Oil Hydraulic Cylinder for Truss Arm Crawler Crane

An oil hydraulic cylinder for a truss arm crawler crane is a critical mechanical device designed to provide the lifting, lowering, and positioning capabilities essential for heavy-duty operations. These hydraulic cylinders are powered by hydraulic fluid, typically oil, which transmits force through pressurized systems to create linear motion. In a truss arm crawler crane, the hydraulic cylinder is responsible for extending and retracting the crane’s arm, adjusting its angle, or supporting load-bearing elements during operation.

An oil hydraulic cylinder for a truss arm crawler crane is a critical mechanical device designed to provide the lifting, lowering, and positioning capabilities essential for heavy-duty operations. These hydraulic cylinders are powered by hydraulic fluid, typically oil, which transmits force through pressurized systems to create linear motion. In a truss arm crawler crane, the hydraulic cylinder is responsible for extending and retracting the crane's arm, adjusting its angle, or supporting load-bearing elements during operation.

The truss arm, which is a lattice-like structure made of high-strength steel, benefits from the hydraulic cylinder's precision and power, enabling smooth and controlled movements. These hydraulic systems are designed to handle high loads and withstand harsh working environments, such as construction sites or industrial applications.

Oil Hydraulic Cylinder Dimensions

| Product Name: | Oil Hydraulic Cylinder |

| Function: | buffering effect |

| Cylinder diameter: | 120mm-300mm |

| Rod diameter: | 100mm-280mm |

| Travel: | 148mm-320mm |

| Maximum pressure: | 40MPa |

| Maximum thrust: | 2463KN |

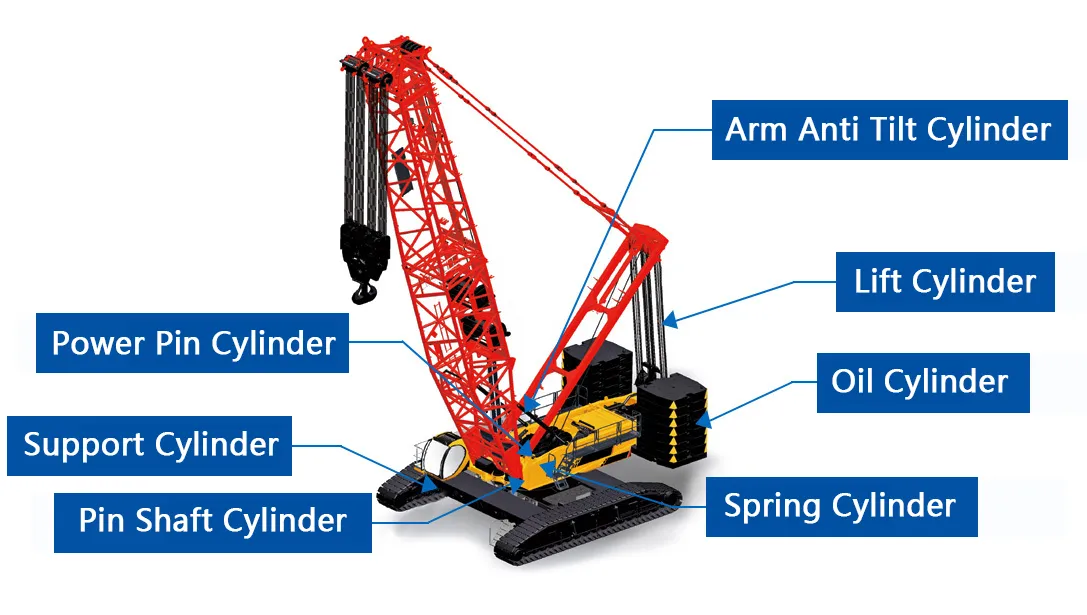

Truss Arm Crawler Crane Hydraulic Cylinder Types

- Lift Hydraulic Cylinders

Lift hydraulic cylinders are responsible for raising and lowering the truss arm of the crawler crane. These cylinders provide the powerful vertical motion needed to lift heavy materials safely. Designed for high load capacity, they ensure smooth and controlled lifting operations, even when handling large weights. Their durability and precision allow the crane to operate efficiently in demanding environments. - Support Hydraulic Cylinders

Support hydraulic cylinders stabilize the truss arm and other critical crane components during operations. They are engineered to bear significant loads and maintain structural balance. These cylinders prevent unwanted movements or vibrations, ensuring safety and operational accuracy. Their robust construction is essential for maintaining stability on uneven or rough terrains. - Arm Anti-Tilt Hydraulic Cylinders

Arm anti-tilt hydraulic cylinders prevent the truss arm from tilting sideways or losing alignment during heavy lifting or extended maneuvers. They maintain the arm’s proper position and orientation, reducing operational risks. By ensuring the arm remains steady, these cylinders enhance overall safety and improve the precision of crane operations. - Pin Shaft Hydraulic Cylinders

Pin shaft hydraulic cylinders play a crucial role in connecting and adjusting moving parts within the crane’s arm structure. They allow for controlled articulation and movement between sections of the truss arm. These cylinders are built to endure constant stress and wear, ensuring consistent performance even in high-pressure working conditions. - Spring Hydraulic Cylinders

Spring hydraulic cylinders are designed to provide controlled spring-based motion for specific crane functions. They combine the power of hydraulic pressure with the flexibility of spring mechanisms to absorb shocks and manage operational impacts. These cylinders enhance smooth transitions in crane movements and reduce wear on other components. - Power Pin Hydraulic Cylinders

Power pin hydraulic cylinders are specialized for locking and unlocking pin connections in the crane’s structure. They use hydraulic power to secure or release joints, ensuring quick and reliable adjustments. These cylinders are critical for efficient assembly, disassembly, and repositioning of the truss arm during operations or transport.

Truss Arm Crawler Crane Oil Hydraulic Cylinder Components

- Cylinder Barrel

The cylinder barrel is the main body of the hydraulic cylinder that contains the hydraulic fluid under pressure. It provides the structural framework for the entire system and houses the piston assembly. Made from high-strength materials like alloy steel, the barrel is designed to withstand high pressures and harsh working conditions. Its internal surface is precision-machined to ensure minimal friction and optimal efficiency during operation. - Piston and Piston Rod

The piston and piston rod are critical components that convert hydraulic pressure into mechanical force. The piston moves within the cylinder barrel, while the piston rod extends outward to transmit force to the crane's truss arm. These parts are built to endure bending, tensile stress, and wear. The piston’s high-quality seals prevent fluid leakage, ensuring smooth and efficient motion. - Hydraulic Seals

Hydraulic seals are essential for maintaining the integrity of the hydraulic system by preventing fluid leaks and contamination. They are located around the piston, rod, and other critical areas. These seals are made from durable materials such as polyurethane or rubber and are designed to withstand extreme temperatures and pressures. Proper sealing ensures consistent performance and extends the lifespan of the hydraulic cylinder. - End Caps (Head and Base)

End caps, often referred to as the head and base, seal the hydraulic cylinder at both ends and provide structural strength. The head houses the rod and often contains the rod seal, while the base supports the barrel and connects to the truss arm. These components are precision-engineered for durability and are essential for maintaining the cylinder's alignment and functionality. - Hydraulic Ports

Hydraulic ports connect the cylinder to the external hydraulic system, allowing fluid to flow in and out. These ports regulate the movement of the piston by controlling the flow and pressure of hydraulic oil. Positioned strategically on the barrel, they are reinforced to handle high-pressure operations. Their design ensures efficient fluid transfer and prevents leaks during operation.

Truss Arm Crawler Crane Hydraulic Cylinder Maintenance

- Regular Inspection of Hydraulic Seals

Inspect hydraulic seals frequently to check for wear, cracks, or damage that can lead to fluid leaks. Damaged seals compromise system efficiency and should be replaced promptly to prevent further issues. Ensuring the seals are in good condition maintains the hydraulic cylinder's pressure and performance, especially under heavy loads. - Monitoring Hydraulic Fluid Levels and Quality

Hydraulic fluid should be checked regularly for appropriate levels and contamination. Contaminants like dirt or water can degrade fluid quality and cause internal damage. Replace the fluid periodically to ensure proper lubrication, cooling, and system efficiency. Using the correct grade of hydraulic oil is essential for optimal performance. - Cleaning Cylinder Surfaces and Components

Keep the external surfaces of the crane hydraulic cylinder clean to avoid dirt or debris entering the system. Contaminants can cause premature seal wear and damage internal components. Regular cleaning prevents corrosion and ensures the smooth movement of parts, especially in harsh working environments like construction sites. - Lubricating Moving Parts

Lubricate moving components such as pins, bearings, and mounting hardware to reduce friction and wear. Proper lubrication ensures smoother operation and prolongs the lifespan of the hydraulic cylinder crane. Use suitable grease or lubricants recommended by the manufacturer to avoid compatibility issues with hydraulic systems. - Checking for Structural Damage

Inspect the cylinder barrel, piston rod, and mounting points for dents, cracks, or distortions. Structural damage weakens the cylinder's ability to handle pressure and loads. Immediate repairs or replacements are necessary to maintain safety and prevent operational failure. Regular checks help identify potential issues early. - Testing Hydraulic System Pressure

Test the hydraulic system’s pressure periodically to ensure it operates within the recommended range. Excessive or insufficient pressure can damage the hydraulic cylinder for cranes and other system components. Use calibrated instruments to measure pressure and adjust settings as needed. Proper pressure levels are critical for efficient crane operations and cylinder longevity.

|

|

Additional information

| Edited by | Yjx |

|---|