Lift Hydraulic Cylinder for Large Tonnage Forklift

A lift hydraulic cylinder for a large tonnage forklift is a critical component in the forklift’s hydraulic system, designed to raise and lower heavy loads by manipulating the mast. These hydraulic lift cylinders, typically single-acting or telescopic, convert pressurized hydraulic fluid into linear force, enabling the forklift to lift capacities often exceeding 10 tons. Constructed from high-grade steel to withstand intense pressures, they feature a piston and rod assembly sealed to prevent fluid leaks.

A lift hydraulic cylinder for a large tonnage forklift is a critical component in the forklift’s hydraulic system, designed to raise and lower heavy loads by manipulating the mast. These hydraulic lift cylinders, typically single-acting or telescopic, convert pressurized hydraulic fluid into linear force, enabling the forklift to lift capacities often exceeding 10 tons. Constructed from high-grade steel to withstand intense pressures, they feature a piston and rod assembly sealed to prevent fluid leaks. The forklift lift cylinder’s bore diameter and stroke length are engineered to match the forklift’s load capacity and lift height, ensuring stability and precision.

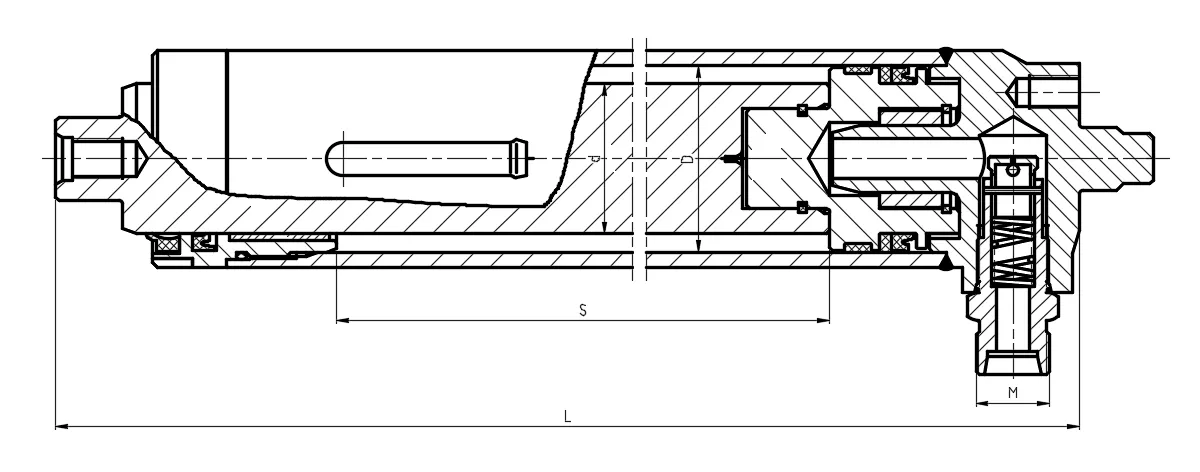

Forklift Lift Hydraulic Cylinder Dimensions

| drawing number | bore diameter (D) | rod diameter (d) | stroke (S) | Installation distance (L) | working pressure | Interface dimensions (M) | weight |

| N30M300-5/400000-000 | Φ56 | Φ45 | 1500 | 1658 | 18.1MPa | G1/2 | 32.6kg |

| A2A30M300-400000-000 | Φ56 | Φ45 | 1500 | 1658 | 18.1MPa | M22*1.5 | 36kg |

| 3.5N4.5H-400000-003 | Φ60 | Φ45 | 1505 | 1780 | 17.5MPa | M22*1.5 | 41kg |

| N35M300-5/400000-001A | Φ60 | Φ45 | 1500 | 1808 | 18.1MPa | G1/2 | 46kg |

| A2A35M300-400000-000 | Φ60 | Φ45 | 1500 | 1808 | 18.1MPa | M22*1.5 | 50kg |

| Product Name: | Lift Hydraulic Cylinder |

| Function: | To achieve the lifting and lowering action of the gantry. |

| Cylinder diameter: | 65mm-190mm |

| Rod diameter: | 50mm-160mm |

| Travel: | 100mm-3490mm |

| Maximum pressure: | 21MPa |

| Maximum thrust: | 596KN |

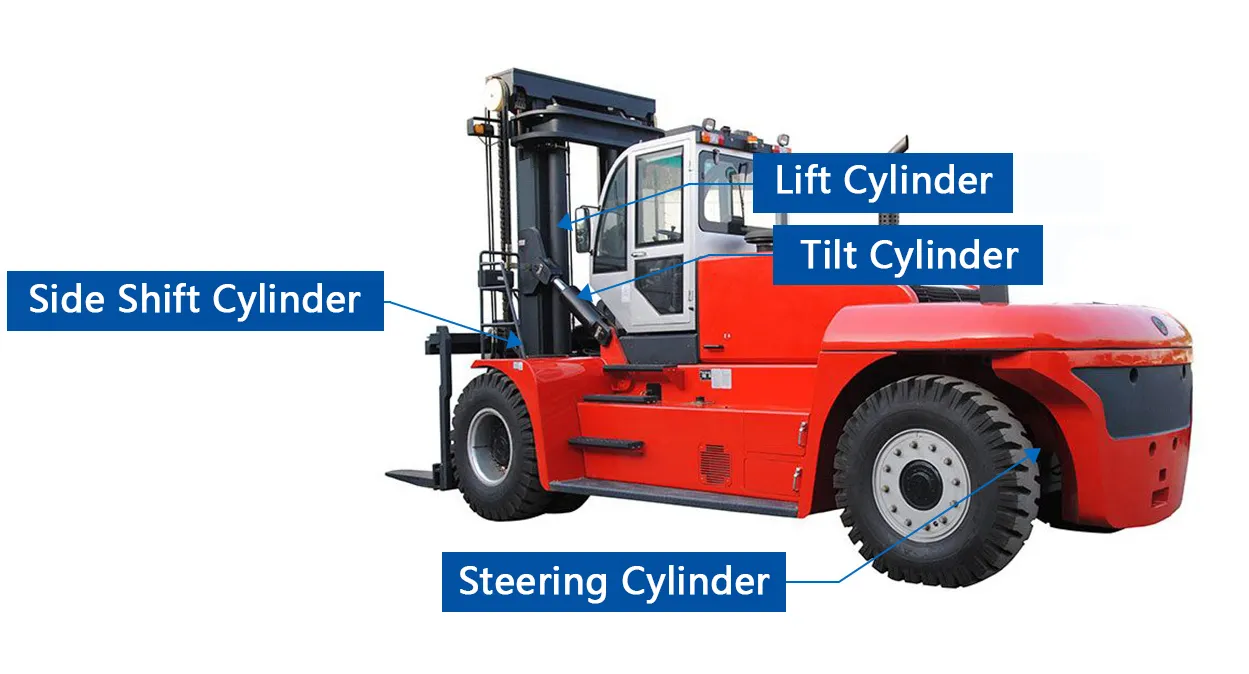

Large Tonnage Forklift Hydraulic Cylinder Types

- Hydraulic Tilt Cylinders

These hydraulic tilt cylinders control the tilting motion of the forklift mast, enabling operators to adjust the angle of the load for stability and precision. They are designed to handle heavy loads while maintaining smooth and reliable operation, even under extreme working conditions. - Hydraulic Lift Cylinders

Responsible for the vertical lifting and lowering of the forklift's mast, these hydraulic lift cylinders translate hydraulic pressure into mechanical force. They are built with high-strength materials to ensure durability and consistent performance when raising heavy loads to various heights. - Hydraulic Steering Cylinders

These hydraulic steering cylinders facilitate the precise maneuvering and steering of large tonnage forklifts, offering smooth directional control. They are engineered for accuracy and designed to withstand continuous use in demanding industrial environments. - Hydraulic Side Shift Cylinders

These hydraulic side shift cylinders enable the lateral movement of the forklift carriage, allowing operators to shift loads side-to-side without repositioning the entire forklift. This enhances efficiency and precision in tight spaces or during load alignment.

Large Forklift Hydraulic Lift Cylinder Benefits

- High Load Capacity

These forklift hydraulic lift cylinders are designed to handle extreme weights, often exceeding 10 tons, allowing large forklifts to lift heavy materials like steel coils or containers with ease, ensuring operational efficiency in demanding industrial settings. - Precision and Control

Hydraulic lift cylinders provide smooth, controlled lifting and lowering, enabling precise positioning of loads. This accuracy minimizes the risk of damage to goods or equipment, enhancing safety and productivity during operations. - Durability and Longevity

Constructed from high-grade steel with robust seals, these forklift hydraulic cylinders withstand intense pressures and harsh environments. Their durable design reduces wear and tear, extending service life and minimizing costly downtime for repairs. - Energy Efficiency

Hydraulic systems efficiently convert fluid power into mechanical force, requiring less energy compared to mechanical alternatives. This efficiency reduces operational costs and supports sustainable practices in high-tonnage material handling tasks. - Versatility in Applications

These hydraulic cylinder forklift support a wide range of lifting heights and configurations, accommodating diverse tasks in warehouses, ports, or construction sites. Their adaptability ensures forklifts meet varying operational demands with consistent performance. - Enhanced Safety Features

Equipped with overload protection and stable lifting mechanisms, hydraulic lift cylinders prevent accidents like load drops or mast drift. This reliability safeguards operators and nearby workers, fostering a secure working environment.

Choose the Right Lift Hydraulic Cylinder for Forklifts

- Assess Load Capacity Requirements

Determine the maximum weight the forklift will lift, typically ranging from 5 to over 50 tons for large forklifts. Select a lifting hydraulic cylinder with a bore size and pressure rating that supports the required tonnage to ensure safe and efficient operation. - Evaluate Lift Height Needs

Consider the maximum lift height needed for your operations, such as stacking pallets or loading containers. Choose a lift hydraulic cylinder with an appropriate stroke length, often telescopic for extended heights, to meet specific application demands. - Check Compatibility with Forklift Design

Ensure the hydraulic lift cylinder matches the forklift’s mast and mounting specifications. Verify dimensions, attachment points, and hydraulic system compatibility to avoid installation issues and maintain optimal performance in material handling tasks. - Prioritize Material and Build Quality

Opt for forklift hydraulic lift cylinders made from high-grade steel with durable seals to withstand high pressures and harsh environments. Quality construction reduces maintenance needs and extends service life, ensuring reliability in heavy-duty applications. - Consider Operating Environment

Assess conditions like temperature, dust, or moisture in the work area. Choose hydraulic lifting cylinders with protective coatings or seals designed for extreme environments to prevent corrosion and ensure consistent performance under challenging conditions.

Additional information

| Edited by | Yjx |

|---|