Lift Hydraulic Cylinder for Truss Arm Crawler Crane

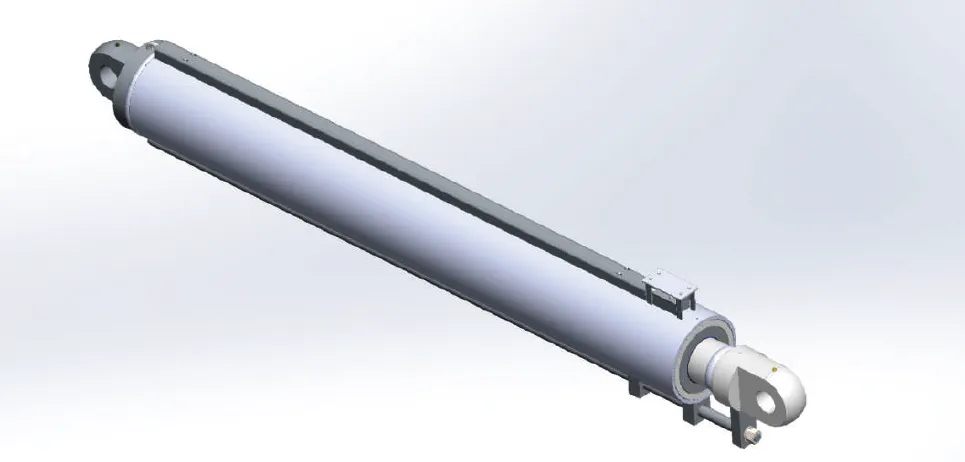

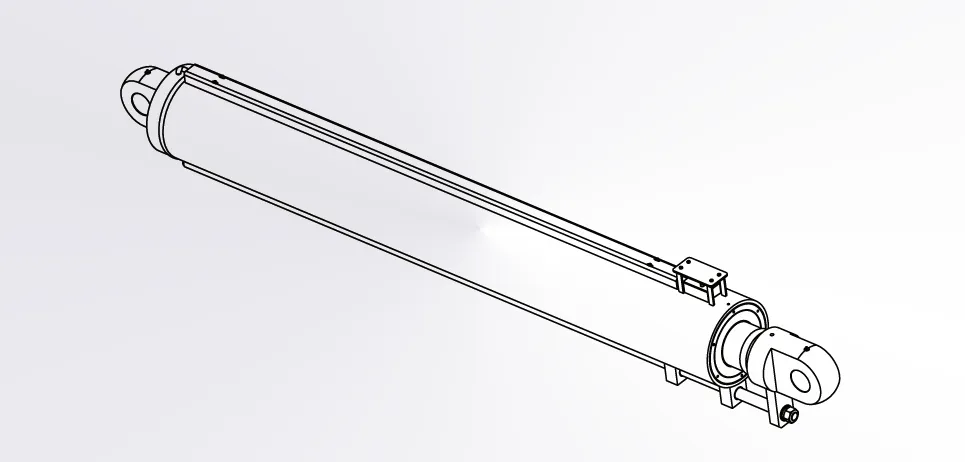

A lift hydraulic cylinder for a truss arm crawler crane is a critical component designed to provide the linear force necessary for lifting and maneuvering heavy loads. It converts hydraulic pressure into mechanical force, enabling the crane’s truss arm—a lattice-structured boom—to raise, lower, or position materials with precision. Typically, these hydraulic lift cylinders are double-acting, featuring a piston, rod, barrel, and seals.

A lift hydraulic cylinder for a truss arm crawler crane is a critical component designed to provide the linear force necessary for lifting and maneuvering heavy loads. It converts hydraulic pressure into mechanical force, enabling the crane’s truss arm—a lattice-structured boom—to raise, lower, or position materials with precision. Typically, these hydraulic lift cylinders are double-acting, featuring a piston, rod, barrel, and seals. They are engineered for durability under high-pressure conditions and rugged environments, ensuring reliable performance for heavy-duty tasks like construction or wind turbine assembly.

Lift Hydraulic Cylinder Dimensions

|

|

|

|

| Hydraulic Lift Cylinder | ||||||

| Cylinder model | Specifications | Working pressure | Maximum withstand pressure | Trip | Installation distance | Weight |

| CMNYY11112018 | Φ280XΦ160X2200 | 31.5MPa | 40MPa | 2200 | 3000 | 1003kg |

| Product Name: | Lift Hydraulic Cylinder |

| Function: | Control the movement of the main arm. |

| Cylinder diameter: | 280mm-400mm |

| Rod diameter: | 160mm |

| Travel: | 1800mm-3000mm |

| Maximum pressure: | 31.5MPa |

| Maximum thrust: | 3958KN |

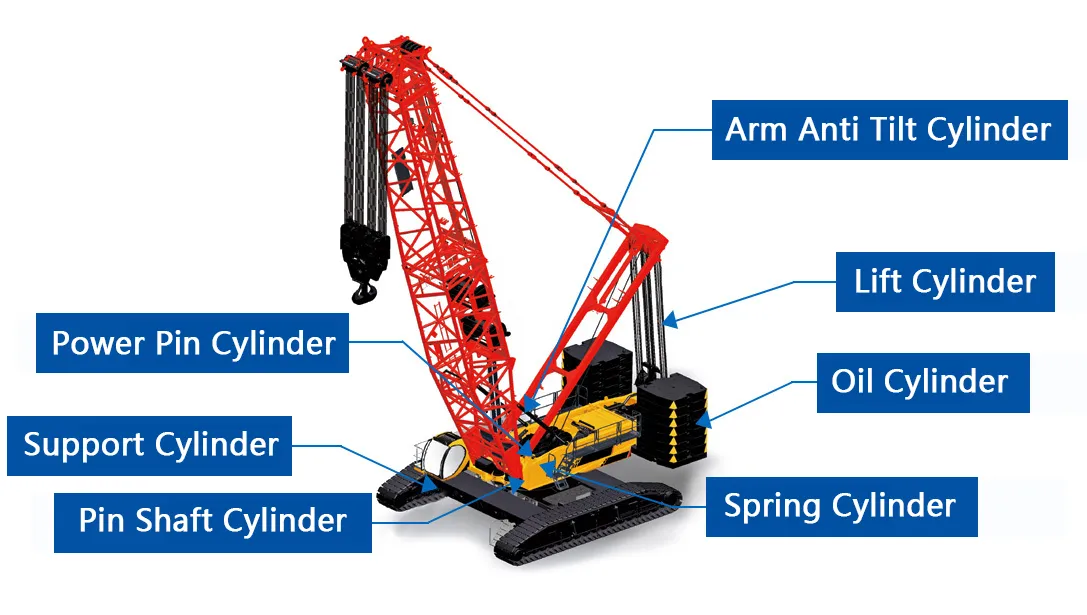

Truss Arm Crawler Crane Hydraulic Cylinder Types

- Pin Shaft Hydraulic Cylinders

Pin shaft hydraulic cylinders are designed to provide rotational motion at pivot points in a truss arm crawler crane. These cylinders facilitate smooth articulation of the crane’s arm by enabling controlled movement around fixed pin shafts. They are built to handle high stress loads and are critical in maintaining the crane's structural stability during operation. - Spring Hydraulic Cylinders

Spring hydraulic cylinders incorporate spring mechanisms within their design to assist in load balancing and shock absorption. They are primarily used to counterbalance the effects of sudden load changes and prevent damage to the crane. These cylinders work in tandem with hydraulic pressure to ensure smooth motion control. - Power Pin Hydraulic Cylinders

Power pin hydraulic cylinders are specialized for managing the crane’s locking and positioning functions. These cylinders generate substantial force to secure the crane’s components, such as the truss arm, in place during operation. Their robust design ensures stability and precision, even under heavy loads. - Arm Anti-Tilt Hydraulic Cylinders

Arm anti-tilt hydraulic cylinders are designed to counteract tilting forces that may destabilize the truss arm. By providing lateral support and maintaining alignment, these cylinders prevent excessive arm sway or imbalance. They are particularly crucial during heavy lifting operations, as they ensure the arm remains stable and aligned with the load. - Support Hydraulic Cylinders

Support hydraulic cylinders play a foundational role in stabilizing the truss arm crawler crane during lifting and positioning tasks. These cylinders provide additional vertical or horizontal support to ensure the crane remains steady under heavy loads. They are engineered to bear immense pressure and distribute forces evenly across the crane’s structure. - Lift Hydraulic Cylinders

Lift hydraulic cylinders are crucial for raising and lowering the crane’s truss arm with precision and control. These cylinders convert hydraulic energy into mechanical force, enabling smooth vertical movement. They are designed to handle the immense loads associated with construction materials and equipment. Lift hydraulic cylinders are built to endure extreme stress, ensuring consistent performance and reliability.

Truss Arm Crawler Crane Hydraulic Lift Cylinder Features

- High Load-Bearing Capacity

Truss arm crawler crane hydraulic lift cylinders are engineered to handle extremely heavy loads, ensuring reliable performance during challenging lifting operations. Their robust construction allows them to withstand immense pressure without compromising efficiency or safety. This high load-bearing capacity is essential for moving large construction materials and equipment, ensuring operational stability under demanding conditions. - Precision Movement Control

These lift hydraulic cylinders provide smooth and precise vertical movement of the crane’s truss arm. Their ability to deliver controlled lifting and lowering ensures accuracy in positioning loads, which is critical for construction tasks. This feature minimizes the risk of misalignment or damage to materials, improving overall operational efficiency and precision. - Durable and Corrosion-Resistant Design

Hydraulic cylinders are designed with durable materials, such as high-grade steel, to resist wear and tear. They are often coated with anti-corrosion layers, making them suitable for harsh environments like construction sites. This durability ensures a longer service life and reduces maintenance requirements, even under continuous heavy-duty usage. - Efficient Hydraulic Energy Conversion

The hydraulic lift cylinders are designed to efficiently convert hydraulic energy into mechanical force. This ensures maximum output with minimal energy loss, making the crane more energy-efficient and cost-effective. The efficiency also reduces strain on the hydraulic system, which helps prolong the lifespan of the equipment. - Adaptability to Diverse Applications

These hydraulic lift cylinders are versatile and can be customized to suit various truss arm crawler crane configurations. Whether for construction, industrial, or engineering purposes, they can be adjusted to meet specific operational demands. This adaptability ensures that the hydraulic lift cylinders can perform effectively in different environments and for a wide range of tasks.

Truss Arm Crawler Crane Hydraulic Cylinder Applications

- Construction and Infrastructure Projects

Hydraulic cylinders in truss arm crawler cranes are extensively used in construction projects for lifting and positioning heavy materials such as steel beams, concrete slabs, and prefabricated structures. Their precision and reliability ensure safe handling of materials, even in complex projects like bridges, high-rise buildings, and tunnels. - Mining and Excavation Operations

These hydraulic cylinders are vital in mining and excavation, where they help lift, position, and transport heavy loads like mining equipment or extracted materials. Their durability and ability to operate in harsh, rugged environments make them indispensable for underground and surface mining tasks. - Shipbuilding and Marine Construction

Truss arm crawler crane hydraulic cylinders are widely used in shipyards for lifting large ship components such as hull sections, engines, and propellers. Their corrosion-resistant properties make them ideal for marine environments, where exposure to saltwater and humidity is common. - Energy and Power Generation Industry

Hydraulic cylinders play a crucial role in energy projects, such as lifting wind turbine components, assembling power plant equipment, or managing heavy loads in hydroelectric dams. Their ability to handle precise, high-capacity lifting ensures smooth operations in these critical infrastructure projects. - Industrial Manufacturing and Assembly

In manufacturing plants, hydraulic cylinders are utilized to lift and position large machinery or assemble heavy industrial components. Their precision and strength make them critical for industries like automotive, aerospace, and heavy equipment production, where accuracy is vital. - Oil and Gas Exploration

Truss arm crawler crane hydraulic cylinders are essential in the oil and gas industry for handling heavy drilling equipment, pipelines, and storage tanks. Their robust design ensures they can withstand extreme pressures and temperatures, making them suitable for both onshore and offshore applications.

Additional information

| Edited by | Yjx |

|---|