Mast Hydraulic Cylinder for Rotary Drilling Rig

A mast hydraulic cylinder in a rotary drilling rig is a critical component used to raise, lower, and stabilize the rig’s mast, which is the vertical structure supporting drilling operations. These double-acting, often telescopic, hydraulic mast cylinders convert pressurized hydraulic fluid into linear motion to adjust the mast’s position, ensuring precise alignment and stability during drilling. Typically mounted on the rig’s chassis or substructure, they handle heavy loads and extreme conditions, such as arctic cold or high heat, with robust materials like corrosion-resistant alloys.

A mast hydraulic cylinder in a rotary drilling rig is a critical component used to raise, lower, and stabilize the rig’s mast, which is the vertical structure supporting drilling operations. These double-acting, often telescopic, hydraulic mast cylinders convert pressurized hydraulic fluid into linear motion to adjust the mast’s position, ensuring precise alignment and stability during drilling. Typically mounted on the rig’s chassis or substructure, they handle heavy loads and extreme conditions, such as arctic cold or high heat, with robust materials like corrosion-resistant alloys.

Rotary Drilling Mast Hydraulic Cylinder Specifications

| Product Name: | Rotary Drilling Hydraulic Mast Cylinder |

| Function: | Control the mast, adjust the angle of the mast and the ground. |

| Bore Diameter: | 140mm-350mm |

| Rod diameter: | 90mm-230mm |

| Stroke: | ≤5550mm |

| Maximum pressure MPa: | 32MPa |

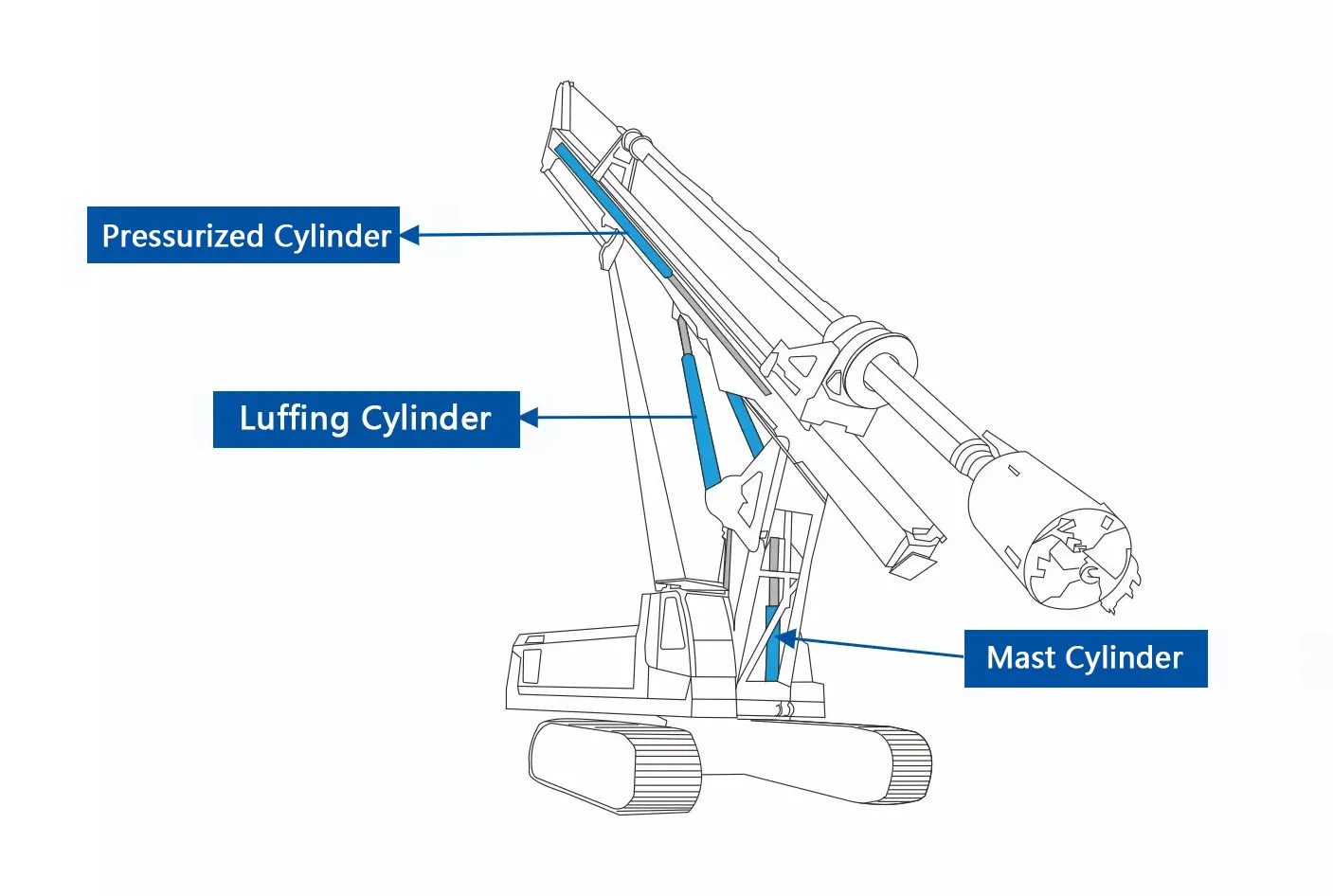

Rotary Drilling Rig Hydraulic Cylinder Types

- Hydraulic Luffing Cylinders

Hydraulic luffing cylinders control the angle and positioning of the boom or mast on a rotary drilling rig. These cylinders provide smooth and precise movement, allowing operators to adjust the drilling angle or position effectively. Built for high load capacity, they ensure stability and safety during operations in various terrains. Their robust design makes them suitable for handling the heavy stresses associated with drilling equipment. - Hydraulic Mast Cylinders

Hydraulic mast cylinders are designed to raise, lower, and stabilize the mast structure of rotary drilling rigs. They ensure the mast remains secure during drilling operations and transportation. These cylinders are engineered to handle significant vertical loads and resist wear from continuous use. Their reliable performance is critical to maintaining the structural integrity of the rig, especially in demanding drilling environments. - Hydraulic Pressurized Cylinders

Hydraulic pressurized cylinders generate the necessary force to drive drilling operations by converting hydraulic pressure into mechanical energy. These cylinders power various rig components, enabling efficient drilling through different soil and rock formations. They are built to operate under extreme pressure conditions while maintaining durability and consistent performance. Their ability to handle intense forces makes them essential for heavy-duty drilling applications.

Rotary Drilling Rig Hydraulic Mast Cylinder Benefits

Choose the Right Mast Hydraulic Cylinder for Rotary Drilling Rig

- Rod Diameter

The rod diameter of the hydraulic cylinder determines its strength and resistance to bending under heavy loads. A thicker rod diameter is essential for withstanding the significant forces exerted during mast operations on rotary drilling rigs. Selecting the correct rod size ensures durability and prevents mechanical failure during prolonged use. - Bore Diameter

The bore diameter affects the cylinder's capacity to generate force. A larger bore diameter allows for greater hydraulic pressure and force output, making it suitable for handling the heavy mast loads. Choosing the right bore diameter ensures efficient operation and prevents underperformance in demanding drilling conditions. - Working Pressure

The working pressure rating of the hydraulic cylinder must match the system's hydraulic pressure requirements. A cylinder capable of operating at high pressure is essential for heavy-duty drilling rigs. Properly matching the working pressure ensures optimal energy transfer and prevents damage to the hydraulic system. - Installation Distance

The installation distance, or the space available for mounting the cylinder, determines its compatibility with the drilling rig. Choosing a cylinder that fits within the available installation dimensions is crucial for seamless integration. Incorrect sizing can lead to operational inefficiencies or mechanical conflicts. - Stroke Length

The stroke length of the hydraulic cylinder determines the range of mast movement it can provide. A longer stroke length allows for greater flexibility in mast positioning and adjustment. Selecting the appropriate stroke ensures the cylinder can meet the operational requirements of the rig. - Thrust Force

The thrust force of the hydraulic cylinder must be sufficient to lift and support the mast along with any attached equipment. Calculating the required force based on the rig's weight and workload is essential. Choosing a cylinder with adequate thrust capacity ensures safe and efficient mast operation.

|

|

Additional information

| Edited by | Yjx |

|---|