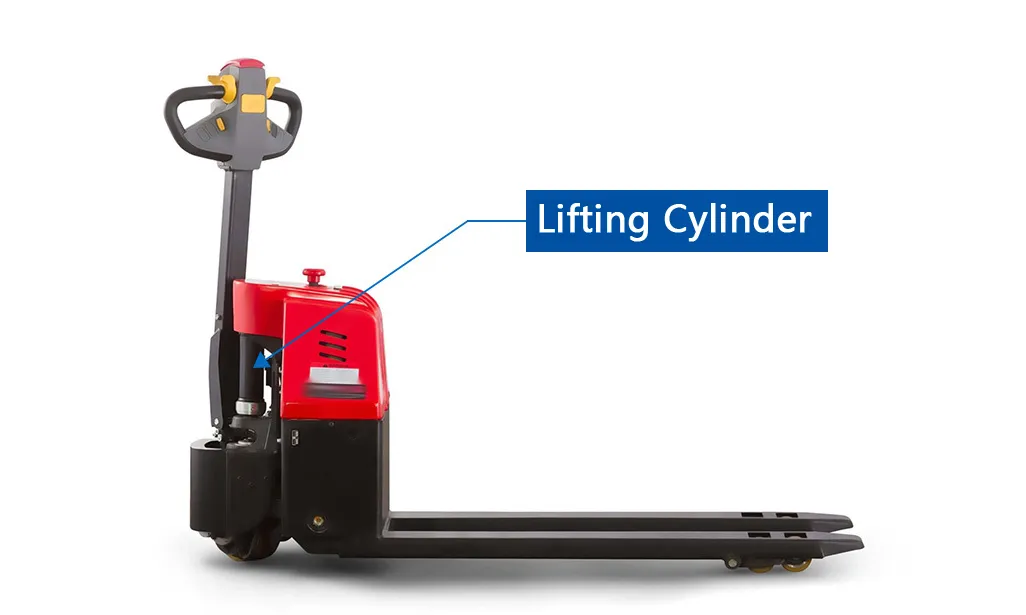

Lifting Hydraulic Cylinder for Warehouse Storage Forklift

A lifting hydraulic cylinder for a warehouse storage forklift is a critical component of the forklift’s hydraulic system, responsible for raising and lowering the mast and forks to handle heavy loads. It operates using pressurized hydraulic fluid, which is pumped into the cylinder to move a piston, generating linear force to lift or lower the mast. Typically single-acting, the lift cylinder is designed for vertical movement, handling high-pressure loads in demanding warehouse environments.

A lifting hydraulic cylinder for a warehouse storage forklift is a critical component of the forklift’s hydraulic system, responsible for raising and lowering the mast and forks to handle heavy loads. It operates using pressurized hydraulic fluid, which is pumped into the cylinder to move a piston, generating linear force to lift or lower the mast. Typically single-acting, the lift cylinder is designed for vertical movement, handling high-pressure loads in demanding warehouse environments.

These forklift hydraulic lifting cylinders are constructed from high-strength materials to ensure durability and reliability under heavy loads, with precise seals to prevent fluid leaks. They are essential for efficient material handling, enabling precise load placement and retrieval in high-rise storage systems, ensuring safety and productivity in warehouse operations.

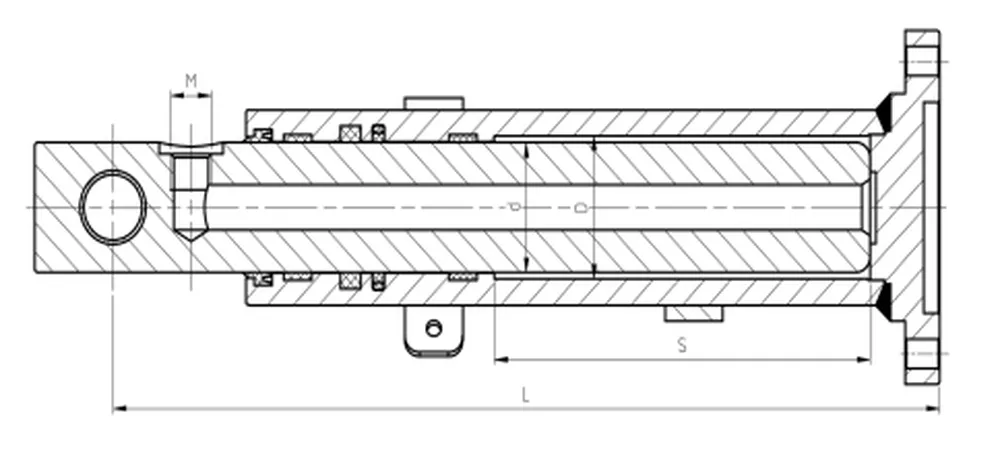

Forklift Lifting Hydraulic Cylinder Dimensions

| drawing number | bore diameter (D) | rod diameter (d) | stroke (S) | Installation distance (L) | working pressure | Interface dimensions (M) | weight |

| AIMBN156-620000-001 | Φ45 | Φ40 | 125 | 313 | 18MPa | M12*1.5 | 6.5kg |

| AIMBJ150-620000-000 | Φ40 | Φ35 | 155 | 354.7 | 22MPa | Φ6 | 6.5kg |

| AIMBA200-620000-000 | Φ45 | Φ40 | 155 | 355 | 20MPa | Φ6 | 6.5kg |

| EPT18H-301-00 | Φ40 | Φ35 | 120 | 233 | 25MPa | M12*1.5 | 3.6kg |

| Product Name: | Lifting Hydraulic Cylinder |

| Function: | Lifting fork feet, realizing the lifting of goods. |

| Cylinder diameter: | 30mm-63mm |

| Rod diameter: | 25mm-55mm |

| Travel: | 50mm-200mm |

| Maximum pressure: | 18MPa |

| Maximum thrust: | 43KN |

Hydraulic Lifting Cylinder for Warehouse Storage Forklift

A hydraulic lifting cylinder for a warehouse storage forklift is a key mechanism that enables the lifting and lowering of the forklift’s mast and forks to handle heavy loads efficiently. It operates within the forklift’s hydraulic system, which uses pressurized fluid to transmit power. The cylinder consists of a cylindrical barrel, a piston, a piston rod, and seals. When the forklift operator activates the lift control, a hydraulic pump draws fluid (typically oil) from a reservoir and forces it into the cylinder’s base through a control valve. This pressurized fluid pushes the piston upward, extending the piston rod, which is connected to the mast, raising the forks and any load they carry.

The lifting process is smooth and controlled due to the precise regulation of fluid flow by the control valve, allowing for accurate positioning of loads in high-rise storage racks. To lower the load, the operator adjusts the valve to release fluid from the cylinder back into the reservoir, reducing pressure. The weight of the load and gravity assist in retracting the piston rod, lowering the mast.

Single-acting hydraulic cylinders, common in forklifts, use hydraulic pressure for lifting and rely on gravity for descent, while double-acting cylinders can use hydraulic pressure for both directions in more advanced systems. High-strength steel construction and robust seals prevent leaks, ensuring reliability under heavy loads (often thousands of pounds).

Forklift Lifting Hydraulic Cylinder Features

- High-strength construction

The lifting hydraulic cylinder is built from robust materials like high-grade steel to withstand heavy loads and intense warehouse use. This ensures durability and resistance to wear, maintaining reliable performance under demanding conditions for extended periods. - Precision sealing system

Advanced seals prevent hydraulic fluid leaks, ensuring consistent pressure and smooth operation. These seals are designed to endure high pressures and frequent cycles, minimizing maintenance needs and enhancing the cylinder’s efficiency in busy warehouse environments. - Smooth lifting mechanism

The hydraulic lifting cylinder provides controlled, jerk-free lifting and lowering of the forklift’s mast. Precise fluid flow regulation allows for accurate load positioning, critical for safe and efficient stacking in high-rise storage racks. - High load capacity

Designed to handle substantial weights, often thousands of pounds, the forklift hydraulic cylinder supports the forklift’s ability to lift heavy pallets. This capability is essential for maximizing storage density and operational productivity in warehouses. - Compact design

The cylinder’s streamlined structure integrates seamlessly into the forklift’s mast, optimizing space without compromising power. This design enhances maneuverability in tight warehouse aisles while maintaining the strength needed for heavy-duty lifting tasks. - Corrosion resistance

Special coatings or materials protect the forklift hydraulic lifting cylinder from rust and environmental damage, even in humid or dusty warehouses. This feature extends the component’s lifespan, reducing replacement costs and ensuring consistent performance over time.

Forklift Hydraulic Lifting Cylinder Applications

- Warehouse stacking

Hydraulic lifting cylinders enable forklifts to lift and stack pallets in high-rise racks, optimizing vertical storage space and ensuring efficient organization of goods in large-scale warehouse operations. - Loading and unloading

These forklift lifting hydraulic cylinders facilitate the smooth lifting and lowering of heavy loads onto trucks or conveyors, streamlining logistics processes and reducing manual handling in busy warehouse environments. - Inventory management

The precise control of lifting cylinders allows forklifts to place or retrieve items from specific rack locations, supporting accurate inventory tracking and efficient stock management in warehouses. - Material handling

Cylinders power forklifts to transport heavy materials like crates or machinery parts within warehouses, ensuring safe and efficient movement across various surfaces and tight spaces. - Order picking

Hydraulic cylinders assist in lifting forks to access specific items on high shelves, enabling quick and accurate order fulfillment for customer shipments in distribution centers. - Construction material transport

In warehouse settings supporting construction, hydraulic lifting cylinders handle heavy materials like steel beams or concrete blocks, ensuring reliable lifting for storage or delivery preparation tasks.

Additional information

| Edited by | Yjx |

|---|