CMN-NRV-VS Worm Gear Reducers/Worm Gearbox

The CMN-NRV-VS worm gear reducer with double input extension shaft, also known as a worm gearbox, is a highly specialized mechanical device used for power transmission and speed reduction in various industrial applications. It employs a worm gear mechanism, which consists of a worm (a screw-like component) and a worm wheel (a helical gear), to achieve high torque output while reducing rotational speed. Its distinctive feature is the double input extension shaft, which allows it to accept power from two separate input sources, enhancing operational flexibility and versatility.

The CMN-NRV-VS worm gear reducer with double input extension shaft, also known as a worm gearbox, is a highly specialized mechanical device used for power transmission and speed reduction in various industrial applications. It employs a worm gear mechanism, which consists of a worm (a screw-like component) and a worm wheel (a helical gear), to achieve high torque output while reducing rotational speed. Its distinctive feature is the double input extension shaft, which allows it to accept power from two separate input sources, enhancing operational flexibility and versatility.

This type of worm drive gearbox is widely used in machinery requiring precise motion control, such as conveyors, lifts, mixers, and packaging systems. It offers advantages like compact design, high load-carrying capacity, and self-locking properties, which prevent back-driving under load. Additionally, the CMN-NRV-VS model worm reducer gearbox is known for its robust construction, efficient performance, and ability to handle high torque with minimal noise. Its adaptability to various mounting positions and compatibility with multiple input configurations make it a preferred choice in industries like manufacturing, automotive, and agriculture.

CMN-NRV-VS Worm Gearbox Specifications

| Product Name: | RV Series Worm Gear Reducer |

| Brand: | CMN |

| Model: | CMN-NRV-VS 025,030,040,050,063,075,090,110,130,150 |

| Input Configurations: | Solid Shaft Input, |

| Worm Shaft Tail Extension Input | |

| Output Configurations: | Keyed Hollow Shaft Output, |

| Hollow Shaft with Output Flange, | |

| Plug-in Solid Shaft Output | |

| Ratio: | 1:7.5,10,15,20,25,30,40,50,60,80,100 |

| Input Power: | 0.12kw,0.18kw,0.25kw,0.37kw,0.55kw,0.75kw,1.1kw,1.5kw,2.2kw,4kw,5.5kw,7.5kw,… |

| Color: | Blue/Black/Silver or On Customer Request |

| Material: | Housing: Die-Cast Iron cast |

| Worm Gear-Tin Copper | |

| Worm Shaft: 20CrMn Ti with carburizing and quenching | |

| Out Shaft-chromium steel-45# | |

| Bearing: | C&U/QC or upon customer request |

| Seal: | SKF/NAK or upon customer request, |

| Lubricant: | Synthetic/Mineral |

| IEC Flange: | 56B14, 63B14, 63B5, 63B5, 71B14,80B14, etc |

CMN-NRV-VS Worm Gear Reducer Dimensions

| CMN-NRV-VS | 025 | 030 | 040 | 050 | 063 | 075 | 090 | 110 | 130 |

| B | 20 | 20 | 23 | 30 | 40 | 50 | 50 | 60 | 80 |

| D1 | 9 j6 | 9 j6 | 11 j6 | 14 j6 | 19 j6 | 24 j6 | 24 j6 | 28 j6 | 30 j6 |

| G2 | 38 | 51 | 60 | 74 | 90 | 105 | 125 | 142 | 162 |

| G3 | 37 | 45 | 53 | 64 | 75 | 90 | 108 | 135 | 155 |

| I | 25 | 30 | 40 | 50 | 63 | 75 | 90 | 110 | 130 |

| b1 | 3 | 3 | 4 | 5 | 6 | 8 | 8 | 8 | 8 |

| f1 | - | - | - | M6 | M6 | M8 | M8 | M10 | M10 |

| t1 | 10.2 | 10.2 | 12.5 | 16 | 21.5 | 27 | 27 | 31 | 33 |

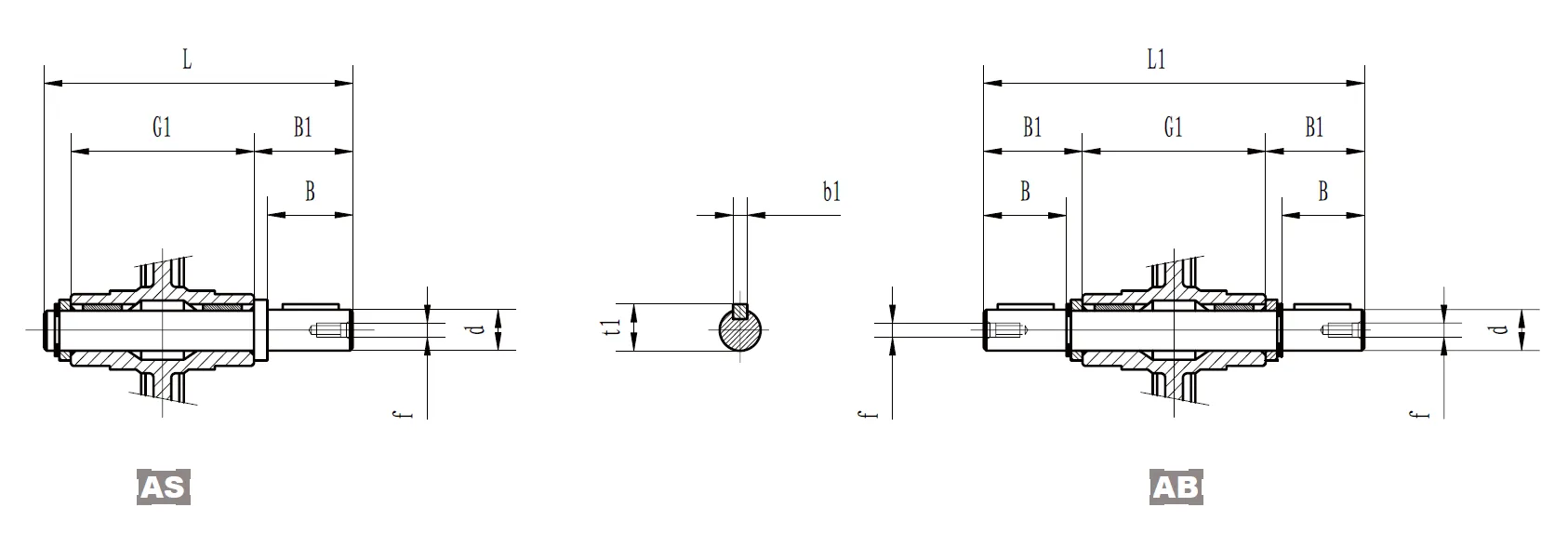

Low Speed Shaft Dimensions

| CMN-NRV-VS | d | B | B1 | G1 | L | L1 | f | b1 | t1 |

| 025 | 11g6 (9) | 23 (25) | 25.5 (30) | 50 | 81 (85.5) | 101 | - | 4 (3) | 12.5 (10.2) |

| 030 | 14g6 | 30 | 32.5 | 63 | 102 | 128 | M6 | 5 | 16 |

| 040 | 18h6 | 40 | 43 | 78 | 128 | 164 | M6 | 6 | 20.5 |

| 050 | 25h6 | 50 | 53.5 | 92 | 153 | 199 | M10 | 8 | 28 |

| 063 | 25h6 | 50 | 53.5 | 112 | 173 | 219 | M10 | 8 | 28 |

| 075 | 28h6 | 60 | 63.5 | 120 | 192 | 247 | M10 | 8 | 31 |

| 090 | 35h6 | 80 | 84.5 | 140 | 234 | 309 | M12 | 10 | 38 |

| 110 | 42h6 | 80 | 84.5 | 155 | 249 | 324 | M16 | 12 | 45 |

| 130 | 45h6 | 80 | 85 | 170 | 265 | 340 | M16 | 14 | 48.5 |

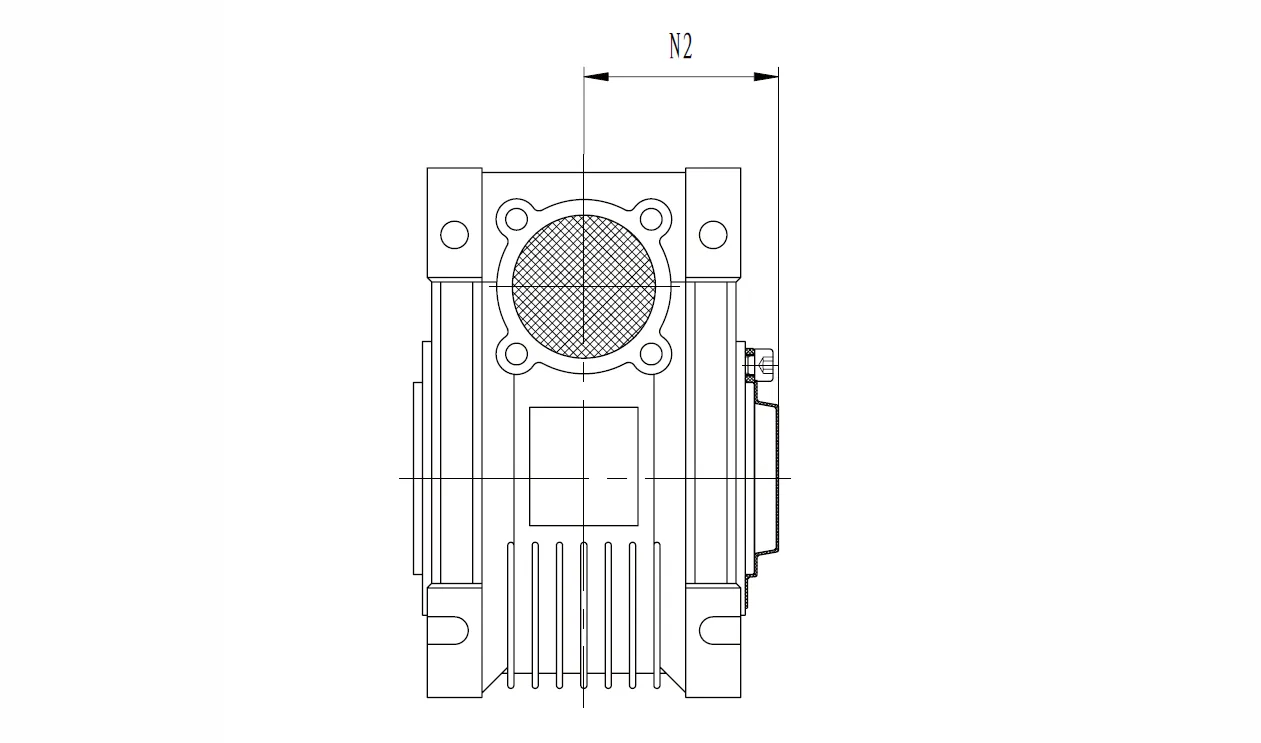

Protective Cover Dimensions

| CMN-NRV-VS | N2 |

| 030 | 42 |

| 040 | 50 |

| 050 | 58 |

| 063 | 69 |

| 075 | 74 |

| 090 | 86 |

| 110 | 94 |

| 130 | 102 |

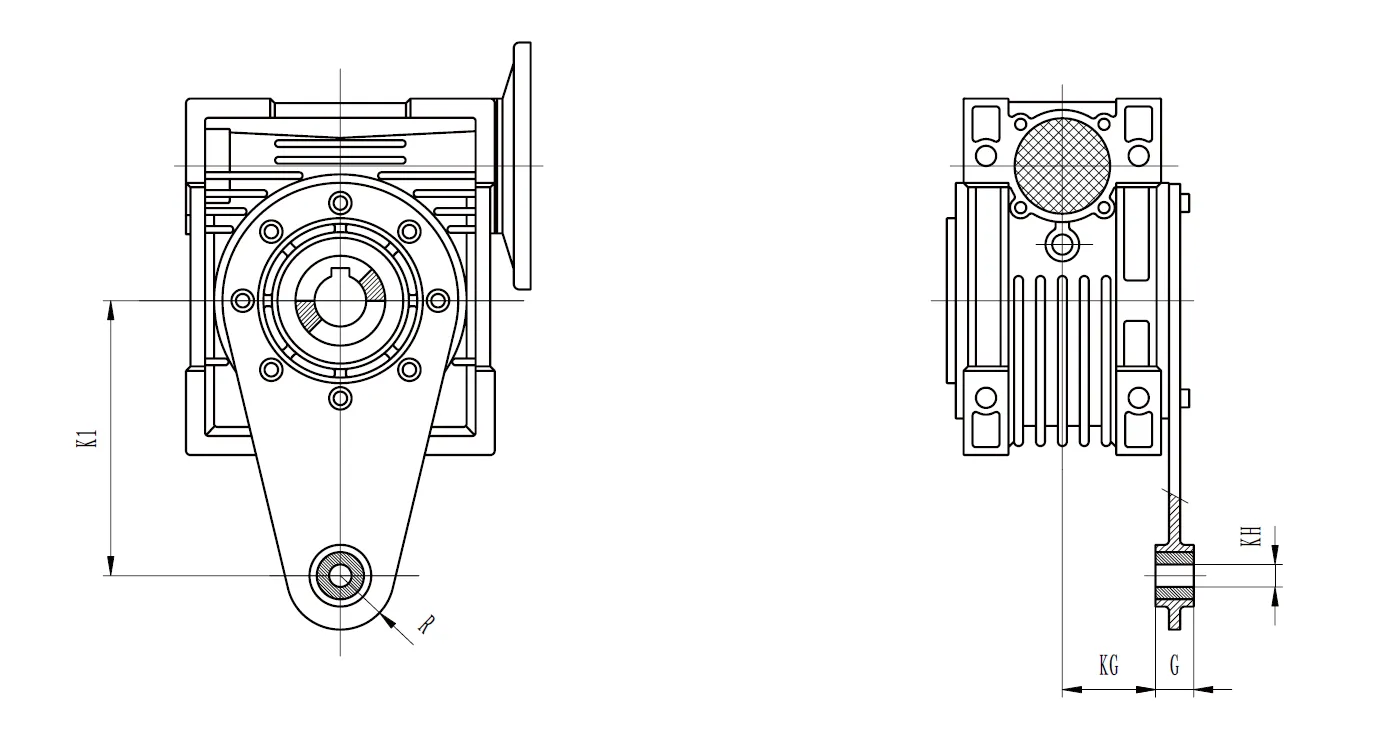

Torque Arm Dimensions

| CMN-NRV-VS | K1 | G | KG | KH | R |

| 025 | 70 | 14 | 17.5 | 8 | 15 |

| 030 | 85 | 14 | 24 | 8 | 15 |

| 040 | 100 | 14 | 31.5 | 10 | 18 |

| 050 | 100 | 14 | 38.5 | 10 | 18 |

| 063 | 150 | 14 | 49 | 10 | 18 |

| 075 | 200 | 25 | 47.5 | 20 | 30 |

| 090 | 200 | 25 | 57.5 | 20 | 30 |

| 110 | 250 | 30 | 62 | 25 | 35 |

| 130 | 250 | 30 | 69 | 25 | 35 |

CMN-NRV-VS Worm Gear Reducer with Double Extension Shaft

- Dual Input Shaft Design

The CMN-NRV-VS worm gear reducer features a double input extension shaft, allowing connection to motors or drive systems on either side. This enhances installation flexibility, making it adaptable for various industrial applications requiring bidirectional input, such as conveyor systems or automation setups. - High Reduction Ratios

This worm drive gearbox offers a wide range of reduction ratios, typically from 5:1 to 100:1, enabling precise speed control and high torque output. It is ideal for applications requiring low-speed, high-torque performance, such as material handling equipment or heavy-duty machinery in industrial environments. - Durable Aluminum Alloy Housing

Constructed with high-quality aluminum alloy, the reducer ensures lightweight yet robust performance. The housing provides excellent corrosion resistance and efficient heat dissipation, extending the worm reducer gearbox’s lifespan in harsh environments like food processing, chemical plants, or outdoor industrial applications. - Maintenance-Free Operation

The CMN-NRV-VS worm gear speed reducer is hermetically sealed, preventing lubricant leakage and contamination. Its self-lubricating design eliminates the need for regular maintenance, reducing downtime and operational costs. This makes it suitable for continuous-use applications like robotics or automated production lines requiring reliable performance. - Low Noise and Vibration

Engineered for smooth and quiet operation, the worm gear reducer minimizes noise and vibration during use. This feature is critical for precision-driven industries, such as packaging or textile manufacturing, where stable, low-noise performance enhances workplace safety and equipment longevity. - Universal Mounting Flexibility

The worm drive reduction gearbox supports multiple mounting positions, allowing easy integration into diverse machinery layouts. Its compact design ensures space efficiency, making it ideal for applications with limited installation space, such as small-scale automation systems or compact conveyor setups in industrial facilities.

Double Input Shaft Worm Gearbox Applications

- Conveyor Systems in Material Handling

Double input shaft worm gearboxes are extensively used in conveyor systems for material handling in industries like manufacturing, logistics, and warehousing. Their high torque output and compact design ensure smooth, efficient operation while maintaining precise speed control for consistent material flow. - Mixing and Agitation Equipment

In industries such as food processing, chemicals, and pharmaceuticals, these worm gear gearboxes are critical for powering mixing and agitation equipment. The dual input capability allows integration with multiple power sources, ensuring continuous operation and precise control of mixing speeds for uniform results. - Lifting Mechanisms in Hoists and Cranes

These worm wheel gearboxes are used in hoists, cranes, and lifting equipment, providing the torque needed to lift heavy loads safely. The self-locking feature prevents reverse motion under load, enhancing safety and reliability in heavy-duty lifting applications across various industries. - Automated Packaging Machinery

Double input shaft worm gearboxes are ideal for automated packaging machines, where precise and synchronized motion is essential. They allow multiple input configurations, enabling seamless integration into complex systems for tasks like filling, sealing, cutting, and labeling with high accuracy and efficiency. - Agricultural Equipment and Machinery

These worm gear reducer gearboxes are widely used in agricultural machinery like seeders, harvesters, and irrigation systems. Their ability to handle high torque and dual power inputs ensures reliable performance in demanding conditions, improving productivity in farming operations while minimizing equipment downtime. - Robotics and Automated Assembly Lines

In robotics and automated assembly lines, these worm reduction gearboxes provide precise motion control and torque transmission. Their compact design and dual input feature allow integration into robotic arms and other automated systems, ensuring smooth operation and accurate movement in high-precision tasks.

CMN-NRV-VS Worm Drive Gearbox Maintenance

- Regular Lubrication for Optimal Performance

Ensure the worm gear gearbox is consistently lubricated with the recommended grade of oil to minimize friction and wear. Regularly check oil levels and replace the lubricant at prescribed intervals to maintain efficient operation and prevent internal damage caused by inadequate lubrication. - Inspect for Wear and Tear on Gears

Periodically examine the worm and worm wheel for signs of wear, pitting, or damage. Timely detection of worn-out components allows for early replacement, preventing further damage and ensuring the gearbox continues to deliver reliable performance under load. - Monitor Operating Temperature to Avoid Overheating

Continuously monitor the operating temperature during use, as overheating can indicate lubrication issues or overloading. Address any abnormal temperature rises immediately by checking for proper lubrication, load limits, or potential faults in the gearbox system. - Check for Loose Bolts and Connections

Regularly inspect the worm gear drive gearbox housing and mounting bolts for looseness or misalignment. Tighten any loose fasteners to avoid vibrations or misalignment issues, which could lead to operational inefficiency or mechanical failure over time. - Clean the Gearbox to Prevent Contamination

Keep the worm reducer gearbox clean and free from dirt, dust, or debris that could enter the system and contaminate the lubricant. Proper cleaning prevents abrasive particles from damaging internal components, ensuring long-lasting and smooth operation. - Conduct Routine Alignment Checks

Ensure the worm drive gearbox shaft alignment is correct to prevent undue stress on the components. Misalignment can lead to vibration, excessive wear, and reduced efficiency. Routine alignment checks will help maintain the longevity and optimal functioning of the gearbox system.

Additional information

| Edited by | Yjx |

|---|