DY Mobile Belt Conveyor for Mining/ Coal Mining/ Port/ Sand Gravel Yard/ Building Materials Industry

The DY mobile belt conveyor is a belt conveyor with high efficiency, convenience, good mobility, and continuous transportation. It is mainly used for occasions where loading and unloading locations often change, such as ports, docks, stations, coal yards, warehouses, construction sites, sand and gravel yards, farms, etc. It is ideal equipment for short-distance transportation and loading of bulk materials or pieces of articles.

The DY mobile belt conveyor is a belt conveyor with high efficiency, convenience, good mobility, and continuous transportation. It is mainly used for occasions where loading and unloading locations often change, such as ports, docks, stations, coal yards, warehouses, construction sites, sand and gravel yards, farms, etc. It is ideal equipment for short-distance transportation and loading of bulk materials or pieces of articles. Mobile belt conveyor structure is reasonable, easy to move, and the use of a winch device, can be adjusted within the scope of the provisions of the lifting height, used for loading and unloading and conveying soil, sand, coal, gravel, grain, and other bulk or pieces of goods.

DY Mobile Belt Conveyor Features

- Lightweight and Easy to Move: The DY mobile belt conveyor is designed to be lightweight, allowing a single operator to move it effortlessly. This portability makes it highly convenient for various applications.

- Adjustable Lifting Height: The conveyor's lifting height can be adjusted to suit your specific needs, making it versatile for different loading and unloading requirements in various working environments.

- Gentle Handling with High Capacity: Its belt conveyor system ensures gentle handling of materials while offering a higher capacity compared to screw conveyors of the same size, improving efficiency and reducing material damage.

- Mobility with Built-In Wheels: Equipped with sturdy wheels, the DY mobile belt conveyor can be relocated to any location as needed. This feature reduces the need for multiple pieces of equipment.

- Labor-Saving for Material Stacking: Ideal for stacking bags or bulk materials in warehouses, it simplifies operations, increases efficiency, and helps save on labor costs through its streamlined design and functionality.

- Chevron Pattern Conveyor Belt: The adoption of a chevron pattern conveyor belt increases the maximum conveyor angle, ensuring materials do not slip during transportation, even at steeper inclines.

- Customizable Conveyor Length: The conveyor length can be customized according to your specific requirements, making it adaptable for different operational needs and ensuring optimal performance in various settings.

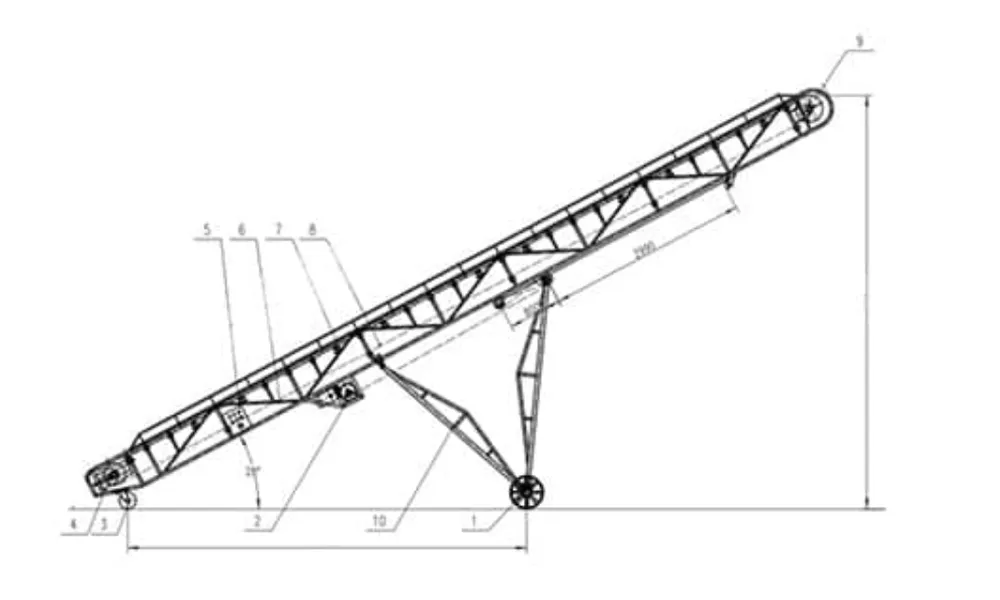

DY Type Mobile Belt Conveyor Parts

| 1 | Driving Pulley | 5 | Middle Bracket |

| 2 | Head Cover | 6 | Guide Chute |

| 3 | Belt | 7 | Return Pulley |

| 4 | Trough Type Support | 8 | Tail Bracket |

DY Mobile Belt Conveyor Specification Sheet

| Belt width(mm) | 500 | 650 | 800 | 1000 | 1200 | 1400 |

| Speed(m/s) | 0.8~2.5 | 0.8~2.5 | 0.8~3.15 | 0.8~4 | 1.0~5 | 1.0~5 |

| Conveying length(m) | 5~30 | |||||

| Conveying capacity(m³/h) | 50~150 | 100~300 | 150~700 | 300~1500 | 500~2300 | 700~3800 |

| Tilt angle(°) | 9°~22° | |||||

DY Mobile Belt Conveyor Application Fields

Ports & Terminals

- Cargo Handling: At ports and docks, mobile belt conveyors are used to unload cargo from ships to the dock or load cargo from the dock onto ships. The rotation function allows flexible adjustment of the conveying direction to accommodate various docking positions and loading/unloading requirements. For example, at bulk cargo terminals, they can efficiently transfer coal, ores, and other materials from ship holds to onshore storage.

- Container Handling: At container terminals, the mobile belt conveyor can work in tandem with container cranes for container loading and unloading. This enhances terminal operations and reduces vessel berthing time.

Mining & Metallurgy

- Ore Conveying: In mining operations, belt conveyors transport extracted ores from underground or open-pit mines to processing or beneficiation plants. Their large capacity and flexible direction control meet the needs of continuous production. For example, in metal mines, the conveyor can transport iron ore to the crushing workshop for initial processing.

- Slag Handling: In metallurgical production, large volumes of slag are generated. Conveyors can transport slag from the production area to designated storage or processing sites for effective waste management.

Logistics & Warehousing

- Goods Sorting and Storage: In large-scale logistics and warehousing operations, where a high volume and variety of goods are handled, the mobile belt conveyor can transfer items from unloading points to designated storage areas, enabling efficient sorting and storage. For example, in e-commerce warehouses, the belt conveyor systems can accurately distribute products for different orders to their corresponding storage shelves.

- Distribution Process: During order fulfillment, the belt conveyor can move goods from storage zones to packaging areas or shipping points, significantly improving distribution efficiency.

Metallurgical Industry

- In ironmaking plants, the conveyor transports iron ore and coke to blast furnaces. Continuous raw material supply is critical for uninterrupted smelting, and the DY mobile belt conveyor offers stable delivery with adjustable capacity, operating reliably in high-temperature, high-dust environments.

- In steel plants, it transports steel billets for instance, moving semi-finished billets from rolling mills to downstream workshops like heat treatment or finishing, supporting continuous production workflows.

Building Materials Industry

- In cement plants, the belt conveyor systems transport raw materials such as limestone, clay, and iron powder from mining or stockpiles to raw mills for grinding. It also handles finished cement, delivering it from silos to packaging areas or bulk loading stations.

- In ceramic factories, it transports both raw materials (e.g., clay, porcelain stone) and finished goods. It moves materials to shaping workshops and transfers fired ceramic products to packaging sections. Belt speed and tension can be adjusted to accommodate products of varying sizes and weights.

|

|

| Belt Conveyor for Mining Industry | Belt Conveyor for Building Materials Industry |

Mobile Belt Conveyor Benefits

- Flexible Conveying Angles

Supports 360° omnidirectional rotation, allowing flexible adjustment of material flow within limited spaces. Unlike traditional linear conveyors, no complex transfer mechanisms are required to send materials to multiple locations, greatly improving operational flexibility and efficiency. - High Space Utilization

Compact structure with a small footprint, ideal for space-constrained work environments. The radial rotation system enables wide-area conveying in minimal space, reducing the need for expansive facilities and lowering factory construction or warehouse rental costs. - High Conveying Efficiency

Capable of transporting materials quickly from one point to another, minimizing wait times. Seamlessly integrates with other machinery or conveying systems to ensure continuous material flow and optimized production processes. - Strong Adaptability

Handles a wide range of materials, including powders, granules, lumps, and items of various sizes and weights. By selecting suitable belt materials, conveying speeds, and rotation radii, the system meets different operational needs. Also performs reliably in harsh environments such as high temperature, humidity, and dust. - Stable Operation

Equipped with advanced drive systems and mechanical structures for smooth and quiet operation with low failure rates. Rotating components are precisely engineered for long-term stability. Includes protection features such as overload protection and anti-deviation devices. - Low Maintenance Costs

Simple structure with easily removable and replaceable parts makes maintenance convenient. Reliable performance reduces downtime and repair costs. Wear components like conveyor belts are easy to replace, reducing maintenance workload and expense. - High Automation Capability

Integrates with automated control systems for remote operation and intelligent control. Automatically adjusts conveying speed and rotation angle based on material flow and positioning data. Enhances overall automation, reduces manual intervention, and lowers labor intensity.

Additional information

| Edited by | Yjx |

|---|