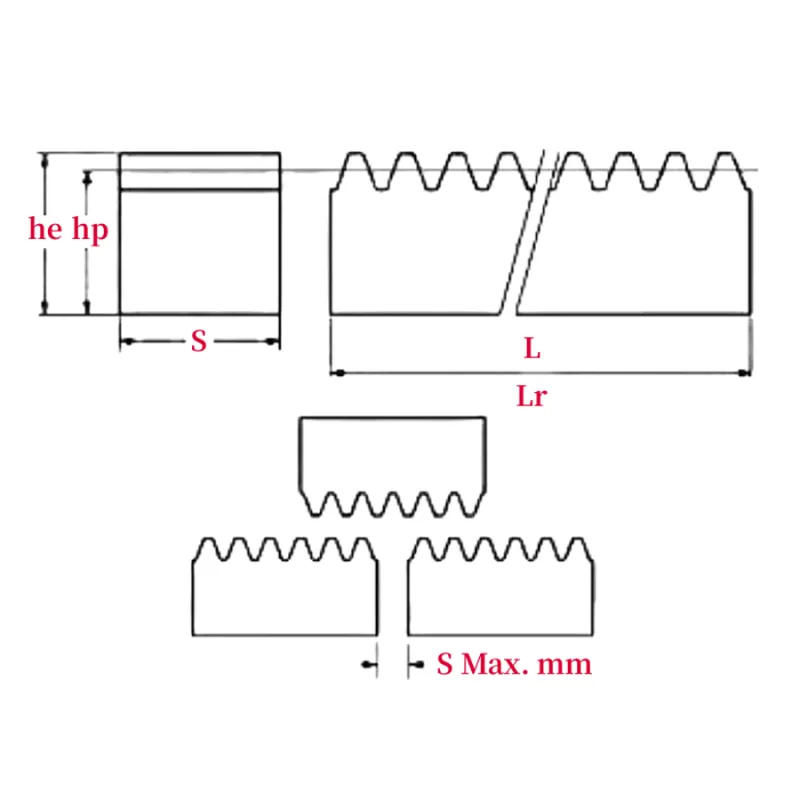

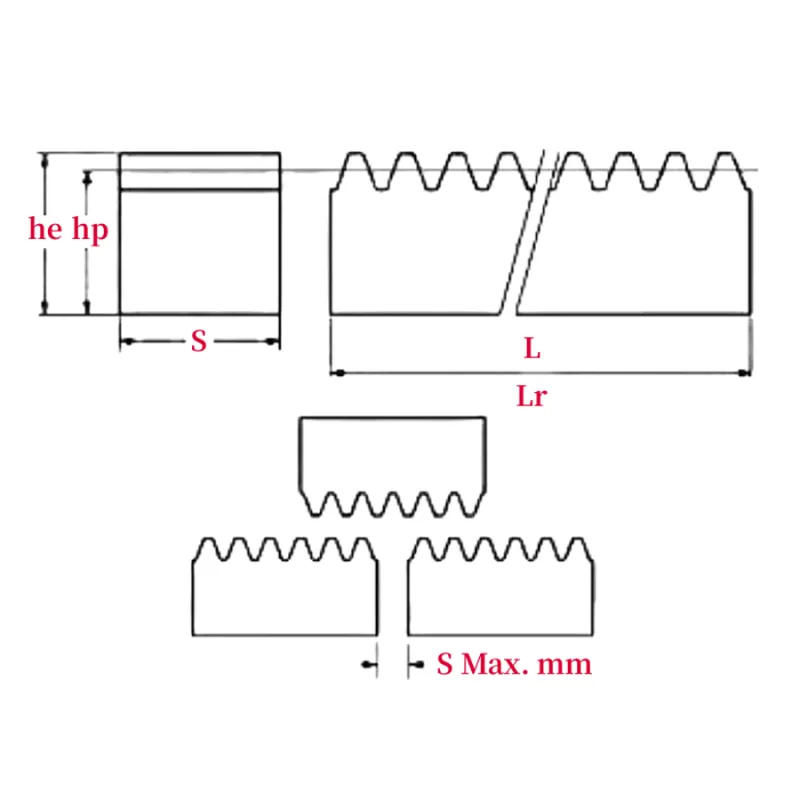

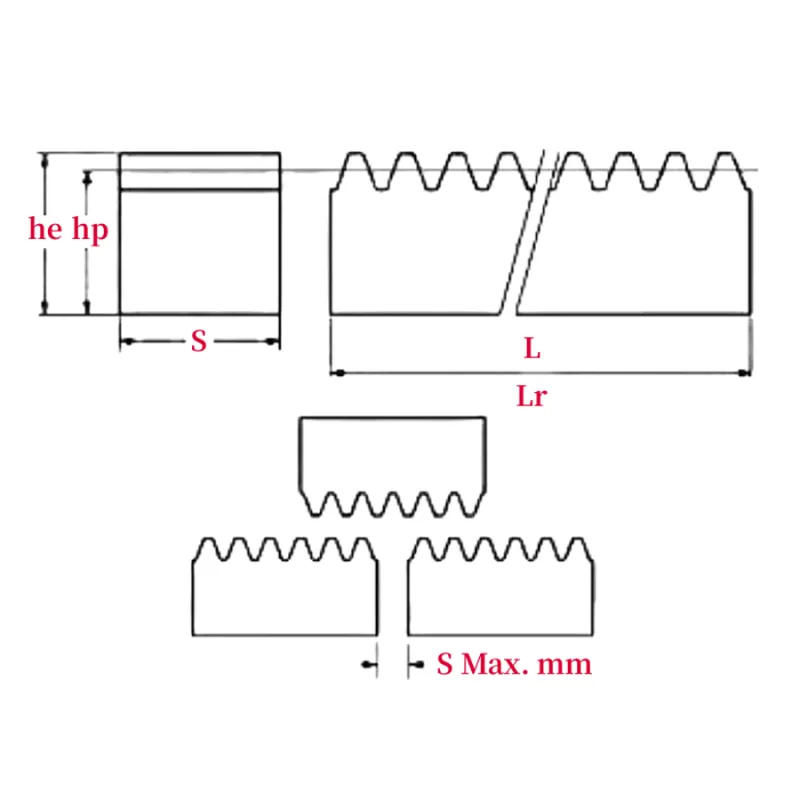

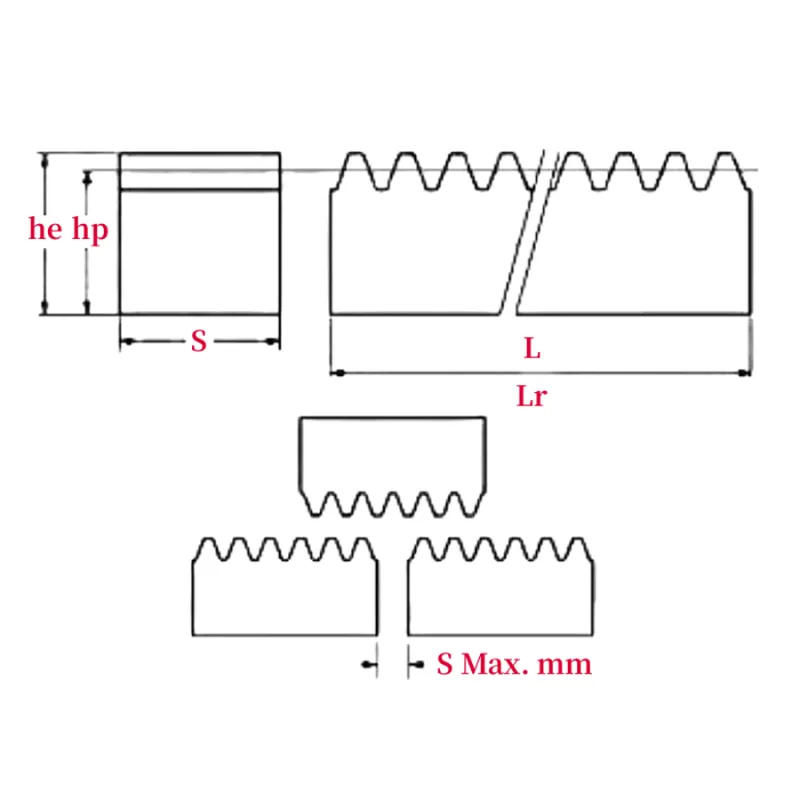

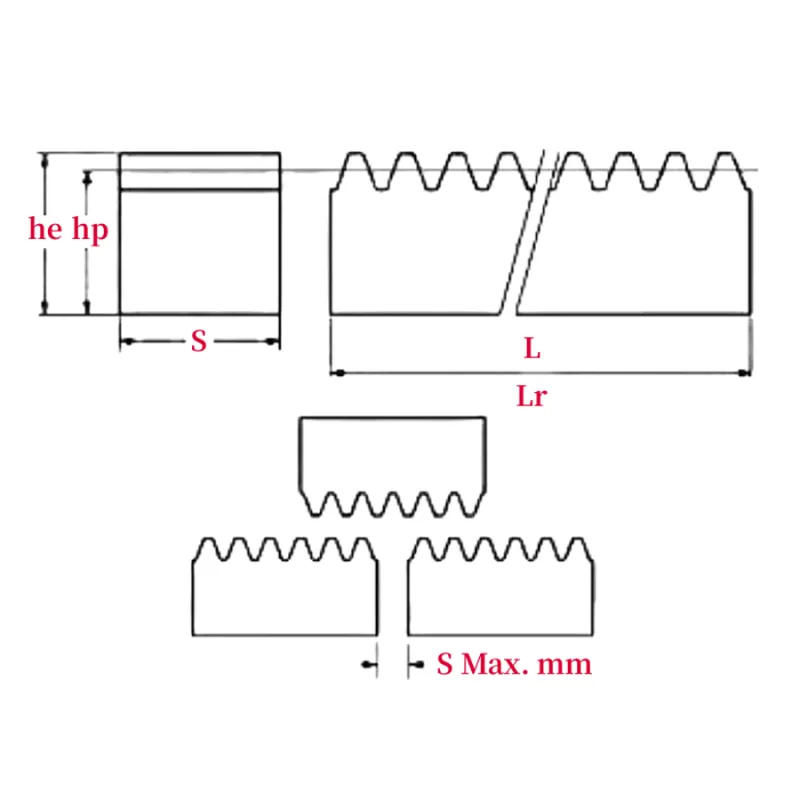

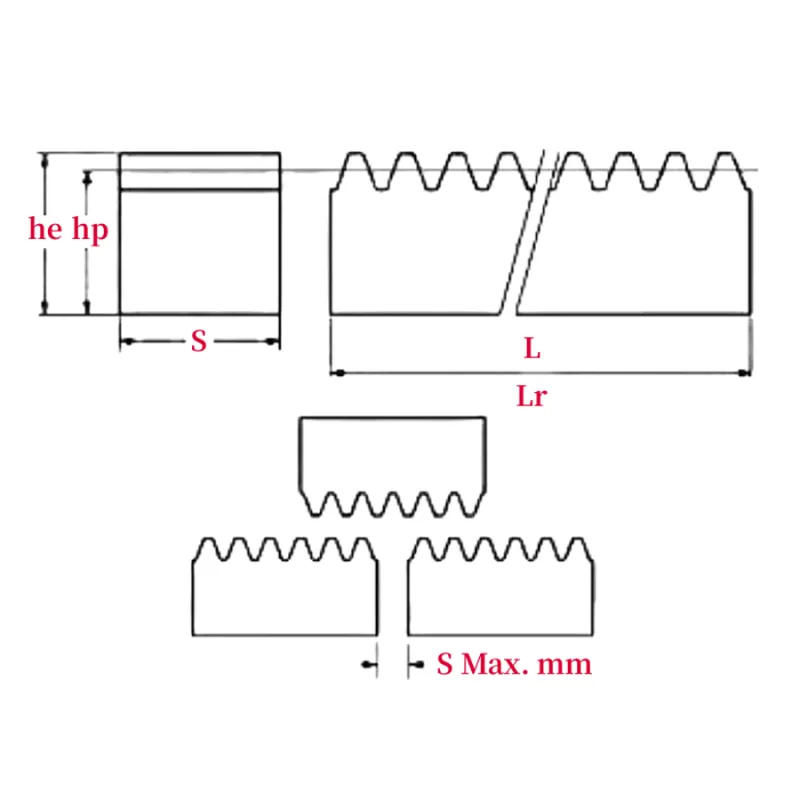

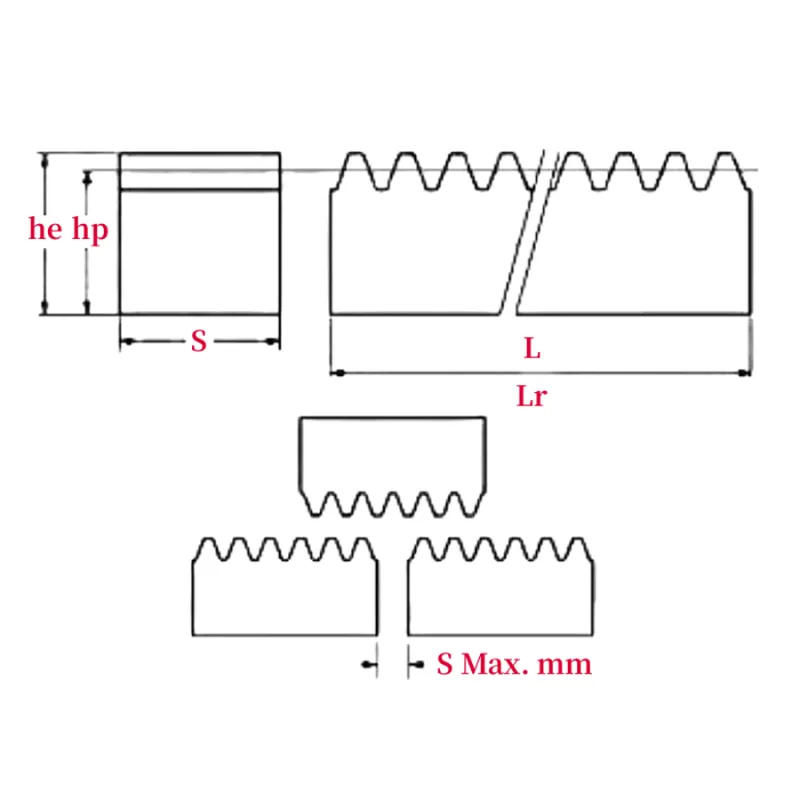

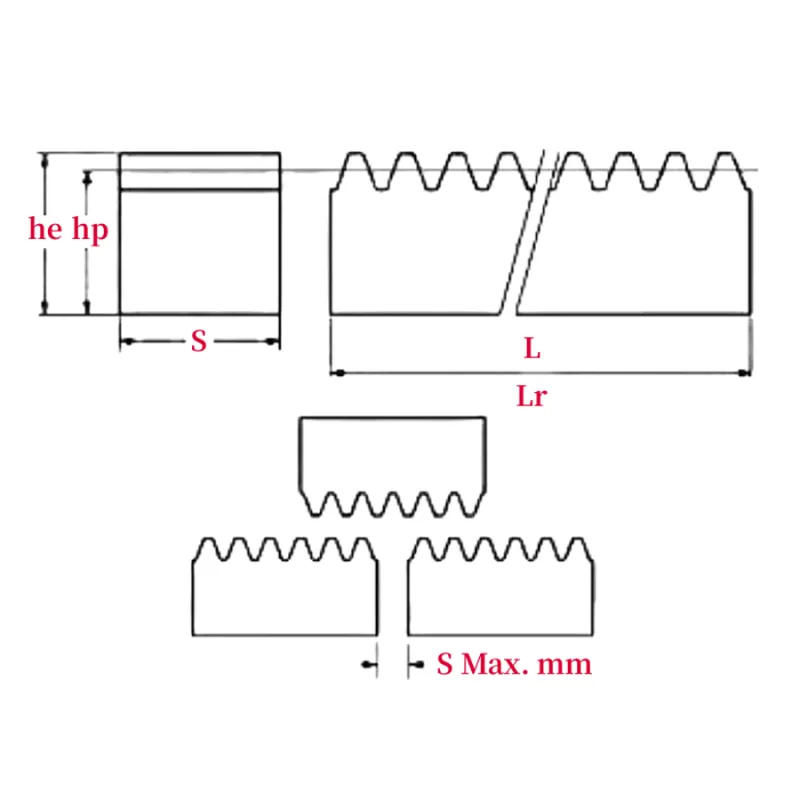

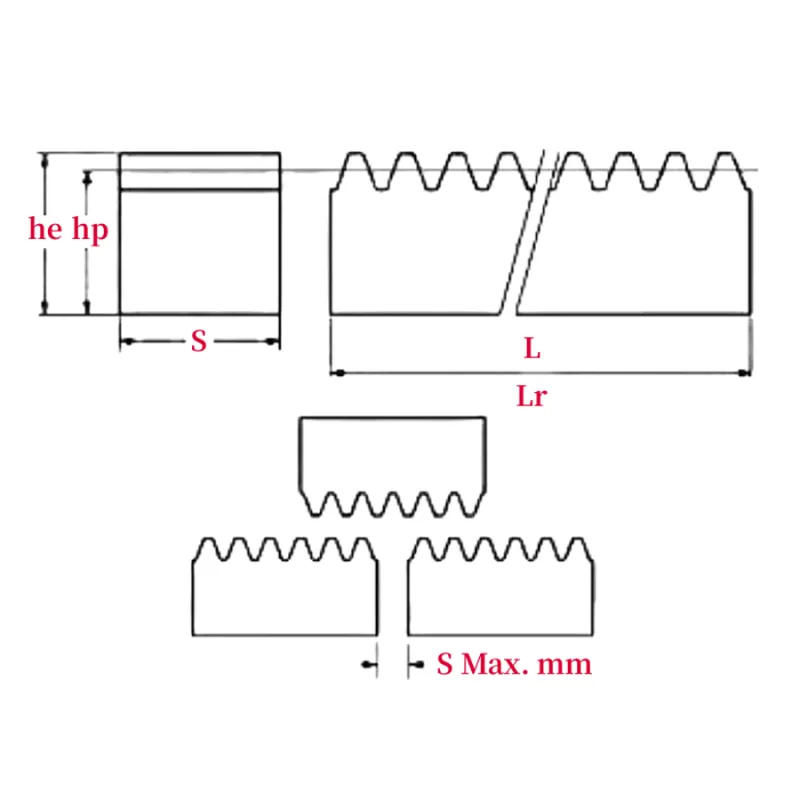

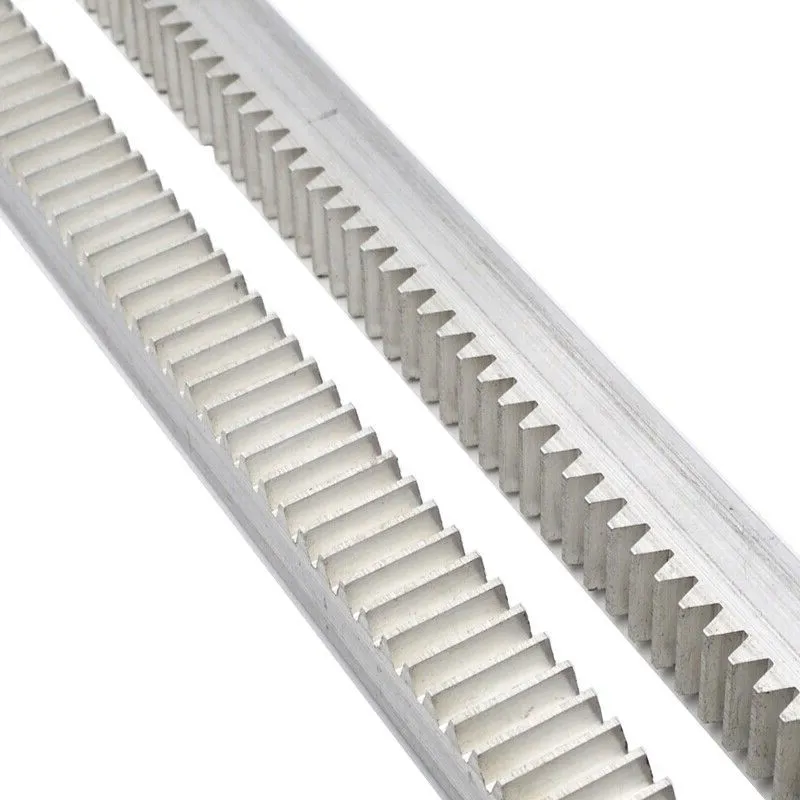

Our metric gear racks, constructed from C1045 steel meeting UNI-EN10083-1 specifications, offer nine size modules (1- 8). Designed for continuous mounting, they feature a high precision tolerance of 0/-20μm on a single pitch and 0/-30μmm on a 500mm length sum of pitches. With teeth set at the optimal 20° pressure angle, meeting DIN 3962/63/67 quality grade, these Gear Racks ensure efficient operation. Available directly from stock, lengths range from 500mm up to 3000mm.

Metric gear racks serve to convert rotational motion into linear movement, often paired with a pinion in a setup known as rack and pinion. For optimal performance and longevity, using gear oil is advisable when operating gears and gear racks. In addition to gear racks, we offer a diverse selection of metric spur gears and a comprehensive range of power transmission products.

Metric Spur Gear Rack Types

(1) Module 1 Metric Spur Gear Rack

| Metric Spur Gear Rack | Module | Length | (hp) | (he X S) | (S) | Actual Length (Lr) | Weight |

|---|

| mm | mm | mm | mm | mm | kg |

|---|

| M1X500 | 1 | 500 | 14 | 15 x 15 | 0.5 | 499.51 | 0.82 |

| M1X1000 | 1 | 1000 | 14 | 15 x 15 | 0.5 | 1002.17 | 1.50 |

| M1X2000 | 1 | 2000 | 14 | 15 x 15 | 0.5 | 2001.20 | 3.10 |

| M1X3000 | 1 | 3000 | 14 | 15 x 15 | 0.5 | 3000.23 | 4.90 |

(2) Module 1.5 Metric Spur Gear Rack

| Metric Spur Gear Rack | Module | Length | (hp) | (he X S) | (S) | Actual Length (Lr) | Weight |

|---|

| mm | mm | mm | mm | mm | kg |

|---|

| M1.5X500 | 1.5 | 500 | 15.5 | 17 x 17 | 0.6 | 499.51 | 1.00 |

| M1.5X1000 | 1.5 | 1000 | 15.5 | 17 x 17 | 0.6 | 1003.74 | 2.00 |

| M1.5X2000 | 1.5 | 2000 | 15.5 | 17 x 17 | 0.6 | 2002.77 | 4.00 |

| M1.5X3000 | 1.5 | 3000 | 15.5 | 17 x 17 | 0.6 | 3001.80 | 6.10 |

(3) Module 2 Metric Spur Gear Rack

| Metric Spur Gear Rack | Module | Length | (hp) | (he X S) | (S) | Actual Length (Lr) | Weight |

|---|

| mm | mm | mm | mm | mm | kg |

|---|

| M2X500 | 2 | 500 | 18 | 20 x 20 | 0.6 | 502.66 | 1.40 |

| M2X1000 | 2 | 1000 | 18 | 20 x 20 | 0.6 | 1005.31 | 2.70 |

| M2X2000 | 2 | 2000 | 18 | 20 x 20 | 0.6 | 2004.34 | 5.40 |

| M2X3000 | 2 | 3000 | 18 | 20 x 20 | 0.6 | 3003.37 | 8.40 |

(4) Module 2.5 Metric Spur Gear Rack

| Metric Spur Gear Rack | Module | Length | (hp) | (he X S) | (S) | Actual Length (Lr) | Weight |

|---|

| mm | mm | mm | mm | mm | kg |

|---|

| M2.5X500 | 2.5 | 500 | 22.5 | 25 x 25 | 0.7 | 502.66 | 2.10 |

| M2.5X1000 | 2.5 | 1000 | 22.5 | 25 x 25 | 0.7 | 1005.31 | 4.30 |

| M2.5X2000 | 2.5 | 2000 | 22.5 | 25 x 25 | 0.7 | 2002.77 | 8.60 |

| M2.5X3000 | 2.5 | 3000 | 22.5 | 25 x 25 | 0.7 | 3000.23 | 11.90 |

(5) Module 3 Metric Spur Gear Rack

| Metric Spur Gear Rack | Module | Length | (hp) | (he X S) | (S) | Actual Length (Lr) | Weight |

|---|

| mm | mm | mm | mm | mm | kg |

|---|

| M3X500 | 3 | 500 | 27 | 30 x 30 | 0.8 | 499.51 | 3.10 |

| M3X1000 | 3 | 1000 | 27 | 30 x 30 | 0.8 | 1008.45 | 6.30 |

| M3X2000 | 3 | 2000 | 27 | 30 x 30 | 0.8 | 2007.48 | 12.50 |

| M3X3000 | 3 | 3000 | 27 | 30 x 30 | 0.8 | 3006.51 | 18.60 |

(6) Module 4 Metric Spur Gear Rack

| Metric Spur Gear Rack | Module | Length | (hp) | (he X S) | (S) | Actual Length (Lr) | Weight |

|---|

| mm | mm | mm | mm | mm | kg |

|---|

| M4X25X500 | 4 | 500 | 21 | 25 x 25 | 0.8 | 502.66 | 1.80 |

| M4X25X1000 | 4 | 1000 | 21 | 25 x 25 | 0.8 | 1005.31 | 3.65 |

| M4X25X2000 | 4 | 2000 | 21 | 25 x 25 | 0.8 | 2010.62 | 7.30 |

| M4X25X3000 | 4 | 3000 | 21 | 25 x 25 | 0.8 | 3003.37 | 10.90 |

| M4X30X500 | 4 | 500 | 26 | 30 x 30 | 0.8 | 502.66 | 3.05 |

| M4X30X1000 | 4 | 1000 | 26 | 30 x 30 | 0.8 | 1005.31 | 6.00 |

| M4X30X2000 | 4 | 2000 | 26 | 30 x 30 | 0.8 | 1005.32 | 11.90 |

| M4X30X3000 | 4 | 3000 | 26 | 30 x 30 | 0.8 | 1005.33 | 18.10 |

| M4X40X500 | 4 | 500 | 36 | 40 x 40 | 0.8 | 1005.34 | 5.50 |

| M4X40X1000 | 4 | 1000 | 36 | 40 x 40 | 0.8 | 1005.35 | 11.10 |

| M4X40X2000 | 4 | 2000 | 36 | 40 x 40 | 0.8 | 1005.36 | 22.00 |

| M4X40X3000 | 4 | 3000 | 36 | 40 x 40 | 0.8 | 1005.37 | 31.30 |

(7) Module 5 Metric Spur Gear Rack

| Metric Spur Gear Rack | Module | Length | (hp) | (he X S) | (S) | Actual Length (Lr) | Weight |

|---|

| mm | mm | mm | mm | mm | kg |

|---|

| M5X500 | 5 | 500 | 45 | 50 x 50 | 1.0 | 1005.38 | 8.30 |

| M5X1000 | 5 | 1000 | 45 | 50 x 50 | 1.0 | 1005.39 | 17.50 |

| M5X2000 | 5 | 2000 | 45 | 50 x 50 | 1.0 | 1005.40 | 34.60 |

| M5X3000 | 5 | 3000 | 45 | 50 x 50 | 1.0 | 1005.41 | 45.30 |

(8) Module 6 Metric Spur Gear Rack

| Metric Spur Gear Rack | Module | Length | (hp) | (he X S) | (S) | Actual Length (Lr) | Weight |

|---|

| mm | mm | mm | mm | mm | kg |

|---|

| M6X500 | 6 | 500 | 54 | 60 x 60 | 1.0 | 1005.42 | 12.65 |

| M6X1000 | 6 | 1000 | 54 | 60 x 60 | 1.0 | 1005.43 | 25.00 |

| M6X2000 | 6 | 2000 | 54 | 60 x 60 | 1.0 | 1005.44 | 51.00 |

(9) Module 8 Metric Spur Gear Rack

| Metric Spur Gear Rack | Module | Length | (hp) | (he X S) | (S) | Actual Length (Lr) | Weight |

|---|

| mm | mm | mm | mm | mm | kg |

|---|

| M8X500 | 8 | 500 | 72 | 80 x 80 | 1.0 | 1005.45 | 22.40 |

| M8X1000 | 8 | 1000 | 72 | 80 x 80 | 1.0 | 1005.46 | 45.00 |

| M8X2000 | 8 | 2000 | 72 | 80 x 80 | 1.0 | 1005.47 | 90.00 |

Metric Spur Gear Rack Design Features

- High-Quality Material Composition

Metric spur gear racks are crafted from C1045 steel, which adheres to UNI-EN10083-1 standards. This material offers superior strength, durability, and resistance to wear, making it ideal for industrial applications that demand reliable performance under continuous operation and heavy loads. - Precision Manufacturing Tolerances

These gear racks are designed with exceptional precision, featuring a tolerance of 0/-20μm for a single pitch and 0/-30μm for a 500mm length sum of pitches. This ensures smooth operation, reduced vibration, and accurate motion transfer, critical for high-performance mechanical systems. - Optimized Tooth Geometry

The gear racks feature teeth with a 20° pressure angle, optimized to meet DIN 3962/63/67 quality grades. This design enhances the efficiency of power transmission by ensuring a stronger interaction between the rack and pinion, reducing wear and improving longevity. - Versatile Size Modules

Available in nine size modules ranging from 1 to 8, these metric gear racks are versatile and compatible with various pinions. This range of sizes allows for customization and adaptability to meet the specific requirements of different machinery and applications. - Wide Range of Length Options

The gear racks are available in lengths from 500mm to 3000mm, allowing for easy integration with diverse systems. Their continuous mounting capability makes them suitable for applications requiring extended lengths and seamless linear motion without compromising performance. - Lubrication and Maintenance Considerations

To ensure optimal performance and extend the lifespan of the gear racks, the use of gear oil during operation is recommended. Proper lubrication minimizes friction, reduces heat generation, and prevents premature wear, maintaining smooth and efficient motion over time.

Spur Gear Rack Applications

- Industrial Automation Systems

Spur gear racks are essential components in industrial automation for converting rotational motion into linear motion. They are commonly used in CNC machines, robotic arms, and assembly lines, where precise and reliable motion control is crucial for operational efficiency and productivity. - Transportation and Rail Systems

In the transportation sector, spur gear racks are integral to rail systems, such as rack railways, where they enable locomotives to climb steep gradients. Their robust construction ensures consistent performance in demanding environments, improving safety and reliability in transportation applications. - Material Handling Equipment

Gear racks are widely used in material handling equipment like conveyor systems, elevators, and hoists. They provide accurate linear movement and contribute to the smooth operation of machinery used for lifting, transporting, or positioning heavy loads in warehouses and factories. - Automotive Steering Mechanisms

In automotive systems, spur gear racks play a vital role in rack-and-pinion steering mechanisms. This setup allows for precise and responsive vehicle steering, enhancing drivability and safety by translating the driver’s rotational input into linear motion for the wheels. - Construction and Heavy Machinery

Spur gear racks are employed in construction equipment such as cranes, excavators, and lifts. Their ability to handle heavy loads and provide precise linear motion makes them a critical component in machinery used for lifting, digging, and other heavy-duty operations. - Elevator and Escalator Systems

In vertical transportation systems like elevators and escalators, spur gear racks ensure smooth and controlled linear motion. They are integral to mechanisms that require consistent movement, supporting the safe and efficient operation of systems in commercial and residential buildings.

|  |

| Gear Rack for Automation and Robotics | Gear Rack for Construction Hoist Machinery |

|  |

| Gear Rack for Material Handling | Gear Rack for Elevators and Lifts |