CMN-NRV Worm Gear Reducers/Worm Gearbox

CMN-NRV is one of the RV series worm gearbox models. CMN-NMRV means flange input, and CMN-NRV means with shaft input. CMN-NRV worm gearbox is generally with a single input shaft, and there are also double input shaft forms, suitable for various transmission needs. The output forms include hollow hole output and flange output. Its internal transmission structure is composed of a worm and a worm gear, which has a compact structure, a large transmission ratio, and a self-locking function under certain conditions.

CMN-NRV is one of the RV series worm gearbox models. CMN-NMRV means flange input, and CMN-NRV means with shaft input. CMN-NRV worm gearbox is generally with a single input shaft, and there are also double input shaft forms, suitable for various transmission needs. The output forms include hollow hole output and flange output. Its internal transmission structure is composed of a worm and a worm gear, which has a compact structure, a large transmission ratio, and a self-locking function under certain conditions. CMN-NRV worm gear reducers manufactured by CMN own the advantages of smooth transmission and low noise.

CMN-NRV series worm gear reducer provides solutions with reduction ratios ranging from 5 to 1000, making them suitable for multiple industrial applications. They are available with different configurations, such as a single-stage gear with an IEC motor adaptor, a double-stage worm gear, and integrated helical/worm combinations. CMN-NRV worm drive gearboxes are versatile and widely used across industries, including material handling, industrial automation, machinery, food processing, renewable energy, mining, marine, and general industrial applications. They power conveyors, robotics, cranes, filling lines, renewable energy systems, and more, ensuring reliable performance, precise motion control, and high torque in diverse environments.

CMN-NRV Worm Gearbox Specifications

| Type | Worm Gear Speed Reducer / Worm Gearbox |

| CMN-NRV MODEL | CMN-NRV25, CMN-NRV30, CMN-NRV40, CMN-NRV50, CMN-NRV63, CMN-NRV75, CMN-NRV90, CMN-NRV110, CMN-NRV130 |

| Power | 0.12kw-15kw |

| Ratio | 1/7.5,1/10,1/15,1/20,1/15,1/30,1/40,1/50,1/60,1/80,1/100 |

| Color | Blue(RAL5010), Silver grey (RAL9022), or on request |

| Material | Housing/Flange: Aluminum Alloy |

| Worm Gear: Copper 9-4&nodular iron | |

| Worm:20CrMn Ti with carburizing and quenching, surface hardness is 56-62HRC | |

| Shaft: chromium steel-45# | |

| IEC Flange | IEC standard flange 56B14, 63B14, 63B5, 63B5, 71B14,80B14 AND SO ON |

| Lubricant | Synthetic & Mineral |

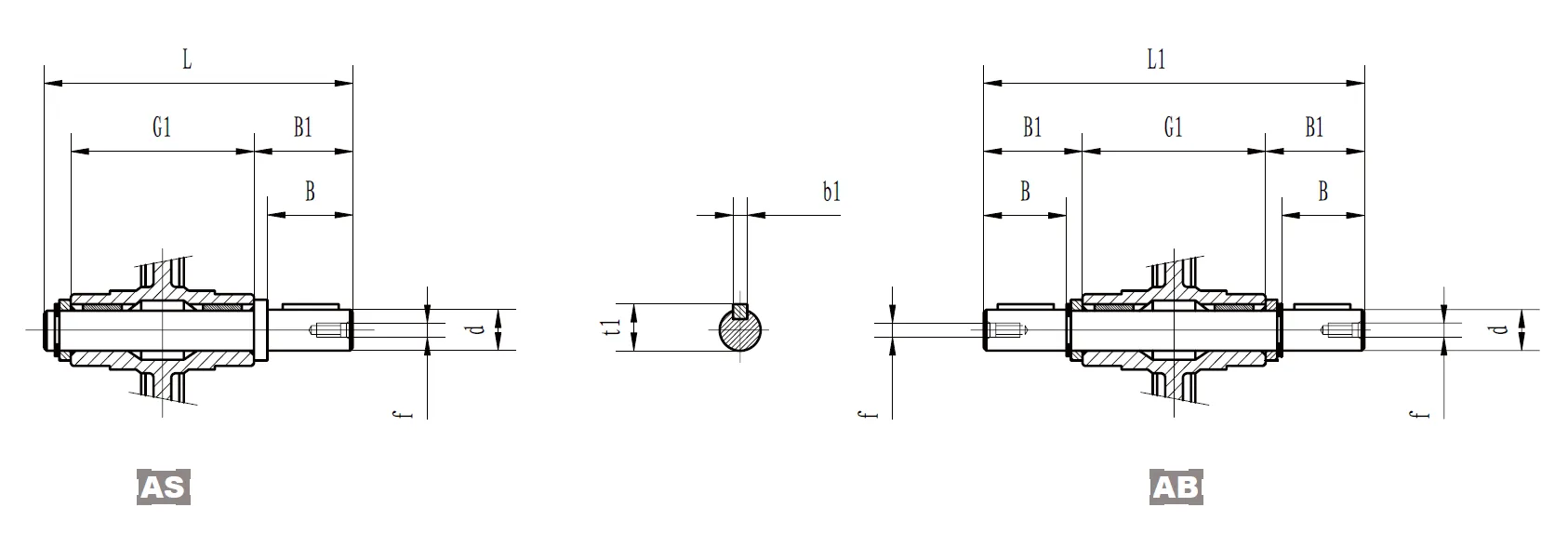

CMN-NRV Worm Gear Reducer Dimensions

| CMN-NRV | 025 | 030 | 040 | 050 | 063 | 075 | 090 | 110 | 130 |

| B | 20 | 20 | 23 | 30 | 40 | 50 | 50 | 60 | 80 |

| D1 | 9 j6 | 9 j6 | 11 j6 | 14 j6 | 19 j6 | 24 j6 | 24 j6 | 28 j6 | 30 j6 |

| G2 | 38 | 51 | 60 | 74 | 90 | 105 | 125 | 142 | 162 |

| G3 | 37 | 45 | 53 | 64 | 75 | 90 | 108 | 135 | 155 |

| I | 25 | 30 | 40 | 50 | 63 | 75 | 90 | 110 | 130 |

| b1 | 3 | 3 | 4 | 5 | 6 | 8 | 8 | 8 | 8 |

| f1 | - | - | - | M6 | M6 | M8 | M8 | M10 | M10 |

| t1 | 10.2 | 10.2 | 12.5 | 16 | 21.5 | 27 | 27 | 31 | 33 |

Low Speed Shaft Dimensions

| CMN-NRV | d | B | B1 | G1 | L | L1 | f | b1 | t1 |

| 025 | 11g6 (9) | 23 (25) | 25.5 (30) | 50 | 81 (85.5) | 101 | - | 4 (3) | 12.5 (10.2) |

| 030 | 14g6 | 30 | 32.5 | 63 | 102 | 128 | M6 | 5 | 16 |

| 040 | 18h6 | 40 | 43 | 78 | 128 | 164 | M6 | 6 | 20.5 |

| 050 | 25h6 | 50 | 53.5 | 92 | 153 | 199 | M10 | 8 | 28 |

| 063 | 25h6 | 50 | 53.5 | 112 | 173 | 219 | M10 | 8 | 28 |

| 075 | 28h6 | 60 | 63.5 | 120 | 192 | 247 | M10 | 8 | 31 |

| 090 | 35h6 | 80 | 84.5 | 140 | 234 | 309 | M12 | 10 | 38 |

| 110 | 42h6 | 80 | 84.5 | 155 | 249 | 324 | M16 | 12 | 45 |

| 130 | 45h6 | 80 | 85 | 170 | 265 | 340 | M16 | 14 | 48.5 |

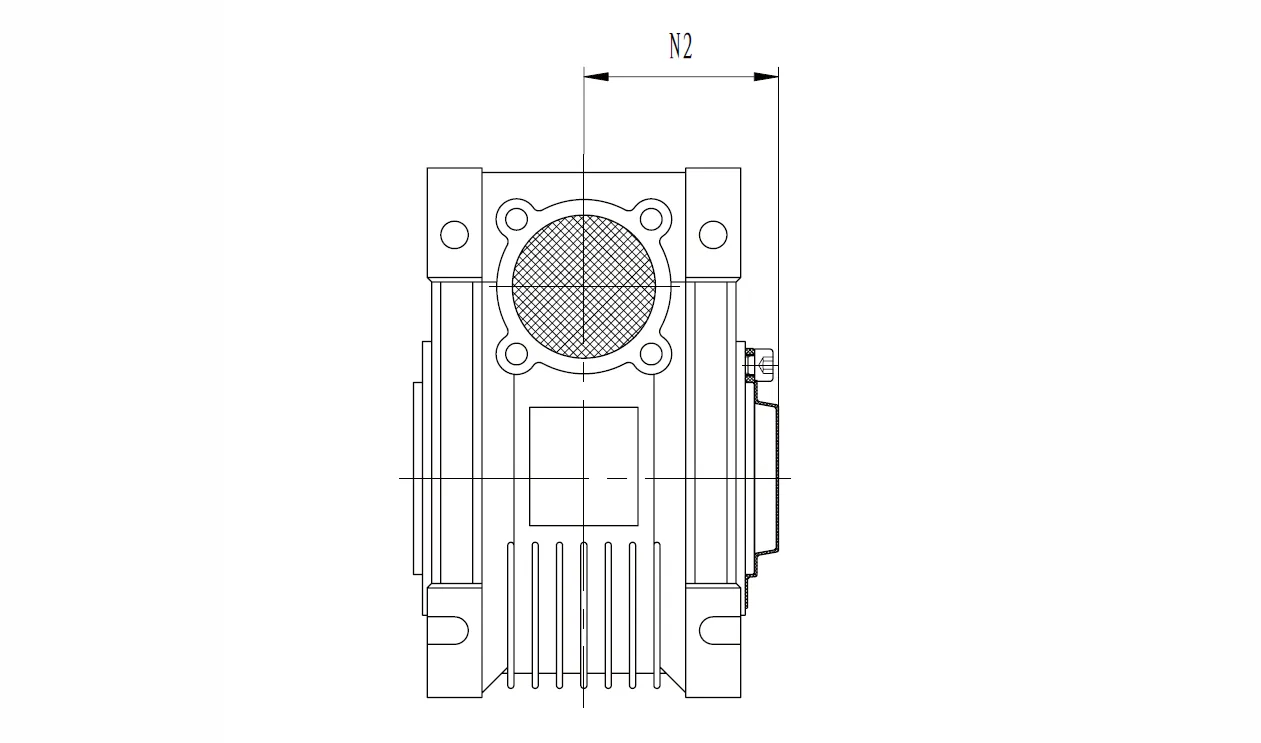

Protective Cover Dimensions

| CMN-NRV | N2 |

| 030 | 42 |

| 040 | 50 |

| 050 | 58 |

| 063 | 69 |

| 075 | 74 |

| 090 | 86 |

| 110 | 94 |

| 130 | 102 |

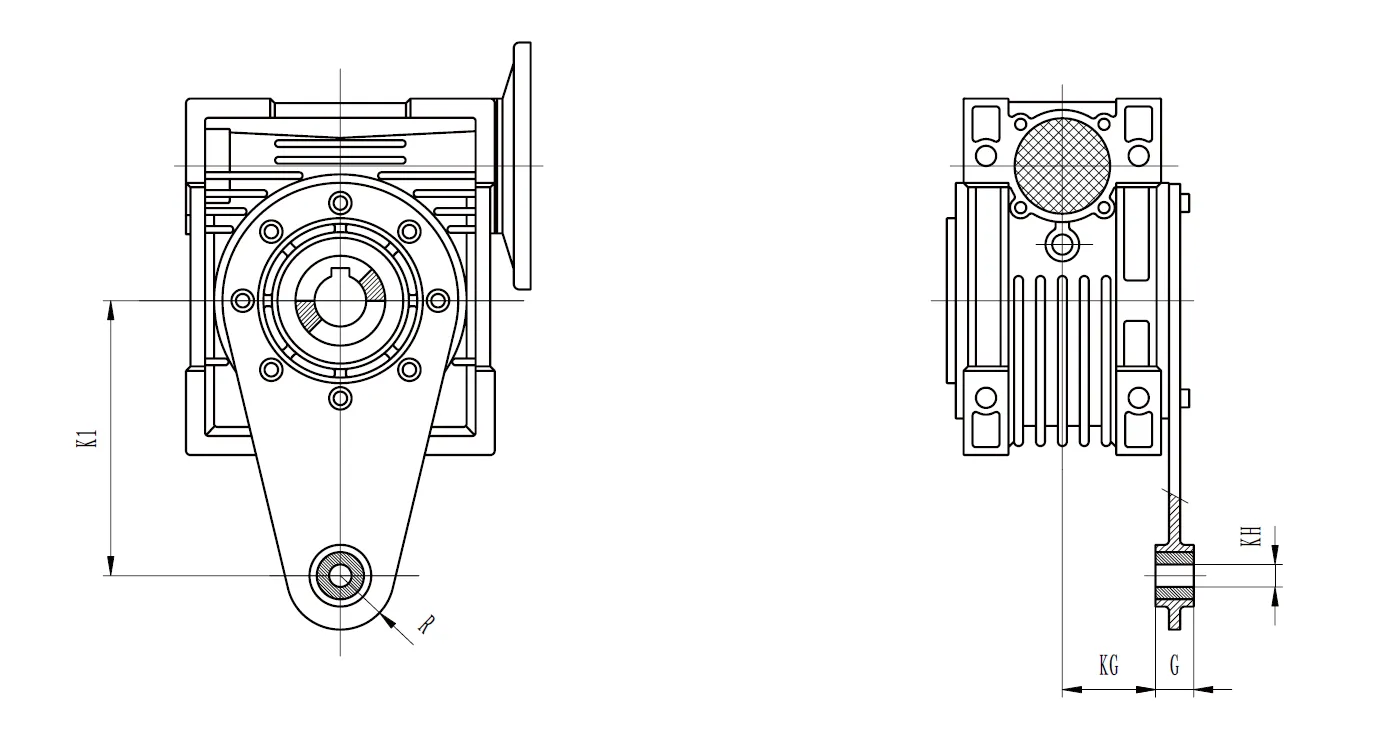

Torque Arm Dimensions

| CMN-NRV | K1 | G | KG | KH | R |

| 025 | 70 | 14 | 17.5 | 8 | 15 |

| 030 | 85 | 14 | 24 | 8 | 15 |

| 040 | 100 | 14 | 31.5 | 10 | 18 |

| 050 | 100 | 14 | 38.5 | 10 | 18 |

| 063 | 150 | 14 | 49 | 10 | 18 |

| 075 | 200 | 25 | 47.5 | 20 | 30 |

| 090 | 200 | 25 | 57.5 | 20 | 30 |

| 110 | 250 | 30 | 62 | 25 | 35 |

| 130 | 250 | 30 | 69 | 25 | 35 |

CMN-NRV Worm Drive Gearbox Parts

- Worm Shaft

The worm shaft is a helical screw-like component made of high-strength steel or alloy. It drives the worm gear by transmitting rotational motion. Its precision-machined surface ensures smooth interaction with the worm gear, minimizing friction and enhancing efficiency. - Worm Gear

The worm gear, typically made from bronze or brass, works in tandem with the worm shaft. Its high wear resistance and compatibility with the worm shaft ensure durability. The gear's teeth are designed for precise engagement, enabling smooth power transmission. - Housing

The gearbox housing, usually made from cast iron or aluminum alloy, encases and protects all internal components. It provides structural stability, dissipates heat effectively, and ensures the gearbox operates with reduced vibration and low noise levels. - Input Shaft

The input shaft connects the power source to the worm gear mechanism. It is engineered for high torque and speed, ensuring seamless power transfer. The input shaft design can vary, including single or double configurations depending on application needs. - Output Shaft

The output shaft delivers the reduced speed and increased torque to the machinery. It is robustly constructed to bear heavy loads. Hollow or solid designs are available, offering flexibility to accommodate different industrial applications. - Bearings

High-quality bearings support the worm shaft and worm gear, ensuring smooth rotation and reducing friction. These components play a critical role in enhancing the gearbox's longevity by handling radial and axial loads efficiently. - Oil Seals

Oil seals are essential for retaining the lubrication inside the gearbox while preventing contaminants like dust or moisture from entering. They ensure the internal components remain well-lubricated, reducing wear and improving the gearbox's overall lifespan.

CMN-NRV Worm Gear Reducer Applications

- Material Handling Equipment

CMN-NRV worm gear reducers are widely used in conveyors, hoists, and lifts within material handling systems. Their high torque output and self-locking feature ensure safe and precise movement of heavy loads, providing reliable performance in warehouses, factories, and logistics centers. - Industrial Automation

These worm drive gearboxes play a crucial role in automation systems such as robotic arms and automated assembly lines. Their ability to provide accurate motion control and compact design helps optimize space and ensures precise, efficient, and repeatable operations in high-demand industrial environments. - Food Processing Machinery

In food processing applications, CMN-NRV worm gear speed reducers are used in mixers, filling lines, and packaging machines. Their smooth and quiet operation, combined with durable and hygienic materials, ensures compliance with strict industry standards while maintaining efficiency in continuous production processes. - Renewable Energy Systems

CMN-NRV worm gear reducers are essential in renewable energy applications like solar tracking systems and small wind turbines. Their ability to handle varying loads, provide high reduction ratios, and operate reliably under different environmental conditions makes them ideal for sustainable energy solutions. - Mining and Heavy Machinery

In mining operations, these worm reducer gearboxes are applied in crushers, conveyors, and drilling equipment. Their robust construction, high torque capacity, and resistance to harsh conditions ensure durability and consistent performance in demanding environments, improving operational efficiency and reducing downtime. - Marine Applications

CMN-NRV worm wheel gearboxes are used in winches, anchor systems, and propulsion systems for marine vessels. Their corrosion-resistant design, ability to handle heavy loads, and reliable self-locking mechanism make them suitable for the challenging conditions of marine environments.

|  |

| Worm Gearbox for Material Handling Equipment | Worm Gearbox for Automotive Steering Systems |

|  |

| Worm Gearbox for Marine and Boating | Worm Gearbox for Mining and Construction |

CMN-NRV Worm Reducer Gearbox Maintenance

- Regular Inspection of Lubrication Levels

Consistently monitor the lubrication levels within the worm gear drive gearbox to ensure smooth operation of the worm and wheel. Lack of proper lubrication can lead to excessive friction, overheating, and accelerated wear of internal components, potentially causing gear misalignment or complete mechanical failure. - Check for Unusual Noise and Vibrations

Regularly listen for abnormal noise or vibrations during gearbox operation. These can indicate misaligned gears or worn bearings. Addressing such issues early prevents further internal damage and ensures the longevity of the CMN-NRV worm reducer gearbox. - Clean External Surfaces and Vents

Keep the gearbox's external surfaces and air vents clean to prevent overheating. Accumulated dirt or debris can obstruct ventilation, reducing the cooling efficiency and potentially causing thermal damage to internal components, which may lead to operational inefficiencies. - Inspect Seals and Gaskets for Leakage

Periodically examine seals and gaskets for any signs of oil leakage. Damaged or worn seals can allow contaminants to enter and compromise the worm gear reducer gearbox's internal components. Promptly replacing faulty seals prevents costly repairs and maintains operational efficiency. - Monitor Gear Wear and Alignment

Conduct regular visual inspections and measurements to assess gear wear and alignment. Excessive wear or misalignment can lead to reduced torque transmission and increased energy consumption. Ensuring proper alignment extends the gearbox's lifespan and maintains system performance. - Tighten Bolts and Fasteners Regularly

Periodically check and tighten all bolts and fasteners to ensure structural integrity. Vibrations during operation can loosen components over time, leading to instability, misalignment, or even structural failure. A secure assembly ensures reliable performance and safety.

Additional information

| Edited by | Yjx |

|---|