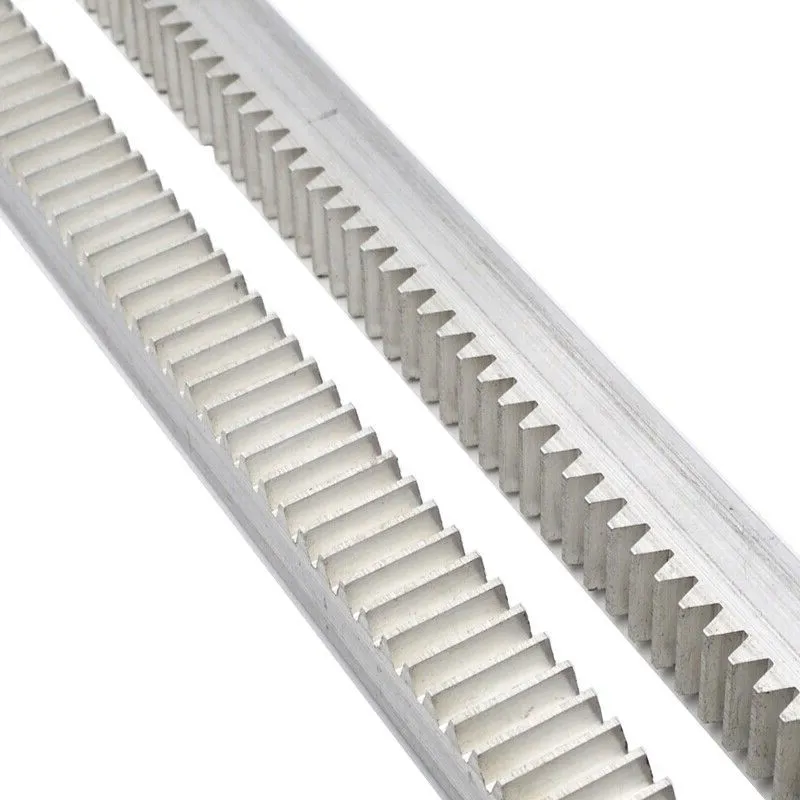

Gear Rack for CNC Machine Tools

The gear rack for CNC machine tools is a high-precision mechanical transmission component designed to facilitate linear motion or enable large-stroke positioning in a variety of industrial equipment. It operates by meshing with a corresponding gear, allowing for smooth, efficient, and accurate movement. This component plays a crucial role in modern CNC (computer numerical control) machines, laser cutting machines, and other advanced equipment, where precise positioning is essential for achieving high-quality results.

The gear rack for CNC machine tools is a high-precision mechanical transmission component designed to facilitate linear motion or enable large-stroke positioning in a variety of industrial equipment. It operates by meshing with a corresponding gear, allowing for smooth, efficient, and accurate movement. This component plays a crucial role in modern CNC (computer numerical control) machines, laser cutting machines, and other advanced equipment, where precise positioning is essential for achieving high-quality results.

Made from high-strength materials, gear racks are engineered to ensure durability, resistance to wear, and consistent performance under high loads and speeds. They are often designed with tight tolerances to maintain accuracy over extended periods of use. In cnc applications, gear racks enable fast, repeatable, and reliable movement, making them indispensable for machining operations that demand both speed and precision.

CMN Transmission manufactures its own rack gears for machine tools with a complete range of specifications, ready-made stock, and fast delivery. We are also able to customize production according to customer-provided drawings to meet customer customization needs.

Specifications of Gear Rack for CNC Machine Tools

| M1 | 10x10x1000 10x15x1000 | M1 | 15x15x250 15x15x500 | M3 | 30x30x250 30x30x500 | M5 | 50x50x250 50x50x500 |

| M1.5 | 15x15x1000 15x20x1000 | 15x15x1000 15x15x2000 | 30x30x1000 30x30x2000 | 50x50x1000 50x50x2000 | |||

| M2 | 20x20x1000 20x25x1000 | M1.5 | 17x17x250 17x17x500 | M6 | 60x60x250 60x60x500 | ||

| M2.5 | 25x25x1000 25x30x1000 | 17x17x1000 17x17x2000 | M4 | 22x22x250 22x22x500 | 60x60x1000 60x60x2000 | ||

| M3 | 30x30x1000 30x35x1000 | M2 | 20x20x250 20x20x500 | 22x22x1000 22x22x2000 | M8 | 80x80x250 80x80x500 | |

| M4 | 40x40x1000 40x45x1000 | 20x20x1000 20x20x2000 | M4 | 30x30x250 30x30x500 | 80x80x1000 80x80x2000 | ||

| M5 | 50x50x1000 50x55x1000 | M2.5 | 25x25x250 25x25x500 | 30x30x1000 30x30x2000 | M10 | 100x100x250 100x100x500 | |

| M6 | 60x60x1000 60x65x1000 | 25x25x1000 25x25x2000 | M4 | 40x40x250 40x40x500 | 100x100x1000 100x100x2000 | ||

| M8 | 80x80x1000 | 40x40x1000 40x40x2000 |

We can also manufacture custom-made gear racks when customers provide us with drawings.

CNC Machine Tool Gear Rack Advanatges

1. High Precision and Accuracy

CNC machine tool gear racks are designed to ensure precise linear motion and positioning. Their tight manufacturing tolerances allow for minimal backlash and consistent performance, ensuring accurate movement. This is essential for tasks requiring intricate machining or cutting with minimal errors.

2. Durable and Long-Lasting Performance

Gear racks are typically constructed from high-strength materials such as hardened steel, which ensures durability and resistance to wear. They can withstand heavy loads, high speeds, and continuous operation, making them ideal for industrial environments with demanding machining requirements.

3. Smooth and Stable Motion

The meshing between the gear and rack is engineered for smooth operation, reducing vibrations during movement. This stability enhances the quality of machining, minimizes mechanical stress on components, and ensures a longer lifespan for the machine tools.

4. Supports Large-Stroke Movement

One of the key advantages of CNC machine gear racks is their ability to support long linear strokes, making them suitable for applications requiring extensive travel distances. Unlike ball screws, they are not limited by length, allowing flexibility in machine design and operation.

5. High-Speed Capability

CNC gear racks enable high-speed linear motion without compromising precision. Their robust construction and efficient power transmission allow for fast acceleration and deceleration, improving productivity in machining processes while maintaining accuracy throughout the operation.

6. Low Maintenance Requirements

Due to their durable design and resistance to wear, gear racks require minimal maintenance over their lifespan. Proper lubrication further reduces friction and wear, ensuring consistent performance while lowering operational costs and downtime for maintenance.

CNC Machine Gear Rack Applications

1. Numerical Control Machine Tools

CNC gear racks are widely used in milling machines, lathes, and machining centers. They enable precise linear motion and positioning, ensuring high accuracy in cutting, shaping, and finishing operations. Their durability supports heavy workloads and continuous operation in industrial environments.

2. Laser Cutting Machines

Gear racks play a vital role in laser cutting machines by providing smooth and precise movement. They allow the laser head to travel accurately along the workpiece, ensuring clean, intricate, and high-quality cuts in materials like metal, wood, and acrylic.

3. Plasma Cutting Machines

In plasma cutting, gear racks are essential for fast and precise positioning of the plasma torch. They ensure consistent linear motion, enabling efficient cutting of thick and conductive materials like steel and aluminum with minimal errors, even during high-speed operations.

4. Robotics and Automation Systems

Gear racks are integral components in robotic arms and automated systems, providing linear motion for tasks such as material handling, assembly, and welding. Their ability to handle high loads and offer accurate positioning makes them ideal for industrial automation applications.

5. Printing and Packaging Machines

In the printing and packaging industry, gear racks facilitate precise motion for processes like cutting, folding, and labeling. Their high-speed capabilities and reliability are critical for maintaining efficiency and accuracy in high-volume production environments.

6. Transportation and Conveyor Systems

CNC gear racks are extensively used in conveyor systems for industries like manufacturing, logistics, and mining. They provide linear motion for transporting goods over long distances while ensuring smooth operation and reliable performance under heavy loads and challenging conditions.

|  |

| Gear Rack for Numerical Control Machine Tools | Gear Rack for Laser Cutting Machines |

|  |

| Gear Rack for Plasma Cutting Machines | Gear Rack for Automation and Robotics |

Choose the Right Gear Rack for CNC Machine Tools

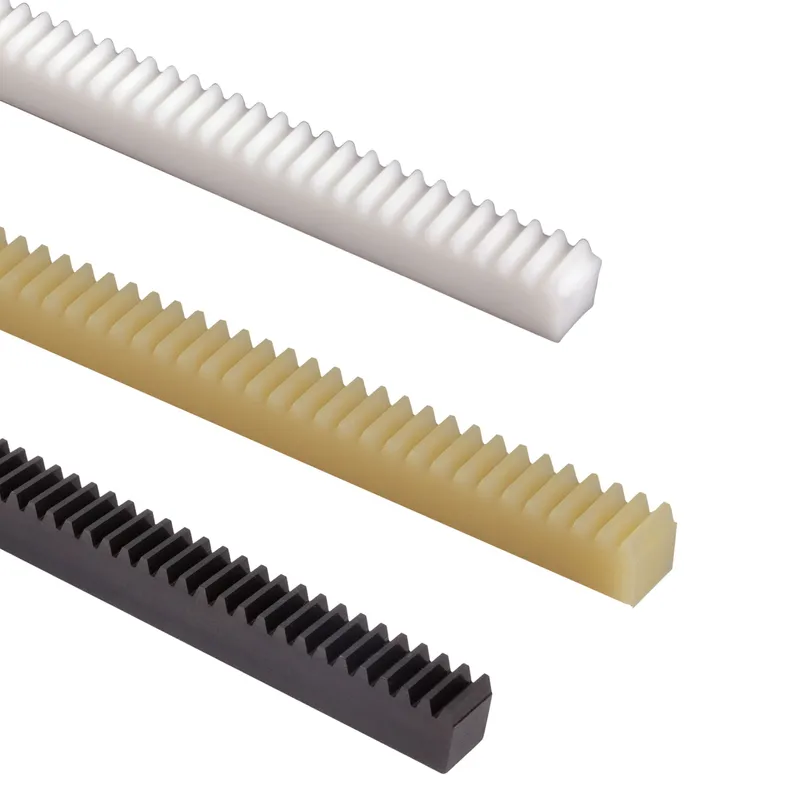

- Material Selection Based on Application

The material of the gear rack determines its durability and performance. For high-load applications, hardened steel is ideal due to its strength and wear resistance. For lighter applications or cost efficiency, materials like aluminum or alloy steel may be suitable. - Precision Grade and Accuracy Standards

Gear racks come in various precision grades, such as DIN, AGMA, or JIS standards. Selecting a rack with the appropriate precision ensures minimal backlash and accurate positioning. High-precision tasks require tighter tolerances, while standard-grade racks may suffice for less demanding operations. - Load Capacity and Strength

Consider the gear rack’s load-bearing capacity to match the demands of your CNC machine. This involves evaluating factors such as the maximum weight it will carry, operational speeds, and torque requirements to ensure reliable performance under heavy or continuous workloads. - Length and Stroke Requirements

The gear rack’s length must align with the machine’s stroke requirements. For large-scale applications, racks can be joined end-to-end for extended travel distances. Ensure that the joints maintain precision and smooth operation to avoid compromising the machine's overall performance. - Surface Treatment and Coatings

Surface treatments like black oxide, nitriding, or chrome plating enhance the gear rack’s resistance to corrosion, wear, and fatigue. Choosing a rack with the proper surface coating ensures longevity and optimal performance, especially in harsh environments or high-speed applications. - Compatibility with Gears and System Design

Ensure the gear rack is compatible with the machine’s gear module, pitch, and system design. Proper meshing between the gear and rack is crucial for smooth motion and efficiency. Mismatched components can lead to excessive wear, noise, and reduced accuracy.

Additional information

| Edited by | Yjx |

|---|