Lifting Hydraulic Cylinder for Scissor Type Aerial Work Platform

A lifting hydraulic cylinder for a scissor-type aerial work platform is a critical component that powers the vertical movement of the platform. It operates using hydraulic fluid, typically oil, which is pressurized by a pump to actuate a piston within the cylinder. This piston movement extends or retracts the cylinder, pushing or pulling the scissor mechanism—characterized by its crisscross metal structure—to raise or lower the platform.

A lifting hydraulic cylinder for a scissor-type aerial work platform is a critical component that powers the vertical movement of the platform. It operates using hydraulic fluid, typically oil, which is pressurized by a pump to actuate a piston within the cylinder. This piston movement extends or retracts the cylinder, pushing or pulling the scissor mechanism—characterized by its crisscross metal structure—to raise or lower the platform.

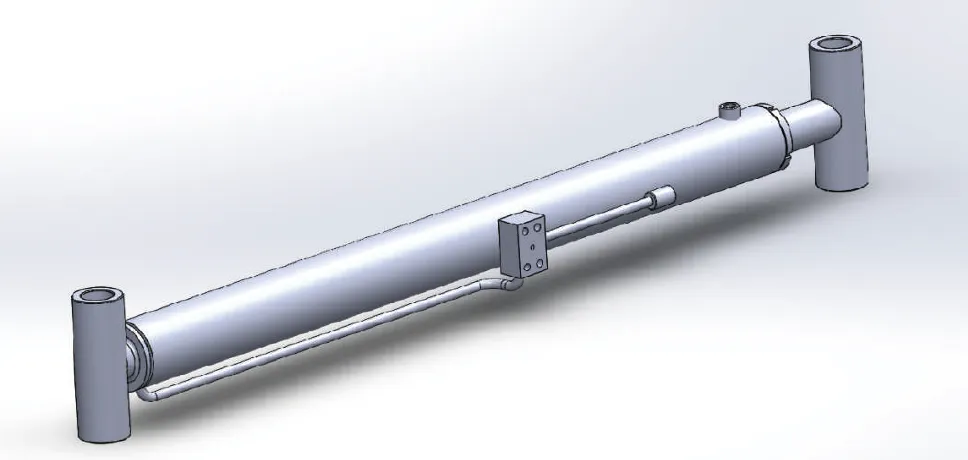

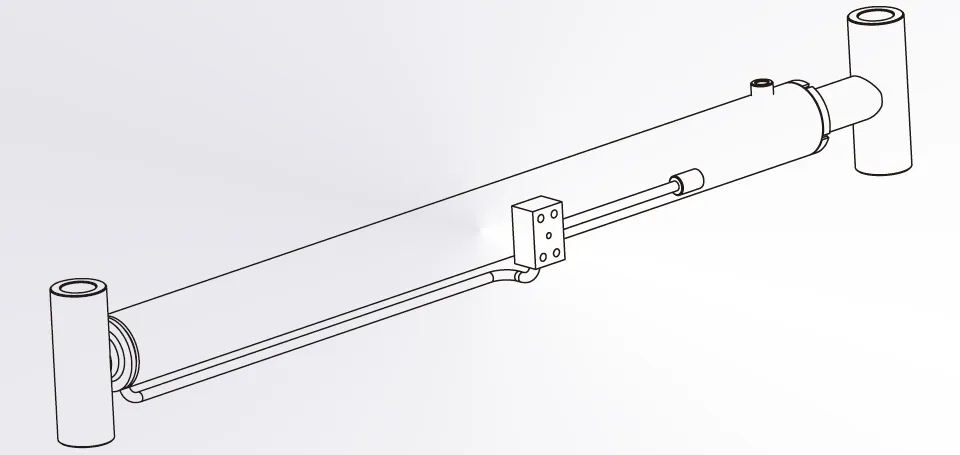

These hydraulic lifting cylinders are designed for reliability, with features like high-strength materials (e.g., aluminum, cast iron, or stainless steel), customizable bore sizes, and stroke lengths. They ensure stable, controlled lifting for heavy loads, enhancing safety and efficiency in applications like construction, warehousing, and maintenance.

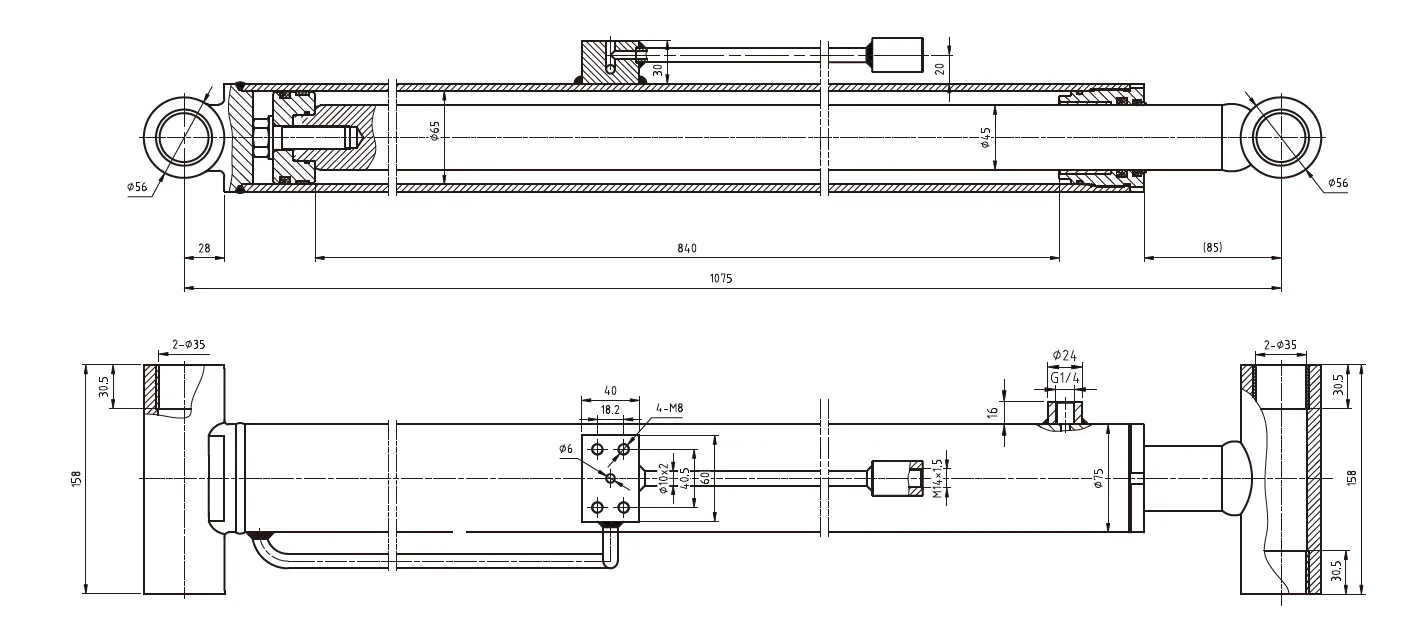

Lifting Hydraulic Cylinder Dimensions

|

|

|

|

| Lifting Hydraulic Cylinder | ||||||

| Cylinder model | Specifications | Working pressure | Maximum withstand pressure | Trip | Installation distance | Weight |

| CMNYY11112003 | Φ65xΦ45x840 | 18MPa | 27MPa | 840 | 1075 | 27kg |

| Product Name: | Lifting Hydraulic Cylinder |

| Function: | Implement the upward and downward movements of the scissor fork. |

| Cylinder diameter: | 55mm-380mm |

| Rod diameter: | 40mm-200mm |

| Travel: | 280mm -2193mm |

| Maximum pressure: | 25MPa |

| Maximum thrust: | 2835KN |

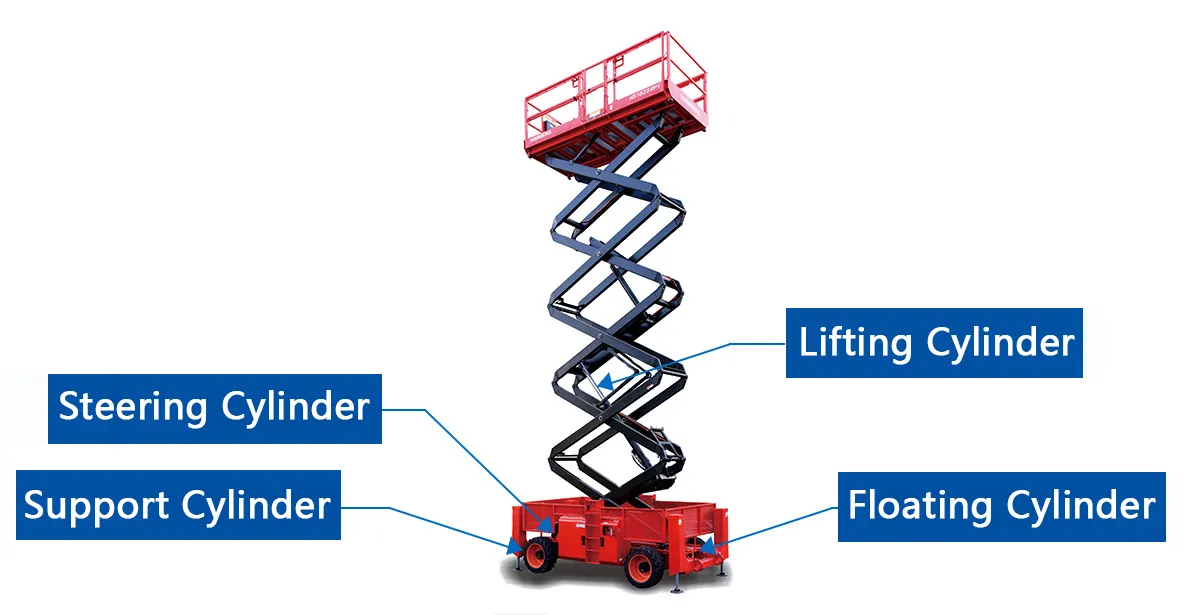

Scissor Type Aerial Work Platform Hydraulic Cylinder Types

- Hydraulic Floating Cylinders

Hydraulic floating cylinders provide flexible movement in scissor-type aerial work platforms. They allow slight lateral adjustments during operation, accommodating uneven surfaces. Constructed with durable materials like stainless steel, they ensure stability and absorb shocks, enhancing platform safety and operational efficiency in challenging environments like construction sites. - Hydraulic Support Cylinders

Hydraulic support cylinders stabilize scissor-type aerial work platforms by maintaining structural integrity during operation. These robust cylinders, often made of high-strength steel, support heavy loads, prevent tipping, and ensure worker safety. They are critical for stationary positioning in tasks like warehouse maintenance or installation work. - Hydraulic Lifting Cylinders

Hydraulic lifting cylinders are the primary actuators for vertical movement in scissor-type platforms. Using pressurized hydraulic fluid, they extend or retract to raise or lower the platform. Built with customizable bore sizes (40mm–300mm), they offer precise control and high load capacity for applications like building maintenance. - Hydraulic Steering Cylinders

Hydraulic steering cylinders enable precise directional control in mobile scissor-type aerial work platforms. They facilitate smooth turning and navigation, using hydraulic pressure to actuate steering mechanisms. Made with corrosion-resistant materials, they ensure reliable performance in outdoor settings like infrastructure projects or large-scale events.

Scissor Type Aerial Work Platform Hydraulic Lifting Cylinder Benefits

- High Load Capacity

Hydraulic lifting cylinders in scissor-type aerial work platforms support heavy loads with ease. Constructed from robust materials like high-strength steel, they handle significant weight, enabling safe lifting of personnel and equipment for tasks such as construction or maintenance. - Precise Control

These lifting cylinders offer exceptional precision in controlling platform height. By regulating hydraulic fluid flow, they ensure smooth and accurate elevation adjustments, allowing operators to position the platform exactly where needed for tasks like painting or electrical repairs. - Enhanced Safety

Hydraulic lifting cylinders enhance safety by providing stable and controlled lifting. Equipped with features like pressure relief valves, they prevent overloading and ensure secure operation, protecting workers during high-altitude tasks in warehousing or installation projects. - Durability and Longevity

Built with corrosion-resistant materials like stainless steel, lift hydraulic cylinders withstand harsh environments. Regular maintenance, such as seal inspections, ensures long-term reliability, reducing downtime and repair costs in demanding applications like outdoor construction or industrial maintenance. - Energy Efficiency

Lifting hydraulic cylinders are energy-efficient, requiring minimal power to operate. Their design optimizes hydraulic fluid use, reducing energy consumption while maintaining high performance, which lowers operational costs for businesses using scissor-type platforms in various settings. - Customizable Design

These scissor-type aerial work platform hydraulic cylinders offer customizable bore sizes (40mm–200mm) and stroke lengths (280mm -2193mm) to suit specific platform requirements. This adaptability ensures compatibility with diverse scissor-type aerial work platforms, enhancing versatility for applications in construction, warehousing, or event setup.

Lifting Hydraulic Cylinder for Scissor Type Aerial Work Platform

The lifting hydraulic cylinder is the core component driving the vertical movement of a scissor-type aerial work platform, enabling safe and efficient elevation for tasks like construction, maintenance, or warehousing. The cylinder operates on hydraulic principles, converting fluid pressure into mechanical force. It consists of a cylindrical barrel, a piston, a piston rod, and seals, typically constructed from high-strength materials like steel or aluminum to withstand heavy loads and harsh environments.

The process begins with a hydraulic pump, which draws fluid (usually oil) from a reservoir and pressurizes it. This pressurized fluid is directed into the cylinder through a control valve. When the fluid enters the cylinder’s base, it pushes the piston upward, extending the piston rod. In a scissor-type platform, this extension forces the crisscross scissor mechanism—composed of interconnected metal arms—to unfold, raising the platform. The scissor design amplifies the cylinder’s movement, allowing significant height increases from a compact mechanism.

To lower the platform, the control valve releases the fluid back to the reservoir, reducing pressure. The piston retracts, either by gravity or hydraulic action in double-acting cylinders, collapsing the scissor mechanism. Safety features like pressure relief valves prevent overloading, while seals ensure no fluid leaks, maintaining efficiency. The cylinder’s bore size and stroke length are tailored to the platform’s load and height requirements, ensuring precise control and stability. Regular maintenance, such as checking seals and fluid levels, ensures reliable operation, making these cylinders ideal for demanding applications.

Additional information

| Edited by | Yjx |

|---|