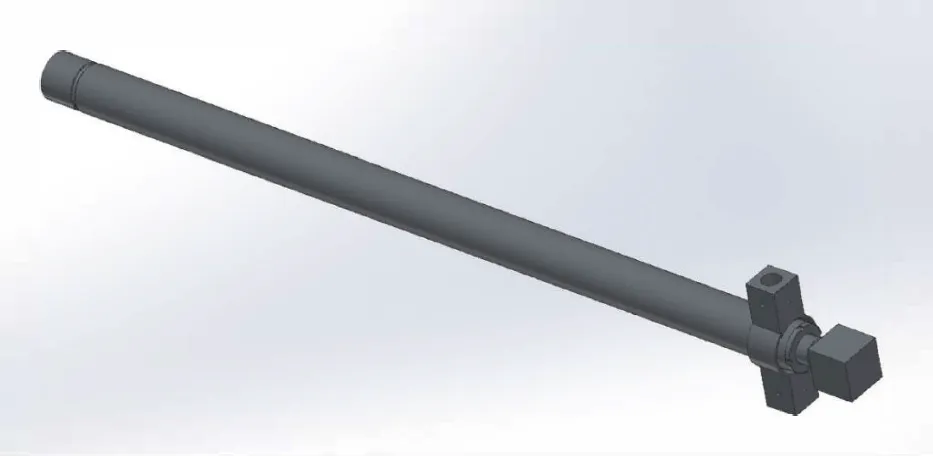

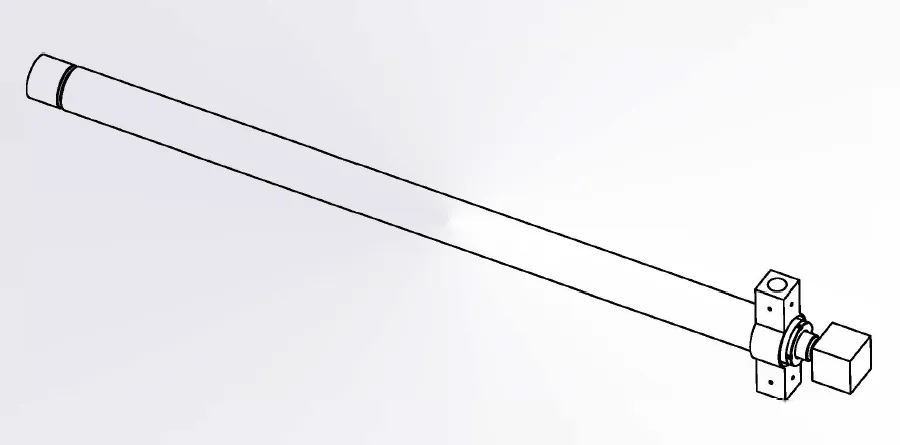

Horizontal Hydraulic Cylinder for Truck Crane

A horizontal hydraulic cylinder for a truck crane is a crucial mechanical component designed to provide linear force and motion in a horizontal direction, enabling precise and controlled movements of the crane’s mechanisms. This type of hydraulic horizontal cylinder operates by utilizing pressurized hydraulic fluid to extend and retract a piston within a cylindrical housing. In truck cranes, horizontal hydraulic cylinders are typically used for stabilizing the crane by controlling the movement of the outriggers, which extend outward to support and balance the crane during lifting operations.

A horizontal hydraulic cylinder for a truck crane is a crucial mechanical component designed to provide linear force and motion in a horizontal direction, enabling precise and controlled movements of the crane's mechanisms. This type of hydraulic horizontal cylinder operates by utilizing pressurized hydraulic fluid to extend and retract a piston within a cylindrical housing.

In truck cranes, horizontal hydraulic cylinders are typically used for stabilizing the crane by controlling the movement of the outriggers, which extend outward to support and balance the crane during lifting operations. They can also be employed to adjust the position of the crane boom or other load-bearing structures.

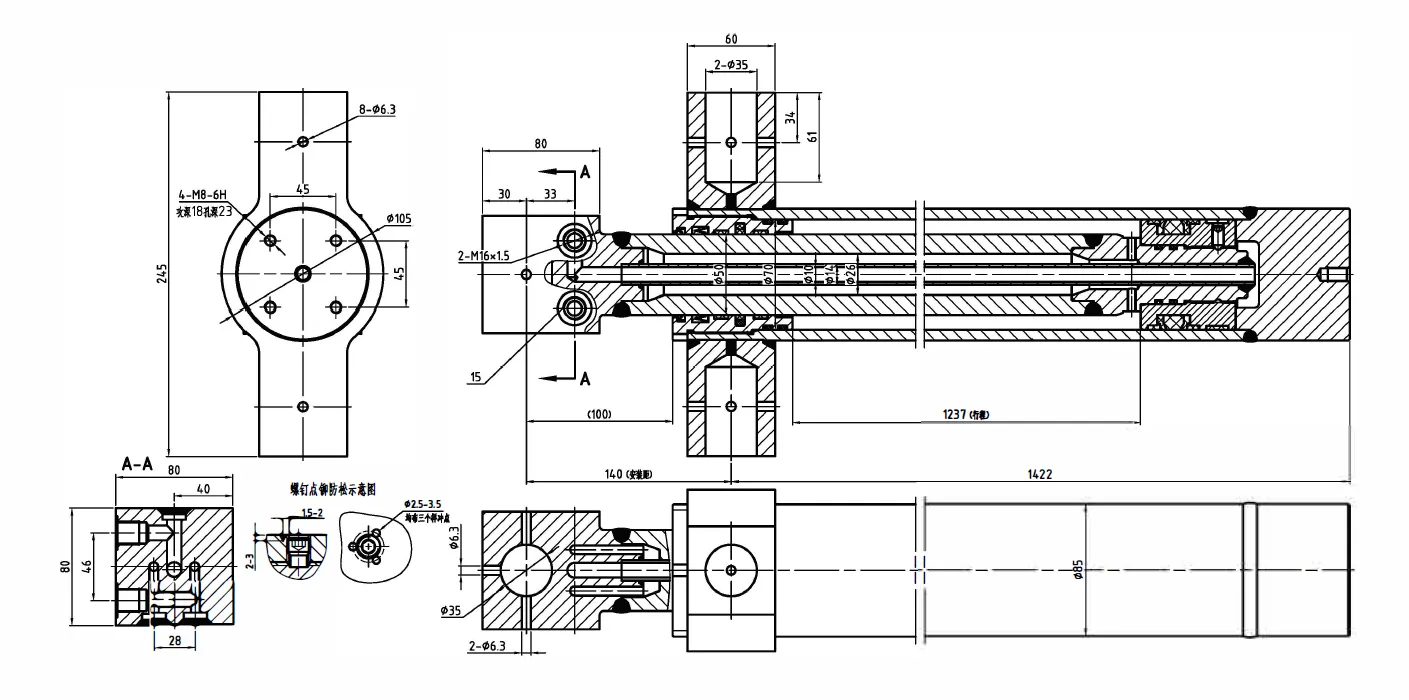

Horizontal Hydraulic Cylinder Dimensions

|

|

|

|

| Hydraulic Horizontal Cylinder | ||||||

| Cylinder model | Specifications | Working pressure | Maximum withstand pressure | Trip | Installation distance | Weight |

| CMNYY11112022 | Φ70xΦ50x1237 | 20MPa | 30MPa | 1237 | 140 | 48kg |

| Product Name: | Horizontal Hydraulic Cylinder |

| Function: | Control the movement of the main arm. |

| Cylinder diameter: | φ 63mm- φ 70mm |

| Rod diameter: | φ 45mm- φ 50mm |

| Travel: | 1200mm-2000mm |

| Maximum pressure Mpa: | 20MPa |

| Maximum thrust KN: | 77KN |

Truck Crane Hydraulic Cylinder Types

Truck Crane Hydraulic Horizontal Cylinder Benefits

- Enhanced Stability for Crane Operations

Horizontal hydraulic cylinders play a crucial role in providing stability by precisely adjusting the position of outriggers or support structures. This ensures the truck crane remains balanced, even when lifting extremely heavy or uneven loads. Their ability to distribute pressure evenly across the crane reduces the chances of tipping or structural failure, making operations safer and more reliable in any environment. - Smooth and Controlled Movements

These cylinders ensure smooth and precise lateral movements, enabling the crane to operate efficiently. The ability to extend or retract with consistent force minimizes sudden jerks or instability during adjustments. This level of control is essential for maintaining the accuracy of crane operations, especially when handling delicate or high-risk lifting tasks in confined or challenging spaces. - Durability and Longevity

Designed with high-strength materials such as hardened steel and advanced seals, hydraulic horizontal cylinders are built to withstand harsh working conditions. Their resistance to wear, corrosion, and extreme pressure ensures they remain functional over extended periods, even in demanding environments. This durability reduces maintenance costs and downtime, contributing to long-term operational efficiency. - High Load-Bearing Capacity

Horizontal hydraulic cylinders are engineered to handle significant loads, making them ideal for supporting heavy-duty truck cranes. Their robust construction allows them to manage the immense forces generated during lifting operations. This high load-bearing capacity ensures the crane's stability and performance, even when operating under maximum load conditions. - Increased Operational Safety

By ensuring precise and controlled movements, crane hydraulic cylinders contribute to the overall safety of crane operations. They minimize the risk of accidents caused by instability or mechanical failures. Additionally, their ability to maintain balance during heavy lifting reduces stress on other crane components, preventing potential damage and ensuring safe operation in critical tasks. - Versatility in Applications

Horizontal hydraulic cylinders are highly versatile and can be used across various functions, such as stabilizing outriggers, adjusting boom positions, or operating other crane mechanisms. Their adaptability makes them a valuable component for truck cranes in diverse industries, including construction, logistics, and heavy equipment maintenance. This versatility enhances the overall functionality and efficiency of the crane.

Truck Crane Horizontal Hydraulic Cylinder Failures

- Seal Degradation

Seals in horizontal hydraulic cylinders can degrade due to wear, heat, or contamination, leading to leaks. This reduces pressure, impairs performance, and risks hydraulic fluid loss. Regular inspections and timely hydraulic cylinder seal replacement are critical to maintain functionality and prevent costly downtime. - Fluid Contamination

Contaminated hydraulic fluid, often from dirt or water, can damage cylinder components. This causes erratic movement or reduced efficiency in horizontal adjustments. Routine fluid checks and filtration systems are essential to ensure clean fluid and reliable cylinder operation. - Piston Rod Damage

The hydraulic cylinder piston rod may suffer dents, scratches, or corrosion from harsh environments or improper handling. Such damage compromises the cylinder’s ability to maintain pressure, leading to weak or inconsistent horizontal movements. Protective coatings and careful operation can mitigate this issue. - Cylinder Barrel Wear

Internal wear of the hydraulic cylinder barrel, caused by prolonged use or abrasive particles, reduces sealing efficiency and pressure retention. This results in sluggish or uneven horizontal motion. Regular maintenance and using high-quality hydraulic fluid help minimize barrel wear over time. - Overpressure Failures

Exceeding the cylinder’s pressure rating, often due to overloading or system malfunctions, can cause cracks or component failure. This disrupts horizontal articulation and poses safety risks. Pressure relief valves and load monitoring systems are vital to prevent overpressure issues. - Misalignment Issues

Improper alignment during installation or operation can stress the cylinder, leading to uneven wear or binding. This affects smooth horizontal movement and may cause premature failure. Proper alignment checks and precise installation are necessary to ensure optimal performance and longevity.

Additional information

| Edited by | Yjx |

|---|