LSY Series Screw Conveyor for Mining/ Cement/ Power/ Coal/ Sand Grain/ Chemical/ Metallurgy Industry

LSY series screw conveyor is a new type of conveying equipment specially designed for horizontal or inclined conveying of granular, powdery and small block materials. and is matched with cement silo and concrete mixer to form an efficient concrete batching plant. Working principle is to push the material along the conveying pipeline through the rotating spiral blades in the closed tube. It is widely used in various industries such as building materials, electricity, cement, mining, chemical industry, grain, coal, metallurgy, etc.

LSY series screw conveyor is a new type of conveying equipment specially designed for horizontal or inclined conveying of granular, powdery and small block materials. and is matched with cement silo and concrete mixer to form an efficient concrete batching plant. Working principle is to push the material along the conveying pipeline through the rotating spiral blades in the closed tube. It is widely used in various industries such as building materials, electricity, cement, mining, chemical industry, grain, coal, metallurgy, etc.

The equipment adopts pure copper national standard motor, special reducer for screw conveyor, thickened spiral mandrel and outer tube, etc. LSY screw conveyor is suitable for conveying dry powder, granular and small block materials horizontally or at an elevation angle of less than 45°, such as cement, coal powder, fertilizer, grain, ash, sand, etc. It is particularly suitable for cement transportation from cement silo to mixer or from cement silo to batching machine in concrete batching plant.

LSY Series Screw Conveyor Features

- Strong conveying efficiency: the speed is 175-200/min, which can efficiently convey a large amount of materials in a short time.

- Compact structure: reasonable design, small footprint, easy installation and maintenance.

- Good sealing: the fully enclosed conveying outer pipe can effectively prevent material leakage and reduce environmental pollution.

- Stable Operation: smooth operation, low noise and easy maintenance.

- Adjustability: the conveying speed and angle can be adjusted according to actual needs, and can be flexibly adapted to different working conditions.

- Wide applicability: it can convey a variety of materials, such as cement, sand and gravel, coal powder, grain, fertilizer, etc., to meet different industrial needs.

- Strong wear resistance: made of wear-resistant materials to extend service life.

- Easy to install and move: convenient installation and disassembly, safe operation.

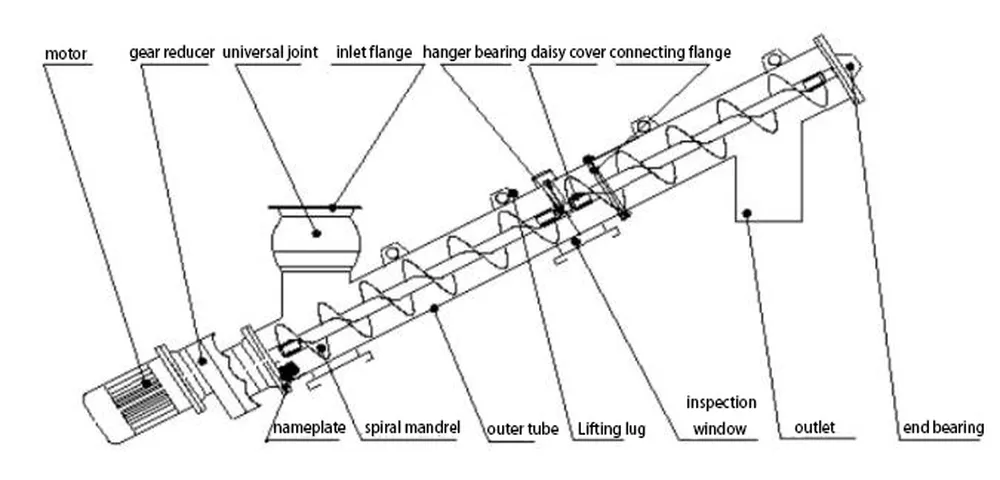

LSY Series Screw Conveyor Parts Diagram

LSY Screw Conveyor Specification Sheet

| Model | Spiral body nominal diameter(mm) |

Conveyor length (m) |

Spiral rotation speed (r/m) |

Shell diameter (mm) |

Work perspective |

Conveying capacity (t/h) |

Motor model |

Electric power (kw) |

| LSY140 | Ø140 | 4.5、6、9 | 300 | Ø168 | ≤45° | 20 | Y132S-4 Y112M-4 |

5.5 4.0 |

| LSY200 | Ø190 | 4.5、6、9、12 | 300(216) | Ø219 | 40 | Y160M-4 Y132M-4 |

11 7.5 |

|

| LSY250 | Ø240 | 4.5、6、9 | 216 | Ø273 | 80 | Y160L-4 Y160M-4 |

15 11 |

|

| LSY300 | Ø290 | 4.5、6、9 | 155 | Ø325 | 110 | Y180M-4 Y180L-4 |

18.5 22 |

LSY Screw Conveyor Applications

- Mining Industry

The LSY screw conveyor is widely used in the mining industry for transporting mined materials such as ores, minerals, and rock debris. Its durable construction ensures efficient handling of abrasive and heavy materials, minimizing wear and tear while maintaining high operational efficiency. It also supports continuous loading and unloading in harsh conditions. - Cement Industry

In the cement industry, the LSY screw conveyor is utilized for conveying cement, fly ash, and other powdered or granular materials. It ensures smooth and dust-free transportation, improving environmental safety. Its ability to handle high-temperature materials makes it ideal for cement production and storage facilities. - Power Industry

Power plants benefit from LSY screw conveyors for transporting coal, ash, and biomass fuels. Their enclosed structure prevents spillage and ensures cleaner operations. The conveyor's adaptability to work under high temperatures and its resistance to clogging make it a reliable choice for power generation facilities. - Coal Industry

The LSY screw conveyor is extensively used in coal mines and processing plants for transporting coal, fine particles, and other by-products. Its robust design ensures safe and efficient material handling, even in explosive environments. It also reduces manual labor and enhances productivity in coal operations. - Sand Grain Industry

In the sand grain industry, the LSY screw conveyor efficiently transports sand, gravel, and other granular materials. Its ability to handle bulk materials with precision makes it suitable for both wet and dry conditions. It also prevents material segregation while maintaining consistency in delivery. - Chemical Industry

The chemical industry relies on the LSY screw conveyor for handling raw materials, powders, and finished chemical products. Its corrosion-resistant construction ensures longevity when working with reactive or hazardous materials. It also supports precise dosing and mixing processes, improving product quality and safety. - Metallurgy Industry

In the metallurgy industry, the LSY screw conveyor is used to transport metal powders, slag, and other by-products from production processes. Its capability to handle hot and abrasive materials makes it an essential tool in smelting and metal finishing plants. It ensures consistent material flow in demanding environments.

|

|

| Screw Conveyor for Cement Industry | Screw Conveyor for Sand Grain Industry |

LSY Series Screw Conveyor Advantages

- High Conveying Efficiency

The LSY series screw conveyor ensures efficient material transport with a high rotation speed of 175–200 rpm. It can handle large volumes of dry powder, granular, and small block materials like cement and coal powder in a short time, enhancing productivity in industrial applications. - Compact and Flexible Design

With a small cross-sectional area and modular structure, the LSY screw conveyor is ideal for confined spaces. Its customizable dimensions and angles allow seamless integration into various layouts, making it versatile for industries like construction, mining, and chemical processing. - Superior Sealing Performance

The fully enclosed outer pipe, made of high-quality seamless steel, prevents material leakage and dust emissions. This design ensures a clean working environment, reduces pollution, and protects materials from external contamination, ideal for sensitive applications like cement transport. - Durable and Wear-Resistant Construction

Constructed with wear-resistant materials and thickened spiral mandrels, the LSY series screw conveyor offers extended service life. The robust design, including cast aluminum alloy hanger connections, minimizes wear and ensures reliable operation under demanding conditions. - Easy Installation and Maintenance

The screw conveyor features a bolted design and universal joints for easy assembly and disassembly. Pre-assembled and debugged in the factory, it reduces installation time. Regular maintenance, like lubricating bearings, is straightforward, ensuring long-term operational efficiency. - Safe and Reliable Operation

Equipped with high-quality reducers and heavy-duty designs, the screw conveyor delivers large torque with low noise and no dust leakage. Its safe operation is enhanced by features like universal ball joints, ensuring smooth and dependable material transport.

|

|

Additional information

| Edited by | Yjx |

|---|