Floating Hydraulic Cylinder for Scissor Type Aerial Work Platform

A floating hydraulic cylinder in a scissor-type aerial work platform is a specialized hydraulic component designed to facilitate smooth and controlled vertical movement of the platform. Unlike traditional fixed hydraulic cylinders, a floating cylinder is engineered to allow slight lateral or angular movement, compensating for misalignments or uneven loads during operation. This flexibility enhances stability and reduces stress on the scissor mechanism, which consists of crisscrossed metal supports that extend and contract to raise or lower the platform.

A floating hydraulic cylinder in a scissor-type aerial work platform is a specialized hydraulic component designed to facilitate smooth and controlled vertical movement of the platform. Unlike traditional fixed hydraulic cylinders, a floating cylinder is engineered to allow slight lateral or angular movement, compensating for misalignments or uneven loads during operation. This flexibility enhances stability and reduces stress on the scissor mechanism, which consists of crisscrossed metal supports that extend and contract to raise or lower the platform.

The hydraulic floating cylinder operates using pressurized hydraulic fluid, typically oil, which drives a piston to create linear motion, lifting the platform. Its compact design, durability, and ability to handle high loads make it ideal for applications in construction, warehousing, and maintenance, ensuring safe and efficient operation.

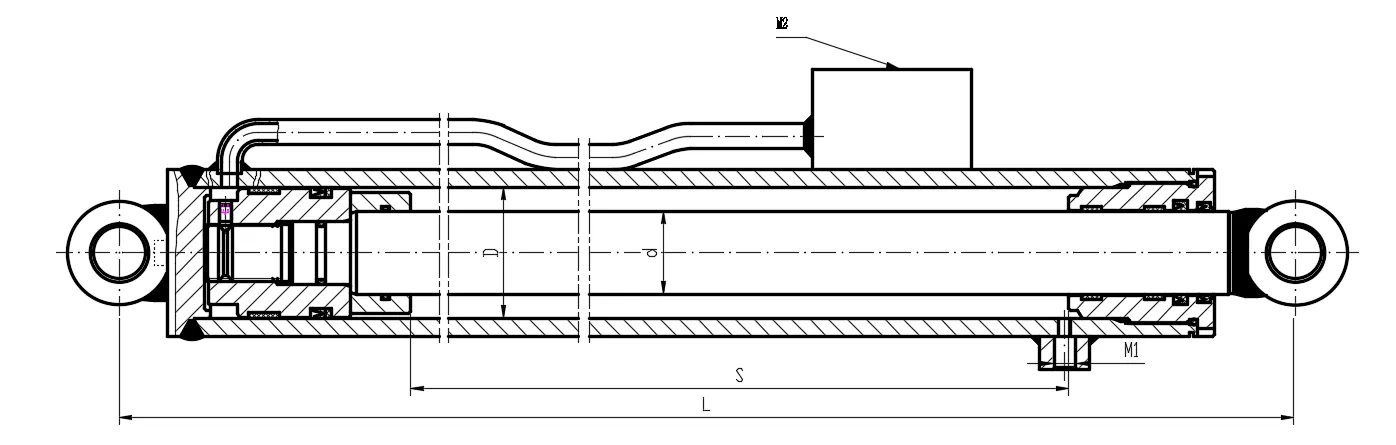

Floating Hydraulic Cylinder Dimensions

| Forklift Floating Cylinder | |||||||

| drawing number | bore diameter (D) | rod diameter (d) | stroke (S) | Installation distance (L) | working pressure | Interface dimensions (M) | weight |

| JCPT1212HD-531000-00A | Φ75 | Φ63 | 1269 | 1530 | 25MPa | G1/4;M18*1.5 | 60kg |

| JCPT0607DCS-531000-00A | Φ63 | Φ40 | 563 | 812 | 20MPa | G1/4;M18*1.5 | 17kg |

| Product Name: | Floating Hydraulic Cylinders |

| Function: | To achieve floating walking, improve passability, maintain vehicle stability, and improve the off-road capability of the entire machine. |

| Cylinder diameter: | 55mm-90mm |

| Rod diameter: | 32mm-45mm |

| Travel: | 60mm-112mm |

| Maximum pressure: | 25MPa |

| Maximum thrust: | 159KN |

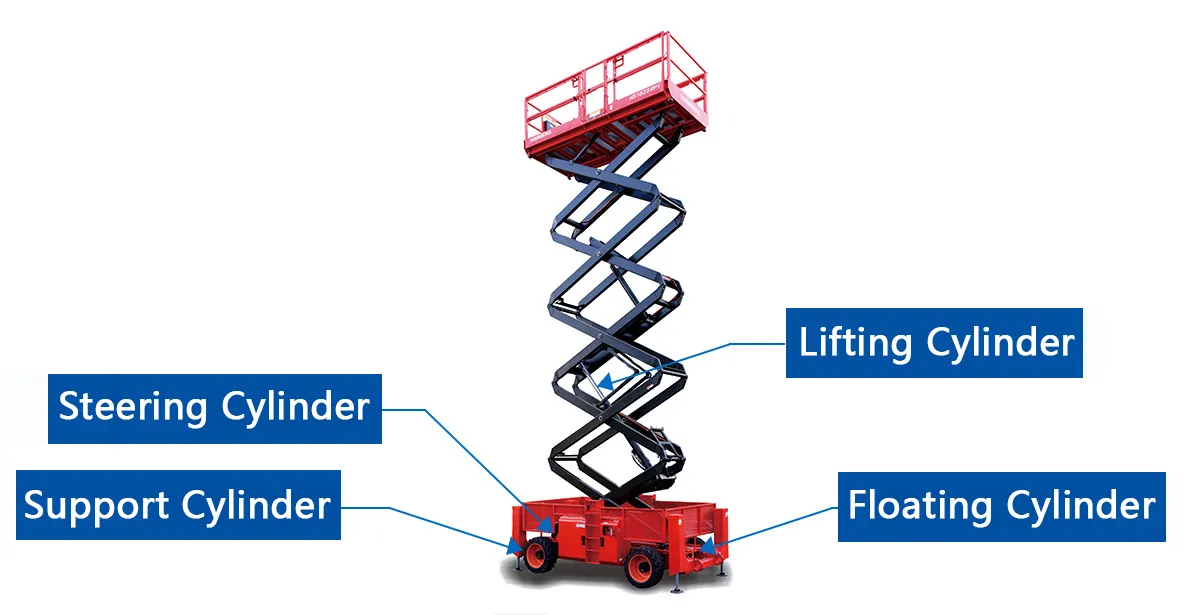

Scissor Type Aerial Work Platform Hydraulic Cylinder Types

- Floating Hydraulic Cylinders

Floating hydraulic cylinders allow slight lateral or angular movement to compensate for misalignments in scissor-type aerial work platforms. They ensure smooth operation by reducing stress on the scissor mechanism. Pressurized hydraulic fluid drives the piston, enabling stable lifting even under uneven loads, enhancing safety and durability. - Support Hydraulic Cylinders

Support hydraulic cylinders provide structural stability to the scissor mechanism during operation. They absorb lateral forces and maintain alignment of the platform. These cylinders are critical for preventing wobbling or tipping, ensuring worker safety at elevated heights in demanding environments like construction or maintenance. - Lifting Hydraulic Cylinders

Lifting hydraulic cylinders are the primary components responsible for raising and lowering the platform. They convert hydraulic pressure into linear motion to extend or contract the scissor structure. Designed for high load capacity, they ensure precise and controlled vertical movement for safe operation. - Steering Hydraulic Cylinders

Steering hydraulic cylinders control the directional movement of the platform’s base or wheels. They enable precise maneuvering in tight spaces by adjusting the orientation of the wheels. These cylinders enhance mobility, making the platform versatile for navigating complex work sites efficiently.

Scissor Type Aerial Work Platform Hydraulic Floating Cylinder Features

- Misalignment Compensation

Floating hydraulic cylinders are designed to accommodate slight lateral or angular misalignments in the scissor mechanism. This flexibility ensures smooth operation, reduces mechanical stress, and prevents damage to the platform, enhancing overall reliability and safety during elevation tasks. - Enhanced Stability

These scissor type aerial work platform hydraulic cylinders provide exceptional stability by evenly distributing loads across the scissor structure. Their ability to adjust to uneven weight or terrain conditions minimizes platform tilting, ensuring a secure working environment for operators at various heights. - Durable Construction

Built with high-strength materials like reinforced steel, hydraulic floating cylinders withstand heavy loads and harsh environments. Their robust design ensures long-term durability, reducing maintenance costs and downtime in demanding applications like construction or warehousing. - Precise Motion Control

Floating cylinders deliver precise linear motion through controlled hydraulic fluid pressure. This allows for smooth and accurate platform elevation, enabling operators to position the platform exactly at the desired height for efficient task execution. - Compact Design

The compact structure of floating hydraulic cylinders optimizes space within the scissor mechanism. This design enables integration into tight configurations, making them ideal for portable or space-constrained aerial work platforms without compromising lifting capacity. - Low Maintenance Requirements

Featuring sealed systems and corrosion-resistant components, these hydraulic cylinders require minimal maintenance. Regular fluid checks and seal inspections ensure consistent performance, reducing operational interruptions and extending the lifespan of the aerial work platform in diverse conditions.

Floating Hydraulic Cylinder Applications

- Construction Sites

Floating hydraulic cylinders enable scissor-type aerial work platforms to lift workers and materials to elevated areas in construction. Their ability to handle misalignments ensures stable operation on uneven terrain, enhancing safety and efficiency during tasks like installing frameworks or facades. - Warehouse Operations

In warehouses, these scissor-type aerial work platform hydraulic cylinders facilitate safe access to high shelving for inventory management. Their flexibility accommodates slight structural shifts, ensuring smooth lifting and lowering of heavy loads, improving productivity in storage and retrieval processes. - Maintenance and Repair

Floating hydraulic cylinders support maintenance tasks in facilities like airports or factories. They provide stable elevation for workers repairing overhead systems, absorbing misalignments to maintain platform stability, ensuring safe and precise operations in confined spaces. - Event Setup

For event setups, such as stage or lighting installations, these aerial work platform hydraulic cylinders enable precise platform positioning. Their compact design and misalignment compensation ensure safe, stable lifting in temporary venues, supporting efficient and secure event preparations. - Industrial Cleaning

In industrial cleaning, hydraulic floating cylinders allow platforms to reach high structures like factory ceilings or large equipment. Their stability and flexibility ensure safe worker positioning, enhancing efficiency in cleaning hard-to-reach areas safely. - Infrastructure Inspection

Hydraulic cylinders aid in inspecting bridges, power lines, or tall structures. Their ability to maintain stability despite misalignments ensures safe and accurate platform positioning, allowing inspectors to perform thorough evaluations at elevated heights.

|

|

Additional information

| Edited by | Yjx |

|---|