CMN-NMRV110 Worm Gear Reducers/Worm Gearbox

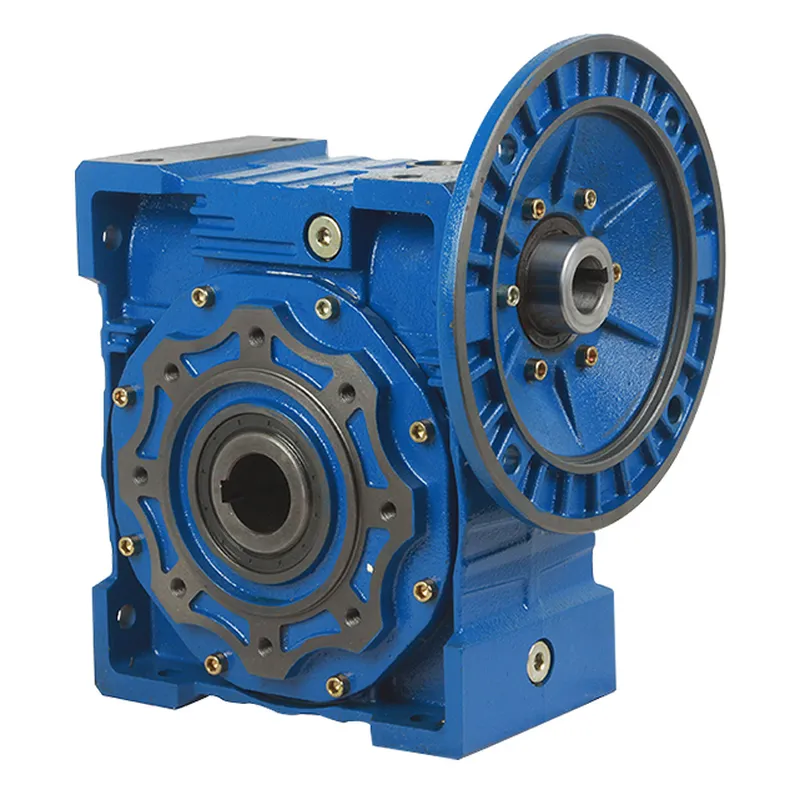

The CMN-NMRV110 worm gear reducer, also known as a worm gearbox, is a compact, high-torque transmission device designed for efficient speed reduction in industrial applications. It features a worm pinion (a screw-like input) meshing with a perpendicular worm gear, producing high torque with a smaller footprint compared to conventional gearsets. Typically constructed with a cast iron housing for durability, the CMN-NMRV110 worm gearbox supports motor power ranges from 0.55KW to 7.5KW and offers gear ratios from 7.5:1 to 100:1, enabling versatile speed and torque adjustments.

The CMN-NMRV110 worm gear reducer, also known as a worm gearbox, is a compact, high-torque transmission device designed for efficient speed reduction in industrial applications. It features a worm pinion (a screw-like input) meshing with a perpendicular worm gear, producing high torque with a smaller footprint compared to conventional gearsets. Typically constructed with a cast iron housing for durability, the CMN-NMRV110 worm gearbox supports motor power ranges from 0.55KW to 7.5KW and offers gear ratios from 7.5:1 to 100:1, enabling versatile speed and torque adjustments.

Its key components include oil seals, bearings, and a worm wheel (often made of bronze or aluminum alloy), ensuring low noise, minimal vibration, and high load capacity. The worm drive gearbox is maintenance-free, hermetically sealed to prevent lubricant loss, and suitable for universal mounting. Ideal for industries like food processing, textiles, and robotics, it provides reliable performance but is not suited for precision positioning due to high backlash (≤1°).

CMN-NMRV110 Worm Gearbox Specifications

| Type | CMN-NMRV110 Worm Gearbox/ Worm Gear Speed Reducer |

| Model | CMN-NMRV110 |

| Reduction Ratio | 5,7.5,10,15,20,25,30,40,50,60,80,100 |

| Flange | FA / FL or as per your demands |

| Matching Motor | 0.06KW~15KW |

| Material | Die-casting Aluminum Alloy |

| Color | Blue /Silver Grey /Customized |

| Flange Standard | PAM / IEC |

| Accessories | Shaft, Flange, Torque arm, etc |

| Lubricant | Synthetic Oil or Worm Gear Oil |

| Usage | Machinery of food stuff, ceramics, chemicals, packing, dyeing, wood working, glass industries, etc |

| Note: 1) Please choose from the above specifications. 2) If the above options can not meet your demands, please send us your requirements(ratio, flange, mounting, application, or a picture of your old one), and we will recommond a suitable type. | |

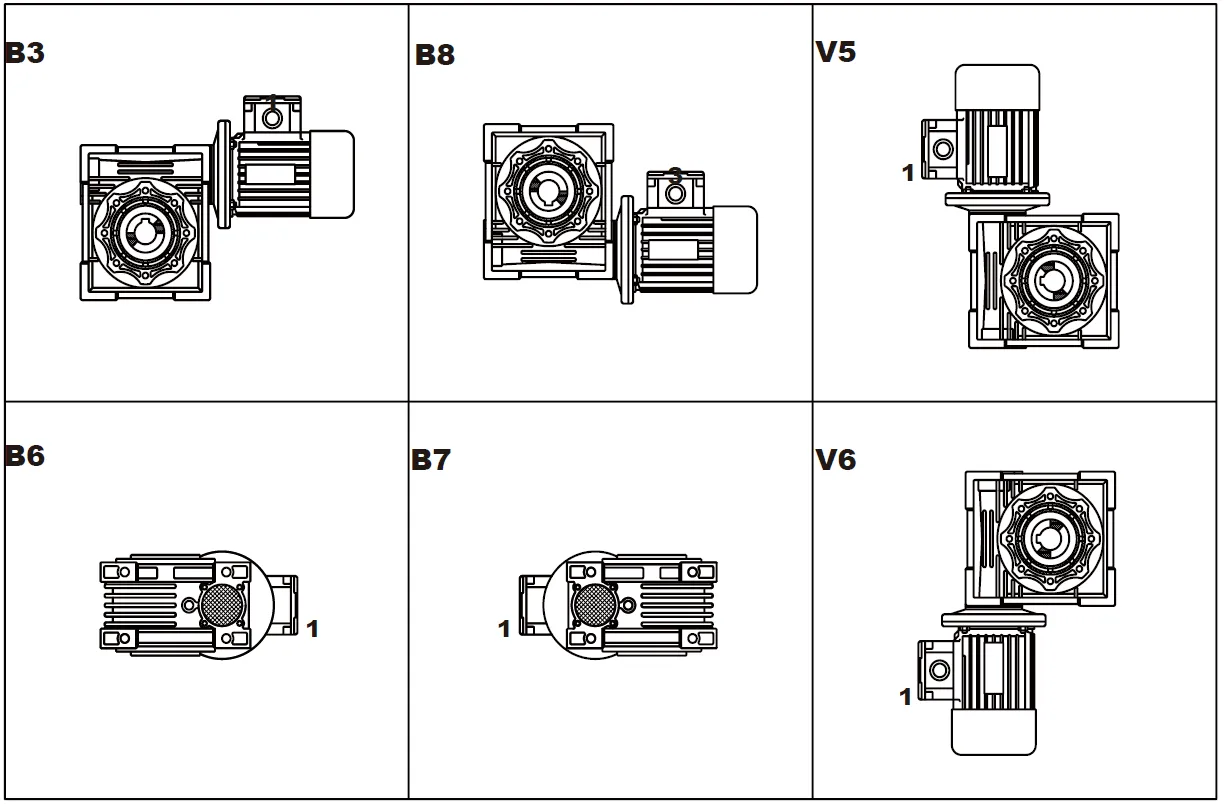

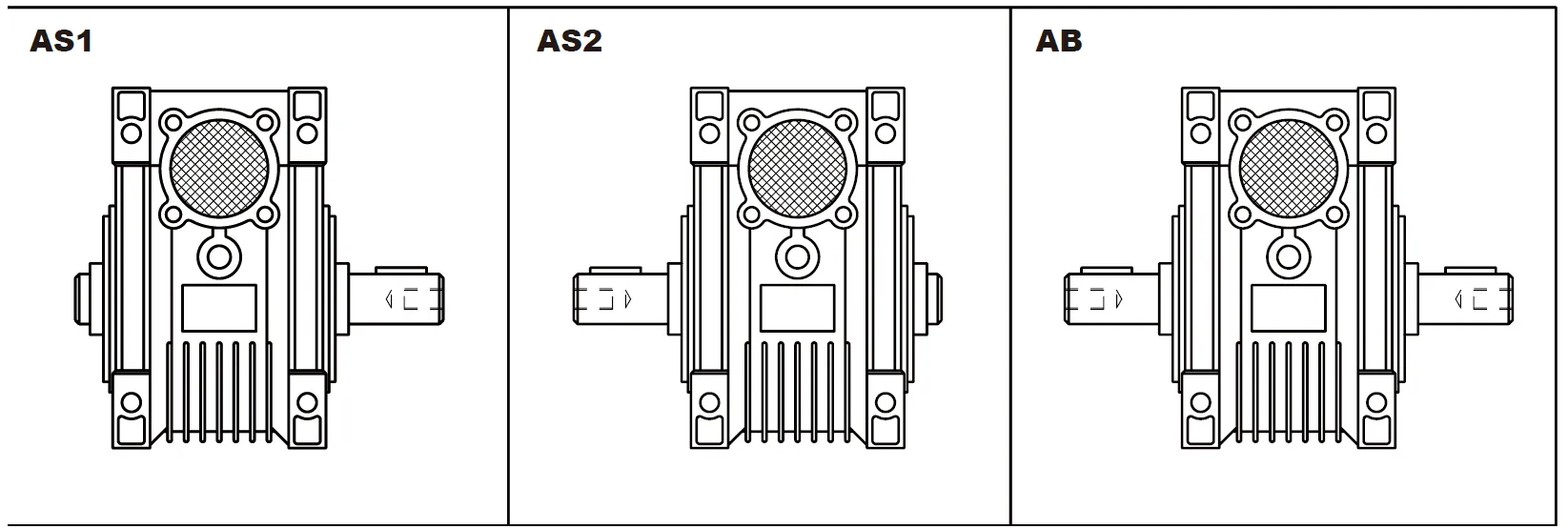

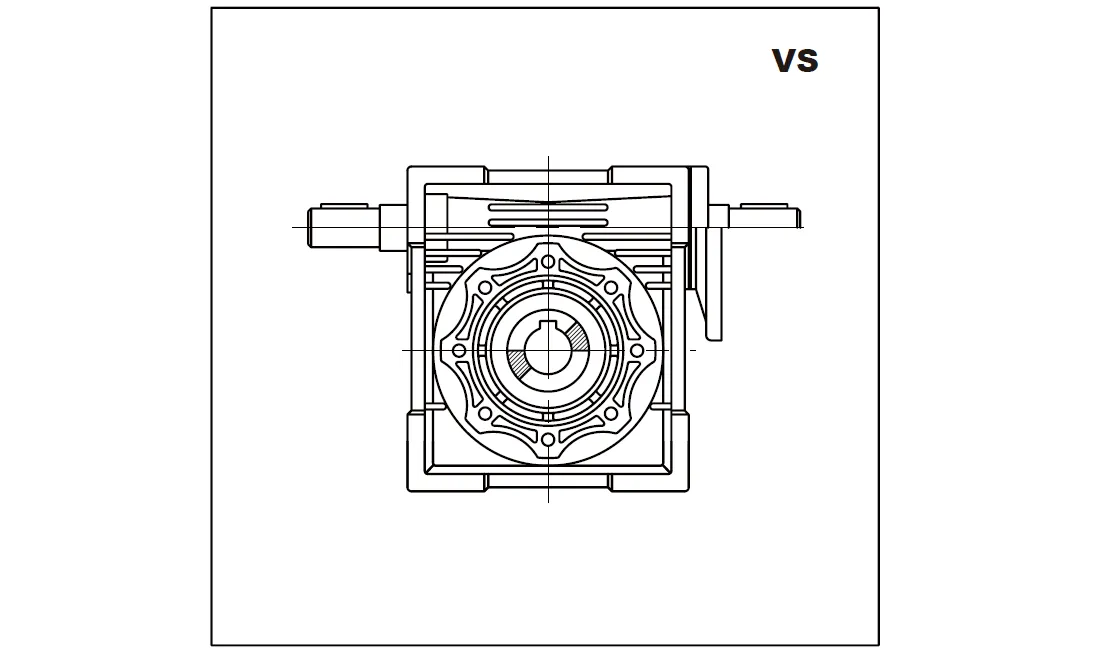

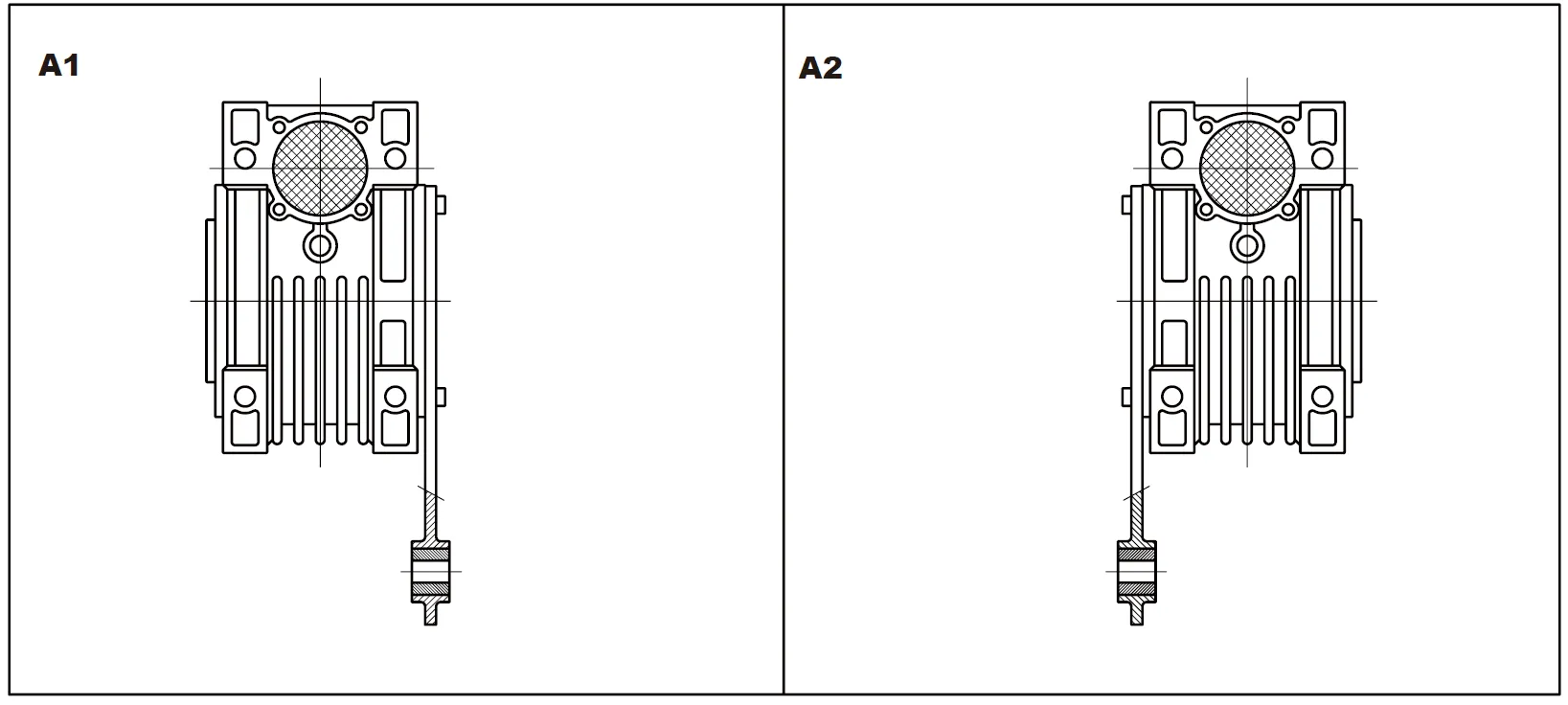

Mounting Position

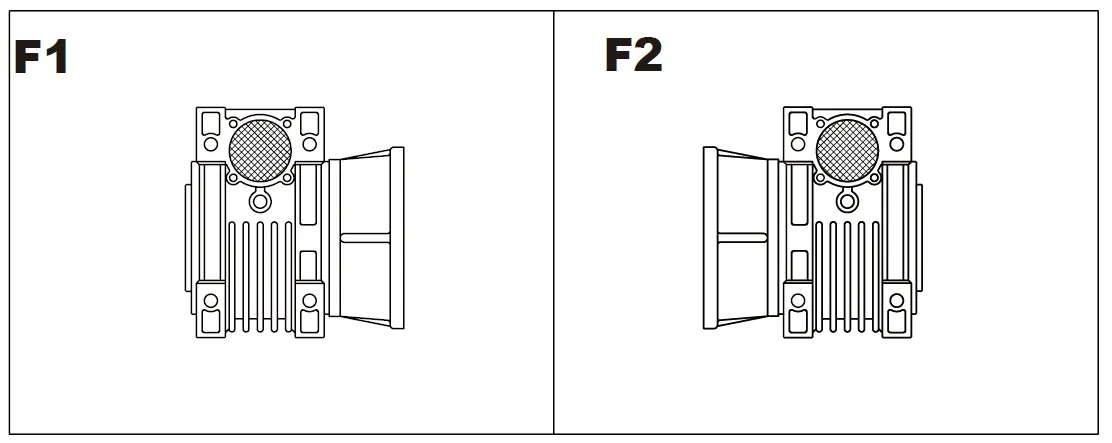

Flange F-FL

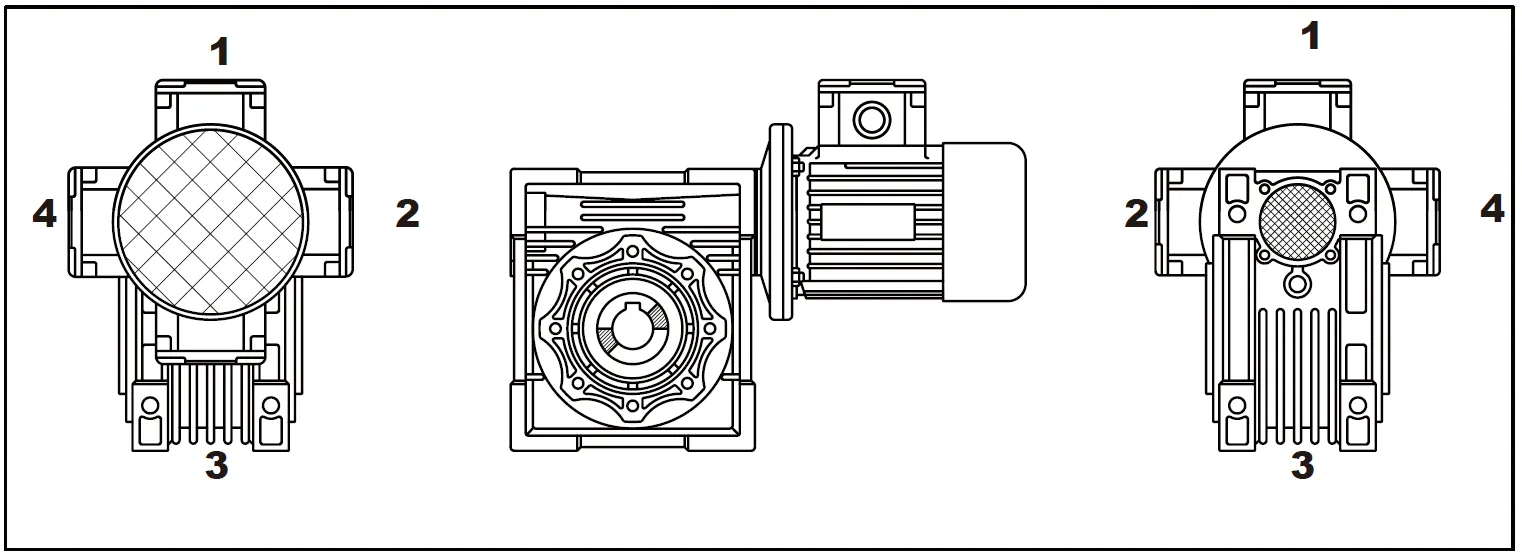

Position of Terminal Box

Position of Output Shaft

Double Extension Worm Shaft

Position of Torque Arm

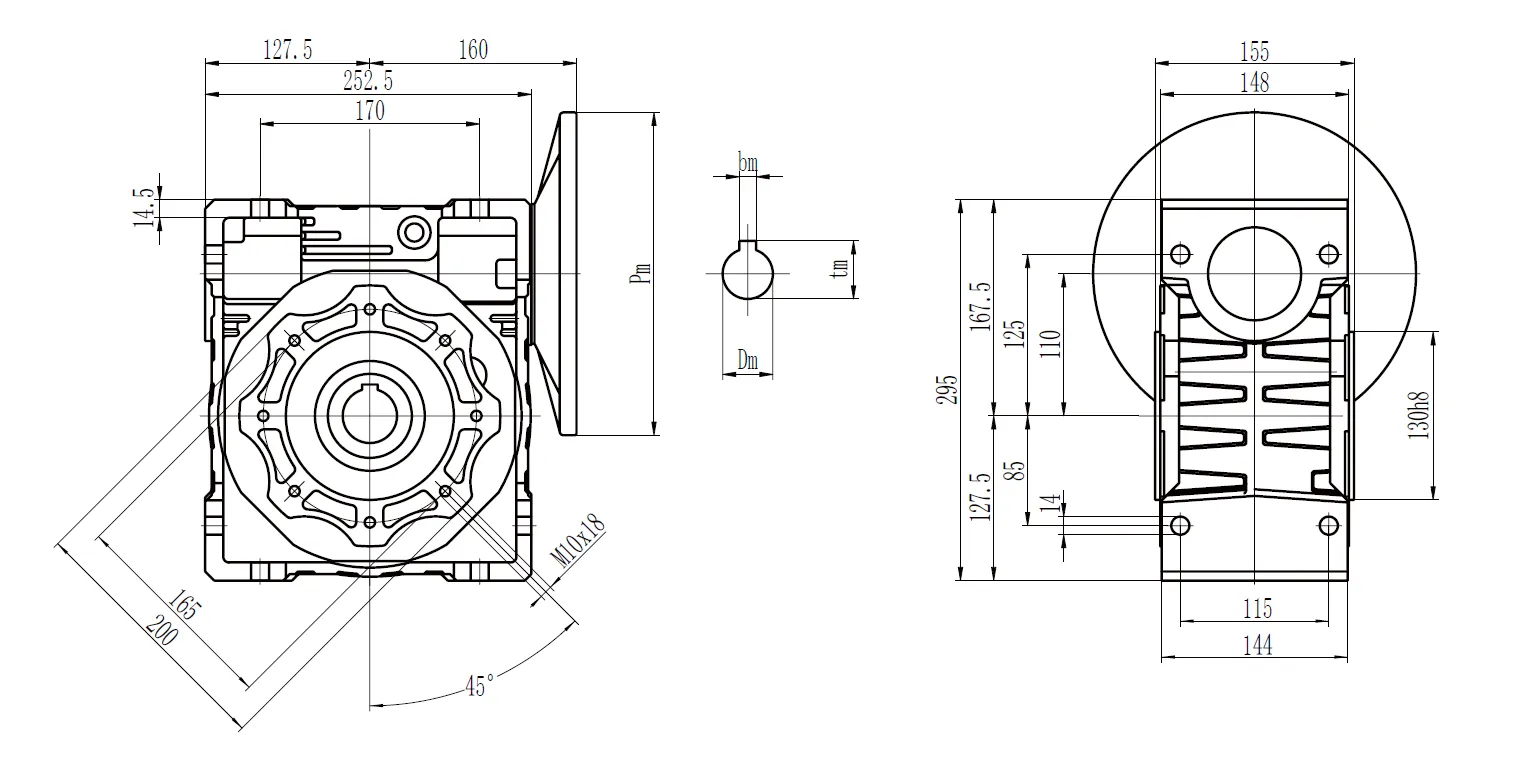

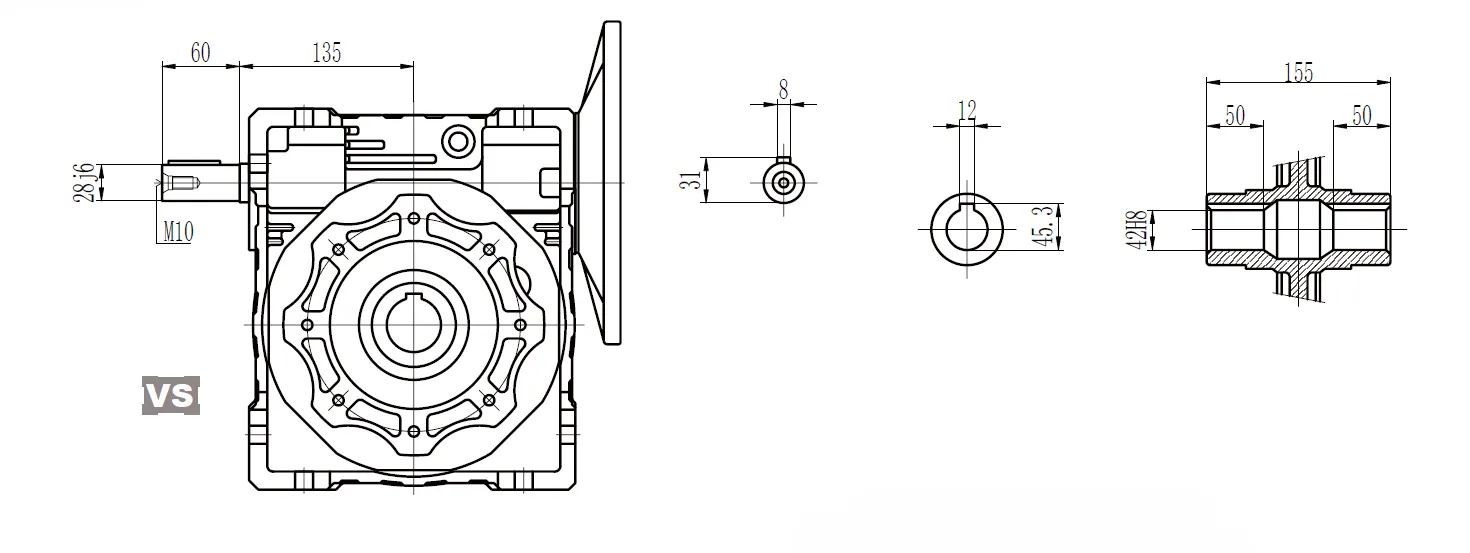

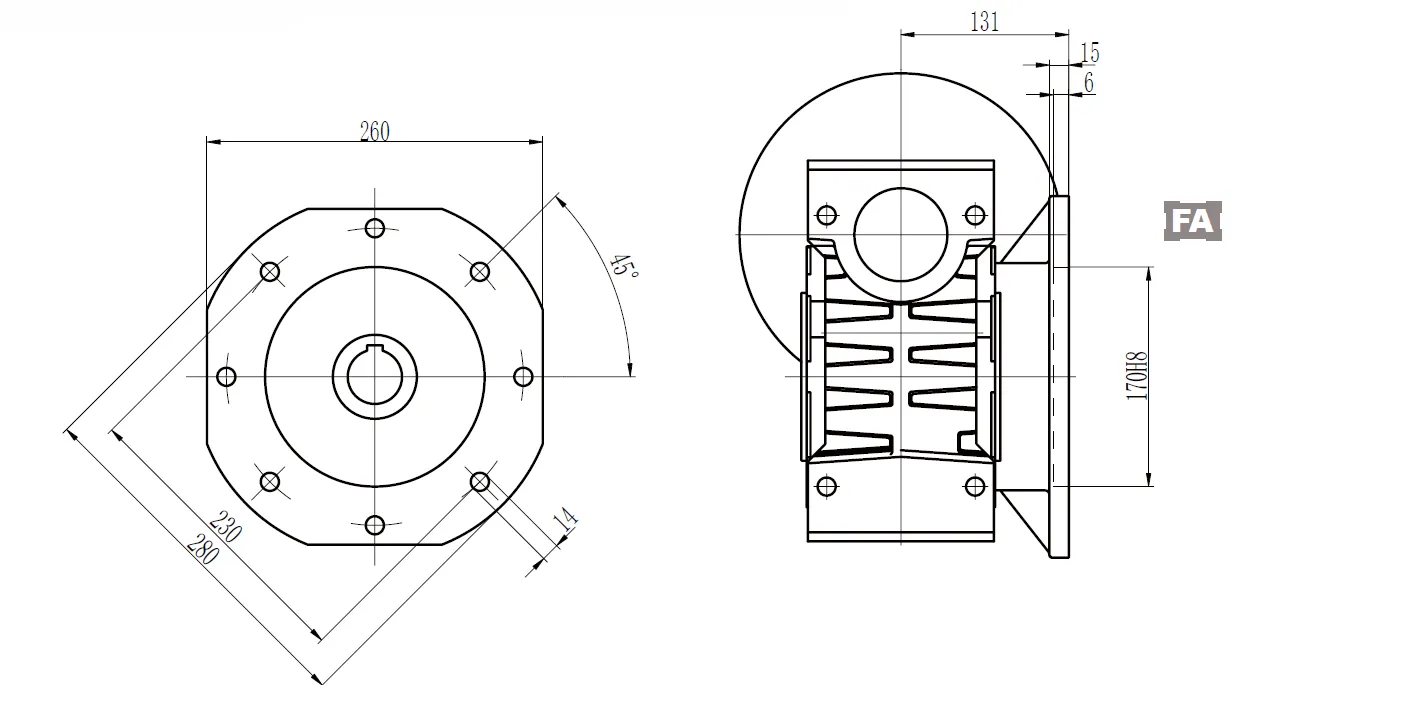

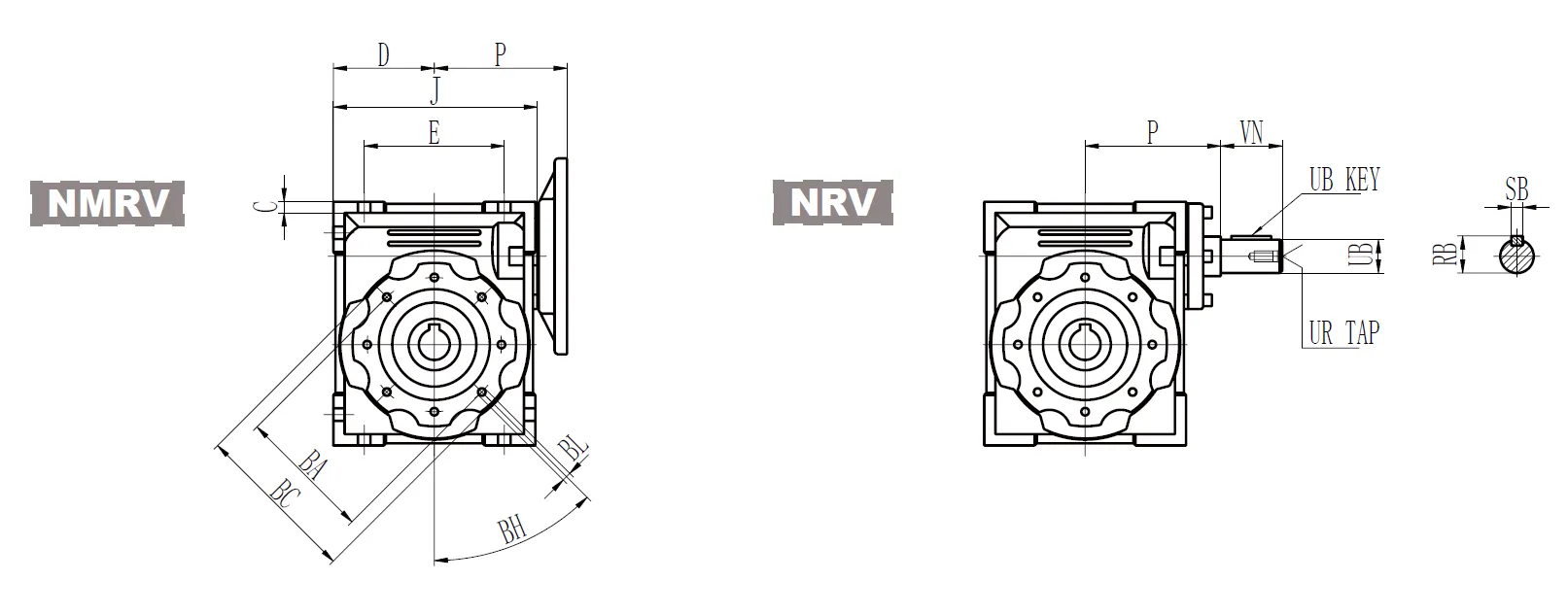

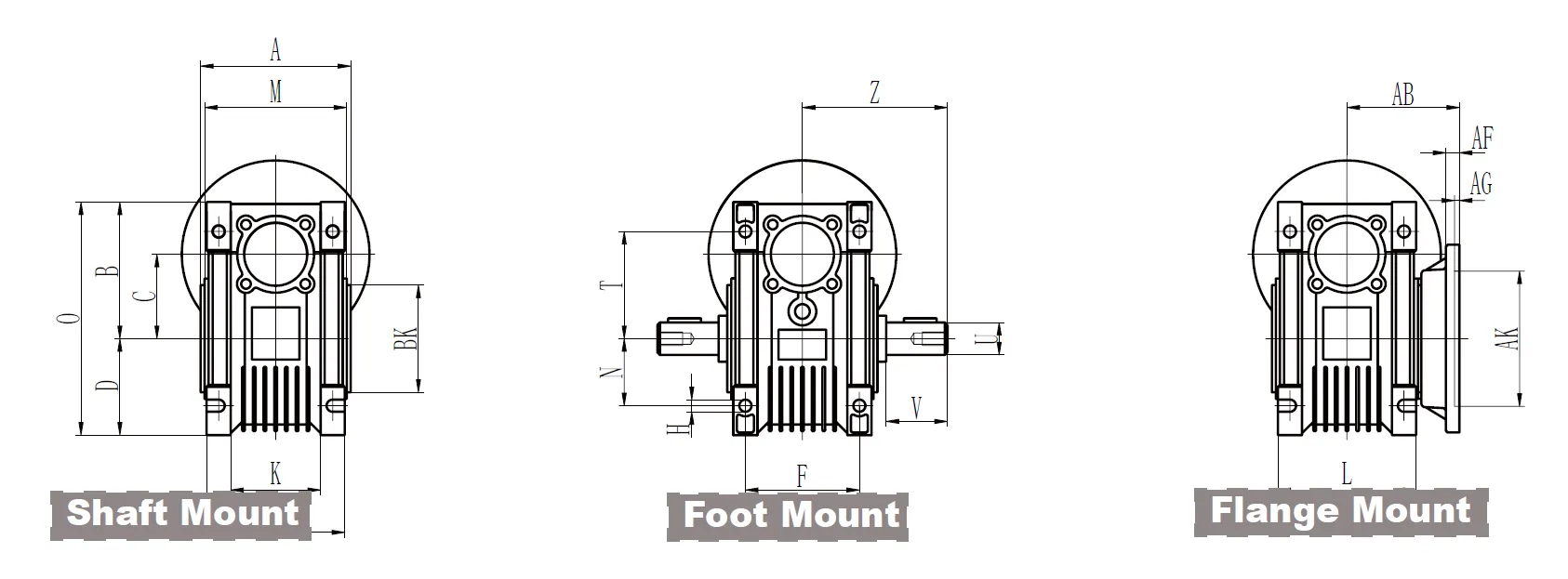

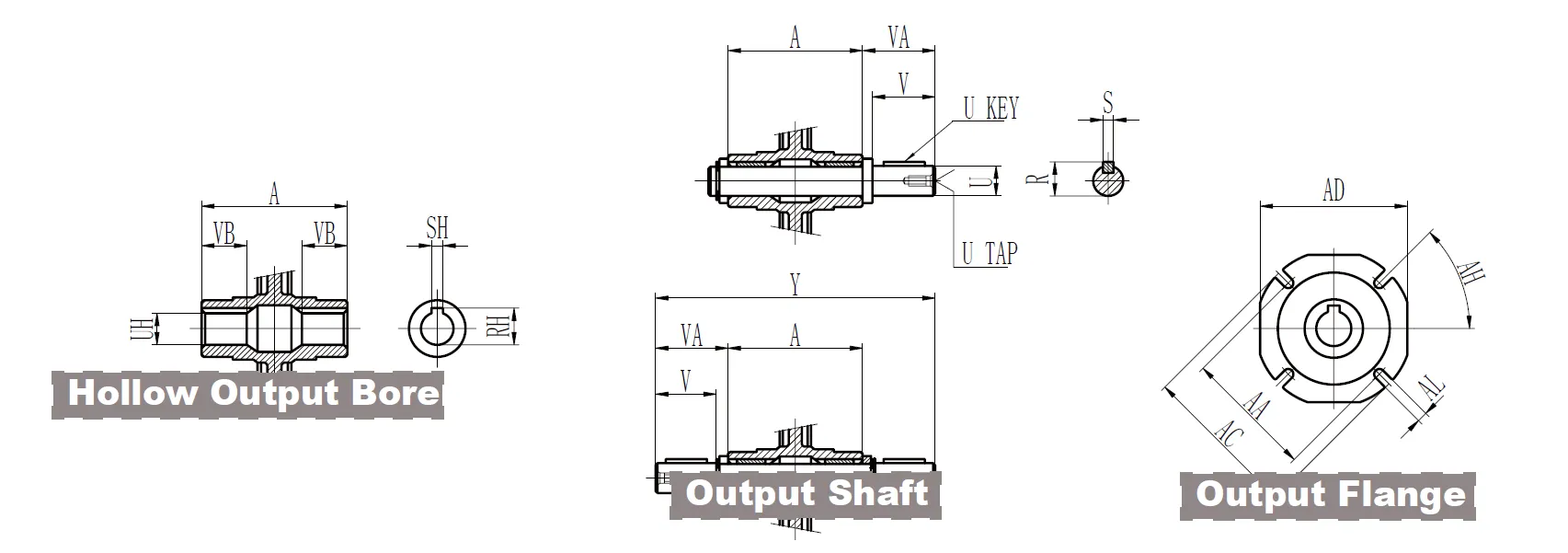

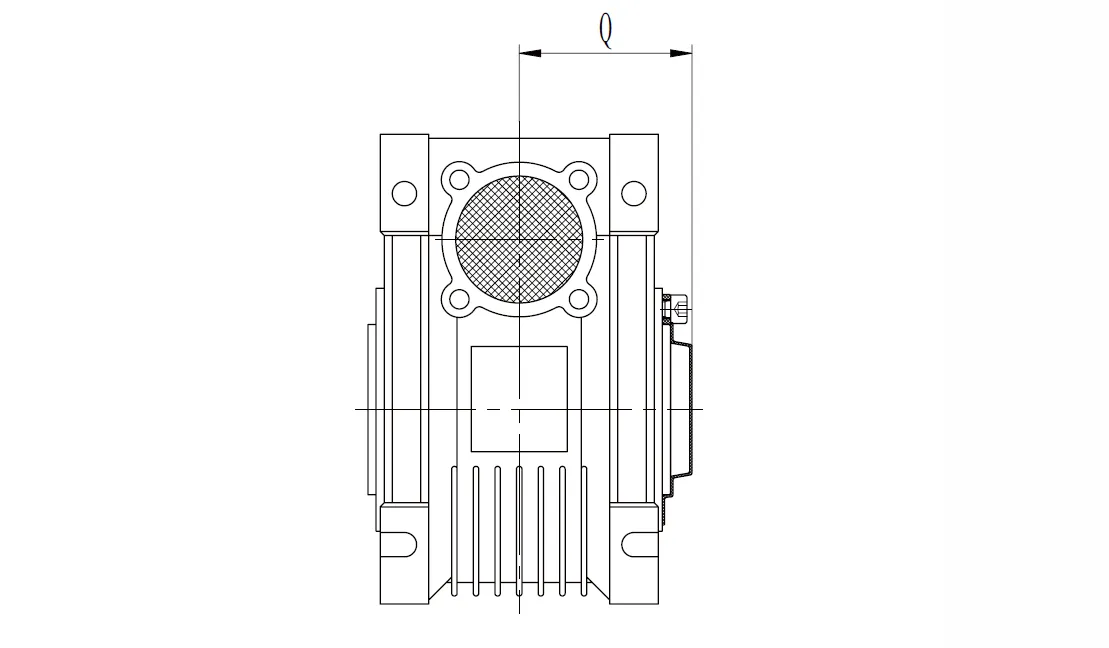

CMN-NMRV110 Worm Gear Reducer Dimensions

CMN-NMRV Worm Gear Reducer Dimensions

CMN-NMRV Inch Series

| Hollow Output Bore | 030 | 040 | 050 | 063 | 075 | 090 | 110 | 130 | |

| RH | 0.71 | 0.84 | 1.12 | 1.24 | 1.37 | 1.52 | 1.8 | 1.93 | |

| SH | 0.188 | 0.188 | 0.25 | 0.25 | 0.25 | 0.313 | 0.375 | 0.375 | |

| UH | 0.625+0.001 0 | 0.75+0.001 0 | 1+0.001 0 | 1.125+0.001 0 | 1.25+0.001 0 | 1.375+0.001 0 | 1.625+0.001 0 | 1.750 | |

| VB | 0.83 | 1.14 | 1.28 | 1.42 | 1.56 | 1.77 | 1.97 | 2.24 | |

| Output Shaft | 030 | 040 | 050 | 063 | 075 | 090 | 110 | 130 | |

| R | 0.7 | 0.83 | 1.11 | 1.23 | 1.36 | 1.51 | 1.79 | 1.92 | |

| S | 0.188 | 0.188 | 0.25 | 0.25 | 0.25 | 0.313 | 0.375 | 0.375 | |

| U | 0.6250 -0.0005 | 0.750 -0.0005 | 10 -0.0005 | 0 -0.0005 | 1.250 -0.0005 | 1.3750 -0.0005 | 1.6250 -0.0005 | 1.750 -0.0005 | |

| U KEY | 0.1875x1.125 | 0.1875x1.5 | 0.25x1.5 | 0.25x1.875 | 0.25x2.25 | 0.3125x2.5 | 0.375x2.75 | 0.375x2.75 | |

| UT | 1/4-20 | 1/4-20 | 3/8-16 | 3/8-16 | 1/2-13 | 1/2-13 | 5/8-11 | 5/8-11 | |

| V | 1.57 | 1.97 | 1.97 | 2.36 | 2.76 | 3.15 | 3.54 | 3.54 | |

| VA | 1.67 | 2.09 | 2.11 | 2.5 | 2.89 | 3.33 | 3.72 | 3.74 | |

| Y | 5.82 | 7.25 | 7.84 | 9.41 | 10.5 | 12.17 | 13.54 | 14.17 | |

| CMN-NMRV | 030 | 040 | 050 | 063 | 075 | 090 | 110 | 130 |

| A | 2.48 | 3.07 | 3.62 | 4.41 | 4.72 | 5.51 | 6.1 | 6.69 |

| B | 2.24 | 2.81 | 3.31 | 4.02 | 4.69 | 5.31 | 6.59 | 7.38 |

| BA | 2.56 | 2.95 | 3.35 | 3.74 | 4.53 | 5.12 | 6.5 | 8.46 |

| BC | 2.95 | 3.43 | 3.94 | 4.33 | 5.51 | 6.3 | 7.87 | 9.84 |

| BH | 90 ° | 45 ° | 45 ° | 45 ° | 45 ° | 45 ° | 45° | 45 ° |

| BK | 2.165 0 -0.0018 | 2.362 0 -0.0018 | 2.756 0 -0.0018 | 3.15 0 -0.0021 | 3.74 0 -0.0021 | 4.331 0 -0.0021 | 5.118 0 -0.0025 | 7.087 0 -0.0025 |

| BL | M6x11 | M6x10 | M8x10 | M8x14 | M8x14 | M10x18 | M10x18 | M12x21 |

| C | 1.18 | 1.57 | 1.97 | 2.48 | 2.95 | 3.54 | 4.33 | 5.12 |

| D | 1.57 | 1.97 | 2.36 | 2.83 | 3.39 | 4.06 | 5.02 | 5.81 |

| E | 2.13 | 2.76 | 3.15 | 3.94 | 4.72 | 5.51 | 6.69 | 7.87 |

| F | 1.73 | 2.36 | 2.76 | 3.35 | 3.54 | 3.94 | 4.53 | 4.72 |

| G | 0.22 | 0.26 | 0.28 | 0.31 | 0.39 | 0.43 | 0.57 | 0.61 |

| H | 0.26 | 0.26 | 0.33 | 0.33 | 0.45 | 0.51 | 0.55 | 0.63 |

| J | 3.15 | 3.98 | 4.76 | 5.75 | 6.85 | 8.19 | 9.94 | 11.52 |

| K | 1.26 | 1.69 | 1.93 | 2.64 | 2.83 | 2.91 | - | - |

| L | 2.2 | 2.8 | 3.35 | 4.06 | 4.41 | 5.12 | 5.67 | 6.1 |

| M | 2.28 | 2.87 | 3.43 | 4.17 | 4.49 | 5.28 | 5.83 | 6.38 |

| N | 1.06 | 1.38 | 1.57 | 1.97 | 2.36 | 2.76 | 3.35 | 3.94 |

| O | 3.82 | 4.78 | 5.67 | 6.85 | 8.07 | 9.37 | 11.61 | 13.19 |

| P | 2.64 | 3.15 | 3.54 | 4.13 | 4.96 | 5.63 | 6.81 | 7.6 |

| Q | 0.83 | 2.36 | 2.91 | 3.54 | 4.13 | 4.92 | 5.59 | 6.38 |

| T | 1.73 | 2.17 | 2.52 | 3.15 | 3.66 | 4.02 | 4.92 | 5.51 |

| Z | 2.91 | 3.63 | 3.92 | 4.71 | 5.25 | 6.09 | 6.77 | 7.09 |

| Output Flange | AA | AB | AC | AD | AF | AG | AH | AK | AL | ||

| 030 | FA | 2.68 | 2.15 | 3.15 | 2.76 | 0.24 | 0.16 | 45° | 1.969 | +0.0015 0 | 0.26 |

| 040 | FA | 2.95 | 2.64 | 4.33 | 3.74 | 0.28 | 0.16 | 45° | 2.362 | +0.0018 | 0.35 |

| 0 | |||||||||||

| FB | 2.95 | 3.82 | 4.33 | 3.74 | 0.28 | 0.16 | 45° | 2.362 | +0.0018 0 | 0.35 | |

| FC | 4.53 | 3.15 | 5.51 | - | 0.35 | 0.2 | 45° | 3.74 | +0.0021 0 | 0.37 | |

| FD | 3.94 | 2.28 | 4.72 | - | 0.47 | 0.2 | 45° | 3.15 | +0.0018 | 0.35 | |

| 0 | |||||||||||

| 050 | FA | 3.35 | 3.54 | 4.92 | 4.33 | 0.35 | 0.2 | 45° | 2.756 | +0.0018 | 0.43 |

| 0 | |||||||||||

| FB | 3.35 | 4.72 | 4.92 | 4.33 | 0.35 | 0.2 | 45° | 2.756 | +0.0018 0 | 0.43 | |

| FC | 5.12 | 3.5 | 6.3 | - | 0.39 | 0.2 | 45° | 4.331 | +0.0021 0 | 0.37 | |

| FD | 4.53 | 2.83 | 5.51 | - | 0.57 | 0.2 | 45° | 3.543 | +0.0021 | 0.43 | |

| 0 | |||||||||||

| 063 | FA | 4.13 | 3.23 | 7.09 | 5.59 | 0.39 | 0.24 | 45° | 4.528 | +0.0021 | 0.43 |

| 0 | |||||||||||

| FB | 5.91 | 4.41 | 7.09 | 5.59 | 0.39 | 0.24 | 45° | 4.528 | +0.0021 | 0.43 | |

| 0 | |||||||||||

| FC | 6.5 | 3.86 | 7.87 | - | 0.39 | 0.2 | 45° | 5.118 | +0.0025 0 | 0.43 | |

| FD | 6.5 | 4.21 | 7.87 | - | 0.39 | 0.2 | 45° | 5.118 | +0.0025 | 0.43 | |

| 0 | |||||||||||

| FE | 5.12 | 3.17 | 6.3 | - | 0.65 | 0.2 | 45° | 4.331 | +0.0021 | 0.43 | |

| 0 | |||||||||||

| 075 | FA | 6.5 | 4.37 | 7.87 | 6.69 | 0.51 | 0.24 | 45° | 5.118 | +0.0025 | 0.55 |

| 0 | |||||||||||

| FB | 5.12 | 3.54 | 6.3 | - | 0.51 | 0.24 | 45° | 4.331 | +0.0021 | 0.55 | |

| 0 | |||||||||||

| 090 | FA | 6.89 | 4.37 | 8.27 | 8.27 | 0.51 | 0.24 | 45° | 5.984 | +0.0025 | 0.55 |

| 0 | |||||||||||

| FB | 8.46 | 4.8 | 9.84 | - | 0.71 | 0.24 | 45° | 7.087 | +0.0025 0 | 0.55 | |

| FC | 6.5 | 4.33 | 7.87 | - | 0.67 | 0.24 | 45° | 5.118 | +0.0025 0 | 0.43 | |

| FD | 6.89 | 5.94 | 8.27 | - | 0.51 | 0.24 | 45° | 5.984 | +0.0025 | 0.55 | |

| 0 | |||||||||||

| 110 | FA | 9.06 | 5.16 | 11.02 | 10.24 | 0.59 | 0.24 | 45° | 6.693 | +0.0025 | 0.55 |

| 0 | |||||||||||

| FB | 9.06 | 7.09 | 11.02 | 10.24 | 0.59 | 0.24 | 45° | 6.693 | +0.0025 | 0.55 | |

| 0 | |||||||||||

| 130 | FA | 10.04 | 5.51 | 12.6 | 11.42 | 0.59 | 0.24 | 22.5° | 7.087 | +0.0025 0 | 0.63 |

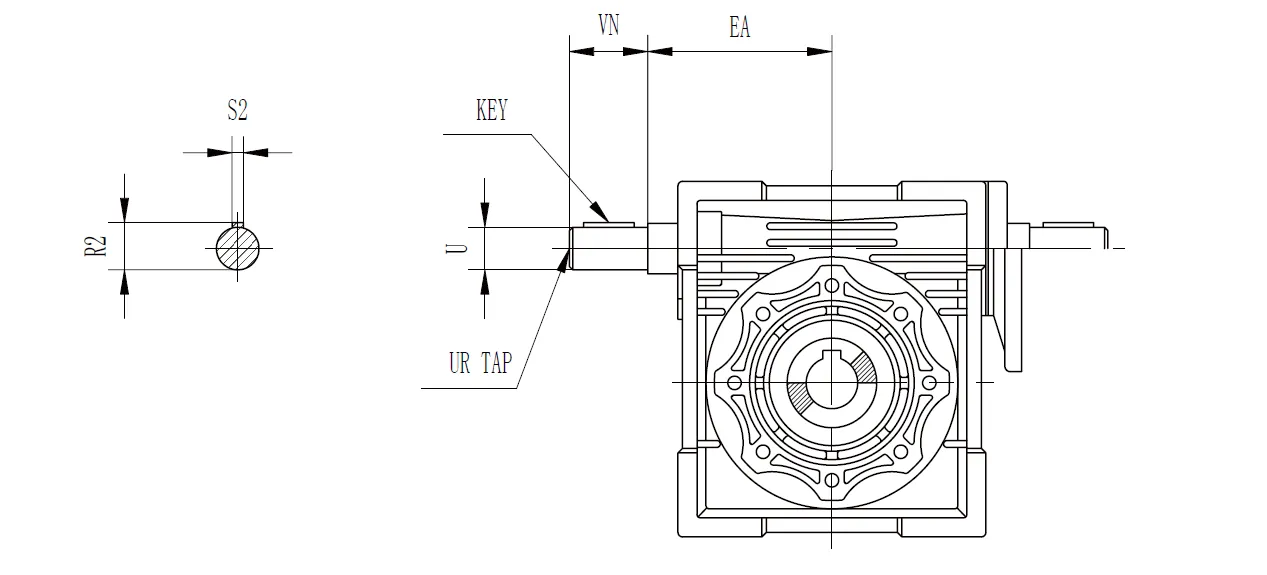

| Input Shaft | 030 | 040 | 050 | 063 | 075 | 090 | 110 | 130 | |

| SB | 0.094 | 0.125 | 0.188 | 0.188 | 0.188 | 0.188 | 0.25 | 0.25 | |

| RB | 0.42 | 0.55 | 0.7 | 0.83 | 0.96 | 0.96 | 1.24 | 1.36 | |

| UB | 0.3750 -0.0005 | 0.50 -0.0005 | 0.6250 -0.0005 | 0.750 -0.0005 | 0.8750 -0.0005 | 0.8750 -0.0005 | 1.1250 -0.0005 | 1.250 -0.0005 | |

| UB KEY | 0.094x0.875 | 0.125x0.875 | 0.1875x1.125 | 0.1875x1.5 | 0.1875x1.875 | 0.1875x1.875 | 0.25x2.25 | 0.25x2.5 | |

| UR | - | 1/4-20 | 1/4-20 | 1/4-20 | 1/4-20 | 1/4-20 | 3/8-16 | 1/2-13 | |

| VN | 1.18 | 1.18 | 1.58 | 1.97 | 2.36 | 2.36 | 2.76 | 3.15 | |

High Speed Extension Shaft Dimensions

| CMN-NMRV | EA | U | VN | UR | S2 | R2 | KEY | |

| Length | Square | |||||||

| 030 | 1.772 | 0.3750 -0.0005 | 1.18 | - | 0.093 | 0.42 | 0.875 | 0.094 |

| 040 | 2.087 | 0.50 -0.0005 | 1.18 | 1/4-20 | 0.13 | 0.55 | 0.875 | 0.125 |

| 050 | 2.52 | 0.6250 -0.0005 | 1.58 | 1/4-20 | 0.19 | 0.7 | 1.125 | 0.188 |

| 063 | 2.953 | 0.750 -0.0005 | 1.97 | 1/4-20 | 0.19 | 0.83 | 1.5 | 0.188 |

| 075 | 3.543 | 0.8750 -0.0005 | 2.36 | 1/4-20 | 0.19 | 0.96 | 1.875 | 0.188 |

| 090 | 4.252 | 0.8750 -0.0005 | 2.36 | 1/4-20 | 0.19 | 0.96 | 1.875 | 0.188 |

| 110 | 5.315 | 1.1250 -0.0005 | 2.76 | 3/8-16 | 0.25 | 1.24 | 2.25 | 0.25 |

| 130 | 6.102 | 1.250 -0.0005 | 3.15 | 1/2-13 | 0.25 | 1.36 | 2.5 | 0.25 |

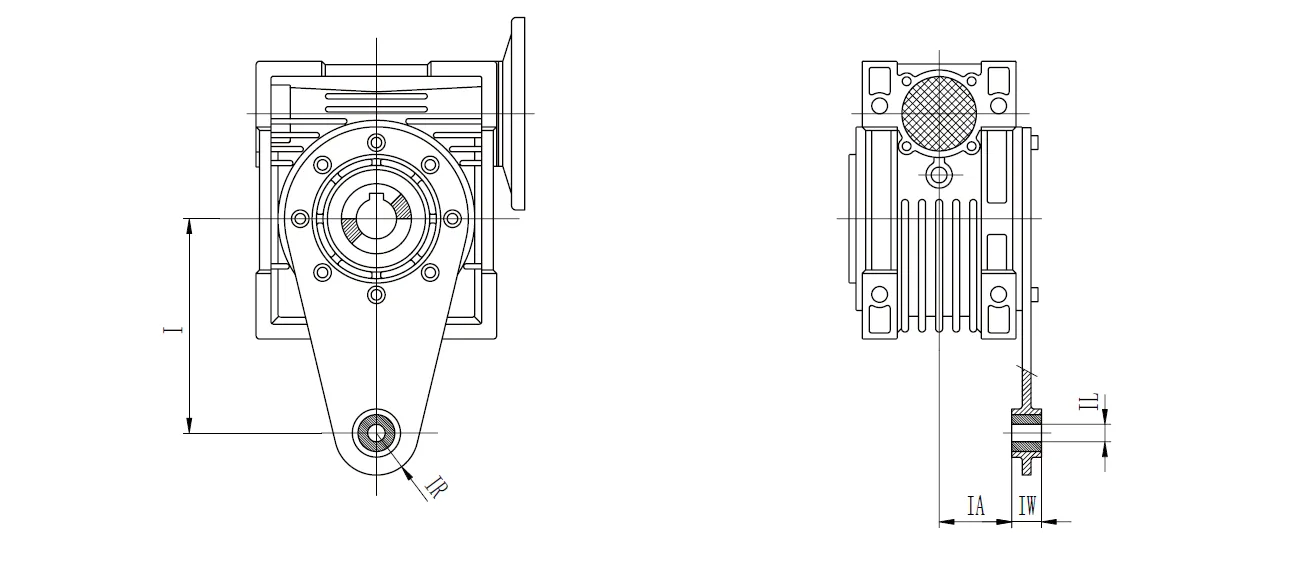

Torque Arm Dimensions

| CMN-NMRV | I | IA | IL | IR | IW |

| 025 | 2.76 | 0.69 | 0.31 | 0.59 | 0.55 |

| 030 | 3.35 | 0.94 | 0.31 | 0.59 | 0.55 |

| 040 | 3.94 | 1.24 | 0.39 | 0.71 | 0.55 |

| 050 | 3.94 | 1.52 | 0.39 | 0.71 | 0.55 |

| 063 | 5.91 | 1.93 | 0.39 | 0.71 | 0.55 |

| 075 | 7.87 | 1.87 | 0.79 | 1.18 | 0.98 |

| 090 | 7.87 | 2.26 | 0.79 | 1.18 | 0.98 |

| 110 | 9.84 | 2.44 | 0.98 | 1.38 | 1.18 |

| 130 | 9.84 | 2.72 | 0.98 | 1.38 | 1.18 |

Protective Cover Dimensions

| CMN-NMRV | Q |

| 030 | 1.65 |

| 040 | 1.97 |

| 050 | 2.28 |

| 063 | 2.72 |

| 075 | 2.91 |

| 090 | 3.39 |

| 110 | 3.7 |

| 130 | 4.02 |

NEMA Flange Availability

| CMN-NMRV | NEMA Flange | Input Bore Diameter | Available Ratios | |||||||||||

| 5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 | 60 | 80 | 100 | |||

| 030 | 48C | 0.5 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |

| 040 | 56C | 0.625 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| 050 | 56C | 0.625 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| 063 | 56C | 0.625 | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| 140TC | 0.875 | ● | ● | ● | ● | ● | ● | ● | ||||||

| 075 | 56C | 0.625 | ● | ● | ● | ● | ||||||||

| 140TC | 0.875 | ● | ● | ● | ● | ● | ● | |||||||

| 180TC | 1.125 | ● | ● | ● | ||||||||||

| 090 | 56C | 0.625 | ● | ● | ||||||||||

| 140TC | 0.875 | ● | ● | ● | ● | ● | ||||||||

| 180TC | 1.125 | ● | ● | ● | ● | ● | ● | ● | ||||||

| 110 | 140TC | 0.875 | ● | ● | ● | ● | ||||||||

| 180TC | 1.125 | ● | ● | ● | ● | ● | ● | |||||||

| 210TC | 1.375 | ● | ● | ● | ● | |||||||||

| 130 | 140TC | 0.875 | ● | ● | ||||||||||

| 180TC | 1.125 | ● | ● | ● | ● | ● | ||||||||

| 210TC | 1.375 | ● | ● | ● | ● | ● | ● | ● | ||||||

CMN-NMRV110 Worm Drive Gearbox Benefits

- High Torque Output

The CMN-NMRV110 worm gearbox delivers exceptional torque multiplication due to its worm and gear design. This makes it ideal for heavy-duty applications like conveyors and lifting systems, ensuring reliable performance under high loads with gear ratios ranging from 7.5:1 to 100:1. - Compact and Space-Saving Design

Its compact structure allows installation in tight spaces, making it suitable for machinery with limited room. The worm gear reducer's small footprint does not compromise its power, offering efficient speed reduction for industries such as robotics, packaging, and material handling. - Low Noise and Vibration

The CMN-NMRV110 worm reducer gearbox operates with minimal noise and vibration thanks to precision-engineered components like bronze worm wheels and high-quality bearings. This ensures a quieter work environment, making it suitable for noise-sensitive applications like food processing and pharmaceutical equipment. - Maintenance-Free Operation

Designed with hermetic sealing and high-quality oil seals, the worm drive gearbox prevents lubricant leakage and contamination. This eliminates the need for frequent maintenance, reducing downtime and operational costs in industries such as textiles, ceramics, and automated production lines. - Versatile Mounting Options

The CMN-NMRV110 worm gear speed reducer supports universal mounting configurations, allowing flexible integration into various systems. Whether horizontal, vertical, or flange-mounted, its adaptability suits diverse applications, from conveyor belts to industrial mixers, enhancing design flexibility for engineers and manufacturers. - Durability and Robust Construction

Built with a cast iron housing, the CMN-NMRV110 worm drive reduction gearbox withstands harsh industrial environments, resisting wear and corrosion. This durability ensures a long service life, making it a cost-effective choice for heavy industries like mining, agriculture, and automotive manufacturing.

CMN-NMRV110 Worm Reducer Gearbox Applications

- Conveyor Systems

The CMN-NMRV110 worm gearbox is widely used in conveyor systems for material handling in industries like mining and logistics. Its high torque and compact design ensure efficient movement of heavy loads, enhancing productivity in automated transport and sorting processes. - Packaging Machinery

In packaging equipment, the worm gear reducers provide precise speed reduction for consistent operation. Its low noise and maintenance-free design make it ideal for high-speed packing lines in food, beverage, and pharmaceutical industries, ensuring reliable performance during continuous production cycles. - Textile Industry

The CMN-NMRV110 worm drive gearbox drives textile machinery such as spinning and weaving equipment. Its robust construction and ability to handle varying loads ensure smooth operation, while the compact size allows integration into complex setups, supporting high-volume textile production with minimal downtime. - Robotics and Automation

In robotics, the worm gear reducer gearbox delivers high torque for precise movements in automated systems. Its universal mounting and durability suit applications like robotic arms and assembly lines, enabling efficient automation in manufacturing sectors such as automotive and electronics. - Food Processing Equipment

The CMN-NMRV110 worm gear motor is ideal for food processing machinery due to its low noise, vibration, and hermetic sealing, which prevents contamination. It powers mixers, grinders, and slicers, ensuring hygienic and efficient operations in food production and processing facilities. - Agricultural Machinery

The worm reduction gearbox supports agricultural equipment like harvesters and irrigation systems. Its durable cast iron housing withstands harsh outdoor conditions, while high torque output ensures reliable performance in demanding tasks, enhancing efficiency in farming and crop processing operations.

Worm Gear Speed Reducer Maintenance Tips

- Regular Lubrication Checks

Ensure the worm gear reducer, such as the CMN-NMRV110, maintains proper lubrication levels using manufacturer-recommended synthetic or mineral oils. Check oil levels monthly to prevent wear and overheating, topping up or replacing as needed to ensure smooth operation and extended gearbox lifespan. - Inspect for Leaks

Routinely examine the worm gearbox for oil leaks around seals and gaskets. Leaks can lead to lubrication loss, causing friction and damage. Clean the exterior and replace worn seals promptly to maintain hermetic sealing and protect internal components from contamination and corrosion. - Monitor Temperature

Regularly check the worm reducer gearbox operating temperature to avoid overheating, which can degrade lubricant and damage gears. Use a thermal sensor to ensure temperatures stay within the manufacturer’s specified range, addressing excessive heat through improved ventilation or lubricant adjustments to prevent failures. - Check for Unusual Noises

Listen for abnormal sounds like grinding or whining during operation, which may indicate misalignment or worn components. Address these issues immediately by inspecting gears and bearings, ensuring timely repairs to prevent further damage and maintain quiet, efficient performance. - Ensure Proper Alignment

Verify that the worm gear speed reducer is correctly aligned with the connected machinery to avoid undue stress on components. Misalignment can cause premature wear. Regularly inspect couplings and mounting bolts, adjusting as needed to maintain optimal performance and prevent mechanical failures. - Clean External Surfaces

Keep the worm gear reducer gearbox exterior free of dust, dirt, and debris to prevent heat buildup and corrosion. Regular cleaning with a soft cloth and non-corrosive cleaner ensures proper heat dissipation, maintaining efficiency and prolonging the lifespan of the worm gear reducer.

Additional information

| Edited by | Yjx |

|---|