Floating Hydraulic Cylinder for Arm Type Aerial Work Platform

A floating hydraulic cylinder for an arm type aerial work platform is a specialized hydraulic component designed to provide controlled motion, stability, and flexibility for the platform’s arm mechanism. It plays a critical role in lifting, lowering, and positioning the platform during operation. The term “floating” refers to its ability to adapt dynamically to varying loads and operational angles without causing stress or misalignment in the system. This adaptability ensures smooth movement, even when the platform is subjected to uneven weight distribution or external forces like wind.

A floating hydraulic cylinder for an arm type aerial work platform is a specialized hydraulic component designed to provide controlled motion, stability, and flexibility for the platform’s arm mechanism. It plays a critical role in lifting, lowering, and positioning the platform during operation. The term "floating" refers to its ability to adapt dynamically to varying loads and operational angles without causing stress or misalignment in the system. This adaptability ensures smooth movement, even when the platform is subjected to uneven weight distribution or external forces like wind.

The hydraulic cylinder operates by pressurizing hydraulic fluid, which generates the necessary force to extend or retract the arm. It is engineered with advanced seals, high-strength materials, and precise tolerances to handle heavy loads while maintaining reliability and durability. Additionally, its floating design minimizes wear on the arm joints, reduces the risk of damage due to overextension, and enhances the safety of the equipment. This makes it an essential component for aerial work platforms used in construction, maintenance, and other industries requiring elevated access.

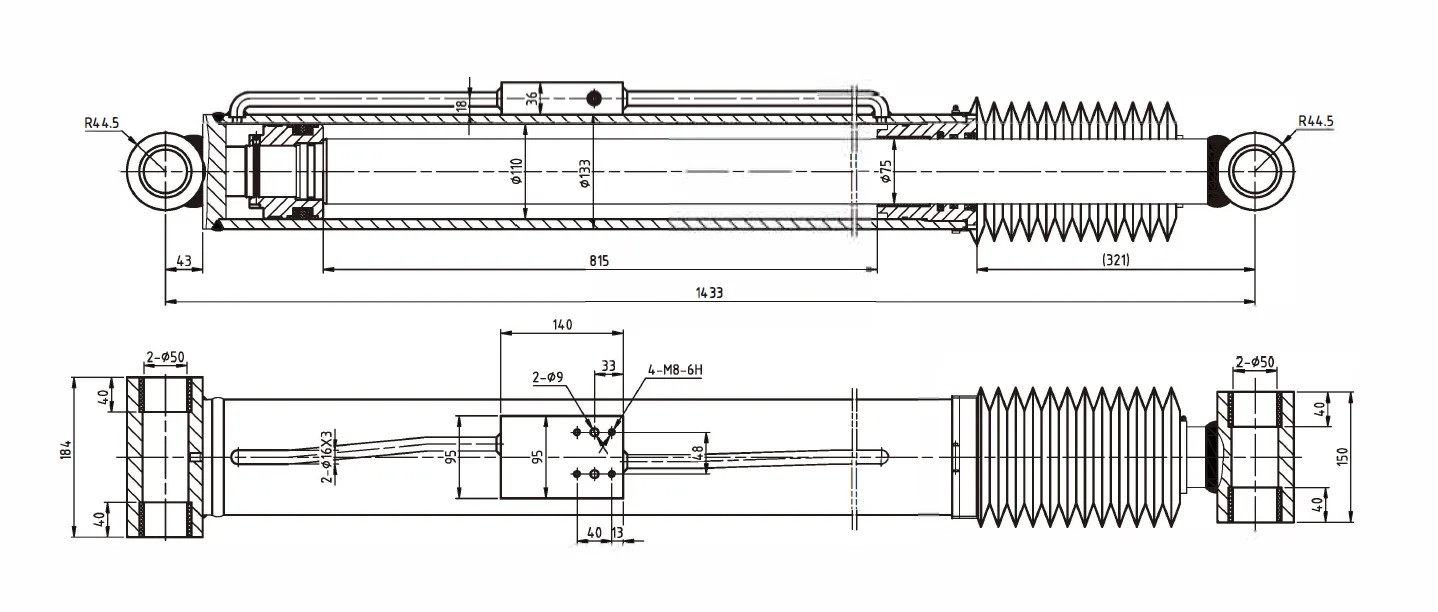

Floating Hydraulic Cylinder Dimensions

|

|

|

|

| Product Name: | Floating Hydraulic Cylinder |

| Function: | To achieve floating walking, improve passability, maintain vehicle stability, and improve the off-road capability of the entire machine. |

| Cylinder diameter: | 80mm-95mm |

| Rod diameter: | 20mm-50mm |

| Travel: | 110mm-300mm |

| Maximum pressure: | 20MPa |

| Maximum thrust: | 100KN |

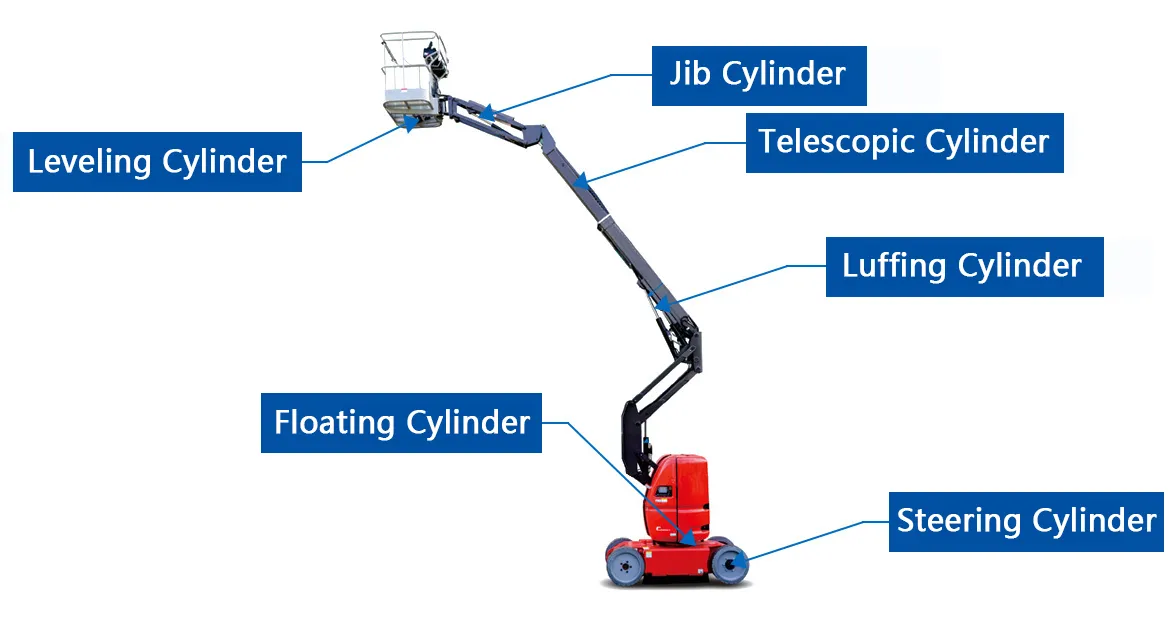

Arm Type Aerial Work Platform Hydraulic Cylinder Types

- Leveling Hydraulic Cylinders

Leveling hydraulic cylinders ensures the work platform remains horizontal during operation. Mounted on the arm or basket, they adjust the platform's angle to compensate for the arm's tilt. Constructed with durable materials, they provide precise control, enhancing operator safety and comfort in tasks like maintenance or construction at height. - Telescopic Hydraulic Cylinders

Telescopic hydraulic cylinders enable the extension and retraction of the arm in aerial work platforms. Comprising multiple nested stages, they offer a compact design with extended reach. High-strength steel construction ensures reliability under heavy loads, ideal for reaching elevated or distant work areas efficiently. - Steering Hydraulic Cylinders

Steering hydraulic cylinders control the directional movement of the aerial work platform's chassis or arm. These double-acting cylinders provide smooth, precise steering for maneuverability in tight spaces. Robust seals and high-pressure resistance ensure durability, supporting safe navigation on uneven terrain or crowded job sites. - Floating Hydraulic Cylinders

Floating hydraulic cylinders absorb shocks and vibrations, enhancing platform stability. Designed with a cushion structure, they allow slight movements to reduce stress on the arm during dynamic loads. Built with corrosion-resistant materials, they ensure smooth operation and longevity in demanding environments like construction or utility maintenance. - Luffing Hydraulic Cylinders

Luffing hydraulic cylinders control the vertical pivoting or tilting of the arm. They enable precise angle adjustments for positioning the platform at desired heights. Made with high-strength alloys, they handle significant loads, ensuring stable and controlled movements for tasks requiring elevation adjustments. - Jib Hydraulic Cylinders

Jib hydraulic cylinders manage the articulation of the jib arm, providing additional reach and flexibility. They allow precise positioning of the platform for accessing hard-to-reach areas. Constructed with advanced seals and robust materials, they ensure reliable performance and safety in complex aerial tasks.

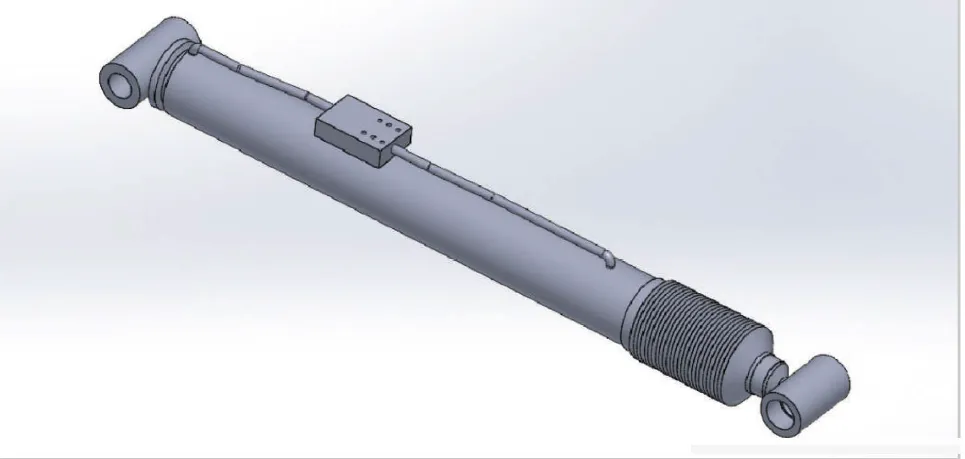

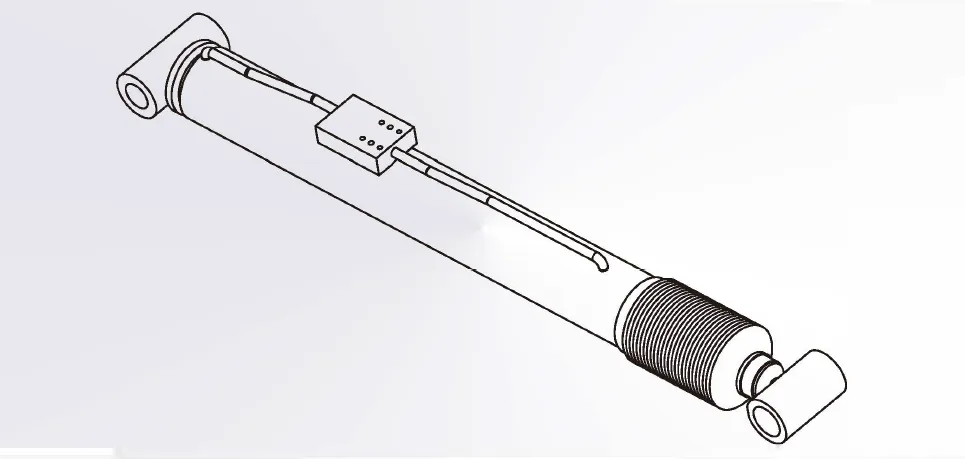

Arm Type Aerial Work Platform Floating Hydraulic Cylinder Parts

- Cylinder Barrel

The hydraulic cylinder barrel is the main housing of the floating hydraulic cylinder, designed to contain the hydraulic fluid under high pressure. It is typically made from high-strength steel to withstand extreme forces and prevent deformation during operation. - Piston and Piston Rod

The hydraulic cylinder piston and piston rod are critical components that transfer hydraulic pressure into mechanical motion. The piston moves inside the cylinder barrel, while the rod extends outward, enabling controlled arm movement and precise positioning of the aerial platform. - Hydraulic Seals

Hydraulic cylinder seals ensure the containment of pressurized fluid within the cylinder, preventing leaks and maintaining efficiency. These seals are made from durable, wear-resistant materials to handle high pressure and continuous operation without compromising performance. - End Caps

Hydraulic cylinder end caps are located at both ends of the cylinder to provide structural support and contain the internal components. They also house ports for hydraulic fluid entry and exit, ensuring smooth fluid flow and pressure regulation. - Mounting Points

Mounting points are connection interfaces that secure the hydraulic cylinder to the arm mechanism. These points are designed to accommodate the floating functionality, allowing flexibility and reducing stress on other structural components during motion. - Hydraulic Ports

Hydraulic cylinder ports are entry and exit points for the hydraulic fluid, facilitating the flow necessary for cylinder operation. These ports are engineered for efficient sealing and compatibility with hydraulic hoses, ensuring reliable performance under varying operational conditions.

Floating Hydraulic Cylinder for Arm Type Aerial Work Platform

A floating hydraulic cylinder in an arm-type aerial work platform (AWP) is a critical component designed to enhance stability and absorb dynamic loads during operation. It functions by utilizing hydraulic fluid pressure within a specialized cylinder design to facilitate controlled movement and shock absorption.

The hydraulic floating cylinder consists of a barrel, piston, piston rod, seals, and a floating cushion mechanism. Hydraulic fluid, typically oil, is pumped into the cylinder through ports in the end caps, creating pressure that moves the piston. This movement extends or retracts the piston rod, which is connected to the platform’s arm or chassis, enabling precise tilting or pivoting to adjust the platform’s position.

The defining feature of a floating hydraulic cylinder is its cushion mechanism, which allows slight lateral or axial movement to absorb shocks and vibrations caused by uneven terrain or sudden load shifts. This reduces stress on the arm, preventing structural damage and ensuring operator safety. The seals and gaskets maintain pressure integrity, preventing leaks while withstanding high pressures and harsh environments.

The floating cylinder barrel, made of high-strength steel or aluminum, houses the components and resists corrosion. By balancing hydraulic force with the cushioning effect, the cylinder ensures smooth, controlled movements, critical for tasks like construction or maintenance at height. This design enhances the AWP’s stability, extends component lifespan, and provides a safer, more reliable operation in dynamic conditions.

Additional information

| Edited by | Yjx |

|---|