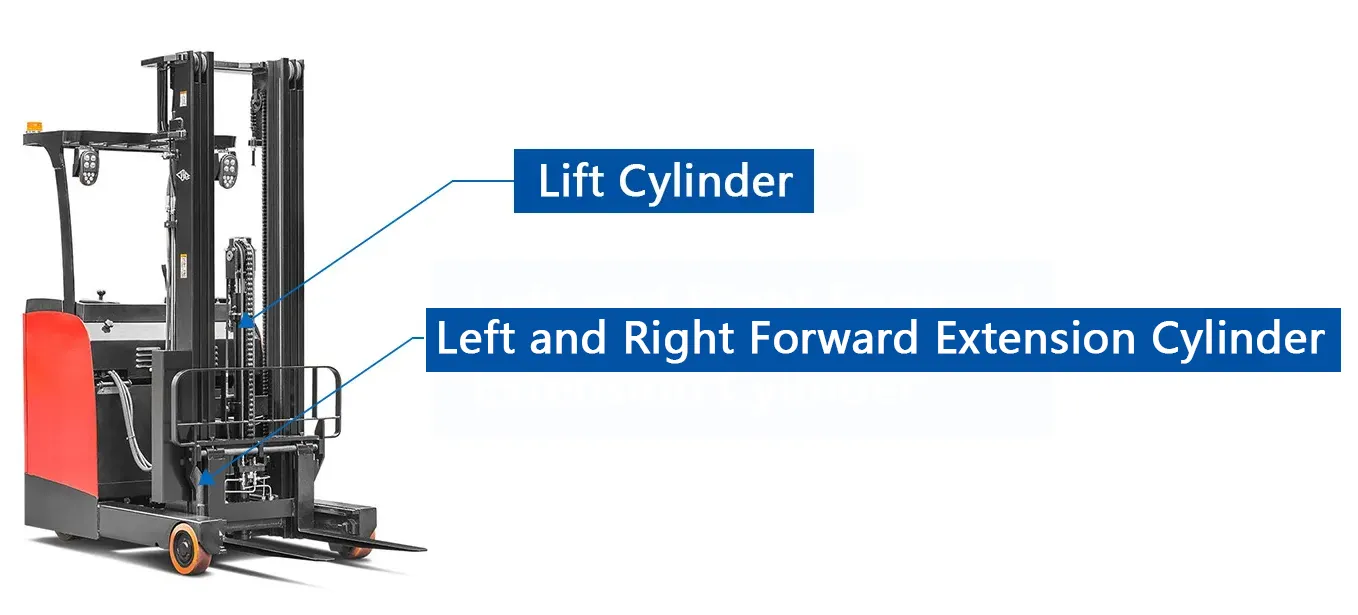

Left and Right Forward Extension Hydraulic Cylinder for Forward Moving Forklift

The left and right forward extension hydraulic cylinders in a forward-moving forklift, often associated with reach trucks, are double-acting hydraulic components that control the mast’s forward and backward extension. These forklift hydraulic cylinders enable the forklift’s carriage and forks to extend horizontally, allowing precise load placement or retrieval in tight spaces, such as narrow warehouse aisles. Mounted on either side of the mast assembly, they connect to the forklift’s frame and provide uniform force to prevent twisting during operation.

The left and right forward extension hydraulic cylinders in a forward-moving forklift, often associated with reach trucks, are double-acting hydraulic components that control the mast’s forward and backward extension. These forklift hydraulic cylinders enable the forklift’s carriage and forks to extend horizontally, allowing precise load placement or retrieval in tight spaces, such as narrow warehouse aisles. Mounted on either side of the mast assembly, they connect to the forklift’s frame and provide uniform force to prevent twisting during operation. Hydraulic fluid, pressurized by a pump, enters the cylinder, pushing the piston to extend or retract the mast. This mechanism enhances the forklift’s versatility, improving efficiency in high-stacking or deep-reach applications while maintaining stability.

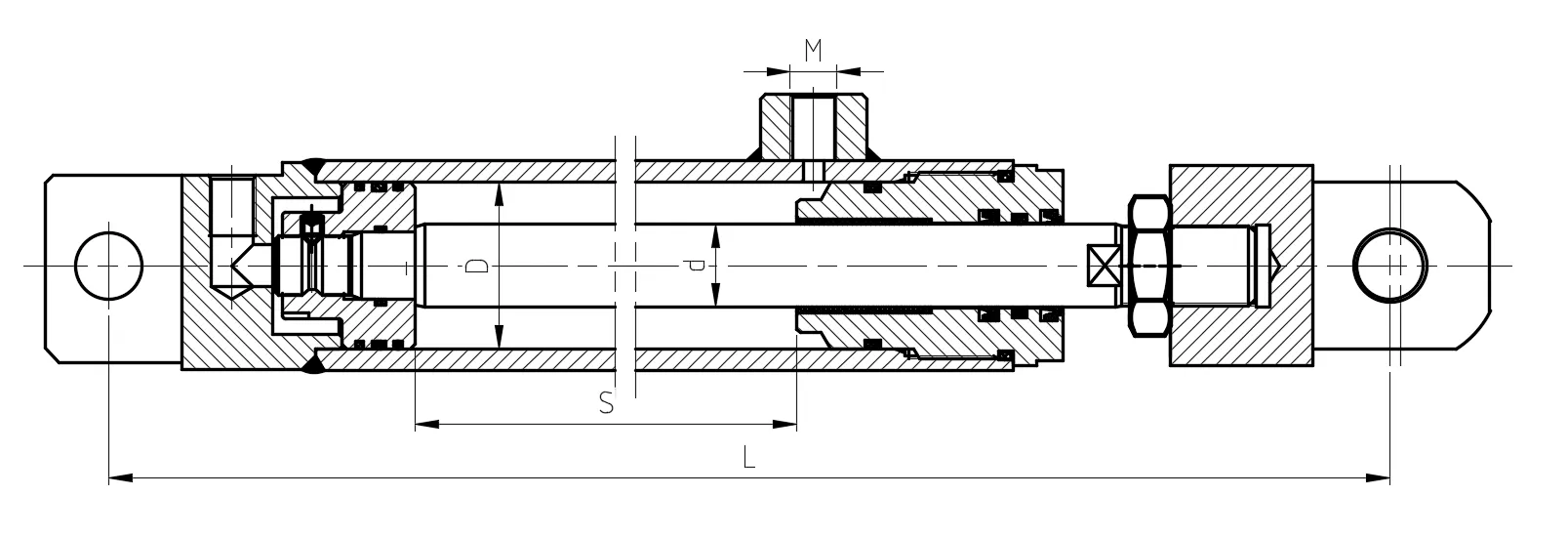

Left and Right Forward Extension Hydraulic Cylinder Dimensions

| drawing number | bore diameter (D) | rod diameter (d) | stroke (S) | Installation distance (L) | working pressure | Interface dimensions (M) | weight |

| 5CS17-40-00Z | Φ50 | Φ25 | 619 | 889 | 15MPa | M14*1.5 | 13kg |

| Product Name: | Left and Right Forward Extension Hydraulic Cylinder |

| Function: | To achieve forward and backward movement of the fork. |

| Cylinder diameter: | 50mm |

| Rod diameter: | 25mm |

| Travel: | 101mm-112mm |

| Maximum pressure: | 20MPa |

| Maximum thrust: | 39KN |

Forward Moving Forklift Hydraulic Cylinder Types

Hydraulic Lift Cylinders

-

Function and Operation: Hydraulic lift cylinders are critical for vertical movement in forward-moving forklifts. They raise and lower the mast to position loads at desired heights. Pressurized hydraulic fluid drives the piston, enabling smooth and controlled lifting, essential for stacking in warehouses.

-

Design and Maintenance: These cylinders are robust, single or multi-stage, to handle heavy loads. Regular maintenance involves checking seals for leaks and ensuring proper fluid levels. Their placement within the mast ensures stability, supporting high lifting capacities in demanding environments.

Hydraulic Left and Right Forward Extension Cylinders

-

Extension Mechanism: These double-acting cylinders enable horizontal mast extension in reach trucks. Mounted on both sides of the mast, they allow forks to extend forward for precise load placement in narrow aisles, enhancing operational flexibility.

-

Stability and Synchronization: The left and right cylinders work in tandem to ensure uniform movement, preventing mast twisting. Regular inspections for hydraulic fluid leaks and synchronized operation are vital to maintain stability and efficiency during deep-reach tasks.

Hydraulic Left and Right Forward Extension Cylinder Benefits

- Enhanced Reach Capability

Hydraulic left and right forward extension cylinders allow forklifts to reach loads located in deep shelves or tight spaces. This extended reach capability improves efficiency in warehouses and loading areas, reducing the need for manual adjustments or repositioning. - Improved Load Stability

These forklift hydraulic cylinders ensure synchronized and balanced movement of the forks when extending or retracting. This minimizes the risk of tipping or load imbalance, making the forklift safer and more reliable for handling heavy or unevenly distributed materials. - Increased Operational Efficiency

By enabling smooth and precise forward extension, these hydraulic cylinders for forklifts reduce the time required to load or unload materials. This efficiency minimizes delays in material handling operations, boosting overall productivity in demanding industrial or warehouse environments. - Reduced Operator Fatigue

The hydraulic mechanism automates forward and backward fork movements, eliminating the need for manual intervention. This reduces the physical strain on operators, allowing them to work more comfortably and efficiently during long shifts. - Versatility in Material Handling

These hydraulic cylinders enhance the forklift’s ability to handle a variety of loads by enabling flexible forward adjustments. This makes them suitable for diverse applications, such as loading trucks, accessing confined spaces, or working with irregularly shaped goods. - Durability and Reliability

Constructed with high-strength materials, hydraulic left and right forward extension cylinders are designed to withstand heavy loads and high-pressure operations. Their robust design ensures long-lasting performance, reducing maintenance needs and costs over time.

Left and Right Forward Extension Hydraulic Cylinder Troubleshooting

- Uneven Fork Extension or Retraction

If the forks extend unevenly, it may indicate a hydraulic fluid imbalance or air trapped in the forklift hydraulic cylinders. Inspect the hydraulic fluid levels and bleed the cylinders to remove air, ensuring synchronized movement for safe operation. - Fluid Leaks Around the Cylinder

Visible hydraulic fluid leaks can signify damaged seals, worn-out gaskets, or cracks in the distance adjustment cylinder body. Regularly inspect these components and replace any damaged parts immediately to prevent performance issues and maintain system pressure. - Slow or Non-Responsive Movement

If the forks extend or retract slowly, check for clogged hydraulic lines or a malfunctioning pump. Clean or replace clogged components and ensure the pump delivers sufficient pressure to restore the cylinder’s proper functionality. - Excessive Noise During Operation

Unusual noises, such as knocking or squealing, might indicate air in the hydraulic system or worn-out internal components. Bleed the system to remove trapped air and inspect for internal wear, replacing any damaged parts as needed. - Forks Failing to Extend Fully

If the forks do not reach their full extension, inspect the hydraulic fluid levels and check for bent left and right forward extension hydraulic cylinder rods or obstructions in the extension path. Address these issues promptly to restore full range of motion. - Overheating of Hydraulic Components

Excessive heat can result from overworked cylinders, low hydraulic fluid levels, or poor fluid quality. Regularly check fluid levels, use the correct hydraulic oil, and avoid overloading the forklift to prevent overheating and maintain performance.

Additional information

| Edited by | Yjx |

|---|