 Grams |

| 29711605 | 29711705 | 2.5 | 25mm | 25mm | 22.5mm | 1,000mm | 800 Grams |

| 29811601 | 29811701 | 3 | 30mm | 30mm | 27.0mm | 250mm | 400 Grams |

| 29811603 | 29811703 | 3 | 30mm | 30mm | 27.0mm | 500mm | 800 Grams |

| 29811605 | 29811705 | 3 | 30mm | 30mm | 27.0mm | 1,000mm | 1,600 Grams |

Benefits of Plastic Gear Racks

- Corrosion Resistance

Plastic gear racks are inherently resistant to corrosion, making them ideal for environments exposed to moisture, chemicals, or harsh conditions. Unlike metal gear racks, they do not rust or degrade over time, ensuring longer-lasting performance in demanding applications. - Lightweight Design

Made from materials like Polyacetal and POM, plastic gear racks are significantly lighter than their metal counterparts. This reduces the overall weight of machinery or systems, making them easier to handle, transport, and integrate into lightweight or compact equipment designs. - Low Noise Operation

Due to the inherent properties of plastic materials, these gear racks operate with minimal noise. They absorb vibrational energy and reduce sound during operation, making them perfect for applications in environments where noise levels must be kept to a minimum. - Chemical Resistance

Plastic gear racks offer excellent resistance to a wide range of chemicals, including oils, solvents, and cleaning agents. This makes them suitable for use in industries like food processing and medical equipment, where exposure to such substances is common. - Durability and Wear Resistance

Engineered plastics like Polyketon and Polyacetal are highly durable and resistant to wear, even under continuous usage. They can maintain their structural integrity and performance over time, reducing the need for frequent replacements or maintenance. - Versatility Across Applications

Plastic gear racks are used in diverse industries, including robotics, scientific instruments, and automated systems. Their adaptability to various operational requirements, coupled with easy customization options, makes them a go-to solution for specialized or unique applications.

Applications of Plastic Gear Racks

- Medical Equipment

Plastic gear racks are widely used in medical devices such as imaging systems, laboratory automation equipment, and surgical tools. Their lightweight, corrosion resistance, and low noise operation make them ideal for maintaining precision and hygiene in critical healthcare environments. - Food and Beverage Industry

In the food and beverage sector, plastic gear racks are employed in machinery such as conveyors, packaging systems, and dispensing equipment. Their chemical resistance and compliance with hygiene standards ensure safe and efficient operation in environments exposed to food products and cleaning agents. - Robotics and Automation

Plastic gear racks are essential components in robotics, enabling accurate linear motion for robotic arms, pick-and-place systems, and automated machinery. Their durability, lightweight nature, and ability to withstand wear allow for reliable performance in high-precision and dynamic automation applications. - Scientific Instruments

In scientific devices, such as microscopes, spectrometers, and testing equipment, plastic gear racks provide precise motion control. Their low noise and smooth operation are critical for enhancing the accuracy and reliability of measurements in research and laboratory settings. - Aerospace and Lightweight Machinery

Plastic gear racks are used in aerospace systems and lightweight machinery where minimizing weight is crucial. Their ability to provide efficient motion control without adding unnecessary mass makes them an excellent choice for aircraft components and compact, portable equipment.

|  |

| Gear Rack for Medical Equipment | Gear Rack for Automation and Robotics |

|  |

| Gear Rack for Packaging Machines | Gear Rack for CNC Machine Tool |

Choose the Right Plastic Gear Rack

- Assess Load and Strength Requirements

Consider the weight and force your application will exert on the gear rack. For heavy-duty tasks, select materials like Polyketon for superior strength and durability, while lighter loads may benefit from Polyacetal or POM for cost efficiency and reliability. - Evaluate Environmental Conditions

Analyze the operating environment for factors like moisture, chemicals, and temperature. If the gear rack will be used in corrosive or wet conditions, choose materials with high chemical and corrosion resistance, such as POM, to ensure long-lasting performance. - Determine Noise Reduction Needs

If noise reduction is critical, such as in medical or laboratory equipment, opt for plastic gear racks known for their quiet operation. Materials like Polyacetal excel at minimizing operational noise, making them ideal for noise-sensitive environments. - Match the Module Size to Your Application

Select the appropriate module size based on the precision and torque requirements of your system. Applications requiring fine adjustments, like robotics, may need smaller module sizes, while industrial systems might demand larger modules for handling greater loads. - Consider Longevity and Maintenance

For systems requiring minimal maintenance, choose materials with high wear resistance and durability, such as Polyketon. This reduces the frequency of replacements and downtime, ensuring consistent performance and lower long-term operating costs. - Account for Customization and Compatibility

Evaluate whether standard gear racks meet your needs or if custom designs are required. Ensure compatibility with existing pinion gears and mounting systems, and consider suppliers offering customization options and installation aids to simplify integration into your application.

Additional information

| Edited by | Yjx |

|---|