Lift Hydraulic Cylinder for Forward Moving Forklift

A lift hydraulic cylinder for a forward-moving forklift is a critical component of the forklift’s hydraulic system, responsible for the vertical movement of the mast and forks to lift and lower loads. It is typically a single-acting hydraulic cylinder, meaning it applies force in one direction—upward—using pressurized hydraulic fluid to push a piston, which raises the mast and forks. The hydraulic lift cylinder consists of a barrel, a piston, and a rod, with seals to prevent fluid leaks.

A lift hydraulic cylinder for a forward-moving forklift is a critical component of the forklift’s hydraulic system, responsible for the vertical movement of the mast and forks to lift and lower loads. It is typically a single-acting hydraulic cylinder, meaning it applies force in one direction—upward—using pressurized hydraulic fluid to push a piston, which raises the mast and forks. The hydraulic lift cylinder consists of a barrel, a piston, and a rod, with seals to prevent fluid leaks. When the operator activates the lift controls, a hydraulic pump forces fluid into the cylinder, moving the piston and lifting the load. The forks lower by gravity when fluid pressure is released through a control valve. These cylinders are designed to handle heavy loads and high pressures, ensuring reliable and safe operation in material handling tasks.

Forward Moving Forklift Lift Hydraulic Cylinder Dimensions

| drawing number | bore diameter (D) | rod diameter (d) | stroke (S) | Installation distance (L) | working pressure | Interface dimensions (M) | weight |

| N30M300-5/400000-000 | Φ56 | Φ45 | 1500 | 1658 | 18.1MPa | G1/2 | 32.6kg |

| A2A30M300-400000-000 | Φ56 | Φ45 | 1500 | 1658 | 18.1MPa | M22*1.5 | 36kg |

| 3.5N4.5H-400000-003 | Φ60 | Φ45 | 1505 | 1780 | 17.5MPa | M22*1.5 | 41kg |

| N35M300-5/400000-001A | Φ60 | Φ45 | 1500 | 1808 | 18.1MPa | G1/2 | 46kg |

| A2A35M300-400000-000 | Φ60 | Φ45 | 1500 | 1808 | 18.1MPa | M22*1.5 | 50kg |

| Product Name: | Lift Hydraulic Cylinder |

| Function: | To achieve the lifting and lowering action of the gantry. |

| Cylinder diameter: | 45mm-75mm |

| Rod diameter: | 45mm-65mm |

| Travel: | 500mm-3980mm |

| Maximum pressure: | 21MPa |

| Maximum thrust: | 93KN |

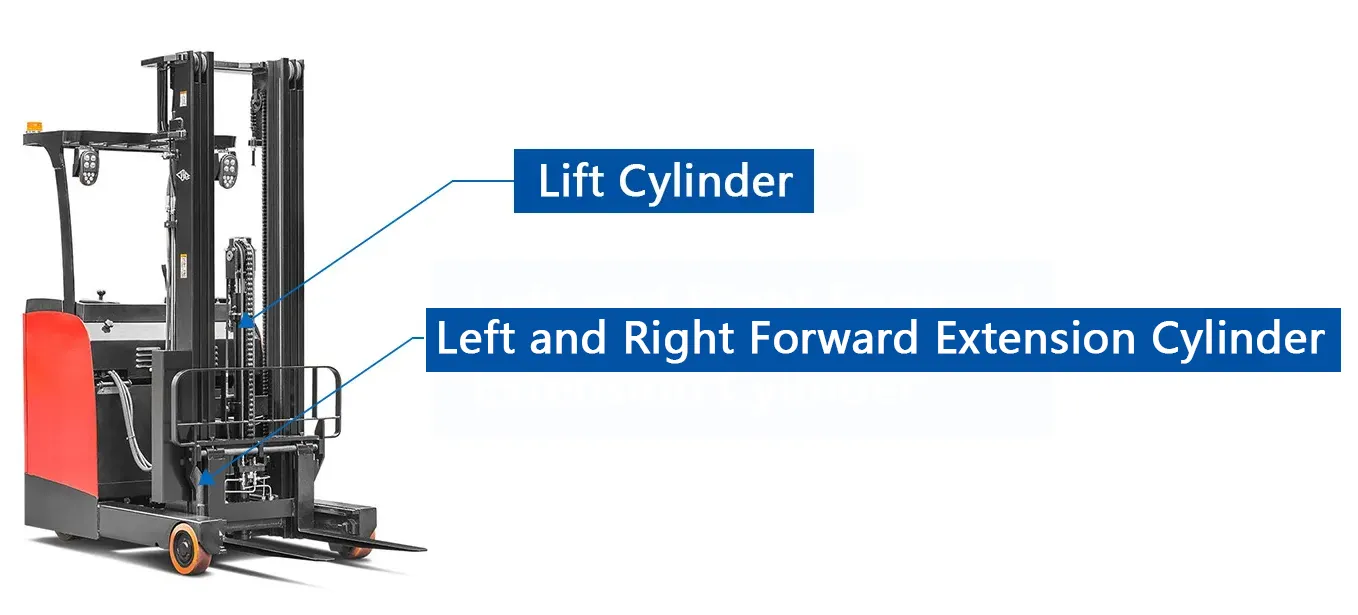

Forward Moving Forklift Hydraulic Cylinder Types

Lift Hydraulic Cylinder

- This cylinder powers the vertical movement of the forklift’s mast and forks. Hydraulic fluid under pressure drives the piston upward to lift heavy loads. The single-acting design relies on gravity for lowering, ensuring precise control and safety in material handling.

- Constructed with a robust barrel, piston, and seals, it withstands high pressures and heavy loads. Regular maintenance, including fluid checks and seal inspections, ensures durability and prevents leaks, maintaining reliable operation in demanding environments.

Left and Right Forward Extension Hydraulic Cylinders

- These cylinders control the forward and backward movement of the forklift’s mast or carriage. They extend and retract to position loads accurately, enabling precise placement in tight spaces or during stacking operations.

- Typically double-acting, they use hydraulic fluid to move the piston in both directions. Their sturdy design handles lateral forces, and synchronized operation ensures balanced movement, enhancing stability and efficiency during load handling tasks.

Forward Moving Forklift Hydraulic Lift Cylinder Features

- High Load Capacity

The lift hydraulic cylinder is engineered to handle substantial weight, enabling the forklift to lift heavy loads efficiently. Its robust construction ensures it can support the maximum rated capacity of the forklift, providing reliable performance in demanding warehouse or industrial environments. - Single-Acting Mechanism

This lift cylinder operates using a single-acting design, where hydraulic fluid drives the piston upward to raise the mast and forks. The lowering process relies on gravity, controlled by a valve, ensuring smooth, energy-efficient operation with precise load positioning. - Durable Construction

Built with high-strength steel and precision-machined components, the forklift hydraulic cylinder withstands intense pressure and harsh conditions. Protective coatings resist corrosion, extending their lifespan and maintaining functionality in environments exposed to moisture, dust, or extreme temperatures. - Leak-Proof Seals

Equipped with high-quality seals, the hydraulic lift cylinder prevents hydraulic fluid leaks, maintaining consistent pressure and performance. These seals are designed to endure repeated cycles and high pressures, reducing maintenance needs and ensuring safe operation during load handling. - Smooth Operation

The cylinder’s polished piston rod and honed barrel minimize friction, ensuring smooth and controlled lifting and lowering. This enhances operator precision, reduces wear on components, and improves the overall efficiency of material handling tasks in fast-paced settings. - Easy Maintenance

Designed for accessibility, the lifting hydraulic cylinder allows straightforward inspection and maintenance. Features like replaceable seals and accessible fluid ports simplify upkeep, minimizing downtime. Regular checks of fluid levels and seals ensure long-term reliability and optimal performance in daily operations.

Forklift Lift Hydraulic Cylinder Applications

- Warehouse Stacking

Lift hydraulic cylinders enable forklifts to stack pallets vertically in warehouses. They provide precise control for raising and lowering loads, maximizing storage space by safely placing goods on high racks in organized, high-density storage systems. - Loading and Unloading Trucks

These hydraulic lift cylinders facilitate the efficient loading and unloading of goods from trucks. By lifting heavy pallets to the required height, they ensure smooth transfer of materials, reducing manual labor and speeding up logistics operations in distribution centers. - Manufacturing Material Handling

In manufacturing plants, lift hydraulic cylinders move raw materials and finished products between workstations. Their robust design handles heavy loads, supporting assembly lines by ensuring timely and safe transport of components in fast-paced production environments. - Construction Site Operations

On construction sites, these hydraulic lifting cylinders lift heavy materials like bricks or steel beams to elevated platforms. Their durability ensures reliable performance in rugged conditions, aiding in the safe and efficient movement of supplies for building projects. - Cold Storage Facilities

Lifting hydraulic cylinders operate in cold storage environments, handling frozen or perishable goods. Their seals and materials withstand low temperatures, ensuring consistent lifting performance for stacking and retrieving items in refrigerated or freezer warehouses.

|

|

Additional information

| Edited by | Yjx |

|---|