Luffing Hydraulic Cylinder for Rotary Drilling Rig

The luffing hydraulic cylinder for a rotary drilling rig is a critical mechanical component used to adjust the inclination or positioning of the drill mast (boom) during drilling operations. This type of cylinder is designed to provide precise control and stability, enabling the rig to operate efficiently in varying angles and challenging terrains. Typically powered by hydraulic pressure, the cylinder exerts force to tilt or raise the mast, ensuring that the drilling process aligns correctly with the desired drilling angle and depth.

The luffing hydraulic cylinder for a rotary drilling rig is a critical mechanical component used to adjust the inclination or positioning of the drill mast (boom) during drilling operations. This type of cylinder is designed to provide precise control and stability, enabling the rig to operate efficiently in varying angles and challenging terrains. Typically powered by hydraulic pressure, the cylinder exerts force to tilt or raise the mast, ensuring that the drilling process aligns correctly with the desired drilling angle and depth.

Constructed from high-strength materials, hydraulic luffing cylinders are engineered to withstand extreme loads, pressure, and harsh environmental conditions encountered during drilling. They often feature a robust piston and seals to prevent hydraulic leaks, ensuring long-lasting performance. Furthermore, these cylinders enhance operational safety by stabilizing the mast against forces like wind or vibrations, especially in deep drilling or large-scale construction projects. Their functionality is essential to achieving precision and reliability in rotary drilling operations.

Rotary Drilling Luffing Hydraulic Cylinder Specifications

| Product Name: | Rotary Drilling Hydraulic Luffing Cylinder |

| Function: | Control the luffing angle, adjust the distance between the mast and the host. |

| Bore Diameter: | 125mm-250mm |

| Rod diameter: | 90mm-160mm |

| Stroke: | ≤1640 mm |

| Maximum pressure MPa: | 32MPa |

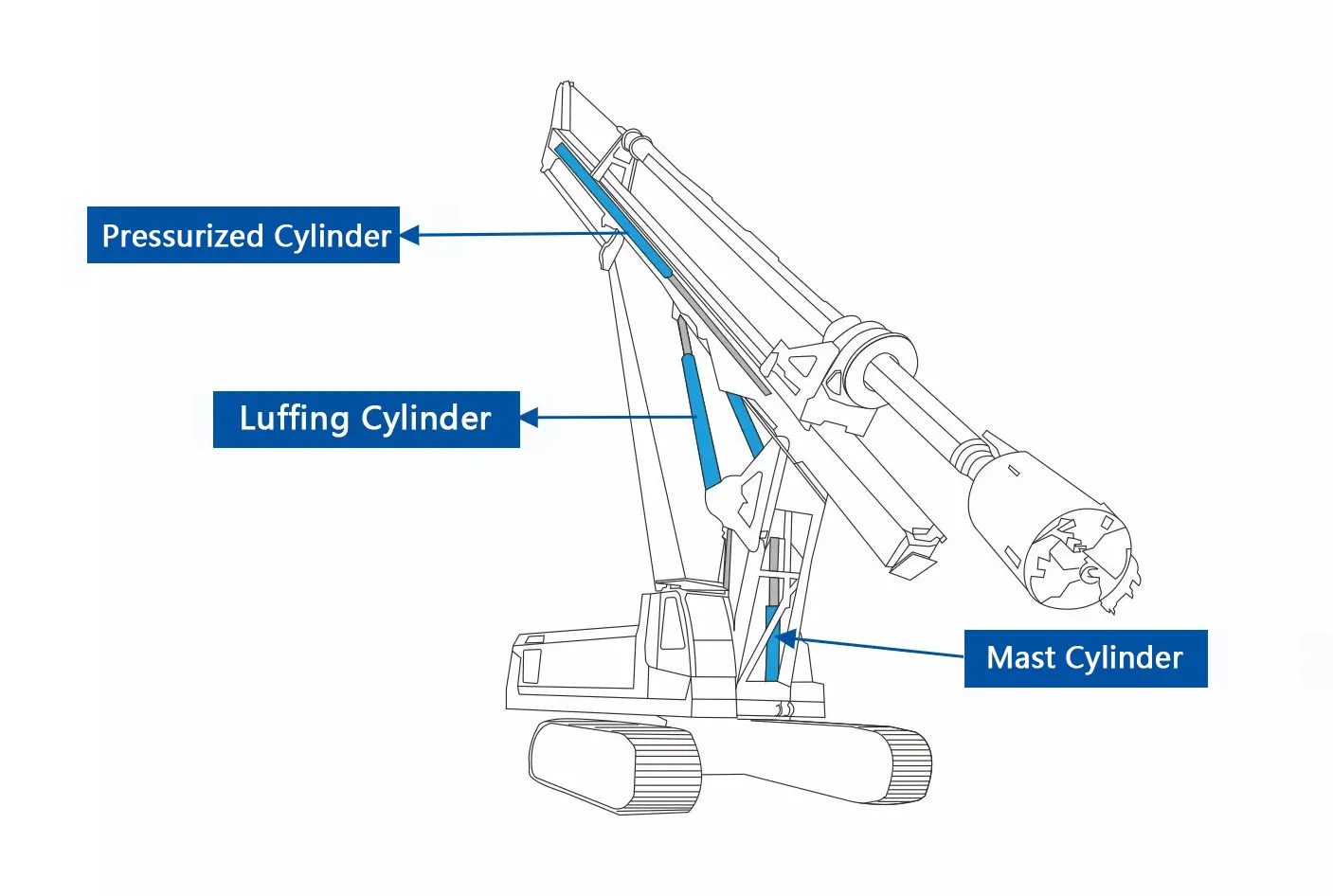

Rotary Drilling Rig Hydraulic Cylinder Types

1. Luffing Hydraulic Cylinders

Luffing hydraulic cylinders are used to adjust the angle or inclination of the drill mast in rotary drilling rigs. They provide precise control over mast positioning, ensuring stability and accuracy during drilling. These cylinders are built to handle heavy loads and operate in harsh environments, making them crucial for maintaining proper alignment in challenging terrains. Their design allows for safe and efficient mast adjustments, even under extreme pressure or wind forces.

2. Mast Hydraulic Cylinders

Mast hydraulic cylinders are responsible for raising, lowering, and stabilizing the drill mast during operation. These cylinders ensure the mast remains secure and aligned, contributing to operational efficiency and safety. Built with high-strength materials, they are designed to withstand the stresses of continuous, heavy-duty operation. Their smooth and reliable performance is essential for maintaining the rigidity of the mast, especially during deep drilling or when handling large rotary tools.

3. Pressurized Hydraulic Cylinders

Pressurized hydraulic cylinders are used to generate the force needed to drive the drill bit into the ground. They convert hydraulic energy into mechanical force, enabling efficient penetration into tough materials like rock or dense soil. These cylinders are designed to deliver consistent pressure, ensuring a smooth and controlled drilling process. Their durability and precision are critical for maintaining consistent performance, even under high operational demands or in extreme drilling conditions.

Rotary Drilling Rig Luffing Hydraulic Cylinder Features

- Double-Acting Mechanism

Luffing hydraulic cylinders utilize a double-acting design, allowing precise control of the drilling rig’s mast movement. Hydraulic fluid powers both extension and retraction, enabling smooth and accurate angular adjustments. This ensures optimal positioning during drilling, enhancing efficiency and safety in complex operations. - High-Strength Construction

These rotary drilling hydraulic cylinders are constructed from high-strength alloy steel to withstand heavy loads and harsh drilling environments. The robust materials resist wear, corrosion, and extreme pressures, ensuring long-term durability. This construction supports reliable performance in demanding applications like construction, mining, and geotechnical drilling. - Advanced Sealing Systems

Hydraulic luffing cylinders feature advanced sealing systems to prevent fluid leaks and contamination. High-quality seals, such as polyurethane or nitrile rubber, ensure reliable operation under high pressure and temperature variations. This enhances cylinder longevity and maintains consistent performance in challenging drilling conditions. - Precision Control Valves

Equipped with precision control valves, these rotary drilling rig hydraulic cylinders allow fine-tuned adjustments of the mast’s angle and position. The valves regulate hydraulic fluid flow, ensuring smooth and accurate movements. This precision is critical for aligning the drilling rig accurately, improving operational efficiency, and reducing downtime. - High Load-Bearing Capacity

- Luffing hydraulic cylinders are designed to handle significant loads, supporting the weight of the drilling mast and attached equipment. Their high load-bearing capacity ensures stability during operation, even in tough geological conditions, making them ideal for heavy-duty rotary drilling applications.

- Corrosion-Resistant Coatings

- These hydraulic luffing cylinders are coated with corrosion-resistant materials, such as chrome plating or specialized paints, to protect against environmental wear. This feature extends service life in harsh conditions, like wet or saline environments, ensuring consistent performance and reducing maintenance costs for drilling operations.

Rotary Drilling Hydraulic Luffing Cylinder Applications

Additional information

| Edited by | Yjx |

|---|