CMN-NMRV075 Worm Gear Reducers/Worm Gearbox

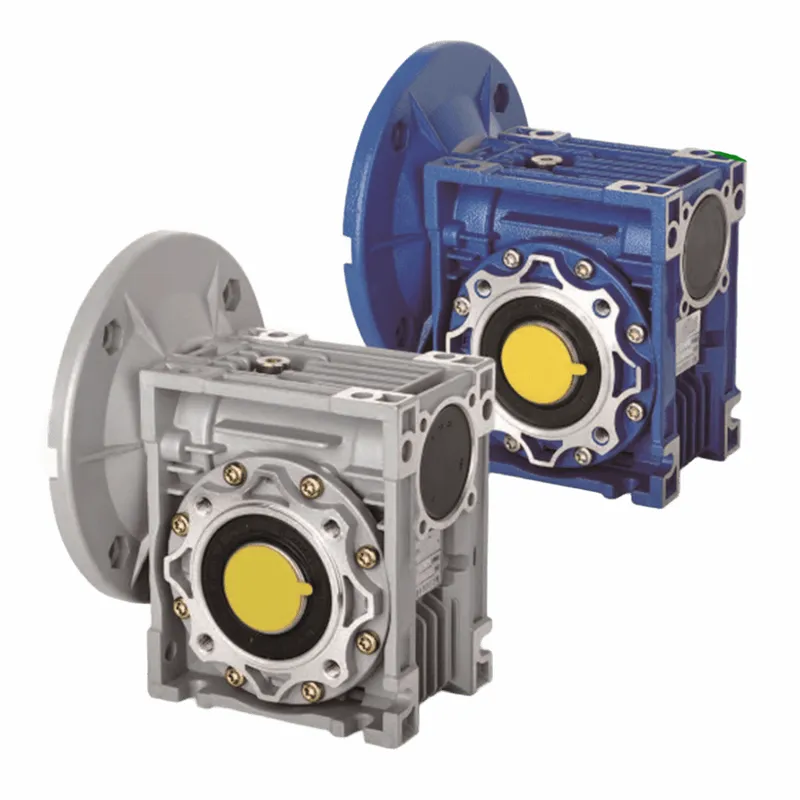

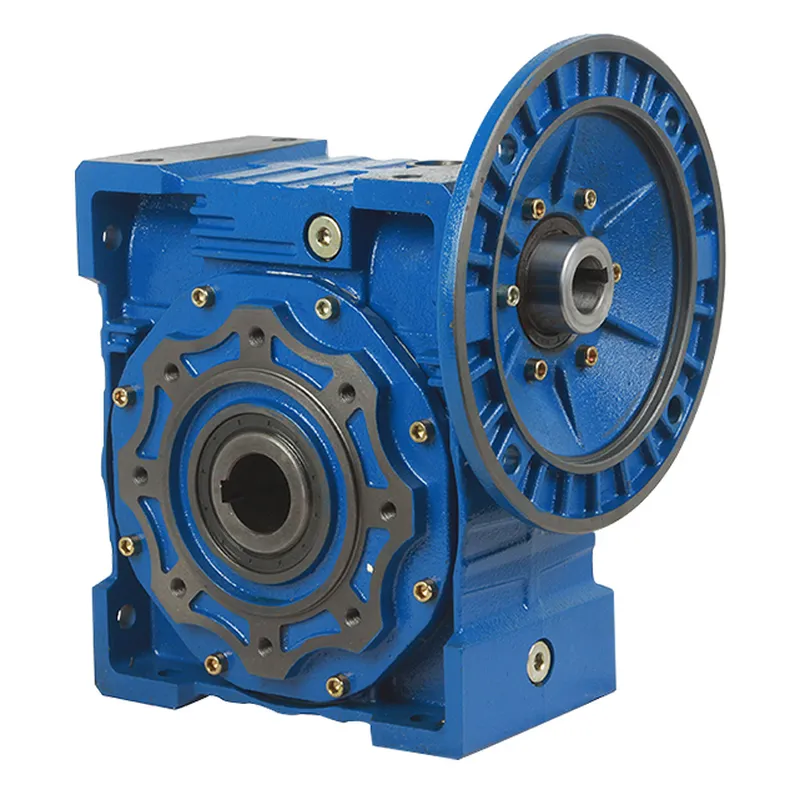

The CMN-NMRV075 worm gear reducers, commonly referred to as worm gearboxes, are highly efficient mechanical devices designed to transmit power and reduce speed in various industrial applications. These worm gear speed reducers feature a compact design, making them ideal for use in confined spaces. Their core mechanism consists of a worm (a screw-like gear) meshing with a worm wheel (a toothed gear), which enables smooth and efficient torque transmission at right angles.

The CMN-NMRV075 worm gear reducers, commonly referred to as worm gearboxes, are highly efficient mechanical devices designed to transmit power and reduce speed in various industrial applications. These worm gear speed reducers feature a compact design, making them ideal for use in confined spaces. Their core mechanism consists of a worm (a screw-like gear) meshing with a worm wheel (a toothed gear), which enables smooth and efficient torque transmission at right angles.

The CMN-NMRV075 model worm gearbox specifically stands out for its robustness, reliability, and lightweight aluminum alloy housing, which ensures durability while reducing overall weight. These gearboxes are widely used in conveyor systems, automation equipment, and packaging machinery due to their excellent torque multiplication, quiet operation, and self-locking capabilities, which prevent reverse motion under load. Additionally, they support flexible mounting options, making them versatile for various setups.

CMN-NMRV075 Worm Gearbox Specifications

| Type | CMN-NMRV075 Worm Gearbox/ Worm Gear Speed Reducer |

| Model | CMN-NMRV075 |

| Reduction Ratio | 5,7.5,10,15,20,25,30,40,50,60,80,100 |

| Flange | FA / FL or as per your demands |

| Matching Motor | 0.06KW~15KW |

| Material | Die-casting Aluminum Alloy |

| Color | Blue /Silver Grey /Customized |

| Flange Standard | PAM / IEC |

| Accessories | Shaft, Flange, Torque arm, etc |

| Lubricant | Synthetic Oil or Worm Gear Oil |

| Usage | Machinery of food stuff, ceramics, chemicals, packing, dyeing, wood working, glass industries, etc |

| Note: 1) Please choose from the above specifications. 2) If the above options can not meet your demands, please send us your requirements(ratio, flange, mounting, application, or a picture of your old one), and we will recommond a suitable type. | |

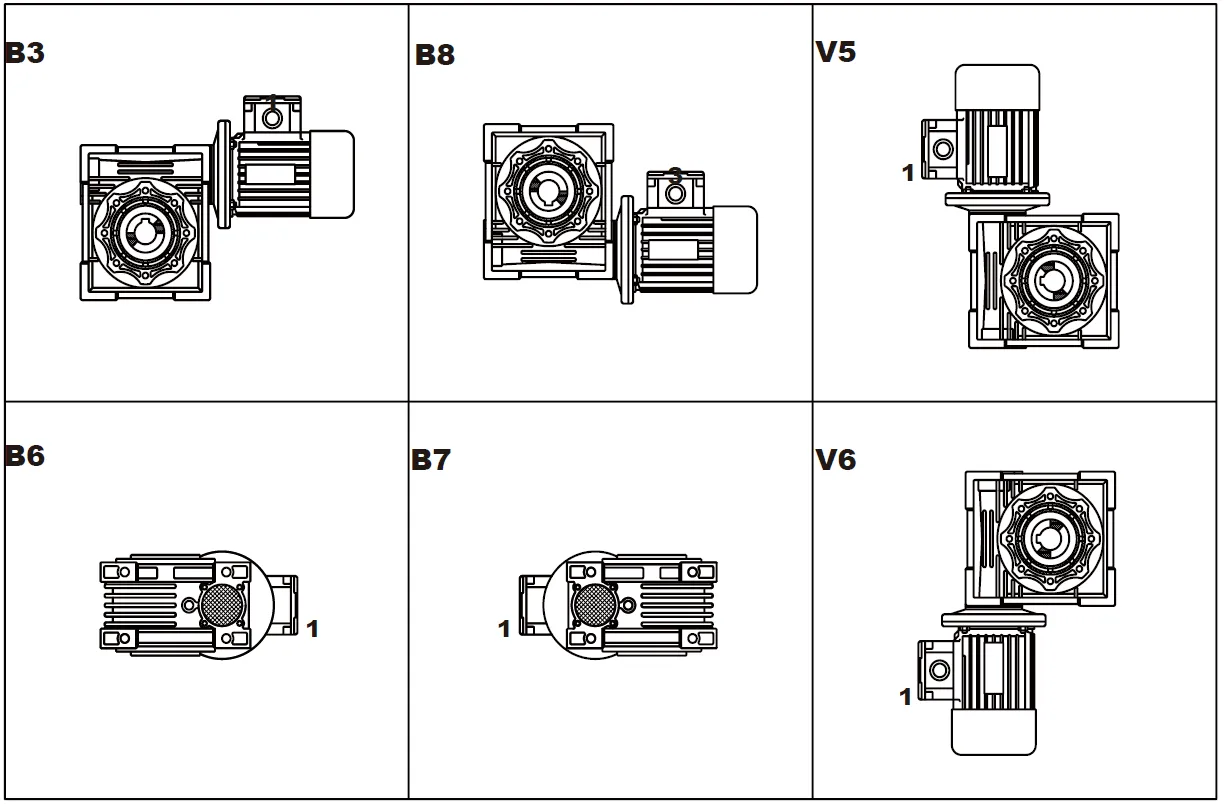

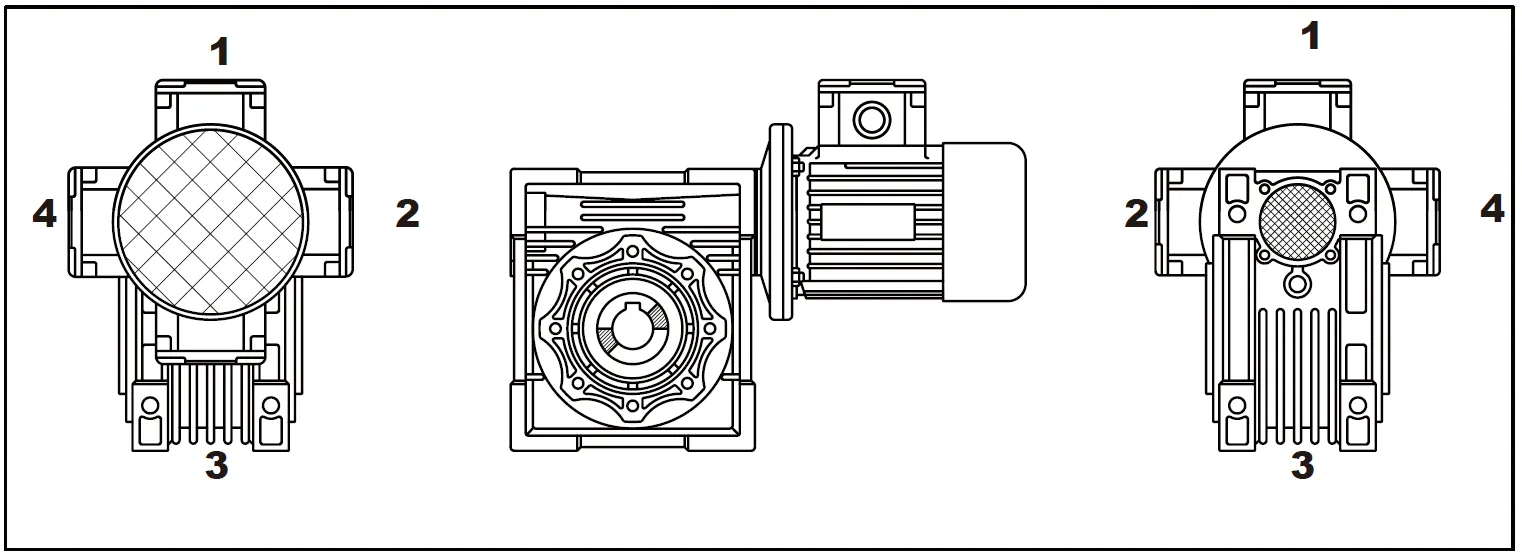

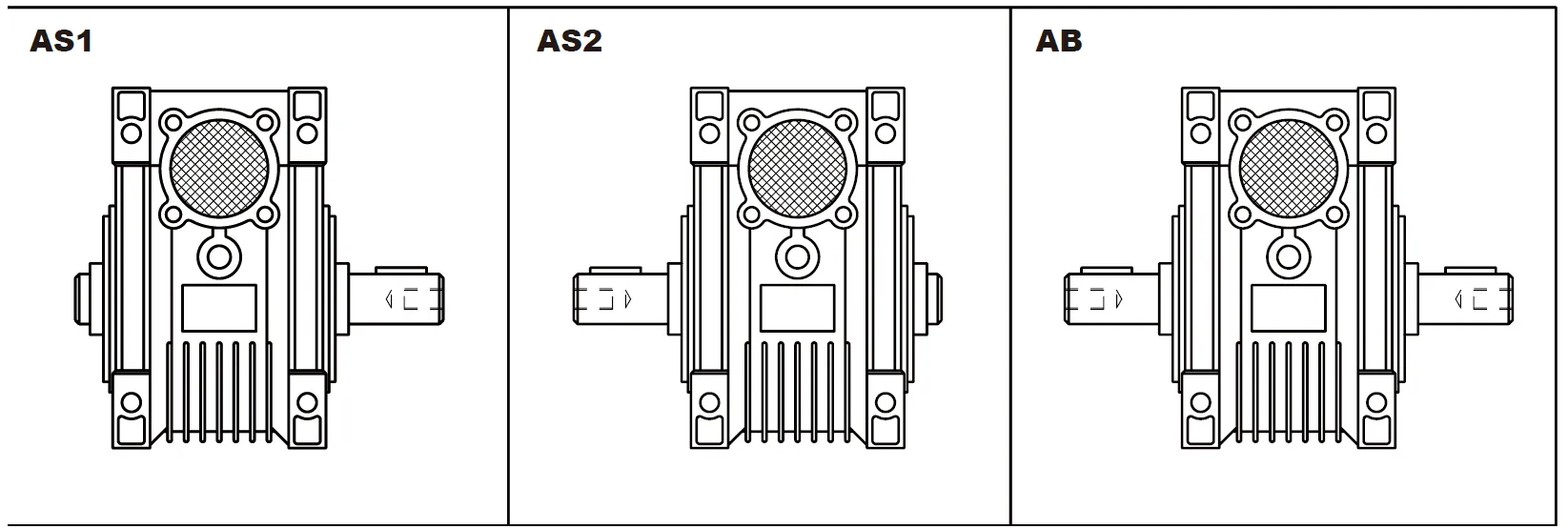

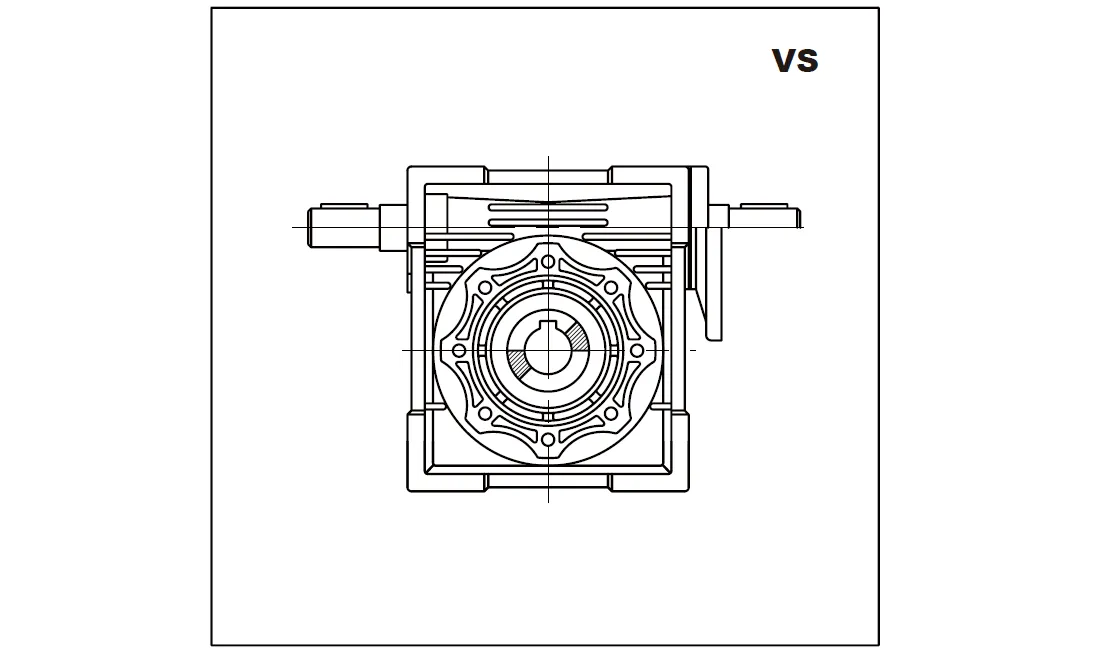

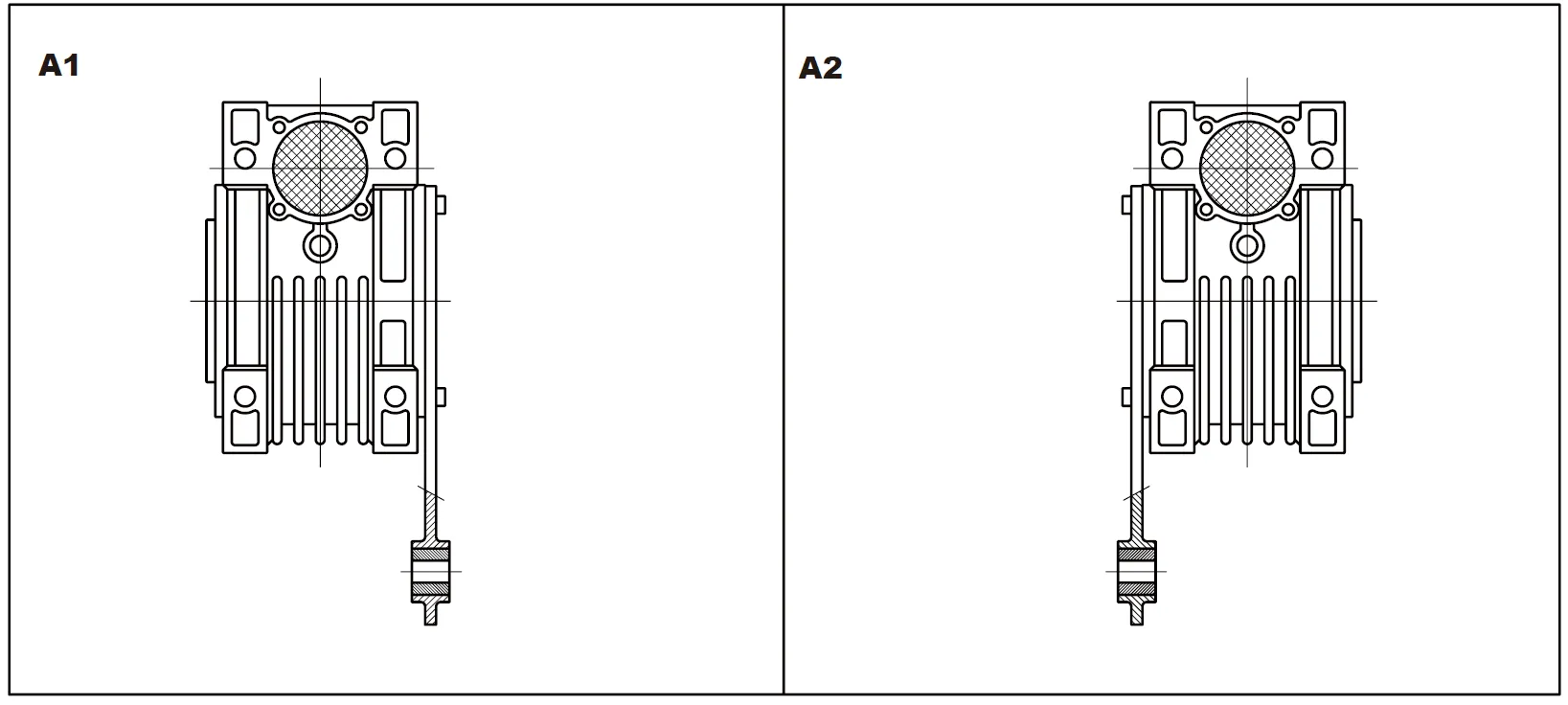

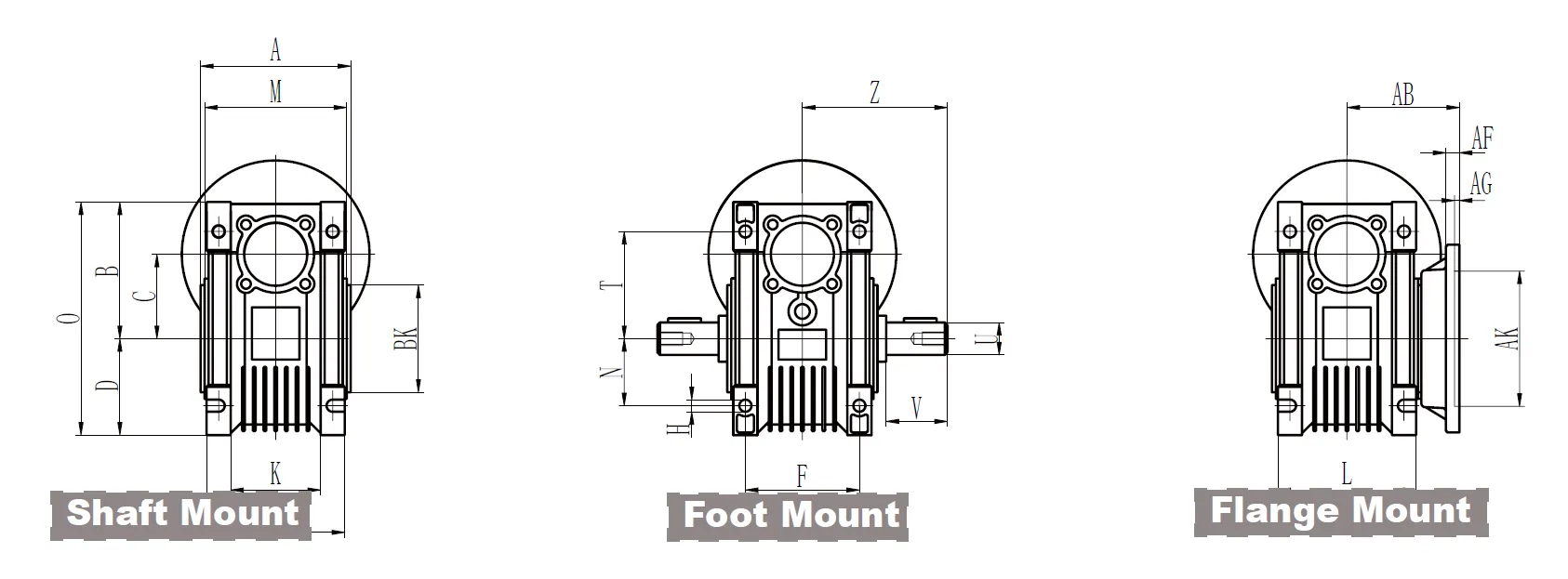

Mounting Position

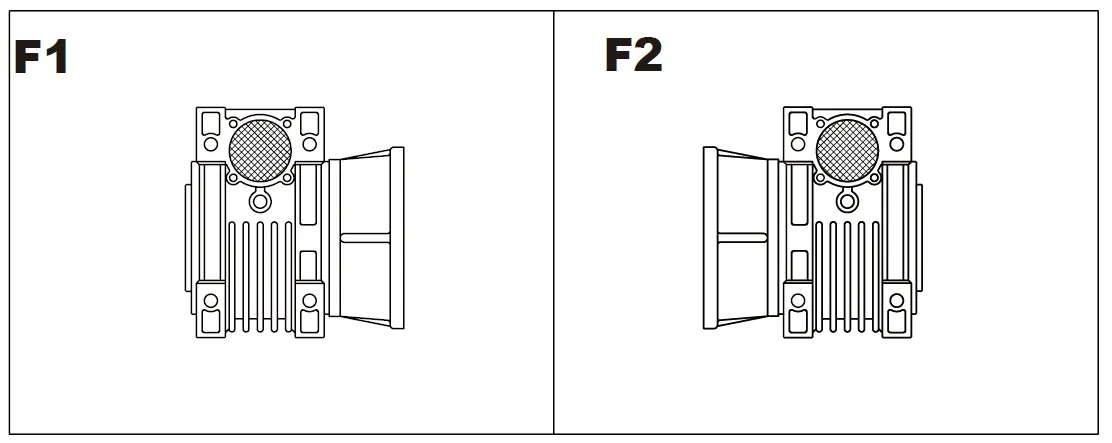

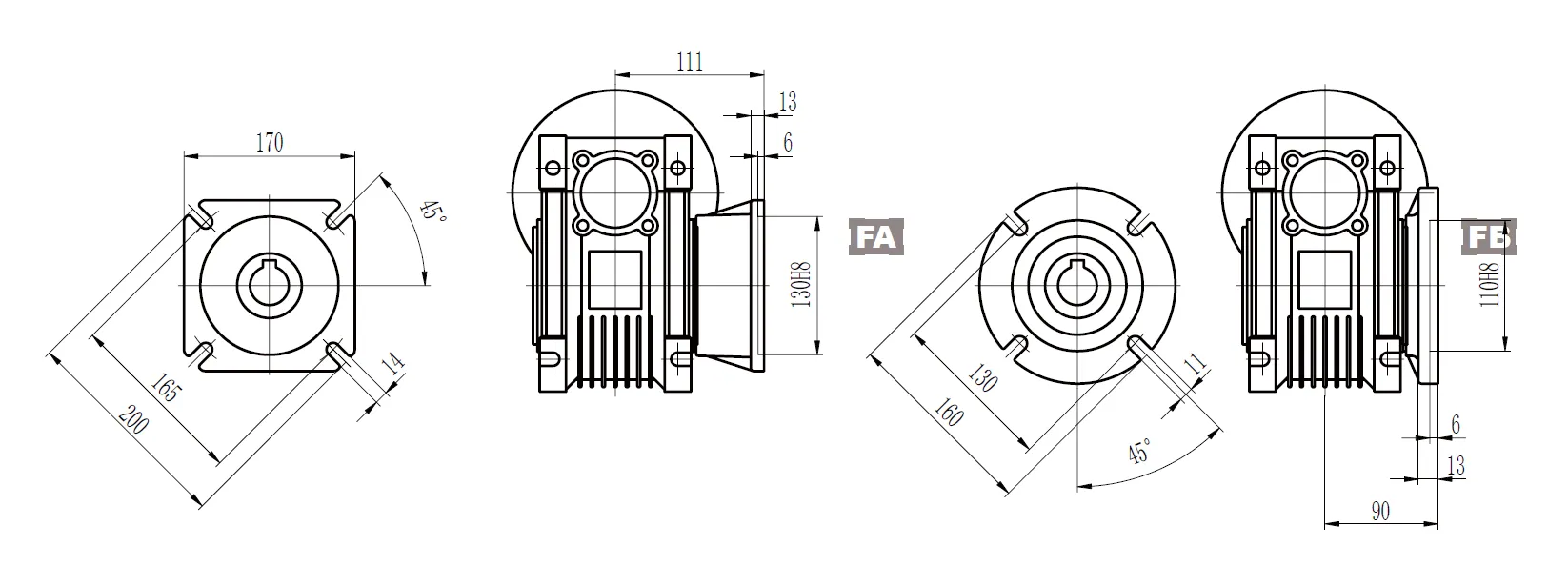

Flange F-FL

Position of Terminal Box

Position of Output Shaft

Double Extension Worm Shaft

Position of Torque Arm

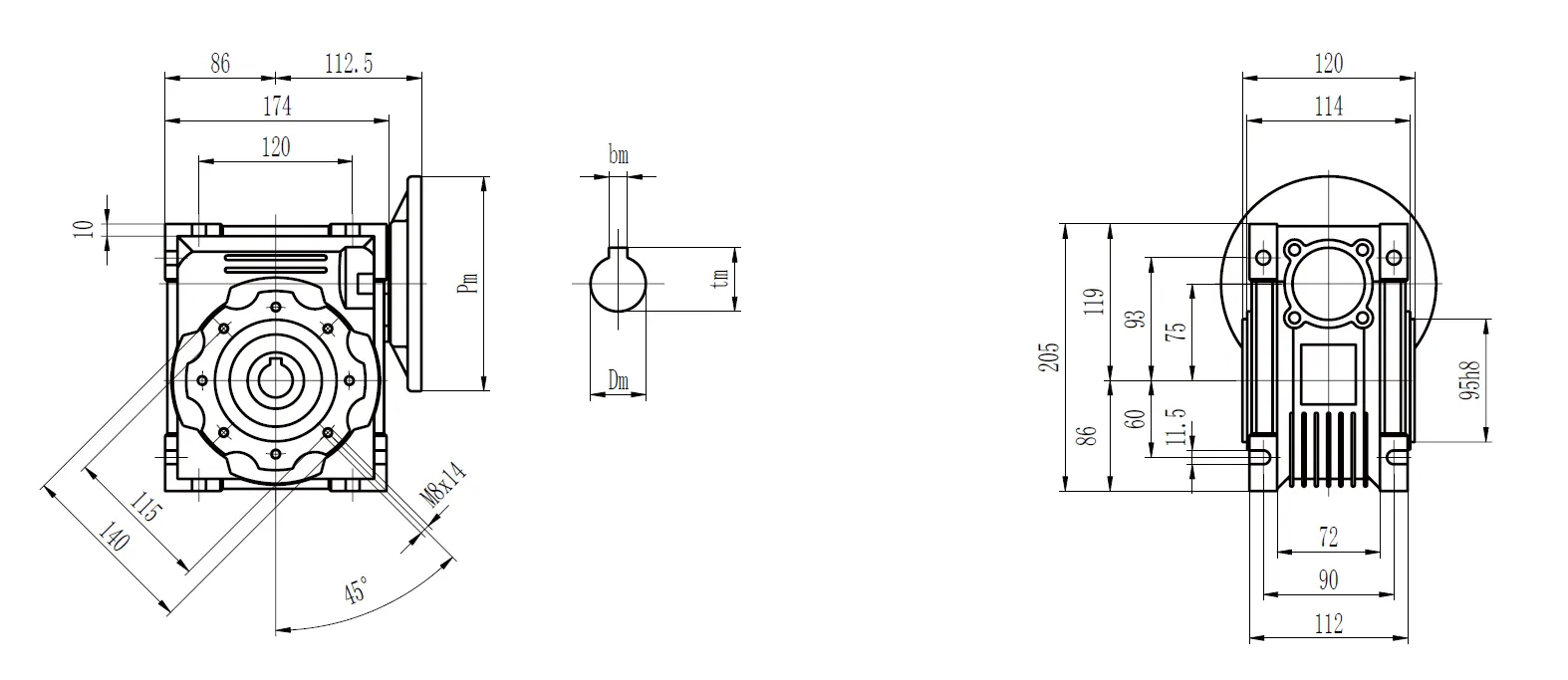

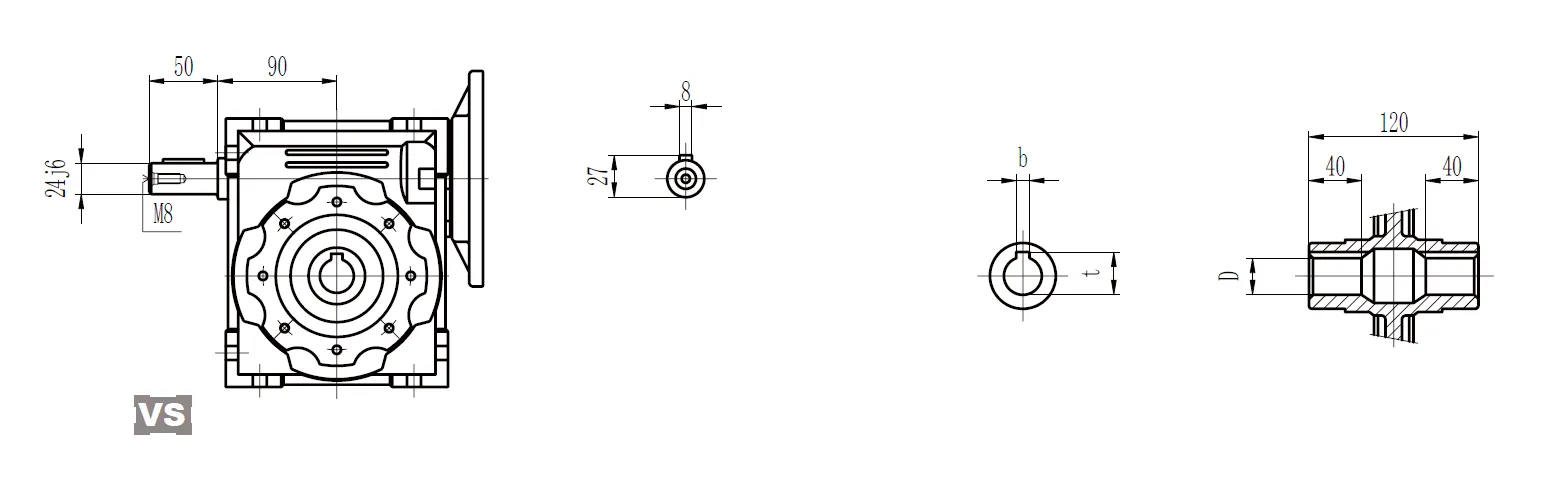

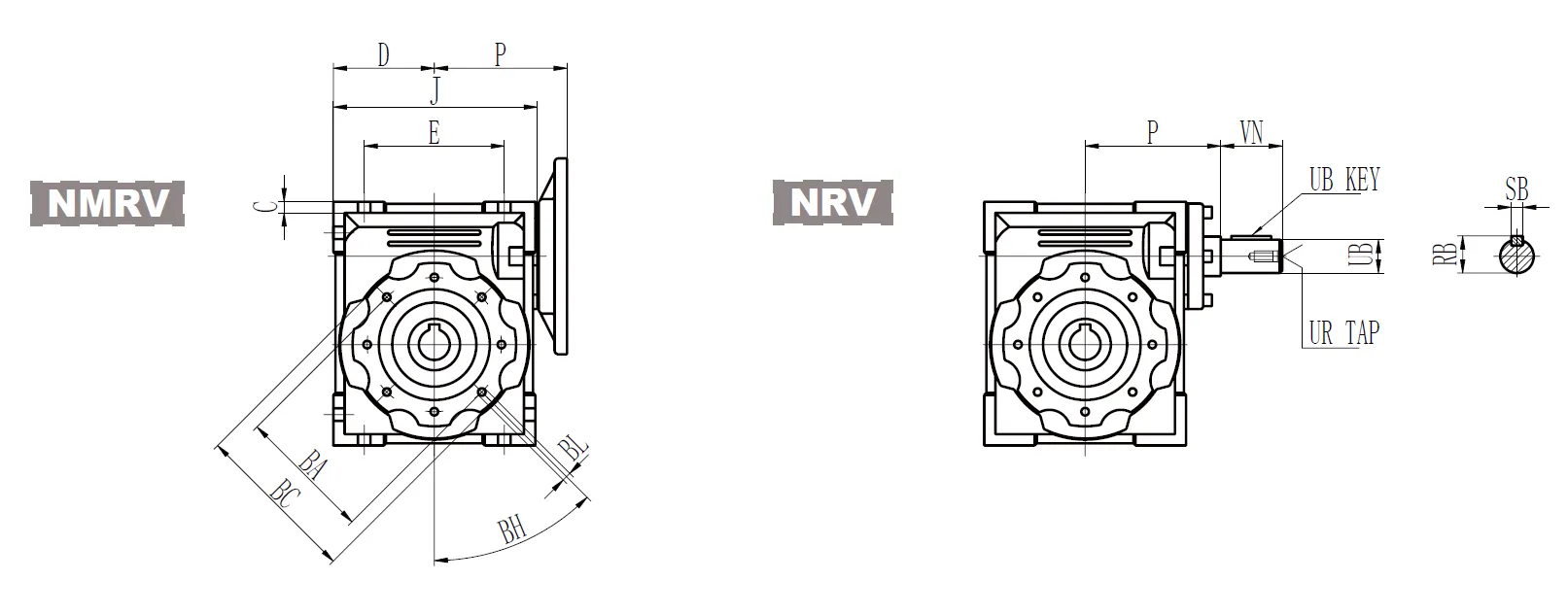

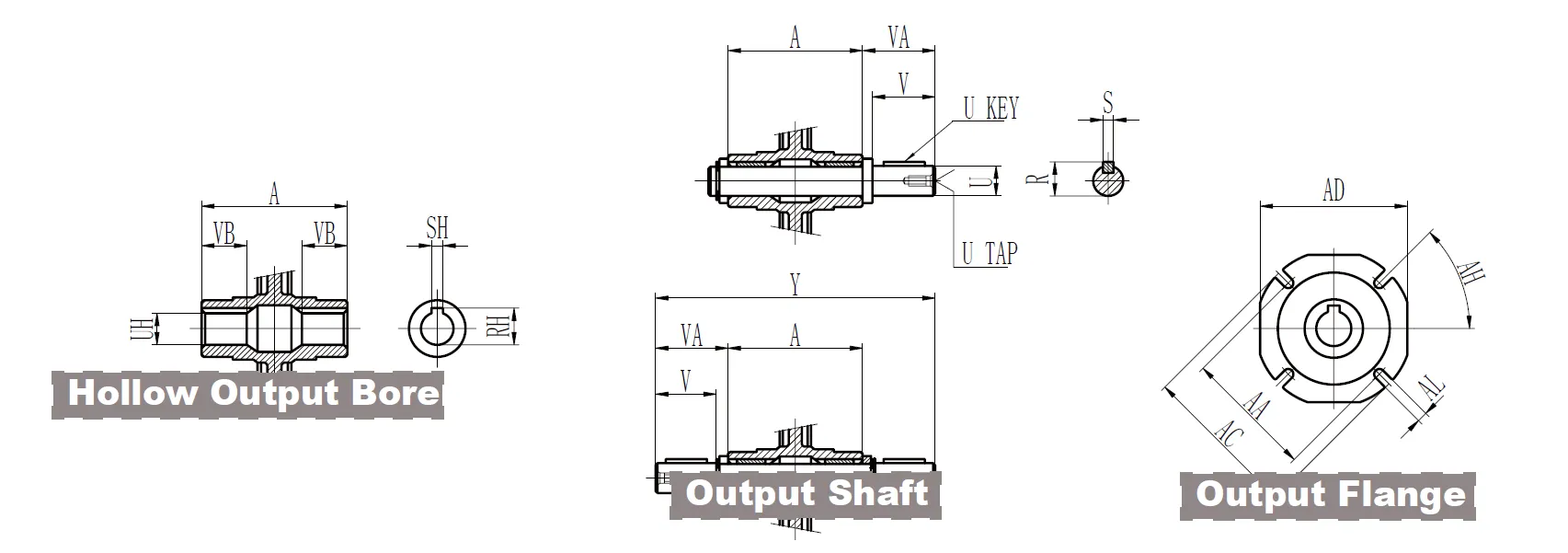

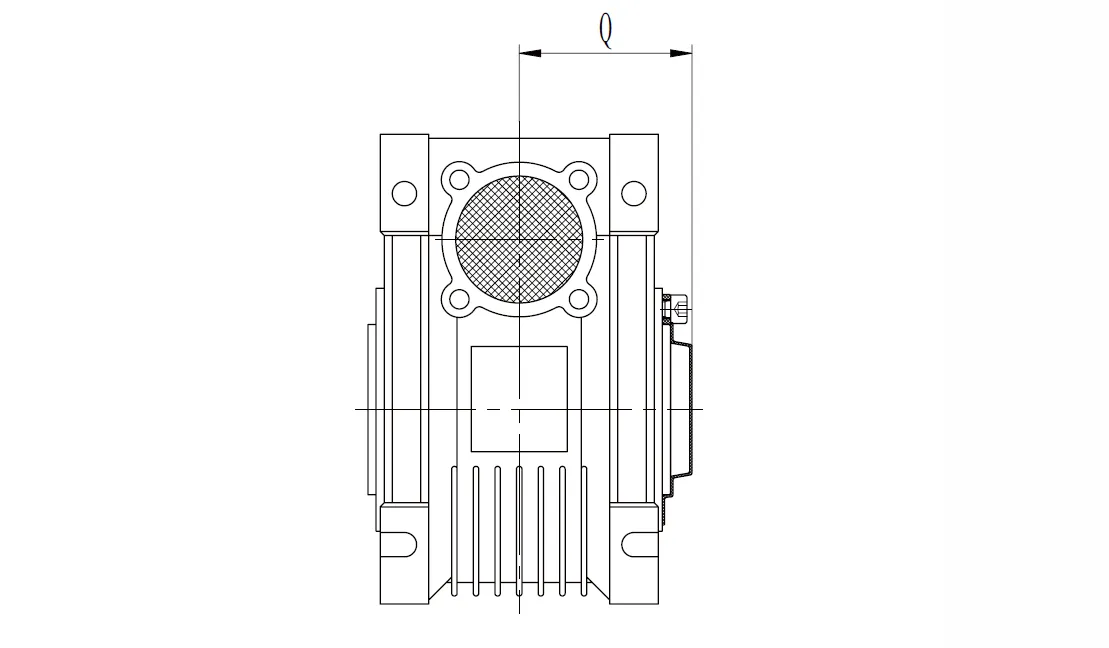

CMN-NMRV075 Worm Gear Reducer Dimensions

CMN-NMRV Worm Gear Reducer Dimensions

CMN-NMRV Inch Series

| Hollow Output Bore | 030 | 040 | 050 | 063 | 075 | 090 | 110 | 130 | |

| RH | 0.71 | 0.84 | 1.12 | 1.24 | 1.37 | 1.52 | 1.8 | 1.93 | |

| SH | 0.188 | 0.188 | 0.25 | 0.25 | 0.25 | 0.313 | 0.375 | 0.375 | |

| UH | 0.625+0.001 0 | 0.75+0.001 0 | 1+0.001 0 | 1.125+0.001 0 | 1.25+0.001 0 | 1.375+0.001 0 | 1.625+0.001 0 | 1.750 | |

| VB | 0.83 | 1.14 | 1.28 | 1.42 | 1.56 | 1.77 | 1.97 | 2.24 | |

| Output Shaft | 030 | 040 | 050 | 063 | 075 | 090 | 110 | 130 | |

| R | 0.7 | 0.83 | 1.11 | 1.23 | 1.36 | 1.51 | 1.79 | 1.92 | |

| S | 0.188 | 0.188 | 0.25 | 0.25 | 0.25 | 0.313 | 0.375 | 0.375 | |

| U | 0.6250 -0.0005 | 0.750 -0.0005 | 10 -0.0005 | 0 -0.0005 | 1.250 -0.0005 | 1.3750 -0.0005 | 1.6250 -0.0005 | 1.750 -0.0005 | |

| U KEY | 0.1875x1.125 | 0.1875x1.5 | 0.25x1.5 | 0.25x1.875 | 0.25x2.25 | 0.3125x2.5 | 0.375x2.75 | 0.375x2.75 | |

| UT | 1/4-20 | 1/4-20 | 3/8-16 | 3/8-16 | 1/2-13 | 1/2-13 | 5/8-11 | 5/8-11 | |

| V | 1.57 | 1.97 | 1.97 | 2.36 | 2.76 | 3.15 | 3.54 | 3.54 | |

| VA | 1.67 | 2.09 | 2.11 | 2.5 | 2.89 | 3.33 | 3.72 | 3.74 | |

| Y | 5.82 | 7.25 | 7.84 | 9.41 | 10.5 | 12.17 | 13.54 | 14.17 | |

| CMN-NMRV | 030 | 040 | 050 | 063 | 075 | 090 | 110 | 130 |

| A | 2.48 | 3.07 | 3.62 | 4.41 | 4.72 | 5.51 | 6.1 | 6.69 |

| B | 2.24 | 2.81 | 3.31 | 4.02 | 4.69 | 5.31 | 6.59 | 7.38 |

| BA | 2.56 | 2.95 | 3.35 | 3.74 | 4.53 | 5.12 | 6.5 | 8.46 |

| BC | 2.95 | 3.43 | 3.94 | 4.33 | 5.51 | 6.3 | 7.87 | 9.84 |

| BH | 90 ° | 45 ° | 45 ° | 45 ° | 45 ° | 45 ° | 45° | 45 ° |

| BK | 2.165 0 -0.0018 | 2.362 0 -0.0018 | 2.756 0 -0.0018 | 3.15 0 -0.0021 | 3.74 0 -0.0021 | 4.331 0 -0.0021 | 5.118 0 -0.0025 | 7.087 0 -0.0025 |

| BL | M6x11 | M6x10 | M8x10 | M8x14 | M8x14 | M10x18 | M10x18 | M12x21 |

| C | 1.18 | 1.57 | 1.97 | 2.48 | 2.95 | 3.54 | 4.33 | 5.12 |

| D | 1.57 | 1.97 | 2.36 | 2.83 | 3.39 | 4.06 | 5.02 | 5.81 |

| E | 2.13 | 2.76 | 3.15 | 3.94 | 4.72 | 5.51 | 6.69 | 7.87 |

| F | 1.73 | 2.36 | 2.76 | 3.35 | 3.54 | 3.94 | 4.53 | 4.72 |

| G | 0.22 | 0.26 | 0.28 | 0.31 | 0.39 | 0.43 | 0.57 | 0.61 |

| H | 0.26 | 0.26 | 0.33 | 0.33 | 0.45 | 0.51 | 0.55 | 0.63 |

| J | 3.15 | 3.98 | 4.76 | 5.75 | 6.85 | 8.19 | 9.94 | 11.52 |

| K | 1.26 | 1.69 | 1.93 | 2.64 | 2.83 | 2.91 | - | - |

| L | 2.2 | 2.8 | 3.35 | 4.06 | 4.41 | 5.12 | 5.67 | 6.1 |

| M | 2.28 | 2.87 | 3.43 | 4.17 | 4.49 | 5.28 | 5.83 | 6.38 |

| N | 1.06 | 1.38 | 1.57 | 1.97 | 2.36 | 2.76 | 3.35 | 3.94 |

| O | 3.82 | 4.78 | 5.67 | 6.85 | 8.07 | 9.37 | 11.61 | 13.19 |

| P | 2.64 | 3.15 | 3.54 | 4.13 | 4.96 | 5.63 | 6.81 | 7.6 |

| Q | 0.83 | 2.36 | 2.91 | 3.54 | 4.13 | 4.92 | 5.59 | 6.38 |

| T | 1.73 | 2.17 | 2.52 | 3.15 | 3.66 | 4.02 | 4.92 | 5.51 |

| Z | 2.91 | 3.63 | 3.92 | 4.71 | 5.25 | 6.09 | 6.77 | 7.09 |

| Output Flange | AA | AB | AC | AD | AF | AG | AH | AK | AL | ||

| 030 | FA | 2.68 | 2.15 | 3.15 | 2.76 | 0.24 | 0.16 | 45° | 1.969 | +0.0015 0 | 0.26 |

| 040 | FA | 2.95 | 2.64 | 4.33 | 3.74 | 0.28 | 0.16 | 45° | 2.362 | +0.0018 | 0.35 |

| 0 | |||||||||||

| FB | 2.95 | 3.82 | 4.33 | 3.74 | 0.28 | 0.16 | 45° | 2.362 | +0.0018 0 | 0.35 | |

| FC | 4.53 | 3.15 | 5.51 | - | 0.35 | 0.2 | 45° | 3.74 | +0.0021 0 | 0.37 | |

| FD | 3.94 | 2.28 | 4.72 | - | 0.47 | 0.2 | 45° | 3.15 | +0.0018 | 0.35 | |

| 0 | |||||||||||

| 050 | FA | 3.35 | 3.54 | 4.92 | 4.33 | 0.35 | 0.2 | 45° | 2.756 | +0.0018 | 0.43 |

| 0 | |||||||||||

| FB | 3.35 | 4.72 | 4.92 | 4.33 | 0.35 | 0.2 | 45° | 2.756 | +0.0018 0 | 0.43 | |

| FC | 5.12 | 3.5 | 6.3 | - | 0.39 | 0.2 | 45° | 4.331 | +0.0021 0 | 0.37 | |

| FD | 4.53 | 2.83 | 5.51 | - | 0.57 | 0.2 | 45° | 3.543 | +0.0021 | 0.43 | |

| 0 | |||||||||||

| 063 | FA | 4.13 | 3.23 | 7.09 | 5.59 | 0.39 | 0.24 | 45° | 4.528 | +0.0021 | 0.43 |

| 0 | |||||||||||

| FB | 5.91 | 4.41 | 7.09 | 5.59 | 0.39 | 0.24 | 45° | 4.528 | +0.0021 | 0.43 | |

| 0 | |||||||||||

| FC | 6.5 | 3.86 | 7.87 | - | 0.39 | 0.2 | 45° | 5.118 | +0.0025 0 | 0.43 | |

| FD | 6.5 | 4.21 | 7.87 | - | 0.39 | 0.2 | 45° | 5.118 | +0.0025 | 0.43 | |

| 0 | |||||||||||

| FE | 5.12 | 3.17 | 6.3 | - | 0.65 | 0.2 | 45° | 4.331 | +0.0021 | 0.43 | |

| 0 | |||||||||||

| 075 | FA | 6.5 | 4.37 | 7.87 | 6.69 | 0.51 | 0.24 | 45° | 5.118 | +0.0025 | 0.55 |

| 0 | |||||||||||

| FB | 5.12 | 3.54 | 6.3 | - | 0.51 | 0.24 | 45° | 4.331 | +0.0021 | 0.55 | |

| 0 | |||||||||||

| 090 | FA | 6.89 | 4.37 | 8.27 | 8.27 | 0.51 | 0.24 | 45° | 5.984 | +0.0025 | 0.55 |

| 0 | |||||||||||

| FB | 8.46 | 4.8 | 9.84 | - | 0.71 | 0.24 | 45° | 7.087 | +0.0025 0 | 0.55 | |

| FC | 6.5 | 4.33 | 7.87 | - | 0.67 | 0.24 | 45° | 5.118 | +0.0025 0 | 0.43 | |

| FD | 6.89 | 5.94 | 8.27 | - | 0.51 | 0.24 | 45° | 5.984 | +0.0025 | 0.55 | |

| 0 | |||||||||||

| 110 | FA | 9.06 | 5.16 | 11.02 | 10.24 | 0.59 | 0.24 | 45° | 6.693 | +0.0025 | 0.55 |

| 0 | |||||||||||

| FB | 9.06 | 7.09 | 11.02 | 10.24 | 0.59 | 0.24 | 45° | 6.693 | +0.0025 | 0.55 | |

| 0 | |||||||||||

| 130 | FA | 10.04 | 5.51 | 12.6 | 11.42 | 0.59 | 0.24 | 22.5° | 7.087 | +0.0025 0 | 0.63 |

| Input Shaft | 030 | 040 | 050 | 063 | 075 | 090 | 110 | 130 | |

| SB | 0.094 | 0.125 | 0.188 | 0.188 | 0.188 | 0.188 | 0.25 | 0.25 | |

| RB | 0.42 | 0.55 | 0.7 | 0.83 | 0.96 | 0.96 | 1.24 | 1.36 | |

| UB | 0.3750 -0.0005 | 0.50 -0.0005 | 0.6250 -0.0005 | 0.750 -0.0005 | 0.8750 -0.0005 | 0.8750 -0.0005 | 1.1250 -0.0005 | 1.250 -0.0005 | |

| UB KEY | 0.094x0.875 | 0.125x0.875 | 0.1875x1.125 | 0.1875x1.5 | 0.1875x1.875 | 0.1875x1.875 | 0.25x2.25 | 0.25x2.5 | |

| UR | - | 1/4-20 | 1/4-20 | 1/4-20 | 1/4-20 | 1/4-20 | 3/8-16 | 1/2-13 | |

| VN | 1.18 | 1.18 | 1.58 | 1.97 | 2.36 | 2.36 | 2.76 | 3.15 | |

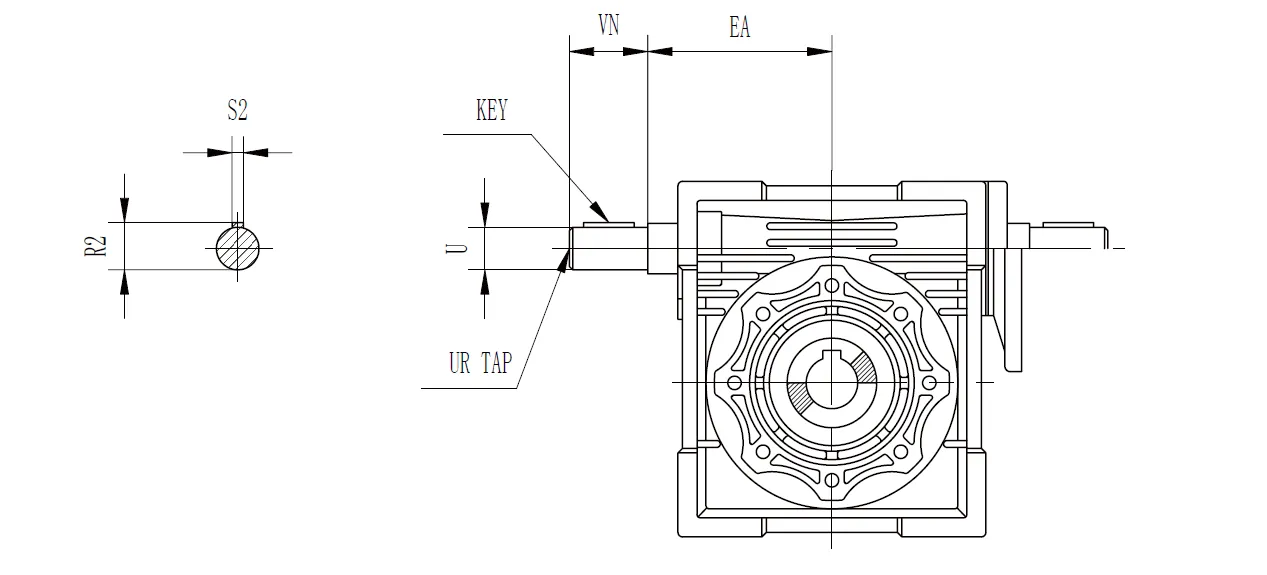

High Speed Extension Shaft Dimensions

| CMN-NMRV | EA | U | VN | UR | S2 | R2 | KEY | |

| Length | Square | |||||||

| 030 | 1.772 | 0.3750 -0.0005 | 1.18 | - | 0.093 | 0.42 | 0.875 | 0.094 |

| 040 | 2.087 | 0.50 -0.0005 | 1.18 | 1/4-20 | 0.13 | 0.55 | 0.875 | 0.125 |

| 050 | 2.52 | 0.6250 -0.0005 | 1.58 | 1/4-20 | 0.19 | 0.7 | 1.125 | 0.188 |

| 063 | 2.953 | 0.750 -0.0005 | 1.97 | 1/4-20 | 0.19 | 0.83 | 1.5 | 0.188 |

| 075 | 3.543 | 0.8750 -0.0005 | 2.36 | 1/4-20 | 0.19 | 0.96 | 1.875 | 0.188 |

| 090 | 4.252 | 0.8750 -0.0005 | 2.36 | 1/4-20 | 0.19 | 0.96 | 1.875 | 0.188 |

| 110 | 5.315 | 1.1250 -0.0005 | 2.76 | 3/8-16 | 0.25 | 1.24 | 2.25 | 0.25 |

| 130 | 6.102 | 1.250 -0.0005 | 3.15 | 1/2-13 | 0.25 | 1.36 | 2.5 | 0.25 |

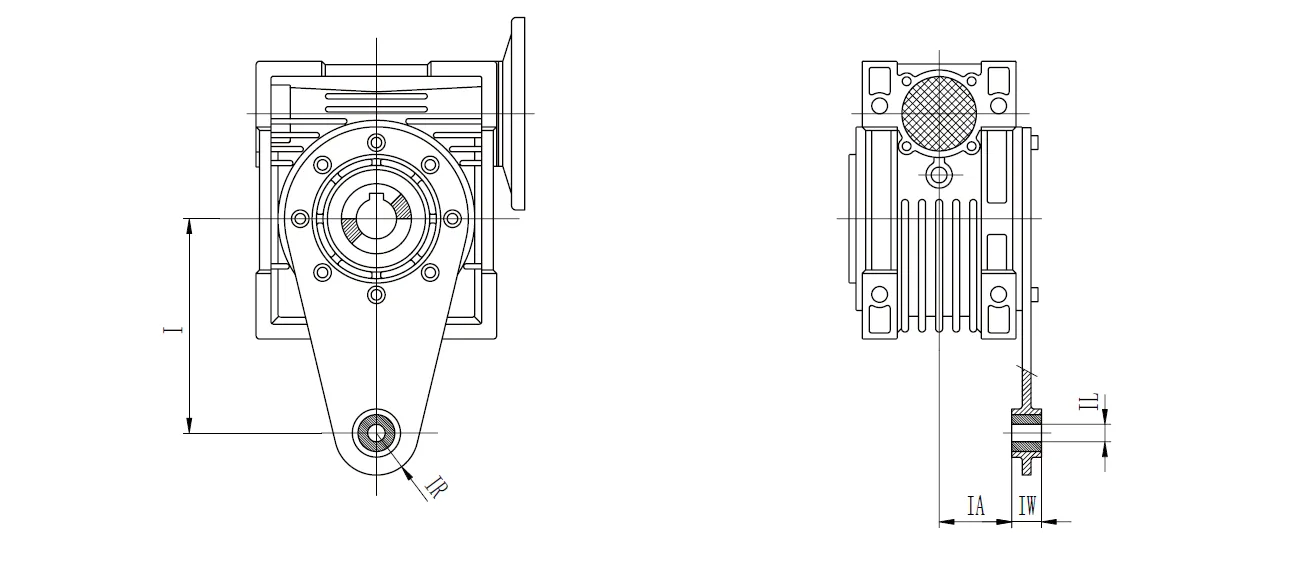

Torque Arm Dimensions

| CMN-NMRV | I | IA | IL | IR | IW |

| 025 | 2.76 | 0.69 | 0.31 | 0.59 | 0.55 |

| 030 | 3.35 | 0.94 | 0.31 | 0.59 | 0.55 |

| 040 | 3.94 | 1.24 | 0.39 | 0.71 | 0.55 |

| 050 | 3.94 | 1.52 | 0.39 | 0.71 | 0.55 |

| 063 | 5.91 | 1.93 | 0.39 | 0.71 | 0.55 |

| 075 | 7.87 | 1.87 | 0.79 | 1.18 | 0.98 |

| 090 | 7.87 | 2.26 | 0.79 | 1.18 | 0.98 |

| 110 | 9.84 | 2.44 | 0.98 | 1.38 | 1.18 |

| 130 | 9.84 | 2.72 | 0.98 | 1.38 | 1.18 |

Protective Cover Dimensions

| CMN-NMRV | Q |

| 030 | 1.65 |

| 040 | 1.97 |

| 050 | 2.28 |

| 063 | 2.72 |

| 075 | 2.91 |

| 090 | 3.39 |

| 110 | 3.7 |

| 130 | 4.02 |

NEMA Flange Availability

| CMN-NMRV | NEMA Flange | Input Bore Diameter | Available Ratios | |||||||||||

| 5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 | 60 | 80 | 100 | |||

| 030 | 48C | 0.5 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |

| 040 | 56C | 0.625 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| 050 | 56C | 0.625 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| 063 | 56C | 0.625 | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| 140TC | 0.875 | ● | ● | ● | ● | ● | ● | ● | ||||||

| 075 | 56C | 0.625 | ● | ● | ● | ● | ||||||||

| 140TC | 0.875 | ● | ● | ● | ● | ● | ● | |||||||

| 180TC | 1.125 | ● | ● | ● | ||||||||||

| 090 | 56C | 0.625 | ● | ● | ||||||||||

| 140TC | 0.875 | ● | ● | ● | ● | ● | ||||||||

| 180TC | 1.125 | ● | ● | ● | ● | ● | ● | ● | ||||||

| 110 | 140TC | 0.875 | ● | ● | ● | ● | ||||||||

| 180TC | 1.125 | ● | ● | ● | ● | ● | ● | |||||||

| 210TC | 1.375 | ● | ● | ● | ● | |||||||||

| 130 | 140TC | 0.875 | ● | ● | ||||||||||

| 180TC | 1.125 | ● | ● | ● | ● | ● | ||||||||

| 210TC | 1.375 | ● | ● | ● | ● | ● | ● | ● | ||||||

CMN-NMRV075 Worm Drive Gearbox Features

- Compact and Robust Housing Design

The CMN-NMRV075 worm drive gearbox features a die-cast aluminum alloy housing, ensuring lightweight yet durable construction. This design minimizes heat buildup, enhances corrosion resistance, and provides structural integrity for demanding industrial environments, supporting applications like conveyors and packaging machinery with reliable performance. - High-Efficiency Worm Gear Mechanism

The worm reducer gearbox incorporates a precision-engineered worm gear made from bronze and a 20CrMnTi steel worm shaft with 56-62HRC hardness. This combination ensures efficient power transmission, high torque output (90-369N.m), and reduced wear, delivering smooth operation and extended service life in heavy-duty applications. - Versatile Gear Ratio Options

Offering gear ratios from 5:1 to 100:1, the CMN-NMRV075 worm gear reducers accommodate diverse speed reduction needs. This flexibility allows precise customization for specific applications, ensuring optimal performance in industries such as food processing, textiles, and ceramics, where varying speeds are critical. - Multiple Mounting Configurations

The worm gear speed reducer supports universal mounting positions, including foot, flange, and torque arm setups. This adaptability simplifies integration into existing systems, reduces installation complexity, and caters to space-constrained environments, making it suitable for automation, robotics, and material handling equipment. - Low Noise and Vibration Operation

Designed with precision-machined components, the CMN-NMRV075 worm gearbox minimizes noise and vibration during operation. Its optimized gear meshing and high-quality bearings ensure quiet performance, making it ideal for noise-sensitive environments like pharmaceutical manufacturing or indoor industrial settings requiring minimal disruption. - Compatibility with Servo/Stepper Motors

The right angle worm gearbox is compatible with NEMA42/52 servo or stepper motors, with input shaft diameters of 19mm, 22mm, 24mm, or 28mm. This ensures seamless integration with modern automation systems, providing precise control and high torque for applications like CNC machinery and conveyor systems.

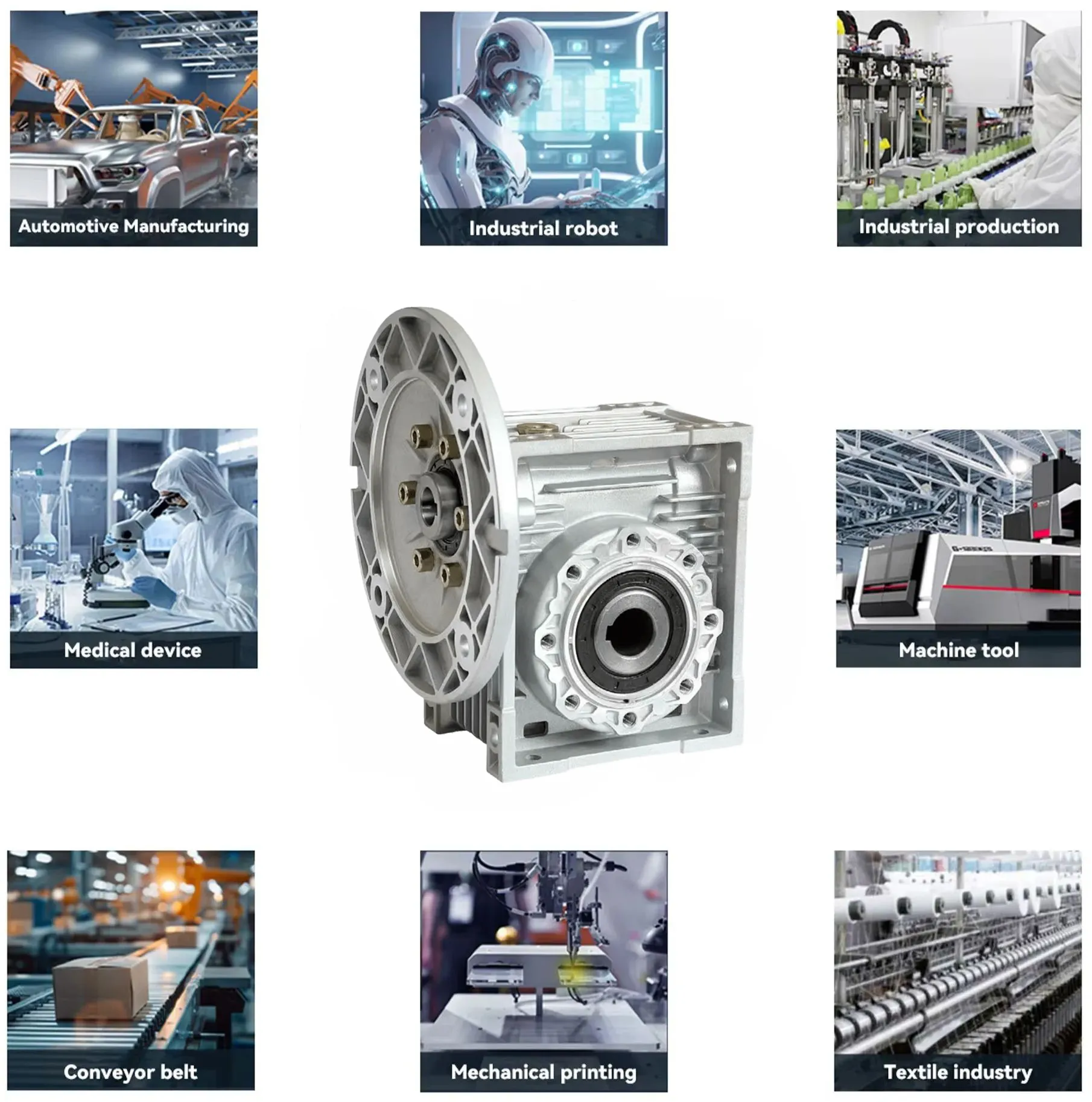

CMN-NMRV075 Worm Gear Reducer Applications

- Food Processing Industry

The CMN-NMRV075 worm gear reducer is widely used in food processing equipment, such as mixers and conveyors. Its corrosion-resistant aluminum housing and smooth operation ensure hygiene and reliability, meeting strict industry standards while delivering consistent torque for efficient production processes. - Textile Manufacturing

In textile machinery, the worm reducer gearbox provides precise speed control for spinning and weaving equipment. Its high torque output and versatile gear ratios enable smooth handling of varying loads, ensuring fabric quality and operational efficiency in high-speed, continuous production environments. - Ceramics Production

The CMN-NMRV075 worm gear drive gearbox is ideal for ceramics manufacturing, powering equipment like kilns and molding machines. Its robust design withstands harsh conditions, while low noise and vibration ensure stable operation, supporting precise material handling and consistent output in demanding industrial settings. - Automation and Robotics

In automation systems, the worm drive reduction gearbox supports robotic arms and automated conveyors. Its compatibility with NEMA42/52 motors and multiple mounting options allows seamless integration, providing high torque and precise control for tasks requiring accuracy in automated production lines. - Packaging Machinery

The CMN-NMRV075 worm reduction gearbox drives packaging equipment, such as filling and sealing machines. Its compact design and high-efficiency gear mechanism ensure reliable performance in space-constrained setups, delivering consistent speed reduction and torque for high-throughput packaging operations in various industries. - Material Handling Systems

For material handling applications like conveyor belts and hoists, the aluminum worm gearboxes offer dependable torque and speed control. Its durable construction and universal mounting flexibility support heavy loads and continuous operation, enhancing efficiency in warehouses and logistics facilities.

CMN-NMRV075 Worm Gearbox Materials Optional

- Aluminum Alloy Housing

The standard housing for the worm gear reduction gearbox is crafted from high-strength aluminum alloy. This material offers excellent corrosion resistance, lightweight properties, and durability, making it ideal for applications in harsh environments where weight reduction and long-term reliability are critical. - Bronze Worm Wheel

The worm wheel is typically made from high-quality bronze, known for its exceptional wear resistance and ability to handle high friction. This material ensures smooth operation and longevity, even under continuous heavy loads, while minimizing the risk of gear failure. - Hardened Steel Worm Shaft

The worm shaft is manufactured from hardened steel to provide maximum strength and durability. Its hardened surface resists wear and deformation, ensuring precise torque transmission and extending the working life of the gearbox, even in demanding industrial applications. - Cast Iron Housing Option

For heavy-duty applications, a cast-iron housing can be selected instead of aluminum. Cast iron offers superior strength and impact resistance, making it suitable for environments with extreme mechanical stress or where additional protection against external forces is required. - High-Performance Seals and Bearings

The worm reducer gearbox incorporates advanced seals and bearings made from materials like stainless steel or specialized composites. These components ensure efficient lubrication, prevent contamination, and extend service life, even in environments with extreme temperatures, dust, or moisture.