Leveling Hydraulic Cylinder for Arm Type Aerial Work Platform

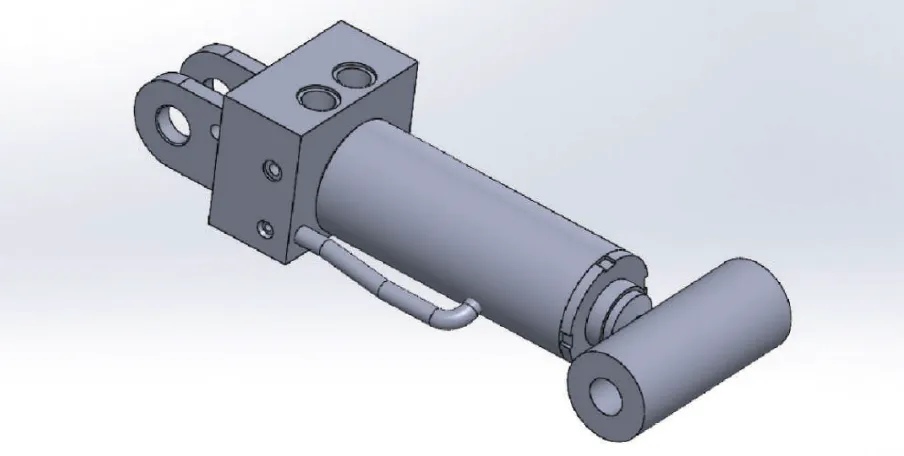

A leveling hydraulic cylinder for an arm-type aerial work platform is a critical component designed to maintain the stability and levelness of the work platform, ensuring operator safety during elevated operations. Typically mounted at the platform’s base or chassis, it adjusts the platform’s position to remain horizontal, even on uneven terrain or during boom movements. The hydraulic leveling cylinder operates using pressurized hydraulic fluid, which drives a piston and rod to extend or retract, compensating for tilting caused by the movement of the platform’s articulated or telescopic arms.

A leveling hydraulic cylinder for an arm-type aerial work platform is a critical component designed to maintain the stability and levelness of the work platform, ensuring operator safety during elevated operations. Typically mounted at the platform’s base or chassis, it adjusts the platform’s position to remain horizontal, even on uneven terrain or during boom movements. The hydraulic leveling cylinder operates using pressurized hydraulic fluid, which drives a piston and rod to extend or retract, compensating for tilting caused by the movement of the platform’s articulated or telescopic arms.

Equipped with control valves, such as counterbalance or pilot-controlled check valves, it ensures precise leveling and stability. These cylinders are vital for industries like construction, maintenance, and utilities, providing a safe, stable working environment at height. Regular maintenance, including fluid checks and seal inspections, is essential for optimal performance and durability.

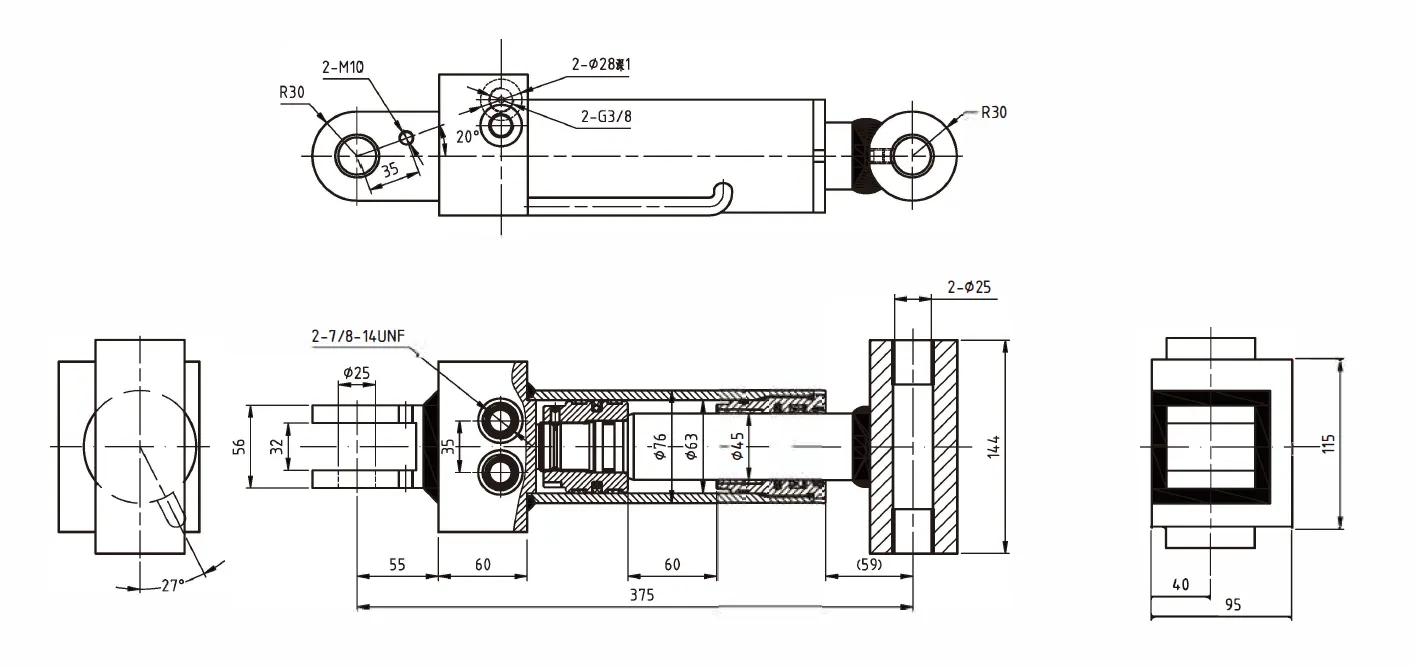

Leveling Hydraulic Cylinder Dimensions

|

|

|

|

| Leveling Hydraulic Cylinder | ||||||

| Cylinder model | Specifications | Working pressure | Maximum withstand pressure | Trip | Installation distance | Weight |

| CMNYY11112008 | Φ63 X Φ45 X 60 | 25MPa | 30MPa | 60 | 375 | 16kg |

| Product Name: | Leveling Hydraulic Cylinder |

| Function: | To achieve horizontal movement of the work platform. |

| Cylinder diameter: | 80mm-135mm |

| Rod diameter: | 40mm-90mm |

| Travel: | 300mm-600mm |

| Maximum pressure: | 24MPa |

| Maximum thrust: | 343KN |

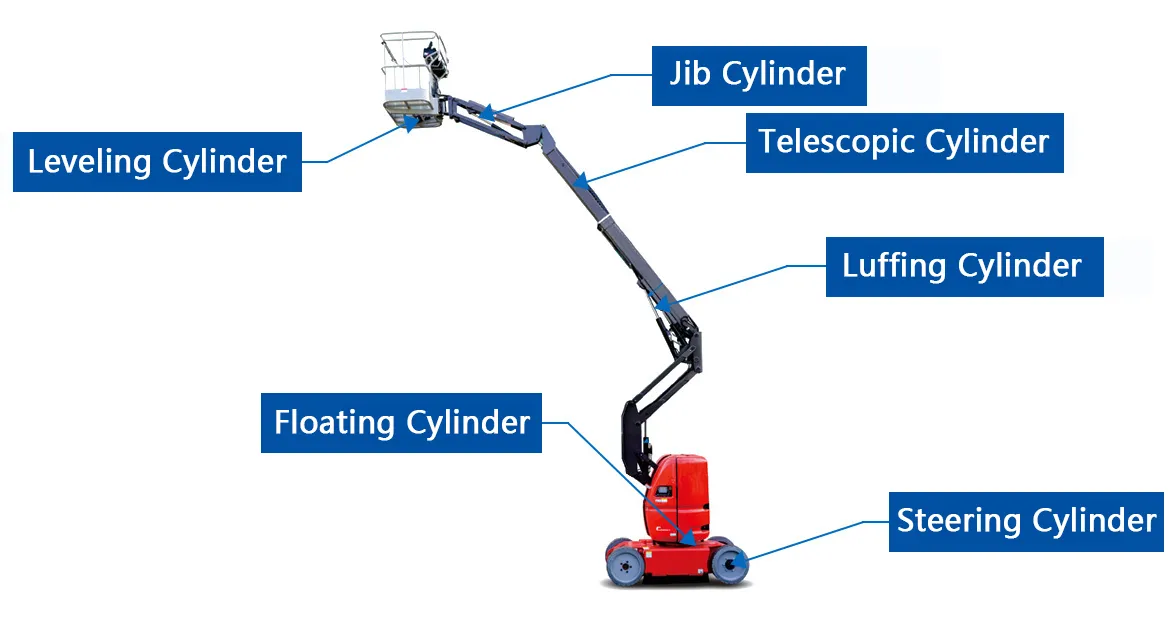

Arm Type Aerial Work Platform Hydraulic Cylinder Types

- Hydraulic Floating Cylinders

Hydraulic floating cylinders allow the platform to adapt to uneven terrain by enabling controlled movement of the chassis or outriggers. They absorb shocks and maintain stability, ensuring safe operation during dynamic positioning on rough surfaces. Their design includes robust seals and fluid systems to handle variable loads effectively. - Hydraulic Luffing Cylinders

Hydraulic luffing cylinders control the vertical movement of the platform’s boom or arm. They facilitate smooth raising and lowering, providing precise angle adjustments. These cylinders are critical for positioning the platform accurately at various heights, ensuring operator safety and operational efficiency. - Hydraulic Telescopic Cylinders

Hydraulic telescopic cylinders extend and retract the boom sections, enabling the platform to reach greater heights or distances. Their multi-stage design allows compact storage and extended reach, making them essential for accessing elevated or hard-to-reach work areas safely. - Hydraulic Leveling Cylinders

Hydraulic leveling cylinders maintain the platform’s horizontal position, compensating for tilt during boom movements or on uneven ground. They use hydraulic fluid to adjust the platform’s angle, ensuring a stable and safe working environment for operators at height. - Hydraulic Jib Cylinders

Hydraulic jib cylinders control the articulated jib arm, allowing precise positioning of the platform in confined or complex spaces. They enable flexible movement, enhancing the platform’s ability to maneuver around obstacles, improving access and operational versatility. - Hydraulic Steering Cylinders

Hydraulic steering cylinders manage the directional control of the aerial work platform’s chassis or wheels. They provide smooth and responsive steering, enabling precise navigation on job sites. These cylinders ensure safe maneuverability, especially in tight or crowded work environments.

Arm Type Aerial Work Platform Hydraulic Leveling Cylinder Features

- Precision Leveling Control

Leveling hydraulic cylinders ensures the platform remains horizontal during operation. They use advanced hydraulic systems to make precise adjustments, compensating for boom movements or uneven terrain, providing a stable and safe working environment for operators. - Robust Construction

These hydraulic cylinders are built with high-strength steel to withstand heavy loads and harsh conditions. Their durable design resists corrosion and wear, ensuring long-term reliability in demanding environments like construction sites or outdoor maintenance tasks. - Integrated Control Valves

Equipped with counterbalance or pilot-controlled check valves, hydraulic leveling cylinders maintain stable positioning. These valves regulate hydraulic fluid flow, preventing unintended movements and enhancing safety by ensuring consistent platform alignment during dynamic operations. - High-Pressure Hydraulic System

The hydraulic leveling cylinders operate under high-pressure hydraulic fluid to deliver powerful and smooth adjustments. This system enables rapid response to tilt changes, ensuring the platform remains level even during fast boom movements or load shifts. - Compact and Lightweight Design

Designed to be compact and lightweight, these hydraulic cylinders integrate seamlessly into the platform’s structure without adding excessive weight. This enhances the machine’s mobility and efficiency while maintaining structural integrity and operational stability. - Low Maintenance Requirements

Leveling hydraulic cylinders feature sealed components and high-quality materials, reducing the need for frequent maintenance. Regular fluid checks and seal inspections ensure consistent performance, minimizing downtime and extending the cylinder’s operational lifespan in aerial work platforms.

Arm Type Aerial Work Platform Leveling Hydraulic Cylinder Installation

- Site Preparation and Safety Checks

Before installation, ensure the work area is clear and stable. Verify the aerial work platform is powered off and secured. Conduct a safety inspection to confirm all components, including the hydraulic cylinder, are free from defects or damage. - Positioning the Cylinder

Align the leveling hydraulic cylinder at the designated mounting point, typically at the platform’s base or chassis. Ensure precise alignment with the platform’s leveling mechanism to guarantee smooth operation and accurate tilt compensation during use. - Securing the Cylinder

Fasten the leveling cylinder to the mounting brackets using high-strength bolts. Tighten bolts to the manual’s torque specifications to ensure a secure fit. Verify that the cylinder is firmly attached to prevent movement during platform operation. - Hydraulic Line Connection

Connect the hydraulic lines to the hydraulic leveling cylinder’s inlet and outlet ports. Use appropriate fittings and ensure all connections are leak-proof. Bleed the system to remove air, ensuring smooth hydraulic fluid flow for optimal cylinder performance. - Electrical and Control Integration

Integrate the cylinder’s control valves with the platform’s hydraulic control system. Connect any sensors or electronic controls to the platform’s interface. Test the system to ensure accurate leveling adjustments respond to operator inputs effectively. - Testing and Calibration

After installation, test the hydraulic cylinder under controlled conditions. Raise and lower the platform to verify leveling accuracy. Calibrate the system to ensure precise horizontal alignment, adjusting hydraulic pressure or valve settings as needed for optimal performance.

Additional information

| Edited by | Yjx |

|---|