CMN-NRV-NMRV Worm Gear Reducers/Worm Gearbox

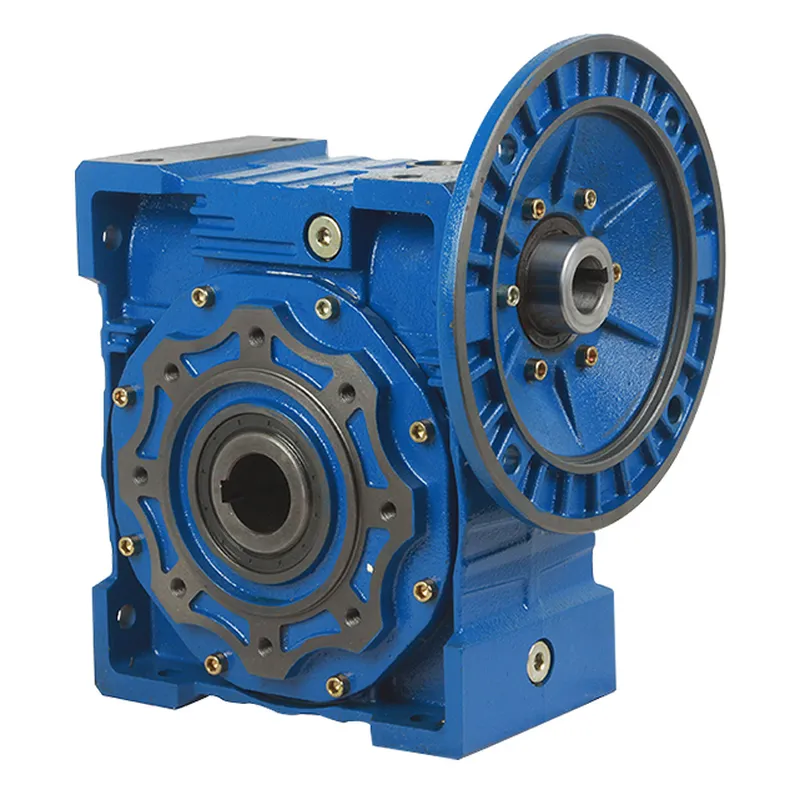

CMN-NRV-NMRV worm gear reducers, also known as worm gearboxes, are compact and highly efficient mechanical devices used to transmit power and reduce speed in various industrial applications. They are designed based on a worm and worm wheel mechanism, where the worm (a screw-like component) meshes with a worm wheel (a toothed gear). This design offers significant torque multiplication while achieving substantial speed reduction in a single stage.

CMN-NRV-NMRV worm gear reducers, also known as worm gearboxes, are compact and highly efficient mechanical devices used to transmit power and reduce speed in various industrial applications. They are designed based on a worm and worm wheel mechanism, where the worm (a screw-like component) meshes with a worm wheel (a toothed gear). This design offers significant torque multiplication while achieving substantial speed reduction in a single stage.

The CMN-NRV-NMRV series worm gearbox is particularly valued for its versatility, durability, and smooth operation. Made from high-quality materials like aluminum or cast iron, these gearboxes are lightweight, corrosion-resistant, and suitable for harsh environments. They are available in various configurations, including flange-mounted or foot-mounted designs, and can be paired with electric motors for optimal performance. Common applications include conveyor systems, packaging machines, and automation equipment.

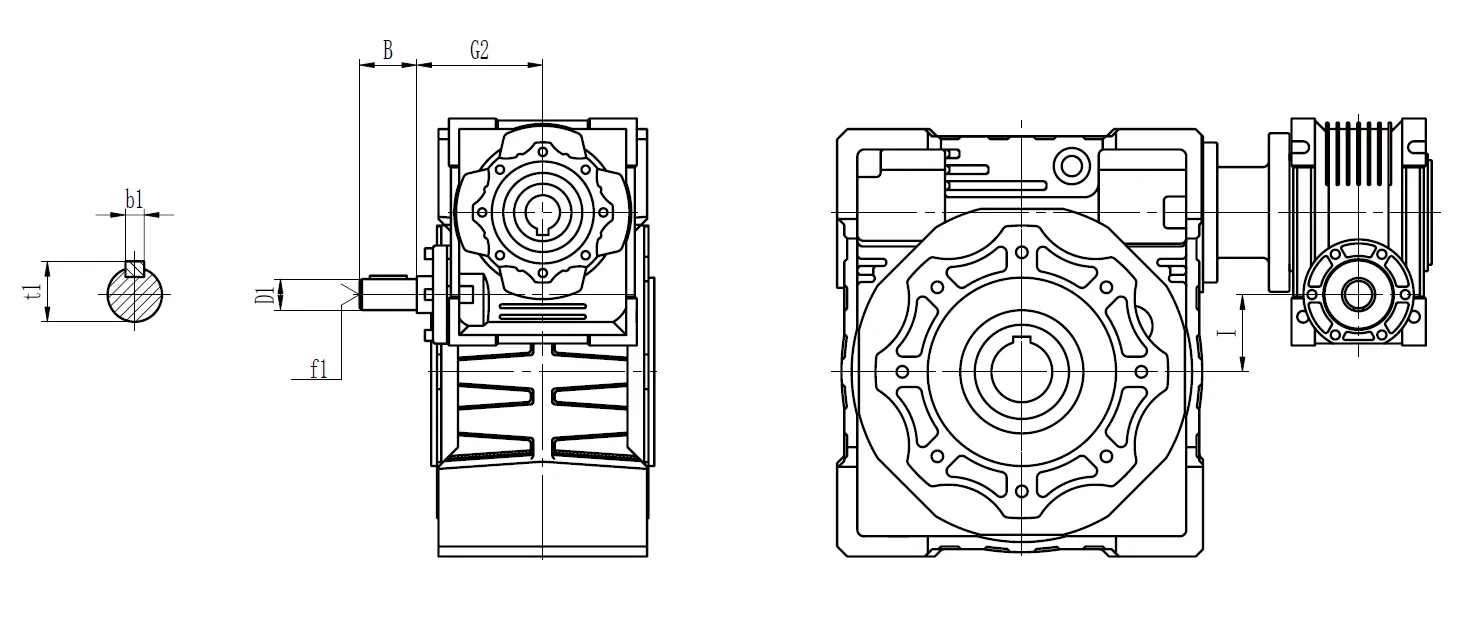

CMN-NRV-NMRV Worm Gearbox Dimensions

| CMN-NRV-NMRV | 030-040 | 030-050 | 030-063 | 040-075 | 040-090 | 050-110 | 063-130 |

| B | 20 | 20 | 20 | 23 | 23 | 30 | 40 |

| D1 | 9 j6 | 9 j6 | 9 j6 | 11 j6 | 11 j6 | 14 j6 | 19 j6 |

| G2 | 51 | 51 | 51 | 60 | 60 | 74 | 90 |

| I | 10 | 20 | 33 | 35 | 50 | 50 | 67 |

| b1 | 3 | 3 | 3 | 4 | 4 | 5 | 6 |

| f1 | - | - | - | - | - | M6 | M6 |

| t1 | 10.2 | 10.2 | 10.2 | 12.5 | 12.5 | 16 | 21.5 |

CMN-NRV-NMRV Worm Gear Reducer Benefits

- Compact and Lightweight Design

CMN-NRV-NMRV worm gear reducers are designed with a compact structure, making them ideal for applications where space is limited. Their lightweight construction, often made from aluminum or cast iron, ensures easy installation and reduces the load on connected components. - High Torque Transmission

These worm drive gearboxes are capable of delivering high torque output relative to their size. The worm and worm wheel mechanism enables efficient torque multiplication, making them suitable for heavy-duty applications that require consistent and reliable power transmission. - Reduced Noise and Smooth Operation

The design of the CMN-NRV-NMRV worm gear speed reducers minimizes vibration and noise during operation. This makes them an excellent choice for environments where quiet and smooth functionality is essential, such as automation systems and packaging machines. - Corrosion Resistance and Durability

Constructed from corrosion-resistant materials, such as aluminum or coated cast iron, these worm reducer gearboxes can withstand harsh operating conditions. They are suitable for use in environments exposed to moisture, chemicals, or extreme temperatures, ensuring long-term durability. - Versatile Mounting Options

CMN-NRV-NMRV worm gearboxes offer flexibility in installation with various mounting configurations, such as flange-mounted or foot-mounted designs. This adaptability allows them to be easily integrated into a wide range of machinery and equipment designs. - High Efficiency and Low Maintenance

These worm reduction gearboxes are engineered for high efficiency in power transmission, minimizing energy losses during operation. Their robust design and reliable components require minimal maintenance, reducing downtime and costs associated with repairs or replacements over their lifespan.

CMN-NRV-NMRV Worm Drive Gearbox Applications

- Conveyor Systems

CMN-NRV-NMRV worm drive gearboxes are widely used in conveyor systems to ensure smooth and controlled movement of materials. Their ability to provide consistent torque and speed reduction makes them ideal for industries like manufacturing, logistics, and packaging, where precision is crucial. - Packaging Machines

These worm gearboxes are crucial in packaging machinery, ensuring accurate and efficient operation in processes like sealing, filling, and labeling. Their quiet performance, compact design, and high torque output make them perfect for high-speed and repetitive tasks in automated packaging lines. - Cranes and Hoists

CMN-NRV-NMRV worm gear reducers are often used in cranes and hoists for lifting and lowering heavy loads. Their high torque capabilities and ability to maintain load stability during operation make them a reliable choice for heavy-duty material-handling applications. - Textile Machinery

In textile manufacturing, these worm wheel gearboxes help power machines like looms, spinning machines, and fabric cutters. Their precise speed control ensures smooth operation and high-quality output, while their compact size allows seamless integration into space-constrained textile equipment. - Food Processing Equipment

Worm drive gearboxes play a critical role in food processing applications, such as mixers, conveyors, and slicers. Their corrosion-resistant materials make them suitable for hygienic environments, while their high efficiency ensures the reliability required for continuous operations in the food industry. - Automated Gates and Barriers

These right angle worm gearboxes are commonly used in automated gates, barriers, and access control systems. Their compact design, low noise operation, and ability to handle varying loads make them an efficient solution for ensuring smooth, safe, and controlled movement in security applications.

|  |

|  |

Additional information

| Edited by | Yjx |

|---|