CMN-PC-NMRV Worm Gear Reducers/Worm Gearbox

CMN-PC-NMRV Helical worm gearbox is a gearbox system that combines a PC prestage helical gear reducer and a CMN-NMRV worm gear reducer. PC prestage helical gear reducer is a helical gear reducer that provides the first stage of speed reduction. Helical gears offer higher efficiency and smoother operation compared to worm gears. PC prestage helical gear reducer can provide gear ratios typically ranging from 2:1 to 10:1. CMN-NMRV worm gear reducer is the second stage of the gearbox, using a worm gear mechanism. Worm gears can provide very high gear ratios, often from 5:1 up to 100:1 or more. The combination of the helical and worm gear stages allows for achieving very high overall gear reduction ratios.

CMN-PC-NMRV Helical worm gearbox is a gearbox system that combines a PC prestage helical gear reducer and a CMN-NMRV worm gear reducer. PC prestage helical gear reducer is a helical gear reducer that provides the first stage of speed reduction. Helical gears offer higher efficiency and smoother operation compared to worm gears. PC prestage helical gear reducer can provide gear ratios typically ranging from 2:1 to 10:1. CMN-NMRV worm gear reducer is the second stage of the gearbox, using a worm gear mechanism. Worm gears can provide very high gear ratios, often from 5:1 up to 100:1 or more. The combination of the helical and worm gear stages allows for achieving very high overall gear reduction ratios.

CMN-PC-NMRV Worm Gearbox Model & Marker

| PC-071-CMN-NMRV-063-30-VS-F1(FA)-AS-71B5-0.37kW-B3 | |||

| PC | Pre-stage helical module | ||

| 071 | Size | ||

| CMN-NMRV | Worm geared motor | ||

| 063 | Center distance | ||

| 30 | Reduction ratio | ||

| VS | Double input shaft | F1(FA) | Output flange |

| AS | Single output shaft | AB | Double output shaft |

| PAM | Fitted for motor coupling | 71B5 | Motor size & mounting position |

| 0.37kW | Power of Electric motor | B3 | Mounting position |

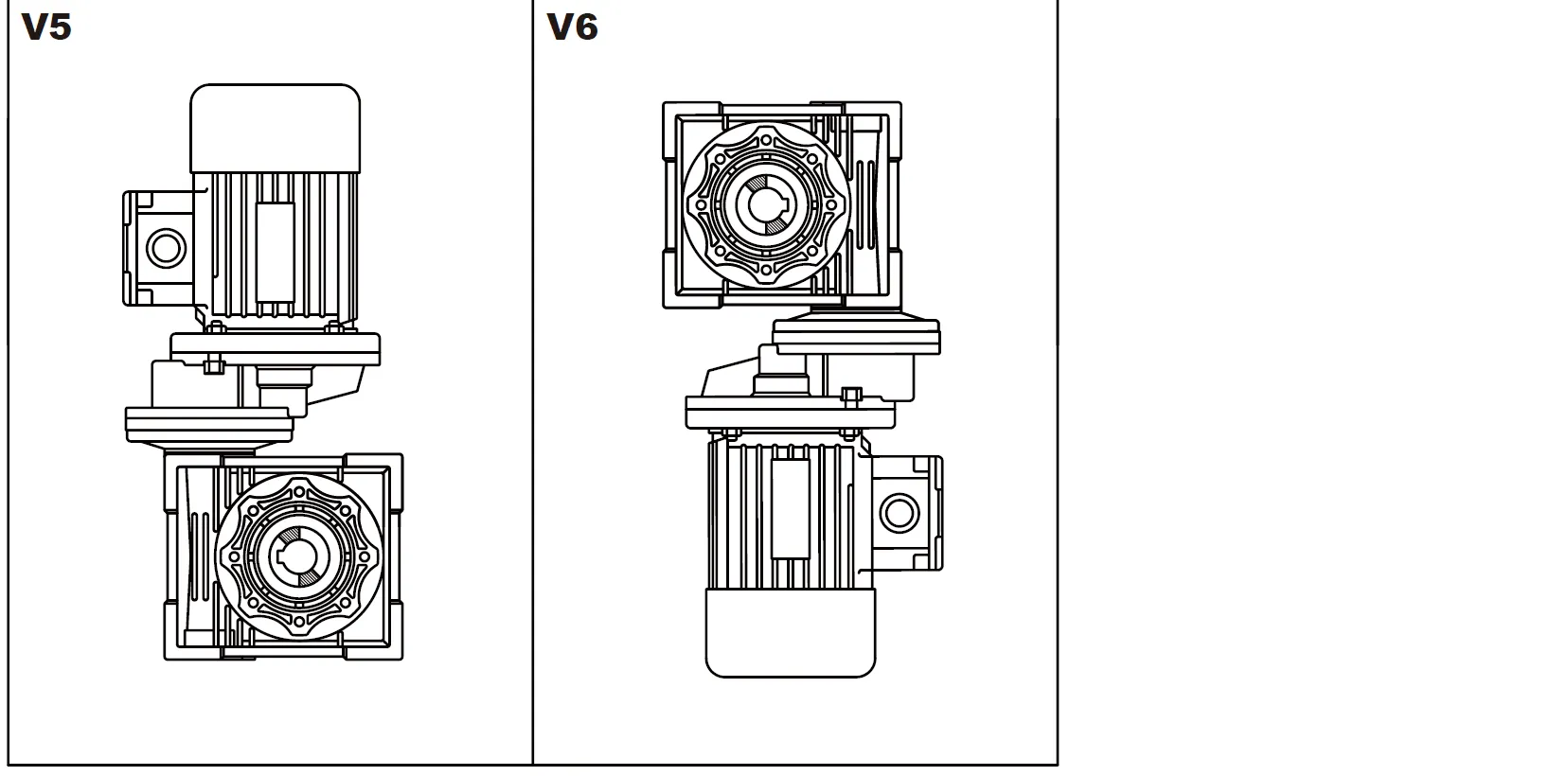

CMN-PC+NMRV Combinations

| P1 | P | (P) | |

| PC 063 | 63B5-140/11 | 105/11 | (105/14) |

| PC 071 | 71B5-160/14 | 120/14 | (120/19) |

| PC 080 | 80B5-200/19 | 160/19 | (160/24) |

| (160/28) | |||

| PC 090 | 90B5-200/24 | 160/24 | (160/19) |

| (160/28) |

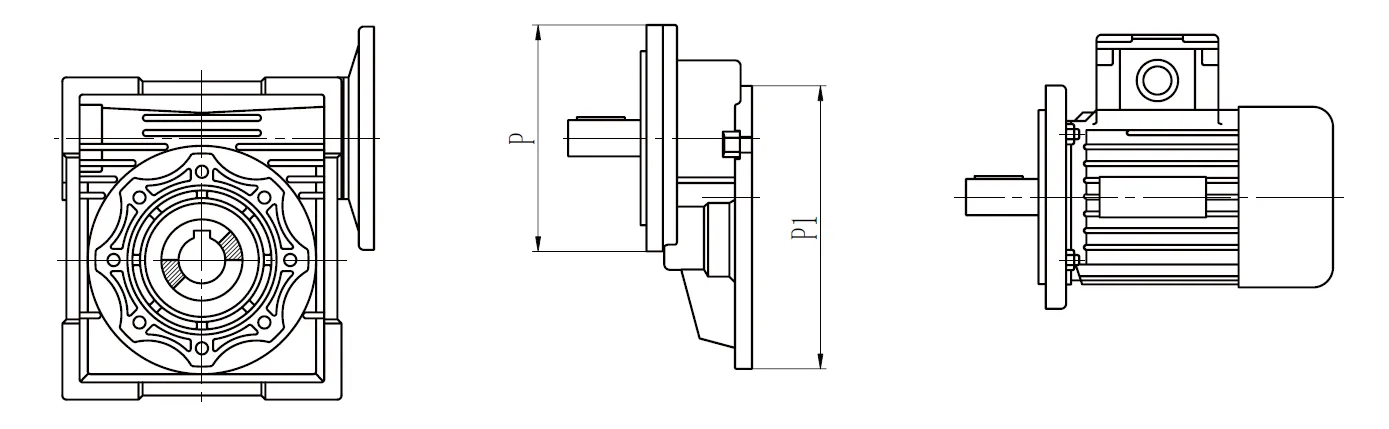

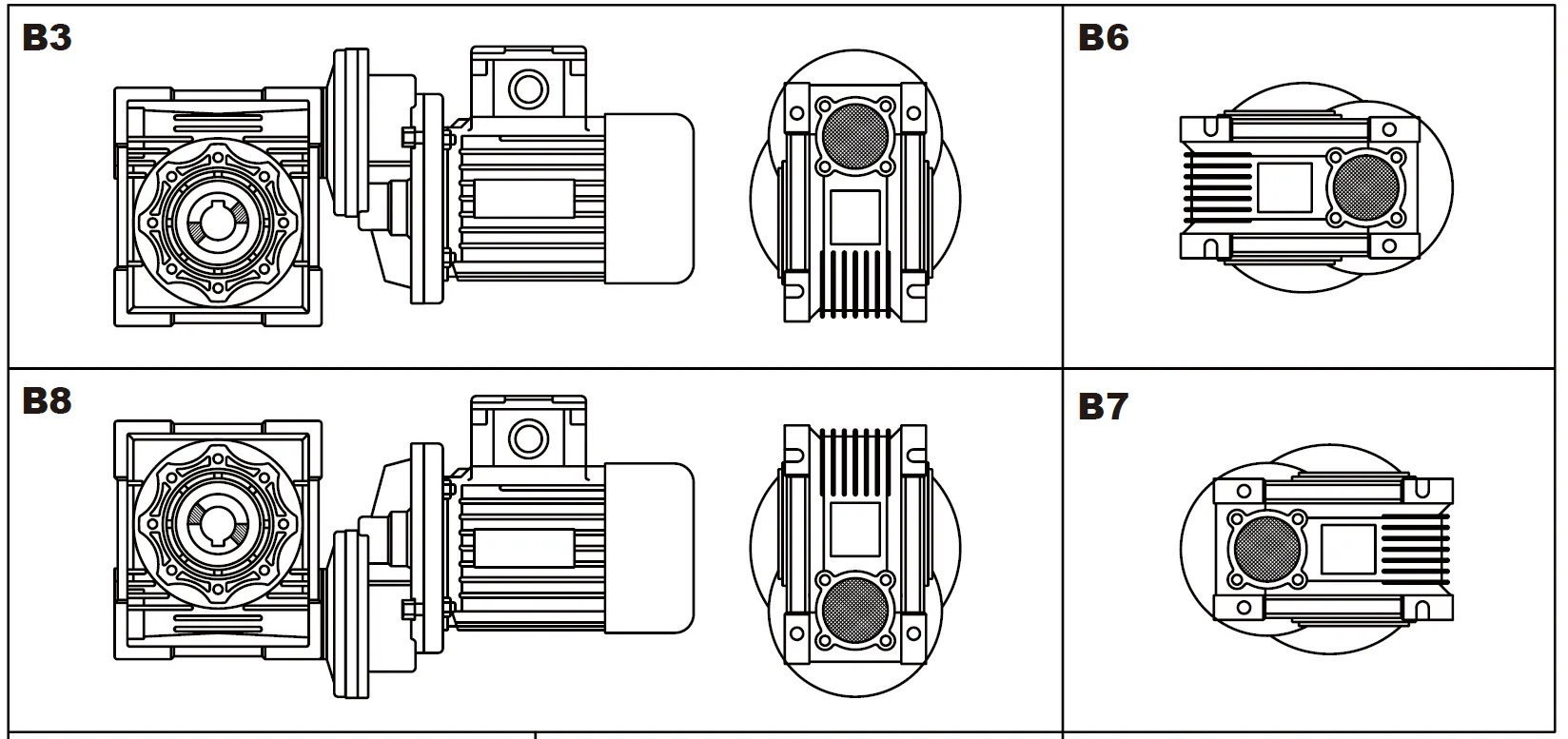

CMN-PC-NMRV Mounting Positions

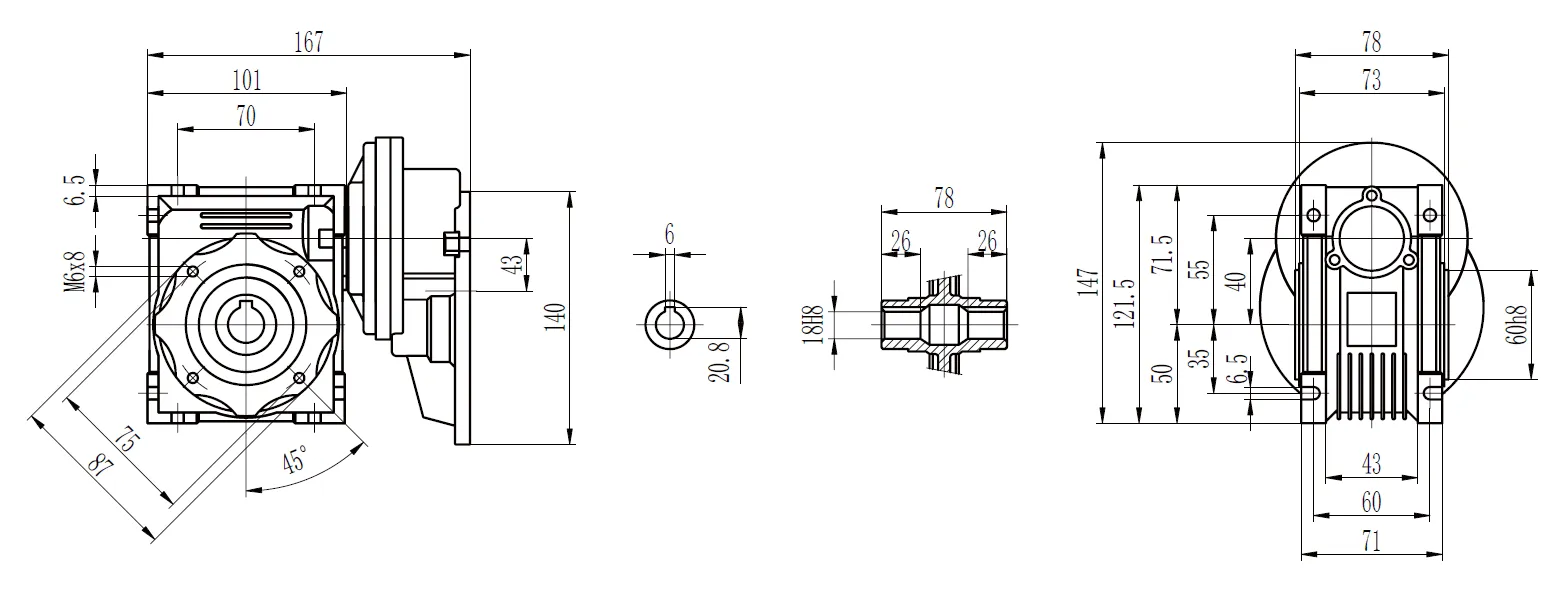

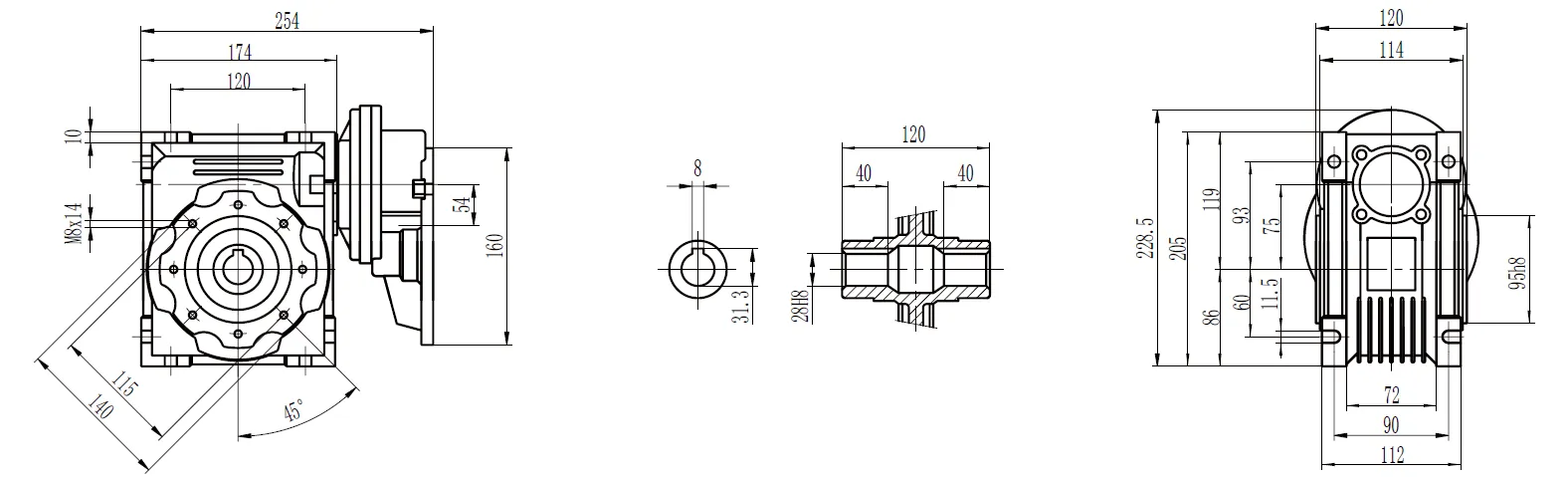

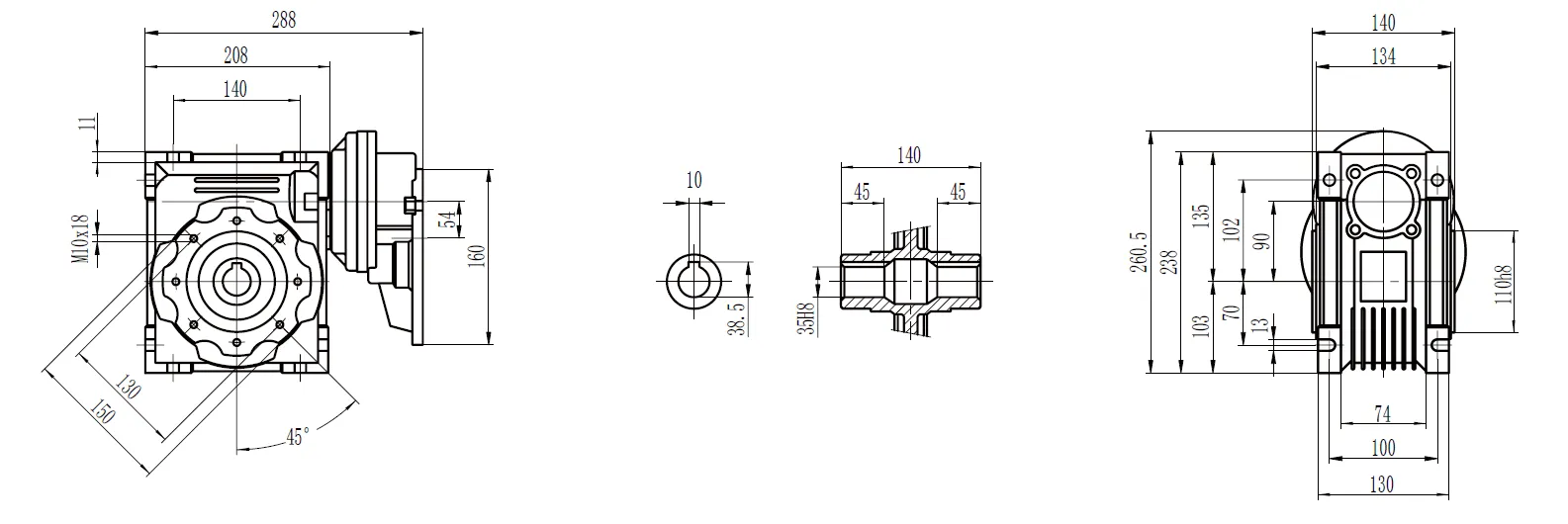

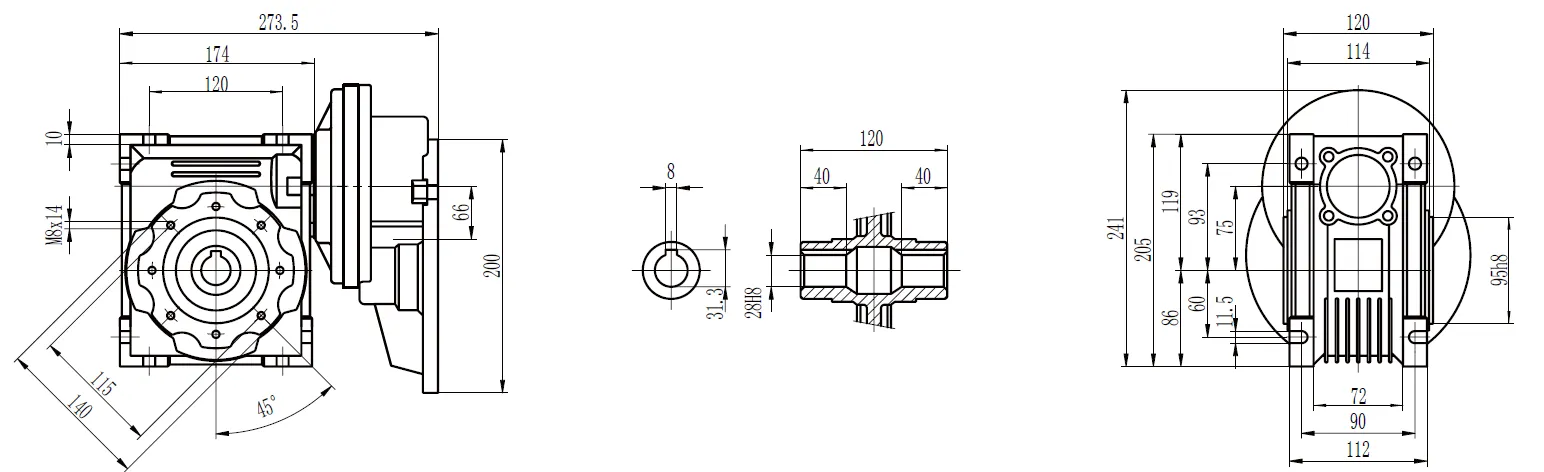

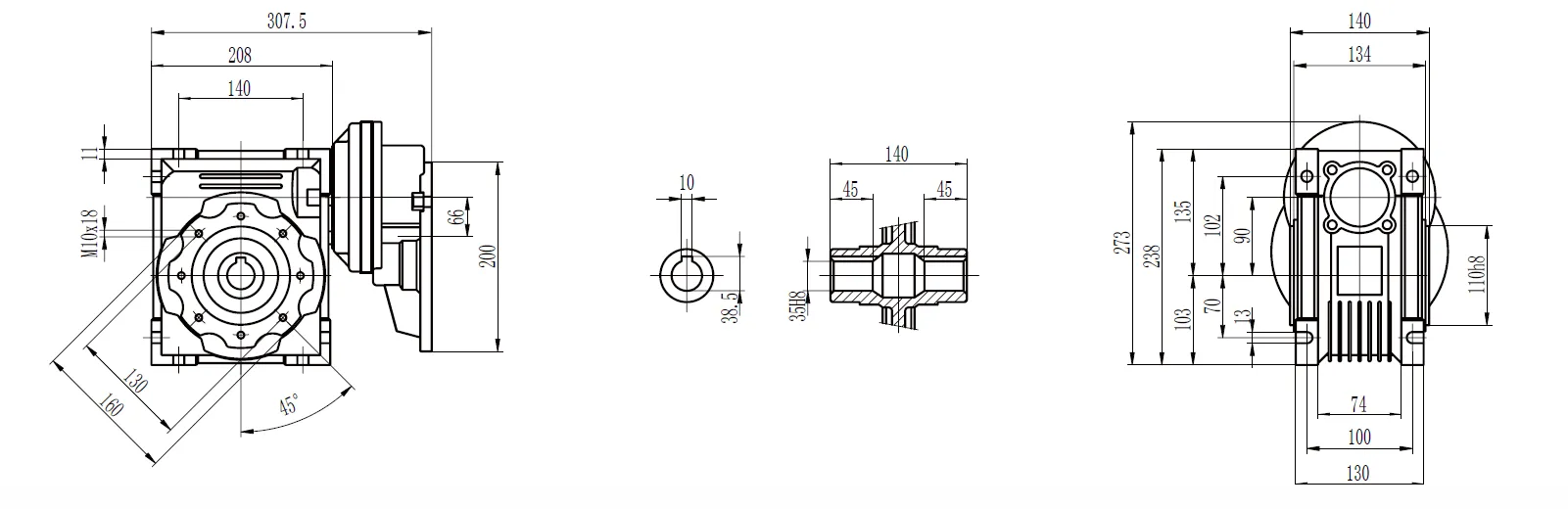

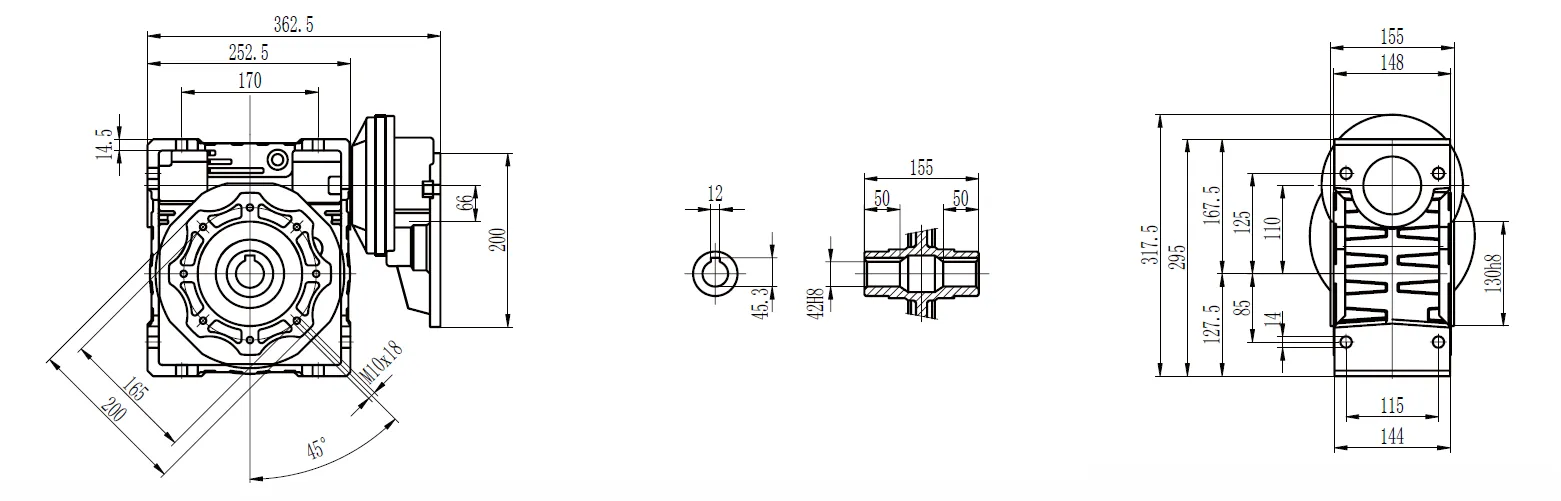

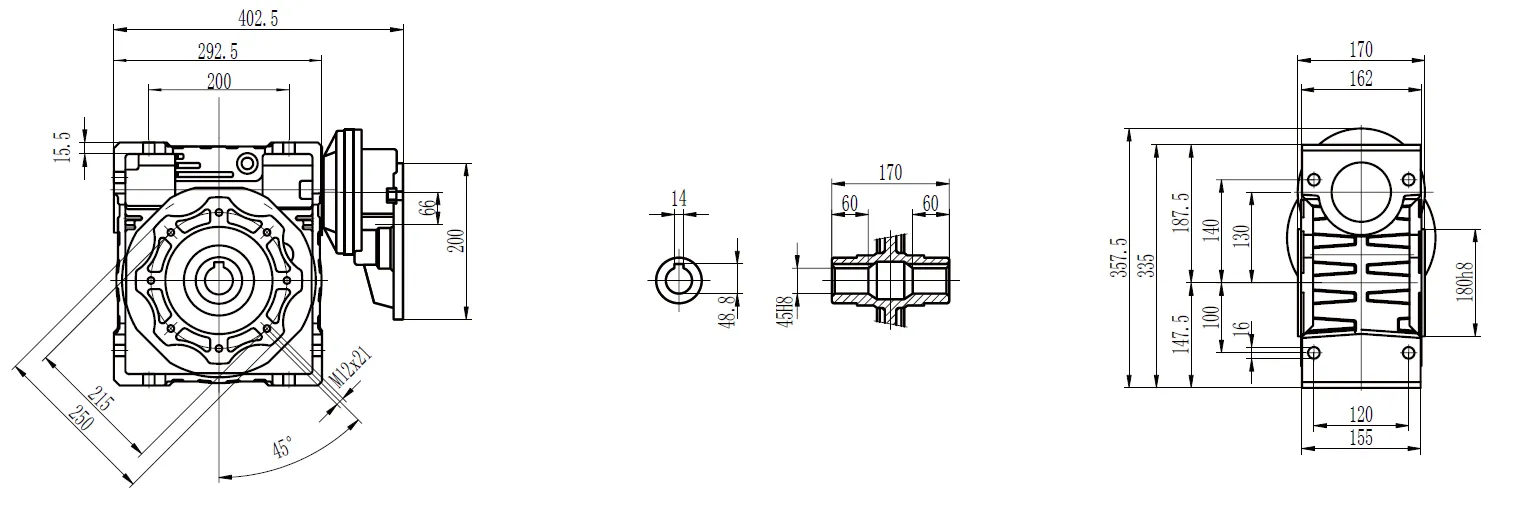

CMN-PC-NMRV Worm Gear Reducer Dimensions

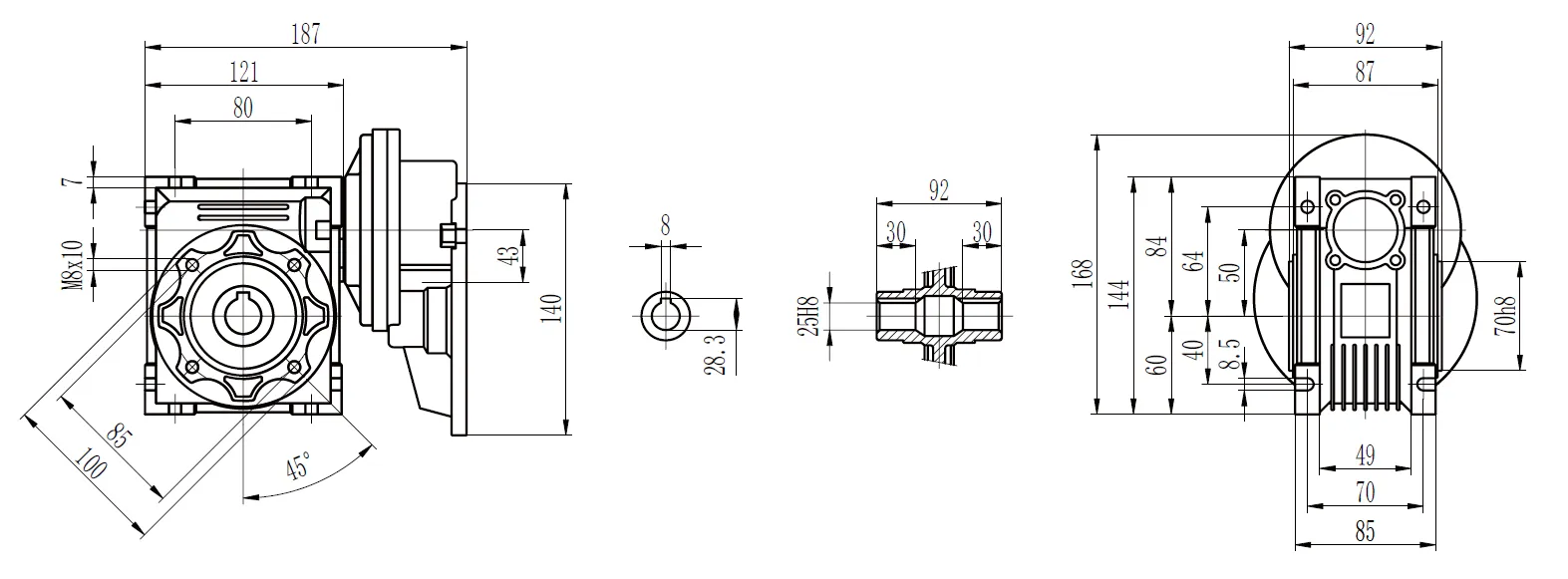

CMN-PC 063 - NMRV 040

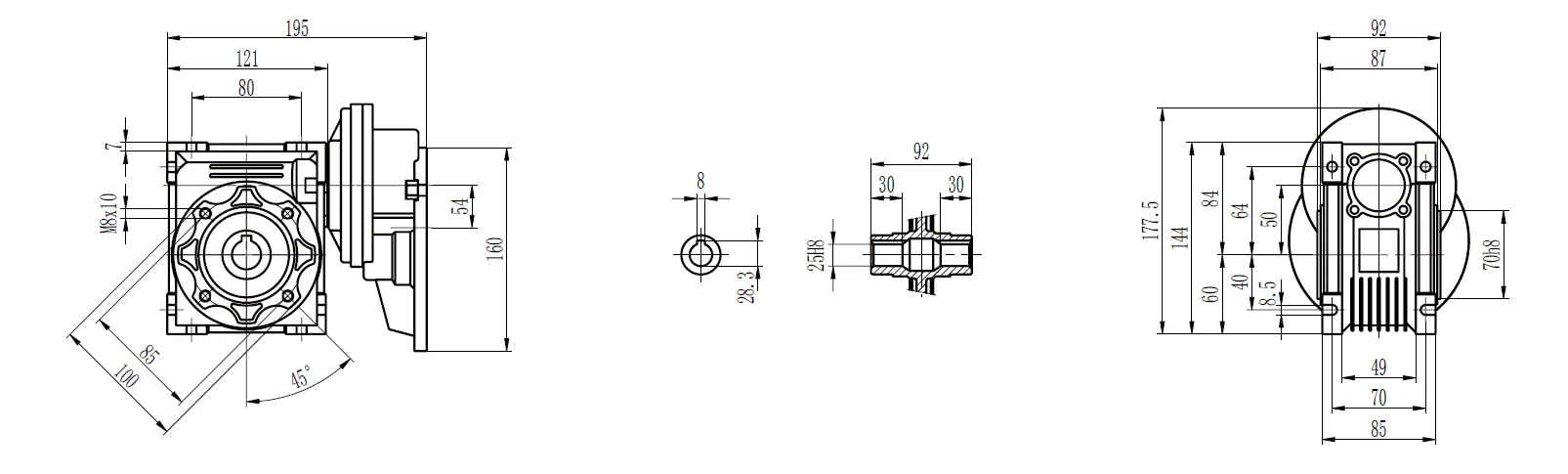

CMN-PC 063 - NMRV 050

CMN-PC 063 - NMRV 063

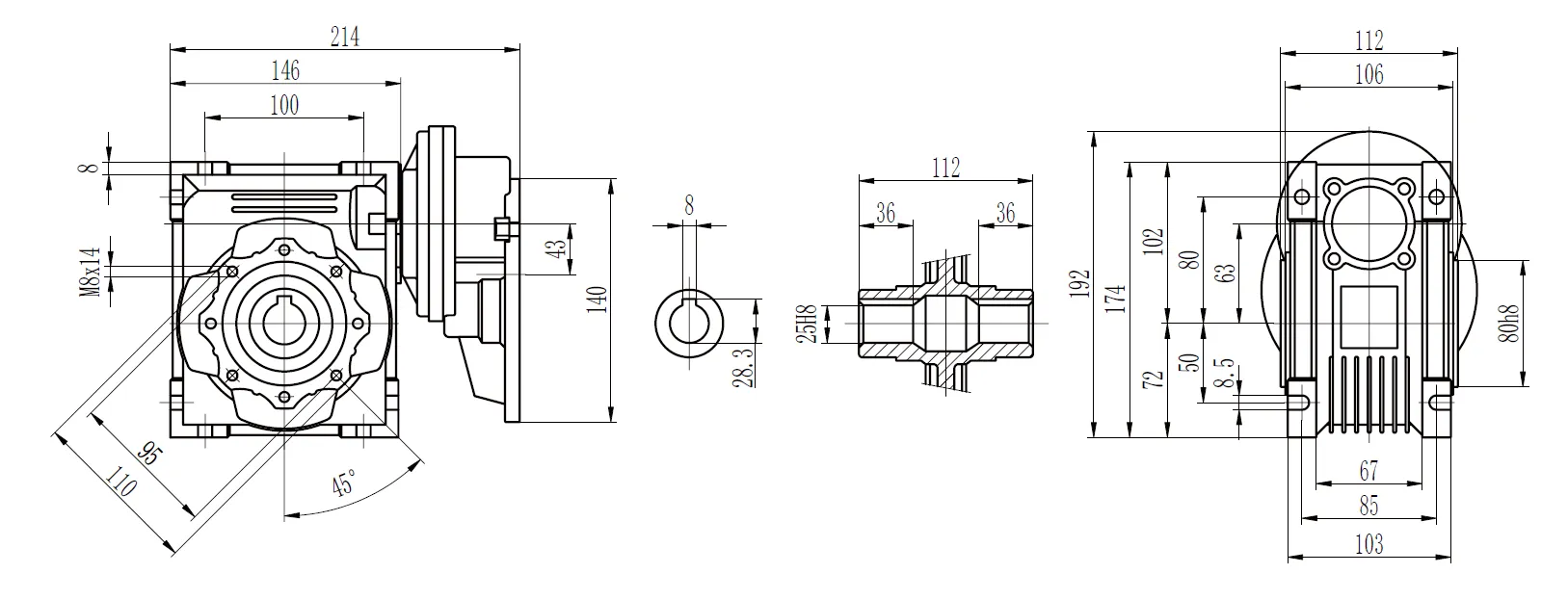

CMN-PC 071 - NMRV 050

CMN-PC 071 - NMRV 063

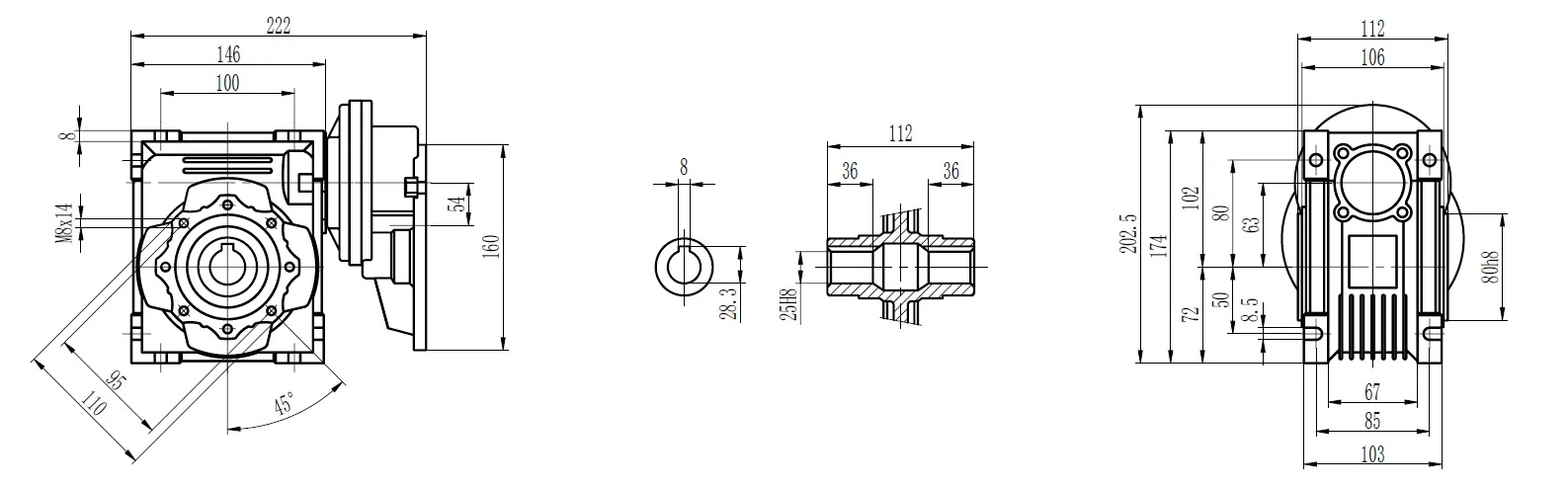

CMN-PC 071 - NMRV 075

CMN-PC 071 - NMRV 090

CMN-PC 080 - NMRV 075

CMN-PC 080 - NMRV 090

CMN-PC 080(090) - NMRV 110

CMN-PC 080(090) - NMRV 130

CMN-PC-NMRV Helical Worm Gearbox Features

1. Compact Design

The CMN-PC-NMRV helical worm gearbox is designed with a compact, space-saving structure that integrates the worm gear and worm shaft into a single unit. This streamlined design not only reduces the footprint of the gearbox but also improves its ease of installation and adaptability in tight spaces, making it ideal for applications with limited room.

2. Wide Gear Ratios

These worm drive gearboxes offer an extensive range of gear ratios, typically from 5:1 to over 100:1, enabling significant speed reduction capabilities. This flexibility allows them to cater to diverse operational requirements, making them suitable for both low-speed, high-torque applications and precision-driven systems.

3. Efficiency Levels

While worm gear reducers generally exhibit lower efficiency compared to other gearbox types, ranging between 50% and 90%, the specific efficiency depends on the model and operating conditions. The inclusion of the helical stage enhances overall efficiency, ensuring smoother operation and reducing energy losses in many applications.

4. Versatile Mounting Options

CMN-PC-NMRV worm reducer gearboxes are available with various mounting configurations to accommodate different application needs. Options include flange-mounted, foot-mounted, and shaft-mounted designs. This versatility ensures ease of integration into machinery and equipment across a wide range of industries and setups.

5. High-Quality Materials

The gears and internal components are made from premium materials such as hardened steel and bronze. These materials are chosen for their superior durability, wear resistance, and long service life, ensuring consistent performance even under heavy loads and demanding operating conditions.

6. Industrial Applications

CMN-PC-NMRV helical worm gearboxes are widely used in industrial applications that require compact, high-reduction-ratio gearboxes. Common uses include conveyors, material handling systems, packaging machinery, and other industrial equipment where precise speed control and torque multiplication are vital to operations.

CMN-PC-NMRV Worm Gear Reducer Applications

1. Conveyors and Material Handling Systems

CMN-PC-NMRV worm gear reducers are widely employed in conveyor systems for industries such as manufacturing and logistics. Their high torque output and compact design make them ideal for driving conveyor belts and handling heavy loads efficiently while maintaining precise speed control in continuous operations.

2. Packaging Machinery

These helical worm gear reducers play a crucial role in packaging machinery by ensuring smooth and precise movements during tasks such as sealing, wrapping, and filling. Their ability to achieve high reduction ratios supports the accurate control of speed and torque, essential for maintaining consistent packaging quality.

3. Automated Machinery and Robotics

CMN-PC-NMRV reducers are often used in automated systems and robotic applications. Their compact design and high torque capacity make them suitable for powering robotic arms and other automation components, ensuring reliable operation and precise positioning in high-performance environments.

4. Agricultural Equipment

In the agricultural sector, these worm gearboxes are used in equipment such as grain conveyors, seeders, and irrigation systems. Their durability and ability to operate under varying load conditions ensure long-lasting and efficient performance, even in demanding agricultural environments.

5. Textile and Printing Machinery

The worm drive gearboxes are commonly found in textile and printing machinery, where precise speed control is critical. They help drive components like rollers and spindles with accuracy, ensuring high-quality production in processes such as weaving, dyeing, and printing on various materials.

6. Industrial Mixers and Crushers

CMN-PC-NMRV worm gear reducers are ideal for heavy-duty applications like industrial mixers and crushers. Their high reduction ratios and torque output enable them to handle the demanding loads of mixing or crushing materials, ensuring smooth and consistent operation under challenging conditions.

|  |

|  |

Select a Right CMN-PC-NMRV Helical Worm Gearbox

1. Required Input Speed

Determine the input speed from the motor or power source to ensure compatibility with the gearbox. Different helical worm gearboxes are designed to handle specific input speed ranges. Selecting a gearbox that matches the input speed ensures optimal performance and prevents premature wear or failure.

2. Output Torque Requirements

Evaluate the torque output needed for the application to ensure the gearbox can handle the specified load. The required torque depends on the operational load, and choosing a gearbox with insufficient torque capacity may lead to performance issues or mechanical damage.

3. Mounting Configuration

Consider the mounting requirements of your system, such as flange-mounted, foot-mounted, or shaft-mounted configurations. The gearbox must fit seamlessly into the design of the equipment and work efficiently without requiring excessive modifications or additional components during installation.

4. Environmental Conditions

Analyze the operating environment, including temperature, humidity, and exposure to dust or chemicals. Gearboxes used in harsh conditions may require additional protection, coatings, or specific designs to ensure durability and continued performance in challenging environments.

5. Gearbox Materials

Choose a helical worm gear reducer made from materials that match the demands of the application. For heavy-duty or corrosive environments, gearboxes with hardened steel gears or corrosion-resistant alloys are ideal. High-quality materials ensure reliability, longevity, and resistance to wear or environmental damage.

6. Efficiency and Reduction Ratio

Select a worm gear drive gearbox with the appropriate reduction ratio and efficiency for the task. Applications requiring precise speed control or higher torque outputs may need a higher reduction ratio, while efficiency considerations are essential for energy savings and minimizing heat generation.

Additional information

| Edited by | Yjx |

|---|