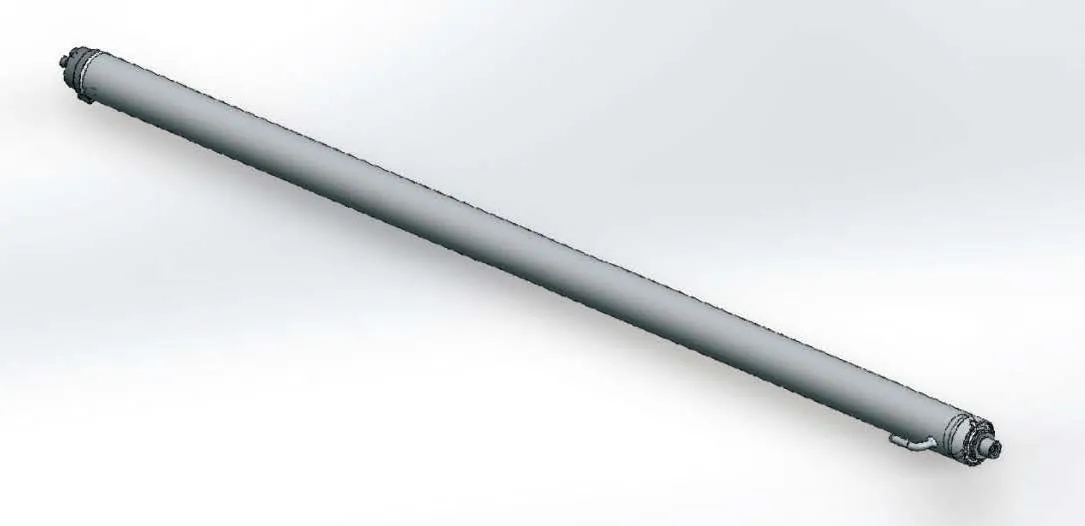

Lift Hydraulic Cylinder for Small Tonnage Forklift

A lift hydraulic cylinder for a small tonnage forklift, typically designed for loads up to 1–3 tons, is a critical component of the forklift’s hydraulic system responsible for raising and lowering the mast and forks. This single-acting cylinder converts pressurized hydraulic fluid into linear force, driving the piston to extend and lift the load. Constructed from high-grade steel, it features a seamless barrel, a piston rod, and seals to withstand high pressures and prevent leaks.

A lift hydraulic cylinder for a small tonnage forklift, typically designed for loads up to 1–3 tons, is a critical component of the forklift’s hydraulic system responsible for raising and lowering the mast and forks. This single-acting cylinder converts pressurized hydraulic fluid into linear force, driving the piston to extend and lift the load. Constructed from high-grade steel, it features a seamless barrel, a piston rod, and seals to withstand high pressures and prevent leaks.

The forklift lift cylinder’s compact design suits smaller forklifts, ensuring efficient operation in tight spaces. Its bore size and stroke length are tailored to the forklift’s lifting capacity and height requirements, providing reliable, controlled vertical movement essential for safe material handling. Regular maintenance, including seal inspections, ensures longevity and performance.

Forklift Lift Hydraulic Cylinder Dimensions

|

|

|

|

| Forklift Lifting Cylinder | ||||||

| Cylinder model | Specifications | Working pressure | Maximum withstand pressure | Trip | Installation distance | Weight |

| CMN11112000 | Φ56xΦ45x 1500 | 18.1MPa | 27.15MPa | 1500 | 1658 | 33kg |

| Product Name: | Lift Hydraulic Cylinder |

| Function: | To achieve the lifting and lowering action of the gantry. |

| Cylinder diameter: | 40mm-60mm |

| Rod diameter: | 30mm-45mm |

| Travel: | 100mm-2600mm |

| Maximum pressure: | 18.1MPa |

| Maximum thrust: | 51KN |

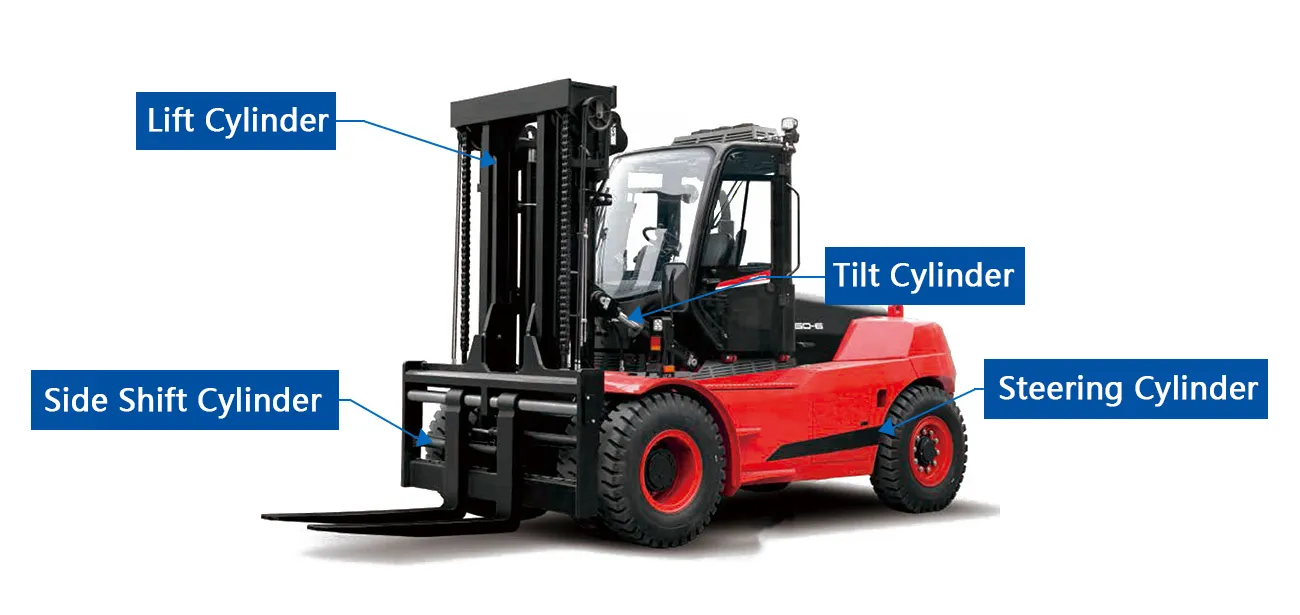

Small Tonnage Forklift Hydraulic Cylinder Types

- Lift Hydraulic Cylinders

Lift hydraulic cylinders are responsible for raising and lowering the forklift’s mast, enabling it to lift loads to various heights. These cylinders provide precise vertical movement by converting hydraulic pressure into mechanical lifting force, ensuring stability and safety during load handling. - Tilt Hydraulic Cylinders

Tilt hydraulic cylinders control the tilting motion of the forklift’s mast. They allow the operator to tilt the load forward or backward, ensuring proper positioning for stacking or unloading. This function is essential for maintaining the balance of the forklift during operation. - Steering Hydraulic Cylinders

Steering hydraulic cylinders enable smooth and precise maneuvering of the forklift. By translating hydraulic pressure into controlled steering motion, these cylinders provide the operator with improved control, especially in tight spaces or during intricate material handling tasks. - Side Shift Hydraulic Cylinders

Side shift hydraulic cylinders allow the forklift’s carriage to move laterally along the mast. This feature enables precise alignment of the load without repositioning the entire forklift, enhancing efficiency and reducing time spent on minor directional adjustments.

Benefits of Lift Hydraulic Cylinder for Small Tonnage Forklift

- Enhanced Lifting Precision: The lift hydraulic cylinder provides precise control over the forklift’s mast movement, allowing operators to position loads accurately. This precision is crucial in confined spaces, reducing the risk of damage to goods or surroundings during material handling tasks.

- Compact Design Efficiency: Designed specifically for small tonnage forklifts, the cylinder’s compact size ensures compatibility with smaller chassis. This allows for efficient operation in tight warehouses or retail environments, maximizing maneuverability without compromising lifting capacity or stability.

- High Load Capacity: Despite its compact nature, the forklift hydraulic lift cylinder delivers robust lifting power for loads up to 1–3 tons. Its high-grade steel construction and optimized hydraulic pressure ensure reliable performance, enabling small forklifts to handle substantial weights effectively.

- Durability and Longevity: Built with materials like seamless steel and durable seals, the forklift hydraulic cylinder withstands high pressures and harsh conditions. Regular maintenance, such as seal replacements, extends its lifespan, reducing downtime and repair costs for small-scale operations.

- Energy Efficiency: The single-acting hydraulic cylinder minimizes energy consumption by using hydraulic fluid only during the lifting phase. This efficiency reduces operational costs and supports eco-friendly practices, making it ideal for businesses with frequent, low-tonnage lifting needs.

- Safety and Stability: The cylinder’s precise engineering ensures smooth, controlled lifting and lowering, minimizing sudden movements. This stability enhances operator safety and protects loads, making it suitable for delicate or high-value goods in small-scale material handling tasks.

Forklift Hydraulic Lift Cylinder Applications

- Warehouse Material Handling

Hydraulic lift cylinders are extensively used in warehouses to lift and stack pallets, boxes, and other goods. They allow forklifts to operate efficiently in storage areas, ensuring quick and precise movement of materials to optimize inventory management. - Construction Sites

In construction, lift cylinders enable forklifts to carry and position heavy building materials like bricks, cement bags, or steel beams. Their ability to handle heavy loads with precision makes them essential for safe and efficient construction operations. - Logistics and Distribution Centers

Forklift hydraulic lift cylinders play a crucial role in logistics and distribution centers by enabling forklifts to load and unload goods from trucks or trailers. They ensure faster material turnover, streamlining supply chain processes and reducing downtime. - Manufacturing Facilities

In manufacturing plants, lift hydraulic cylinders help forklifts transport raw materials and finished products between production lines and storage areas. Their precise lifting capabilities enhance productivity and ensure materials are handled carefully to prevent damage. - Port and Dock Operations

Forklift hydraulic lift cylinders are widely used in ports and docks for loading and unloading goods from ships or containers. They enable forklifts to handle heavy loads efficiently in these high-demand environments, improving turnaround times and operational efficiency.

Additional information

| Edited by | Yjx |

|---|