CMN-NMRV040 Worm Gear Reducers/Worm Gearbox

The CMN-NMRV040 worm gear reducer, also known as a worm gearbox, is a compact, high-performance mechanical device designed to reduce rotational speed and increase torque in various applications. It features a worm gear system, consisting of a worm (a screw-like component) and a worm wheel (a toothed wheel), which work together to achieve a high gear reduction ratio. They are widely used in conveyor systems, material handling equipment, packaging machines, and other industrial applications due to their smooth operation, low noise, and efficiency.

The CMN-NMRV040 worm gear reducer, also known as a worm gearbox, is a compact, high-performance mechanical device designed to reduce rotational speed and increase torque in various applications. It features a worm gear system, consisting of a worm (a screw-like component) and a worm wheel (a toothed wheel), which work together to achieve a high gear reduction ratio. The "040" in the name refers to the frame size of the gearbox, indicating a specific dimension standard.

These worm gear reducers are made from lightweight, corrosion-resistant aluminum alloy housing, making them durable and suitable for demanding environments. They are widely used in conveyor systems, material handling equipment, packaging machines, and other industrial applications due to their smooth operation, low noise, and efficiency. Additionally, CMN-NMRV040 units are compact, easy to install, and highly adaptable, often featuring modular mounting options for flexibility in various setups.

CMN-NMRV040 Worm Gearbox Specifications

| Type | CMN-NMRV040 Worm Gearbox/ Worm Gear Speed Reducer |

| Model | CMN-NMRV040 |

| Reduction Ratio | 5,7.5,10,15,20,25,30,40,50,60,80,100 |

| Flange | FA / FL or as per your demands |

| Matching Motor | 0.06KW~15KW |

| Material | Die-casting Aluminum Alloy |

| Color | Blue /Silver Grey /Customized |

| Flange Standard | PAM / IEC |

| Accessories | Shaft, Flange, Torque arm, etc |

| Lubricant | Synthetic Oil or Worm Gear Oil |

| Usage | Machinery of food stuff, ceramics, chemicals, packing, dyeing, wood working, glass industries, etc |

| Note: 1) Please choose from the above specifications. 2) If the above options can not meet your demands, please send us your requirements(ratio, flange, mounting, application, or a picture of your old one), and we will recommond a suitable type. | |

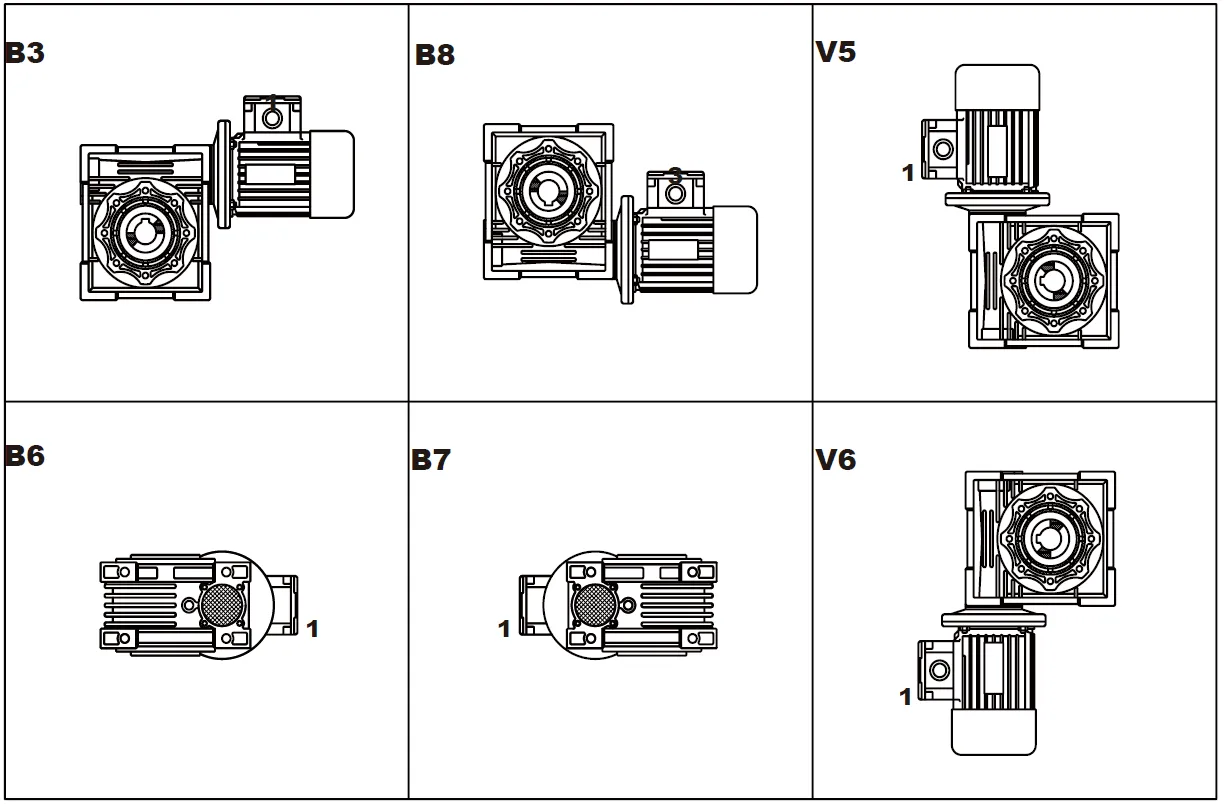

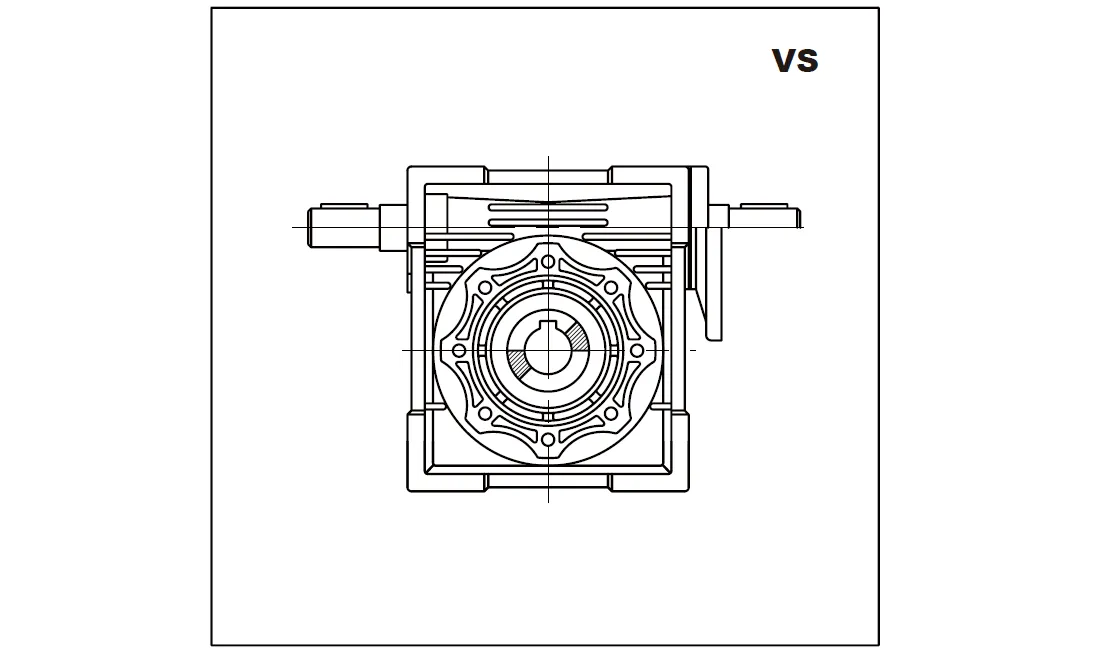

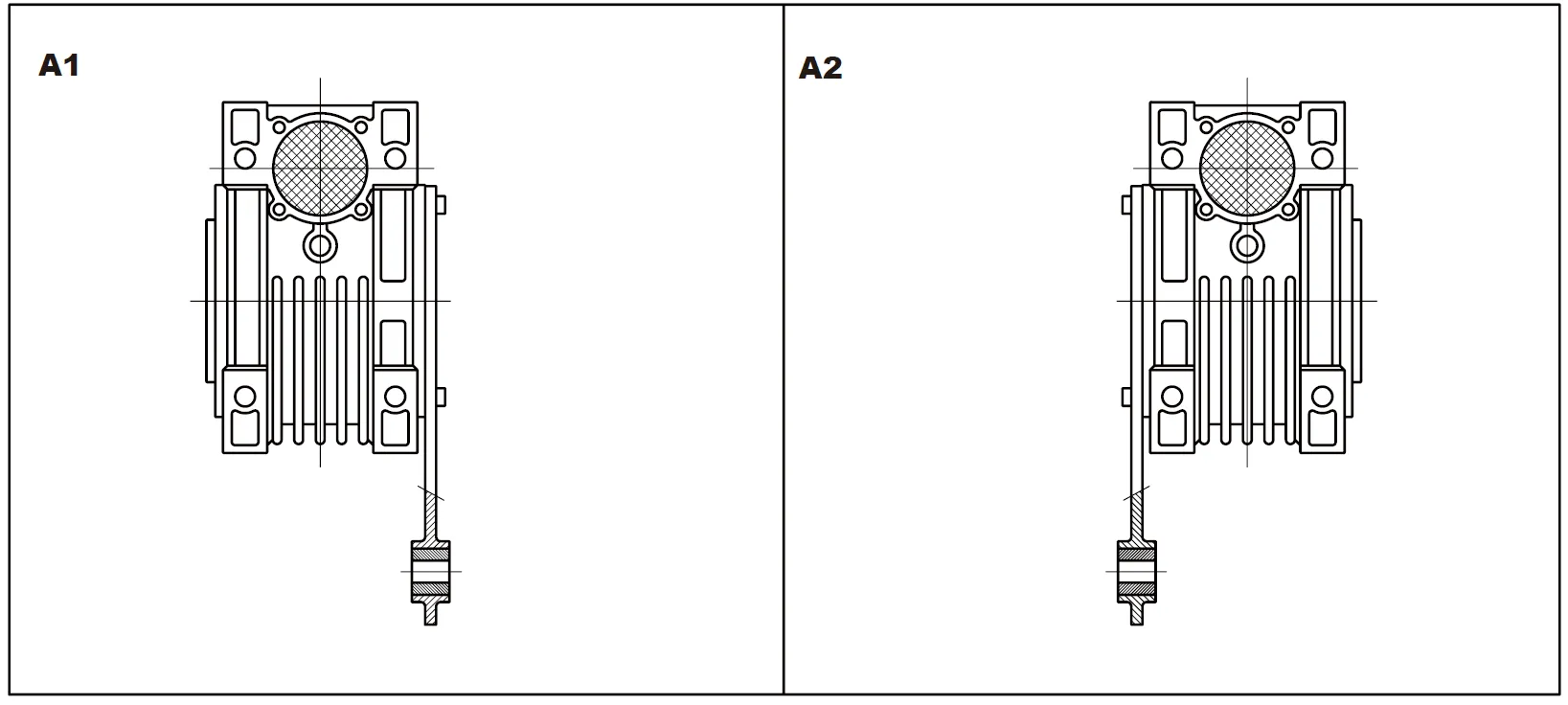

Mounting Position

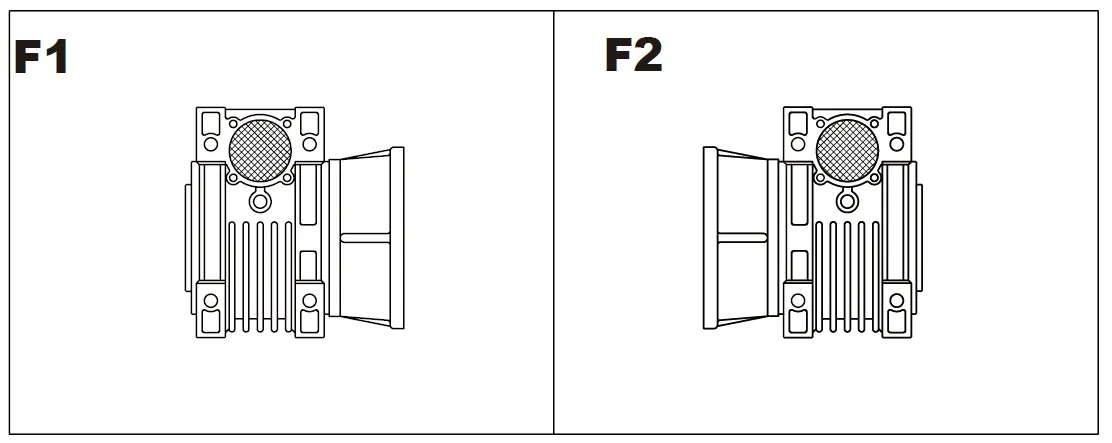

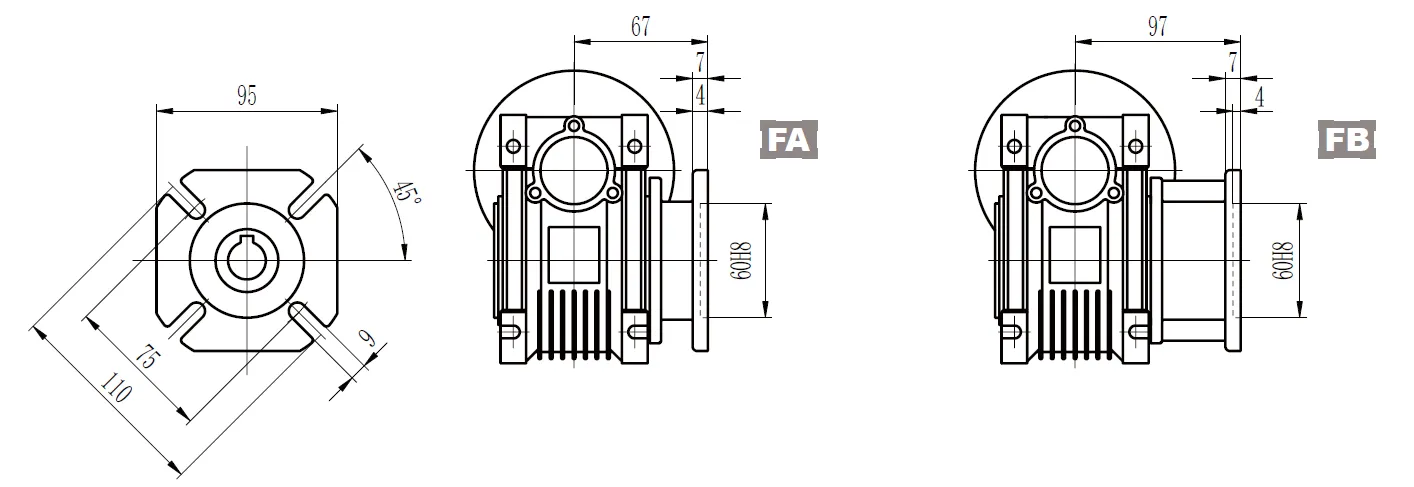

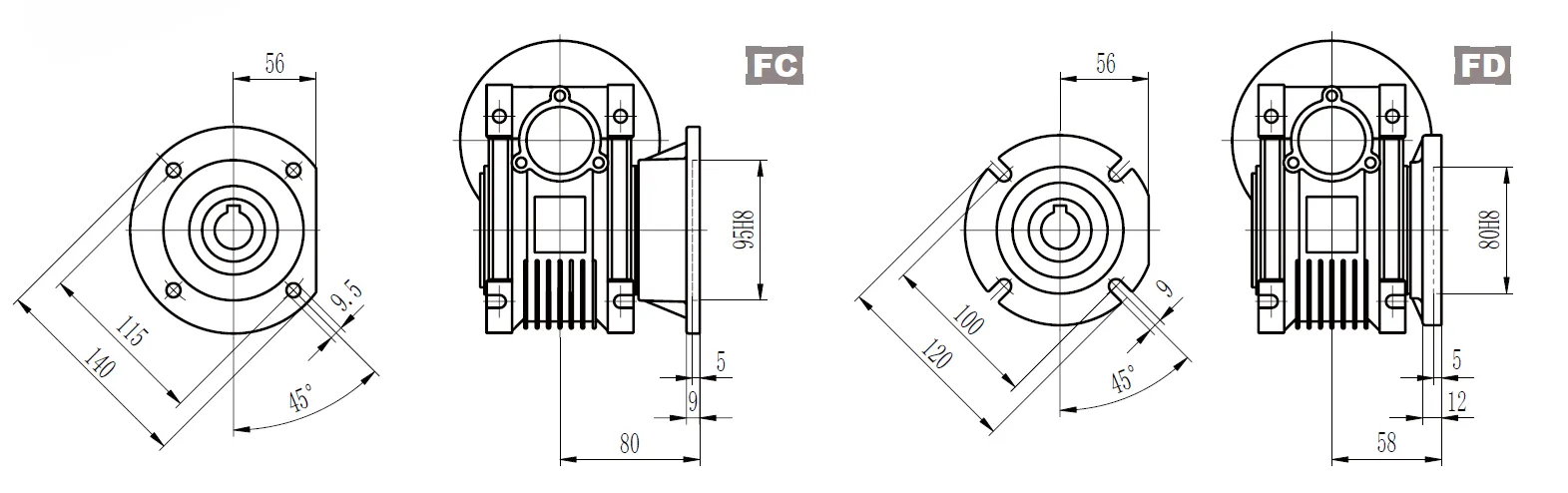

Flange F-FL

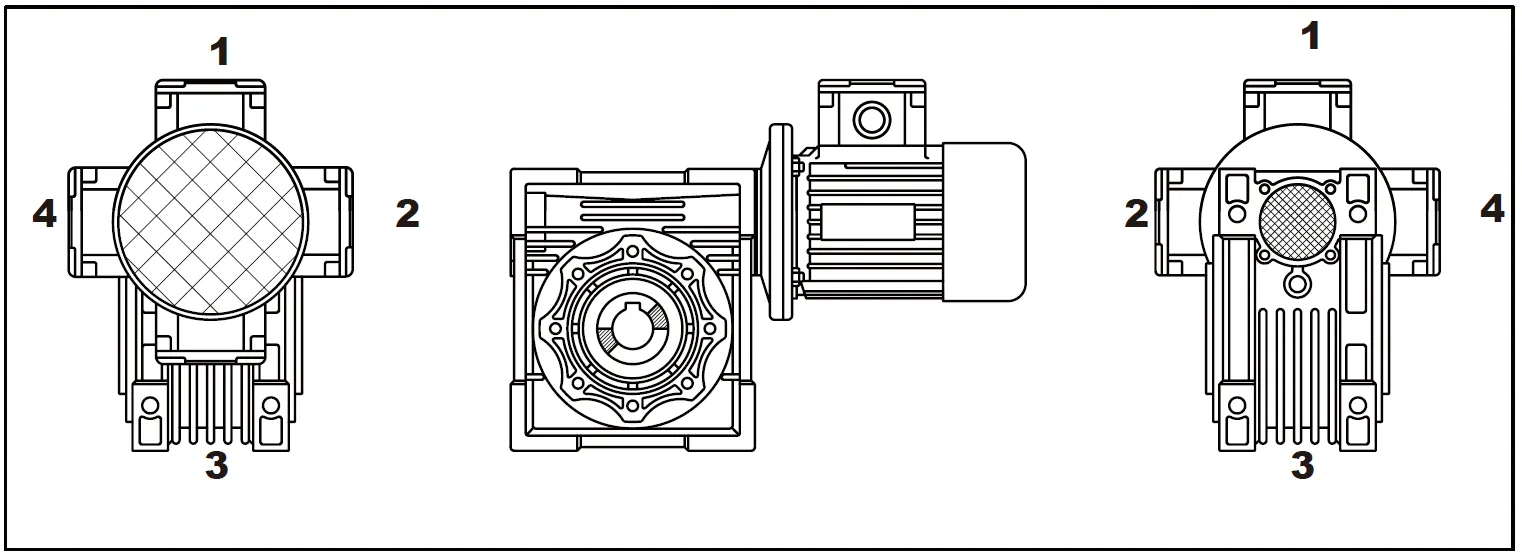

Position of Terminal Box

Position of Output Shaft

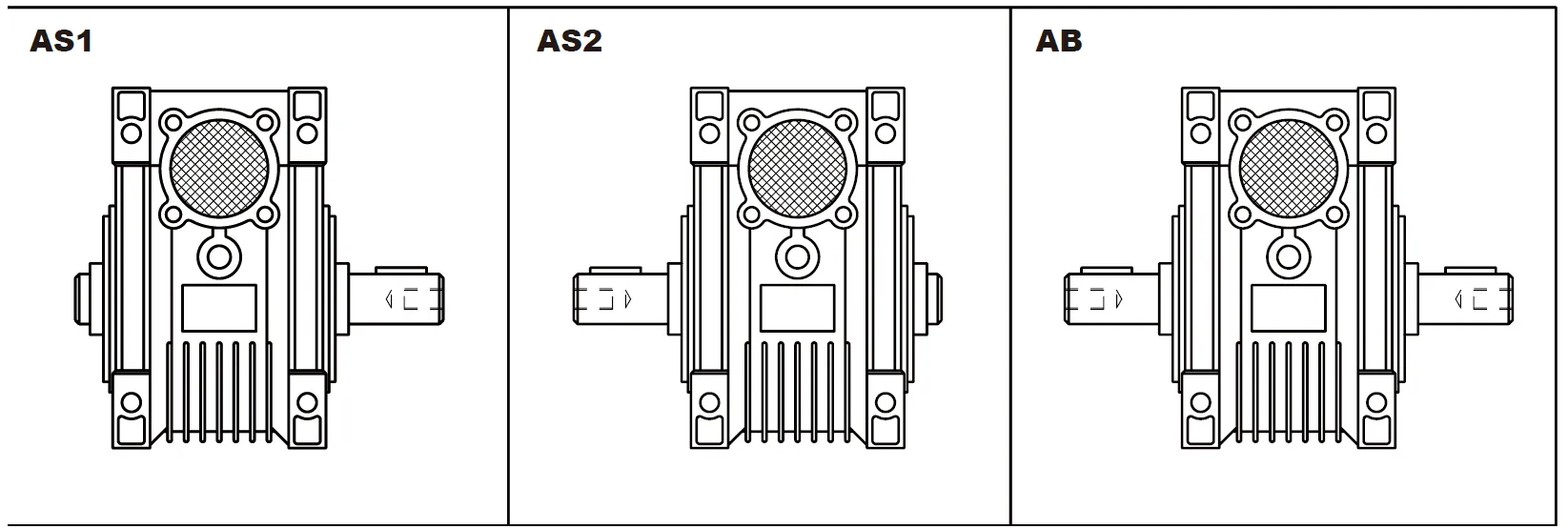

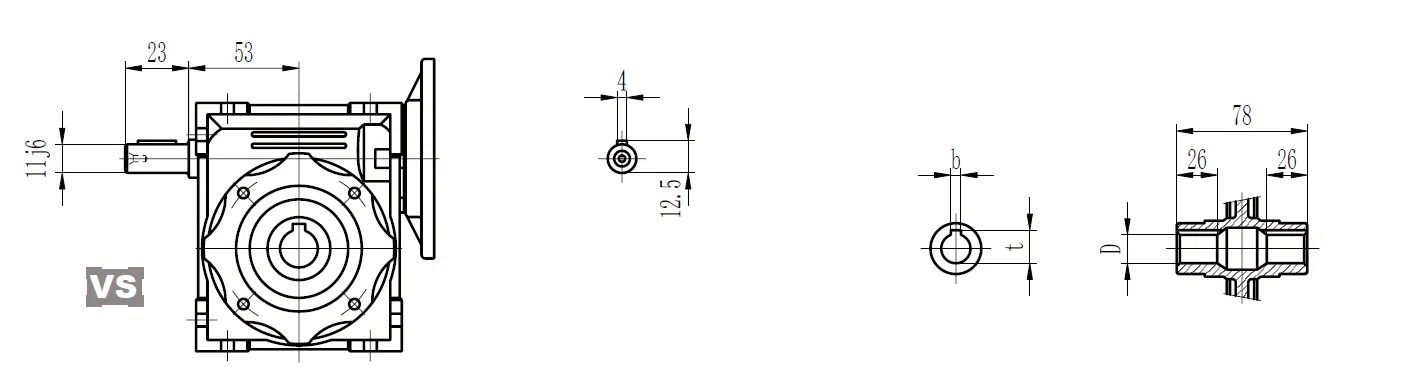

Double Extension Worm Shaft

Position of Torque Arm

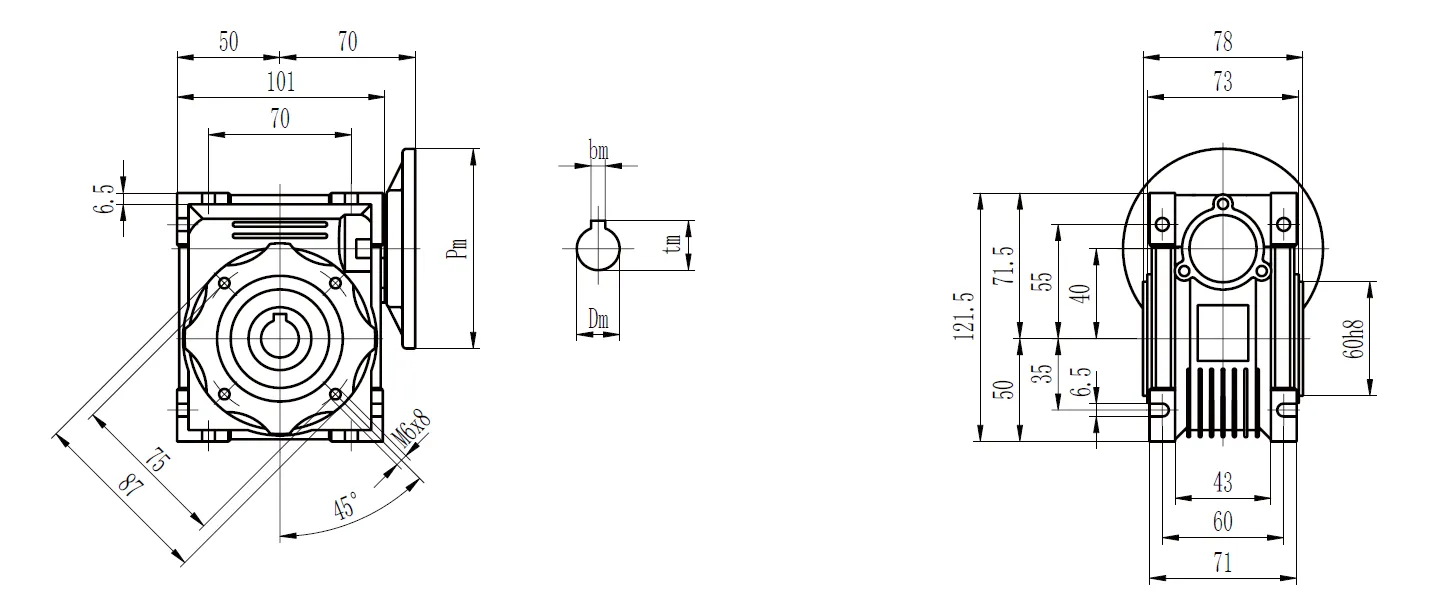

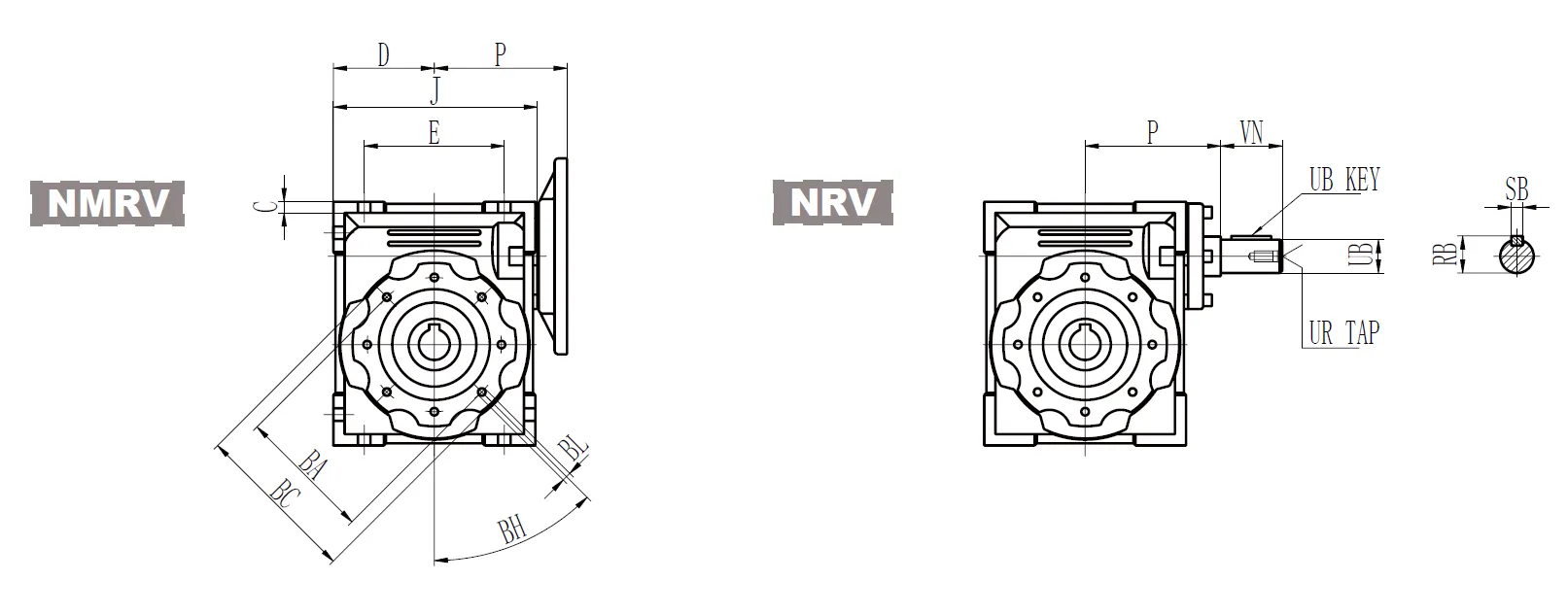

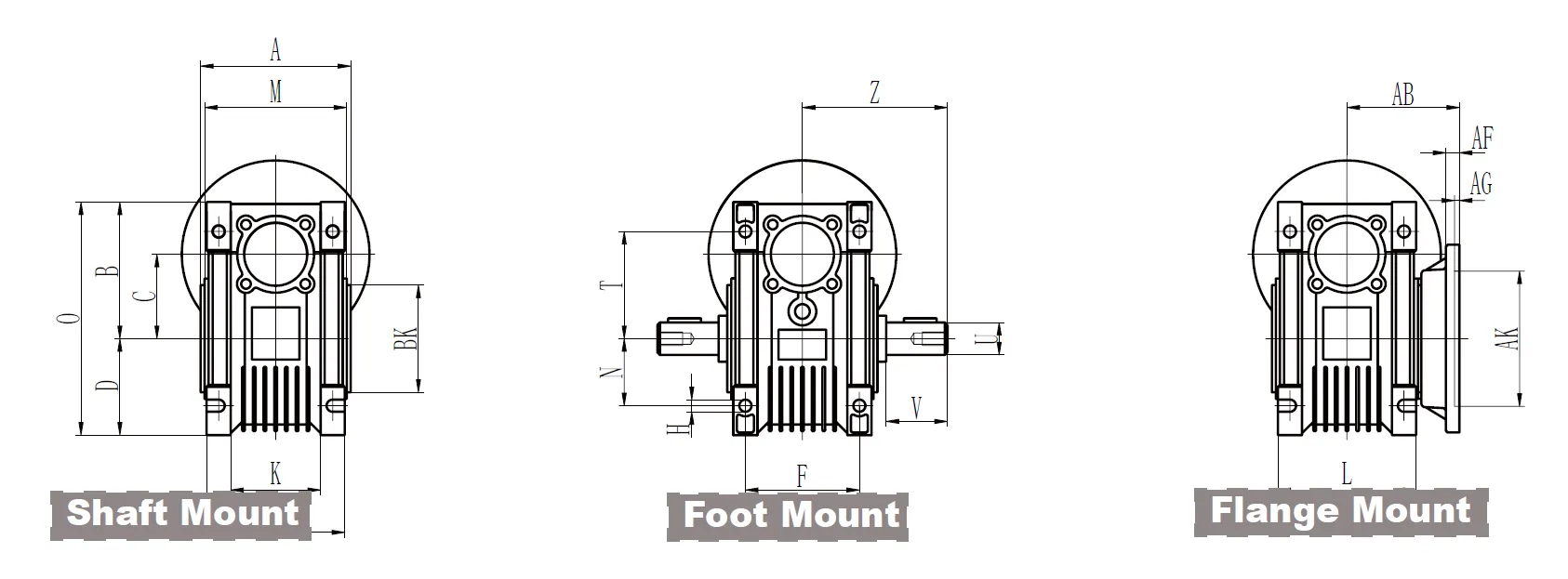

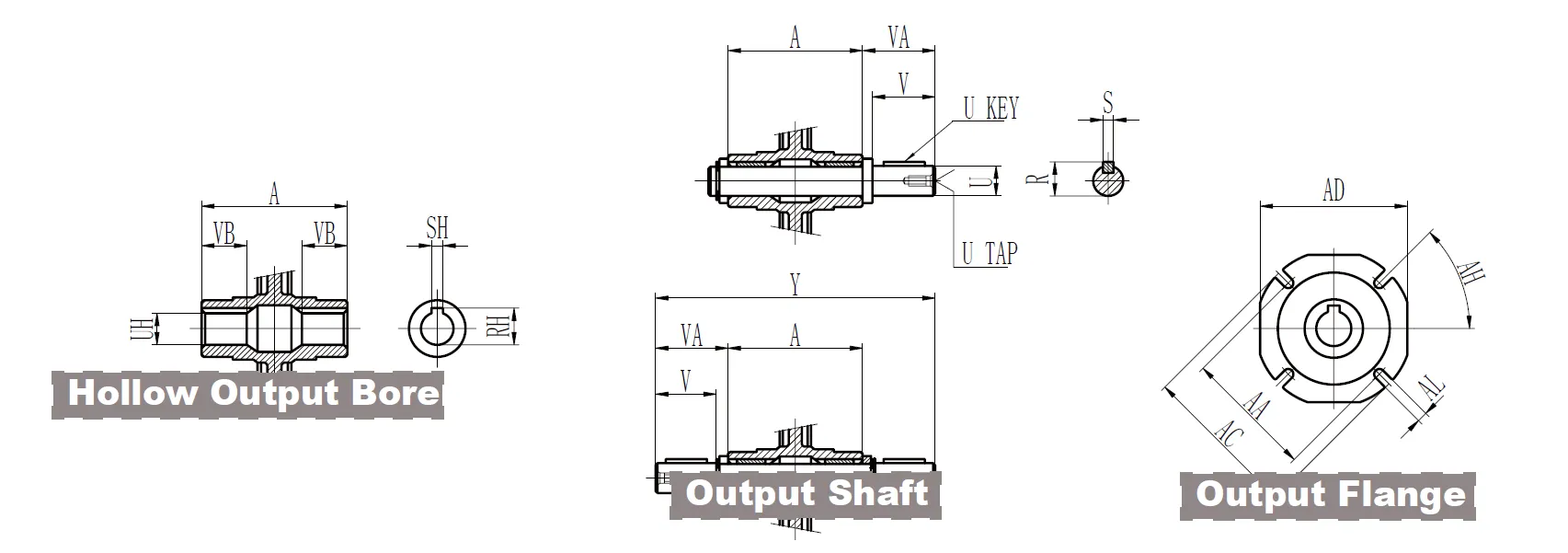

CMN-NMRV040 Worm Gear Reducer Dimensions

CMN-NMRV Worm Gear Reducer Dimensions

CMN-NMRV Inch Series

| Hollow Output Bore | 030 | 040 | 050 | 063 | 075 | 090 | 110 | 130 | |

| RH | 0.71 | 0.84 | 1.12 | 1.24 | 1.37 | 1.52 | 1.8 | 1.93 | |

| SH | 0.188 | 0.188 | 0.25 | 0.25 | 0.25 | 0.313 | 0.375 | 0.375 | |

| UH | 0.625+0.001 0 | 0.75+0.001 0 | 1+0.001 0 | 1.125+0.001 0 | 1.25+0.001 0 | 1.375+0.001 0 | 1.625+0.001 0 | 1.750 | |

| VB | 0.83 | 1.14 | 1.28 | 1.42 | 1.56 | 1.77 | 1.97 | 2.24 | |

| Output Shaft | 030 | 040 | 050 | 063 | 075 | 090 | 110 | 130 | |

| R | 0.7 | 0.83 | 1.11 | 1.23 | 1.36 | 1.51 | 1.79 | 1.92 | |

| S | 0.188 | 0.188 | 0.25 | 0.25 | 0.25 | 0.313 | 0.375 | 0.375 | |

| U | 0.6250 -0.0005 | 0.750 -0.0005 | 10 -0.0005 | 0 -0.0005 | 1.250 -0.0005 | 1.3750 -0.0005 | 1.6250 -0.0005 | 1.750 -0.0005 | |

| U KEY | 0.1875x1.125 | 0.1875x1.5 | 0.25x1.5 | 0.25x1.875 | 0.25x2.25 | 0.3125x2.5 | 0.375x2.75 | 0.375x2.75 | |

| UT | 1/4-20 | 1/4-20 | 3/8-16 | 3/8-16 | 1/2-13 | 1/2-13 | 5/8-11 | 5/8-11 | |

| V | 1.57 | 1.97 | 1.97 | 2.36 | 2.76 | 3.15 | 3.54 | 3.54 | |

| VA | 1.67 | 2.09 | 2.11 | 2.5 | 2.89 | 3.33 | 3.72 | 3.74 | |

| Y | 5.82 | 7.25 | 7.84 | 9.41 | 10.5 | 12.17 | 13.54 | 14.17 | |

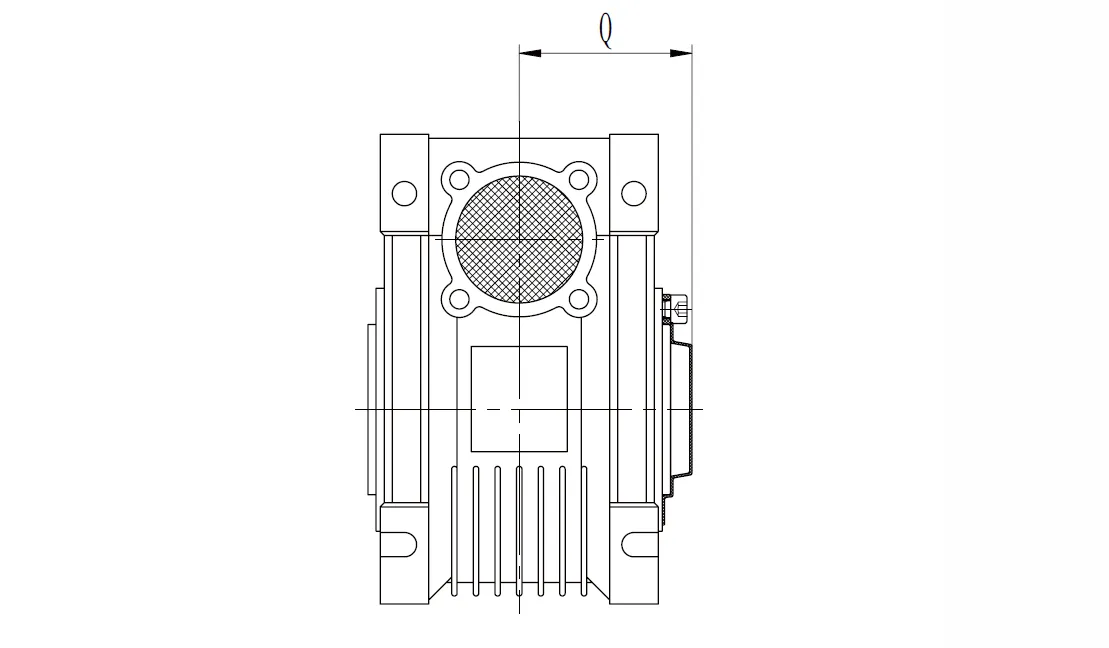

| CMN-NMRV | 030 | 040 | 050 | 063 | 075 | 090 | 110 | 130 |

| A | 2.48 | 3.07 | 3.62 | 4.41 | 4.72 | 5.51 | 6.1 | 6.69 |

| B | 2.24 | 2.81 | 3.31 | 4.02 | 4.69 | 5.31 | 6.59 | 7.38 |

| BA | 2.56 | 2.95 | 3.35 | 3.74 | 4.53 | 5.12 | 6.5 | 8.46 |

| BC | 2.95 | 3.43 | 3.94 | 4.33 | 5.51 | 6.3 | 7.87 | 9.84 |

| BH | 90 ° | 45 ° | 45 ° | 45 ° | 45 ° | 45 ° | 45° | 45 ° |

| BK | 2.165 0 -0.0018 | 2.362 0 -0.0018 | 2.756 0 -0.0018 | 3.15 0 -0.0021 | 3.74 0 -0.0021 | 4.331 0 -0.0021 | 5.118 0 -0.0025 | 7.087 0 -0.0025 |

| BL | M6x11 | M6x10 | M8x10 | M8x14 | M8x14 | M10x18 | M10x18 | M12x21 |

| C | 1.18 | 1.57 | 1.97 | 2.48 | 2.95 | 3.54 | 4.33 | 5.12 |

| D | 1.57 | 1.97 | 2.36 | 2.83 | 3.39 | 4.06 | 5.02 | 5.81 |

| E | 2.13 | 2.76 | 3.15 | 3.94 | 4.72 | 5.51 | 6.69 | 7.87 |

| F | 1.73 | 2.36 | 2.76 | 3.35 | 3.54 | 3.94 | 4.53 | 4.72 |

| G | 0.22 | 0.26 | 0.28 | 0.31 | 0.39 | 0.43 | 0.57 | 0.61 |

| H | 0.26 | 0.26 | 0.33 | 0.33 | 0.45 | 0.51 | 0.55 | 0.63 |

| J | 3.15 | 3.98 | 4.76 | 5.75 | 6.85 | 8.19 | 9.94 | 11.52 |

| K | 1.26 | 1.69 | 1.93 | 2.64 | 2.83 | 2.91 | - | - |

| L | 2.2 | 2.8 | 3.35 | 4.06 | 4.41 | 5.12 | 5.67 | 6.1 |

| M | 2.28 | 2.87 | 3.43 | 4.17 | 4.49 | 5.28 | 5.83 | 6.38 |

| N | 1.06 | 1.38 | 1.57 | 1.97 | 2.36 | 2.76 | 3.35 | 3.94 |

| O | 3.82 | 4.78 | 5.67 | 6.85 | 8.07 | 9.37 | 11.61 | 13.19 |

| P | 2.64 | 3.15 | 3.54 | 4.13 | 4.96 | 5.63 | 6.81 | 7.6 |

| Q | 0.83 | 2.36 | 2.91 | 3.54 | 4.13 | 4.92 | 5.59 | 6.38 |

| T | 1.73 | 2.17 | 2.52 | 3.15 | 3.66 | 4.02 | 4.92 | 5.51 |

| Z | 2.91 | 3.63 | 3.92 | 4.71 | 5.25 | 6.09 | 6.77 | 7.09 |

| Output Flange | AA | AB | AC | AD | AF | AG | AH | AK | AL | ||

| 030 | FA | 2.68 | 2.15 | 3.15 | 2.76 | 0.24 | 0.16 | 45° | 1.969 | +0.0015 0 | 0.26 |

| 040 | FA | 2.95 | 2.64 | 4.33 | 3.74 | 0.28 | 0.16 | 45° | 2.362 | +0.0018 | 0.35 |

| 0 | |||||||||||

| FB | 2.95 | 3.82 | 4.33 | 3.74 | 0.28 | 0.16 | 45° | 2.362 | +0.0018 0 | 0.35 | |

| FC | 4.53 | 3.15 | 5.51 | - | 0.35 | 0.2 | 45° | 3.74 | +0.0021 0 | 0.37 | |

| FD | 3.94 | 2.28 | 4.72 | - | 0.47 | 0.2 | 45° | 3.15 | +0.0018 | 0.35 | |

| 0 | |||||||||||

| 050 | FA | 3.35 | 3.54 | 4.92 | 4.33 | 0.35 | 0.2 | 45° | 2.756 | +0.0018 | 0.43 |

| 0 | |||||||||||

| FB | 3.35 | 4.72 | 4.92 | 4.33 | 0.35 | 0.2 | 45° | 2.756 | +0.0018 0 | 0.43 | |

| FC | 5.12 | 3.5 | 6.3 | - | 0.39 | 0.2 | 45° | 4.331 | +0.0021 0 | 0.37 | |

| FD | 4.53 | 2.83 | 5.51 | - | 0.57 | 0.2 | 45° | 3.543 | +0.0021 | 0.43 | |

| 0 | |||||||||||

| 063 | FA | 4.13 | 3.23 | 7.09 | 5.59 | 0.39 | 0.24 | 45° | 4.528 | +0.0021 | 0.43 |

| 0 | |||||||||||

| FB | 5.91 | 4.41 | 7.09 | 5.59 | 0.39 | 0.24 | 45° | 4.528 | +0.0021 | 0.43 | |

| 0 | |||||||||||

| FC | 6.5 | 3.86 | 7.87 | - | 0.39 | 0.2 | 45° | 5.118 | +0.0025 0 | 0.43 | |

| FD | 6.5 | 4.21 | 7.87 | - | 0.39 | 0.2 | 45° | 5.118 | +0.0025 | 0.43 | |

| 0 | |||||||||||

| FE | 5.12 | 3.17 | 6.3 | - | 0.65 | 0.2 | 45° | 4.331 | +0.0021 | 0.43 | |

| 0 | |||||||||||

| 075 | FA | 6.5 | 4.37 | 7.87 | 6.69 | 0.51 | 0.24 | 45° | 5.118 | +0.0025 | 0.55 |

| 0 | |||||||||||

| FB | 5.12 | 3.54 | 6.3 | - | 0.51 | 0.24 | 45° | 4.331 | +0.0021 | 0.55 | |

| 0 | |||||||||||

| 090 | FA | 6.89 | 4.37 | 8.27 | 8.27 | 0.51 | 0.24 | 45° | 5.984 | +0.0025 | 0.55 |

| 0 | |||||||||||

| FB | 8.46 | 4.8 | 9.84 | - | 0.71 | 0.24 | 45° | 7.087 | +0.0025 0 | 0.55 | |

| FC | 6.5 | 4.33 | 7.87 | - | 0.67 | 0.24 | 45° | 5.118 | +0.0025 0 | 0.43 | |

| FD | 6.89 | 5.94 | 8.27 | - | 0.51 | 0.24 | 45° | 5.984 | +0.0025 | 0.55 | |

| 0 | |||||||||||

| 110 | FA | 9.06 | 5.16 | 11.02 | 10.24 | 0.59 | 0.24 | 45° | 6.693 | +0.0025 | 0.55 |

| 0 | |||||||||||

| FB | 9.06 | 7.09 | 11.02 | 10.24 | 0.59 | 0.24 | 45° | 6.693 | +0.0025 | 0.55 | |

| 0 | |||||||||||

| 130 | FA | 10.04 | 5.51 | 12.6 | 11.42 | 0.59 | 0.24 | 22.5° | 7.087 | +0.0025 0 | 0.63 |

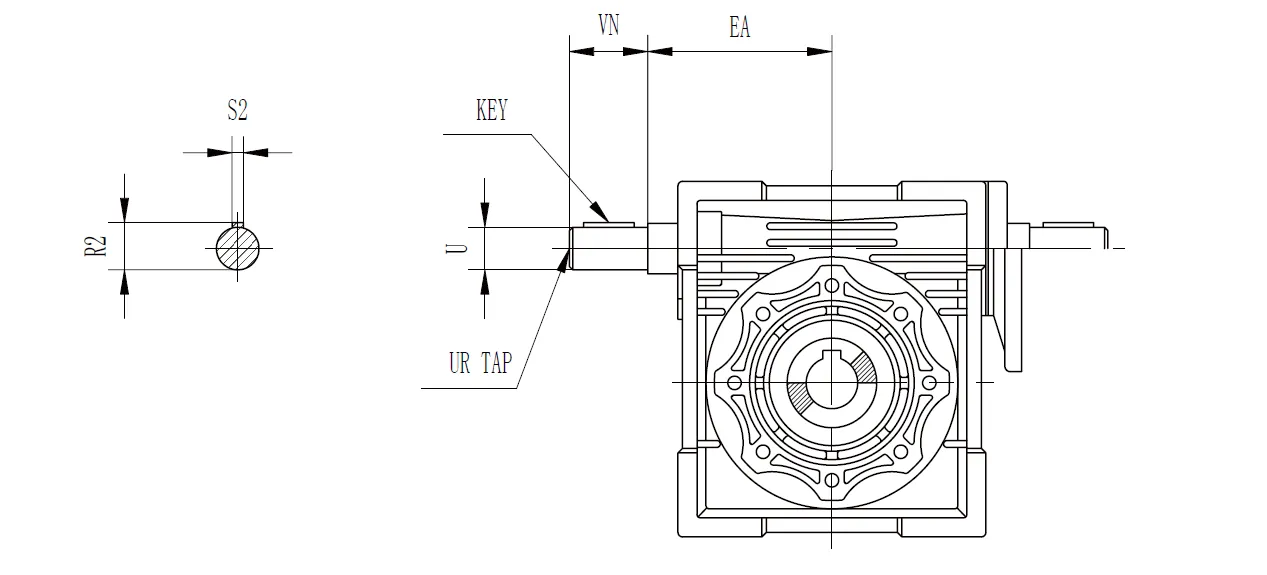

| Input Shaft | 030 | 040 | 050 | 063 | 075 | 090 | 110 | 130 | |

| SB | 0.094 | 0.125 | 0.188 | 0.188 | 0.188 | 0.188 | 0.25 | 0.25 | |

| RB | 0.42 | 0.55 | 0.7 | 0.83 | 0.96 | 0.96 | 1.24 | 1.36 | |

| UB | 0.3750 -0.0005 | 0.50 -0.0005 | 0.6250 -0.0005 | 0.750 -0.0005 | 0.8750 -0.0005 | 0.8750 -0.0005 | 1.1250 -0.0005 | 1.250 -0.0005 | |

| UB KEY | 0.094x0.875 | 0.125x0.875 | 0.1875x1.125 | 0.1875x1.5 | 0.1875x1.875 | 0.1875x1.875 | 0.25x2.25 | 0.25x2.5 | |

| UR | - | 1/4-20 | 1/4-20 | 1/4-20 | 1/4-20 | 1/4-20 | 3/8-16 | 1/2-13 | |

| VN | 1.18 | 1.18 | 1.58 | 1.97 | 2.36 | 2.36 | 2.76 | 3.15 | |

High Speed Extension Shaft Dimensions

| CMN-NMRV | EA | U | VN | UR | S2 | R2 | KEY | |

| Length | Square | |||||||

| 030 | 1.772 | 0.3750 -0.0005 | 1.18 | - | 0.093 | 0.42 | 0.875 | 0.094 |

| 040 | 2.087 | 0.50 -0.0005 | 1.18 | 1/4-20 | 0.13 | 0.55 | 0.875 | 0.125 |

| 050 | 2.52 | 0.6250 -0.0005 | 1.58 | 1/4-20 | 0.19 | 0.7 | 1.125 | 0.188 |

| 063 | 2.953 | 0.750 -0.0005 | 1.97 | 1/4-20 | 0.19 | 0.83 | 1.5 | 0.188 |

| 075 | 3.543 | 0.8750 -0.0005 | 2.36 | 1/4-20 | 0.19 | 0.96 | 1.875 | 0.188 |

| 090 | 4.252 | 0.8750 -0.0005 | 2.36 | 1/4-20 | 0.19 | 0.96 | 1.875 | 0.188 |

| 110 | 5.315 | 1.1250 -0.0005 | 2.76 | 3/8-16 | 0.25 | 1.24 | 2.25 | 0.25 |

| 130 | 6.102 | 1.250 -0.0005 | 3.15 | 1/2-13 | 0.25 | 1.36 | 2.5 | 0.25 |

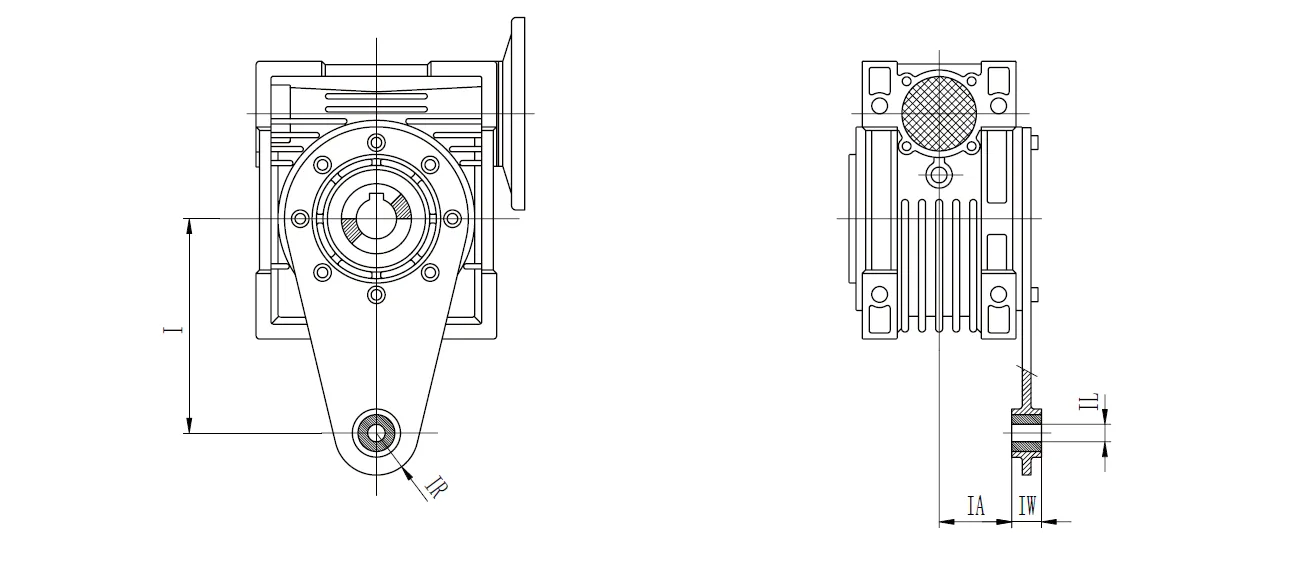

Torque Arm Dimensions

| I | IA | IL | IR | IW | |

| 025 | 2.76 | 0.69 | 0.31 | 0.59 | 0.55 |

| 030 | 3.35 | 0.94 | 0.31 | 0.59 | 0.55 |

| 040 | 3.94 | 1.24 | 0.39 | 0.71 | 0.55 |

| 050 | 3.94 | 1.52 | 0.39 | 0.71 | 0.55 |

| 063 | 5.91 | 1.93 | 0.39 | 0.71 | 0.55 |

| 075 | 7.87 | 1.87 | 0.79 | 1.18 | 0.98 |

| 090 | 7.87 | 2.26 | 0.79 | 1.18 | 0.98 |

| 110 | 9.84 | 2.44 | 0.98 | 1.38 | 1.18 |

| 130 | 9.84 | 2.72 | 0.98 | 1.38 | 1.18 |

Protective Cover Dimensions

| CMN-NMRV | Q |

| 030 | 1.65 |

| 040 | 1.97 |

| 050 | 2.28 |

| 063 | 2.72 |

| 075 | 2.91 |

| 090 | 3.39 |

| 110 | 3.7 |

| 130 | 4.02 |

NEMA Flange Availability

| CMN-NMRV | NEMA Flange | Input Bore Diameter | Available Ratios | |||||||||||

| 5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 | 60 | 80 | 100 | |||

| 030 | 48C | 0.5 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |

| 040 | 56C | 0.625 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| 050 | 56C | 0.625 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| 063 | 56C | 0.625 | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| 140TC | 0.875 | ● | ● | ● | ● | ● | ● | ● | ||||||

| 075 | 56C | 0.625 | ● | ● | ● | ● | ||||||||

| 140TC | 0.875 | ● | ● | ● | ● | ● | ● | |||||||

| 180TC | 1.125 | ● | ● | ● | ||||||||||

| 090 | 56C | 0.625 | ● | ● | ||||||||||

| 140TC | 0.875 | ● | ● | ● | ● | ● | ||||||||

| 180TC | 1.125 | ● | ● | ● | ● | ● | ● | ● | ||||||

| 110 | 140TC | 0.875 | ● | ● | ● | ● | ||||||||

| 180TC | 1.125 | ● | ● | ● | ● | ● | ● | |||||||

| 210TC | 1.375 | ● | ● | ● | ● | |||||||||

| 130 | 140TC | 0.875 | ● | ● | ||||||||||

| 180TC | 1.125 | ● | ● | ● | ● | ● | ||||||||

| 210TC | 1.375 | ● | ● | ● | ● | ● | ● | ● | ||||||

CMN-NMRV040 Worm Drive Gearbox Features

- Compact and Durable Design

The CMN-NMRV040 worm drive gearbox features a high-strength aluminum alloy housing, ensuring corrosion resistance and efficient heat dissipation. Its compact design allows for easy integration into space-constrained applications, providing robust performance in industries like food processing and textiles. - High Torque Output

With reduction ratios ranging from 5:1 to 100:1, the CMN-NMRV040 worm reducer gearbox delivers substantial torque for low to medium-speed applications. The worm and worm wheel configuration ensures efficient power transmission, making it ideal for heavy-duty tasks requiring precise control and high force. - Versatile Mounting Options

The worm gear gearbox supports multiple mounting configurations, including flange inputs like 71B5 and 63B14. This flexibility enables seamless compatibility with various motor types, such as NEMA 34 or smaller stepper and servo motors, enhancing adaptability across diverse industrial setups. - Smooth and Quiet Operation

Precision-engineered worm and worm wheel components, typically made from bronze or nodular cast iron, ensure smooth and quiet performance. The CMN-NMRV040 worm gear speed reducer minimizes vibration and noise, making it suitable for noise-sensitive environments like medical or packaging equipment. - Self-Locking Capability

The worm gear design provides inherent self-locking, preventing back-driving under load. This feature enhances safety in applications like hoisting or lifting, ensuring the system remains stable even when power is off, reducing the need for additional braking mechanisms. - Low Maintenance and Longevity

Filled with synthetic oil, the CMN-NMRV040 worm gear reduction gearbox requires minimal maintenance while offering excellent lubrication for an extended lifespan. Its robust construction and high-quality materials ensure reliable operation under demanding conditions, reducing downtime and maintenance costs in industrial settings.

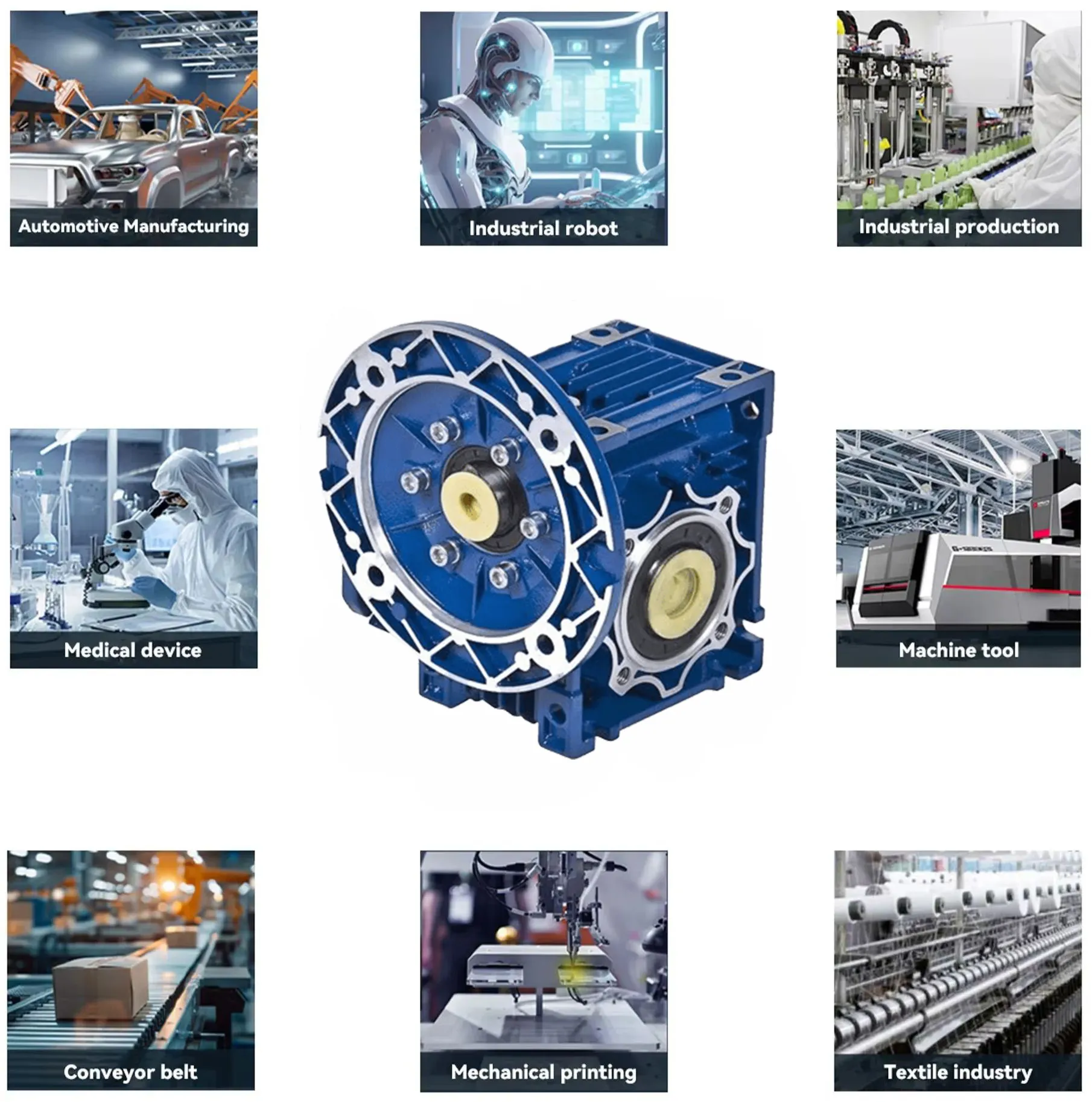

CMN-NMRV040 Worm Reducer Gearbox Applications

- Food Processing Industry

The CMN-NMRV040 worm reducer gearbox is widely used in food processing for conveyors and mixers. Its corrosion-resistant aluminum housing and smooth operation ensure hygiene and reliability, meeting strict industry standards while handling precise speed control for consistent production processes. - Textile Manufacturing

In textile machinery, the right angle worm gearbox drives spinning and weaving equipment. Its high torque and self-locking feature provide stable operation under varying loads, ensuring precision in fabric production, while its compact design fits seamlessly into space-constrained textile manufacturing setups. - Packaging Machinery

The CMN-NMRV040 worm and wheel gearbox is ideal for packaging systems, powering rollers, and labeling machines. Its quiet operation and versatile mounting options enable integration into automated lines, delivering consistent torque for high-speed packaging tasks while maintaining reliability in demanding environments. - Ceramics Production

In ceramics manufacturing, the worm gear drive gearbox supports equipment like clay mixers and kilns. Its robust construction withstands harsh conditions, while the high reduction ratios ensure precise speed control, enhancing efficiency in shaping and processing ceramic materials with minimal maintenance. - Material Handling Systems

The CMN-NMRV040 worm gearbox motor is employed in material handling for conveyors and hoists. Its self-locking capability ensures safety during load lifting, while the compact design and high torque output facilitate efficient movement of goods in warehouses and logistics operations. - Automation and Robotics

In automation, the worm reduction gearbox drives robotic arms and automated guided vehicles. Its compatibility with stepper and servo motors, combined with low noise and precise torque delivery, supports accurate positioning and smooth operation in advanced robotic systems across various industries.

CMN-NMRV040 Worm Gear Reducer Troubleshooting

- Excessive Noise During Operation

Excessive noise can result from improper lubrication, misalignment of the worm and wheel, or worn-out bearings. Regularly inspect and replace worn components and ensure the gearbox is properly lubricated with the correct grade of oil to maintain smooth operation. - Overheating of the Gearbox

Overheating occurs due to excessive load, improper lubrication, or insufficient ventilation. Check the load to ensure it does not exceed the gearbox's capacity. Confirm that the lubricant is at the appropriate level and that the unit has adequate airflow for cooling. - Oil Leakage from the Housing

Oil leaks are often caused by damaged seals, loose bolts, or overfilling of lubricant. Inspect the seals for any wear or damage, tighten all bolts to recommended torque settings, and ensure the correct amount of lubricant is used to prevent overflow. - Reduced Torque Output

A drop in torque output can be due to worn gear teeth, excessive backlash, or improper engagement of the worm and wheel. Inspect the gear teeth for wear, adjust the backlash if necessary, and ensure proper alignment of all internal components. - Gearbox Not Rotating Smoothly

If the gearbox rotates unevenly or gets stuck, it could be due to debris inside the housing, damaged gears, or insufficient lubrication. Disassemble the unit for cleaning, inspect for damaged components, and reassemble with proper lubrication to restore smooth operation. - Unusual Vibrations During Use

Unusual vibrations may result from unbalanced loads, misalignment, or damaged internal components. Check the load balance to ensure even distribution, verify alignment between the gearbox and connected machinery, and replace any damaged gears or bearings to eliminate vibrations.

Additional information

| Edited by | Yjx |

|---|