CMN-NMRV025 Worm Gear Reducers/Worm Gearbox

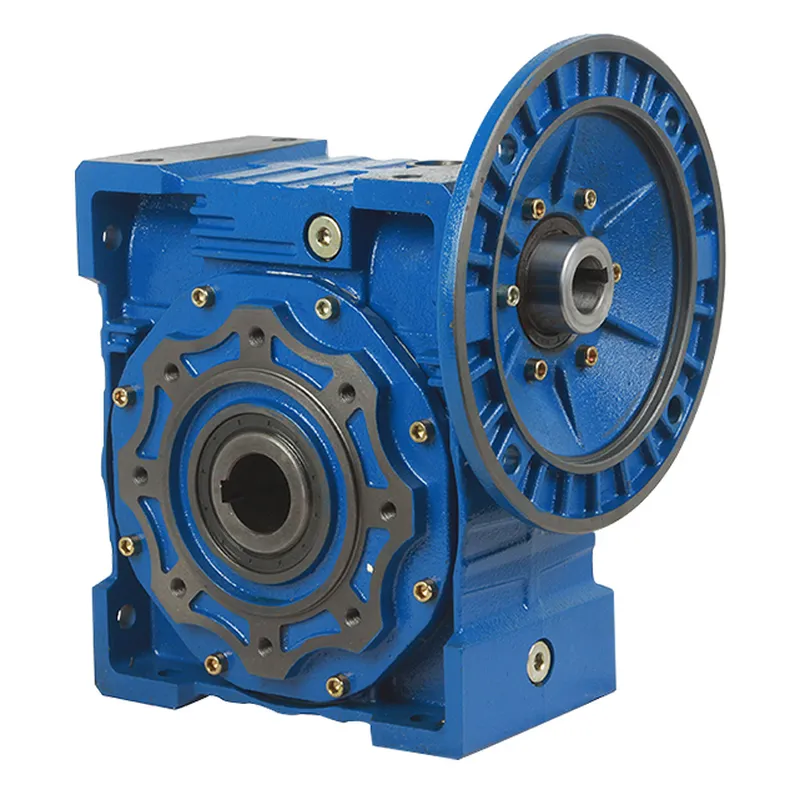

The CMN-NMRV025 worm gear reducer is a compact and efficient mechanical device used to reduce speed and increase torque in various industrial applications. It utilizes a worm and worm wheel mechanism, where the worm (a screw-like component) engages with the worm wheel (a toothed gear). This design allows for smooth, quiet operation and achieves high torque output while minimizing vibration. It is widely used in industries such as conveyor systems, packaging machinery, and automation due to its small size, high efficiency, and versatility.

The CMN-NMRV025 worm gear reducer is a compact and efficient mechanical device used to reduce speed and increase torque in various industrial applications. It utilizes a worm and worm wheel mechanism, where the worm (a screw-like component) engages with the worm wheel (a toothed gear). This design allows for smooth, quiet operation and achieves high torque output while minimizing vibration.

The CMN-NMRV025 model worm gearbox is part of the NMRV series, known for its lightweight aluminum alloy housing, which offers excellent corrosion resistance and durability. It is widely used in industries such as conveyor systems, packaging machinery, and automation due to its small size, high efficiency, and versatility. The worm reducer gearbox supports multiple mounting positions and offers a range of gear ratios to meet diverse operational needs.

CMN-NMRV025 Worm Gearbox Specifications

| Type | CMN-NMRV025 Worm Gearbox/ Worm Gear Speed Reducer |

| Model | CMN-NMRV025 |

| Reduction Ratio | 5,7.5,10,15,20,25,30,40,50,60,80,100 |

| Flange | FA / FL or as per your demands |

| Matching Motor | 0.06KW~15KW |

| Material | Die-casting Aluminum Alloy |

| Color | Blue /Silver Grey /Customized |

| Flange Standard | PAM / IEC |

| Accessories | Shaft, Flange, Torque arm, etc |

| Lubricant | Synthetic Oil or Worm Gear Oil |

| Usage | Machinery of food stuff, ceramics, chemicals, packing, dyeing, wood working, glass industries, etc |

| Note: 1) Please choose from the above specifications. 2) If the above options can not meet your demands, please send us your requirements(ratio, flange, mounting, application, or a picture of your old one), and we will recommond a suitable type. | |

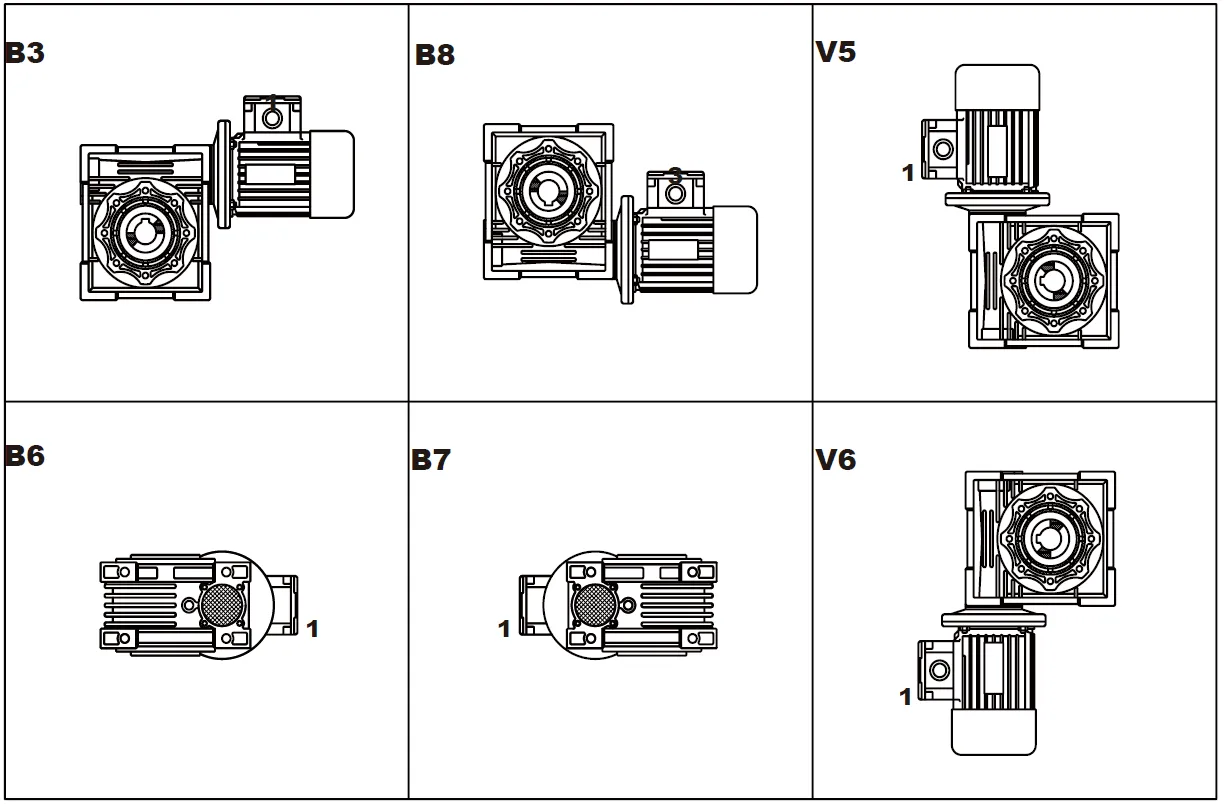

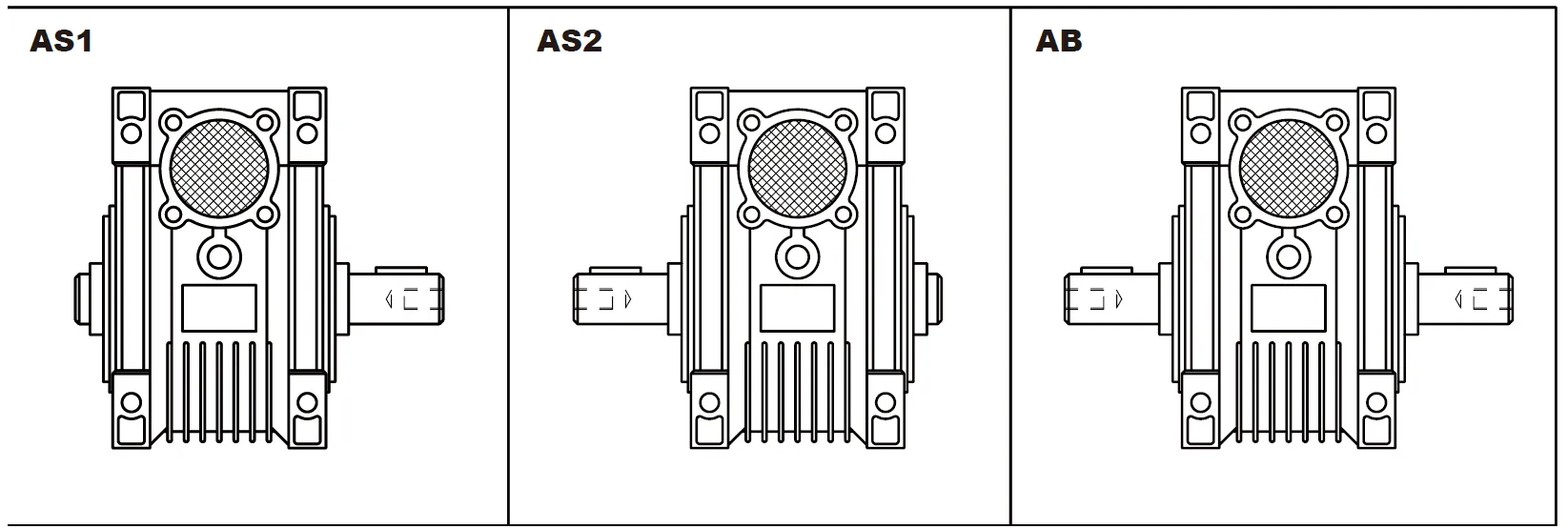

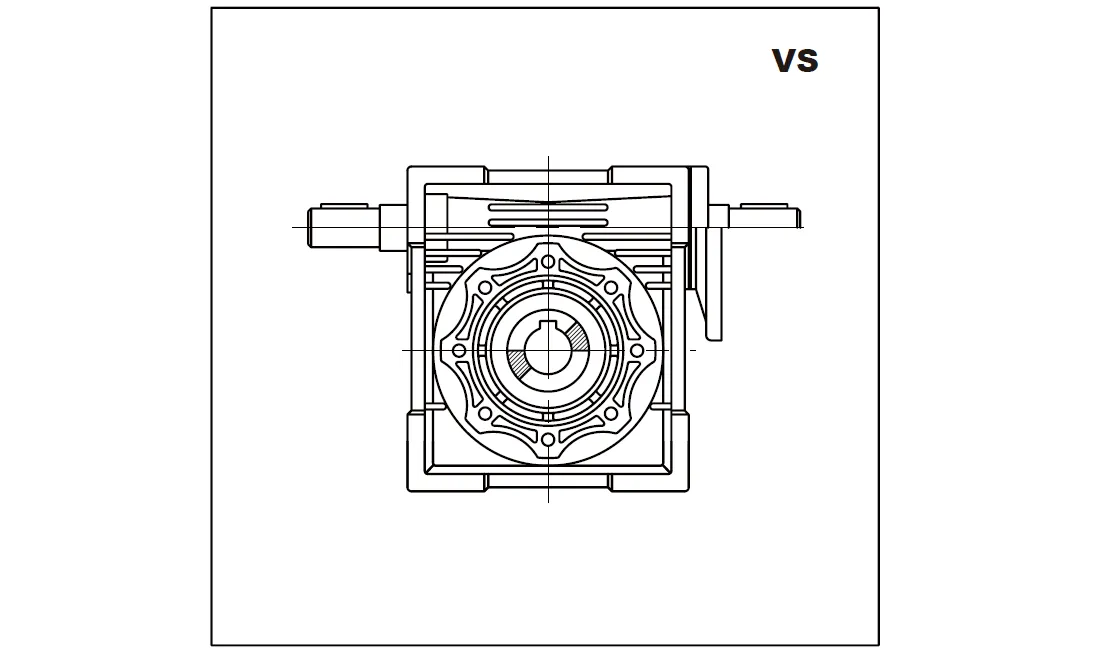

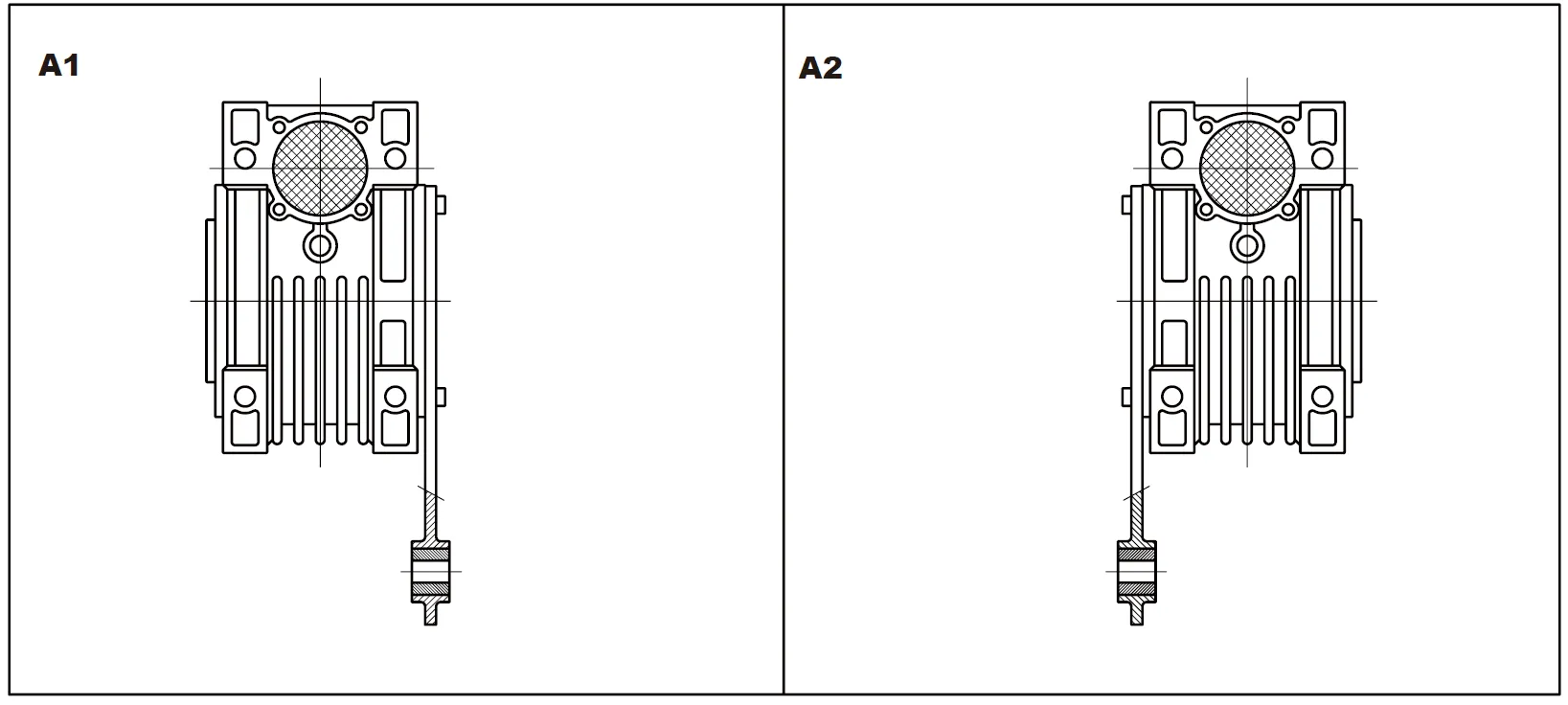

Mounting Position

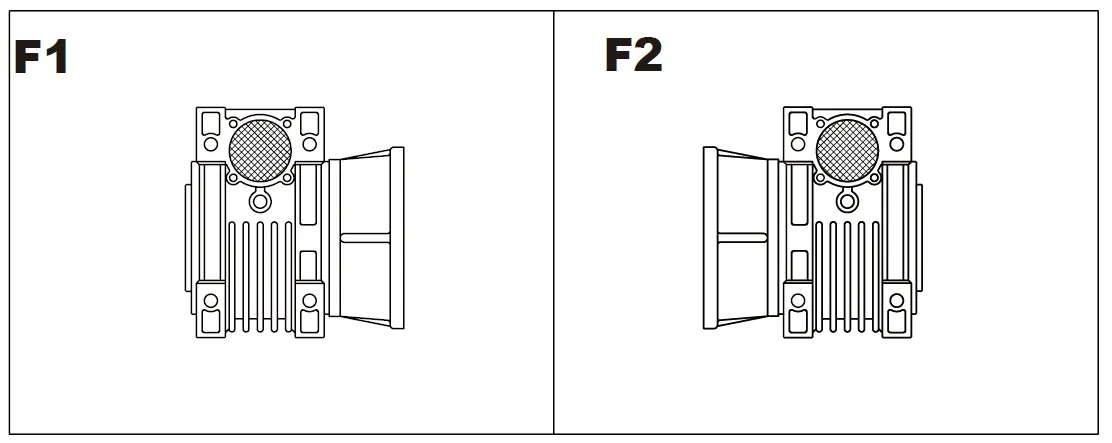

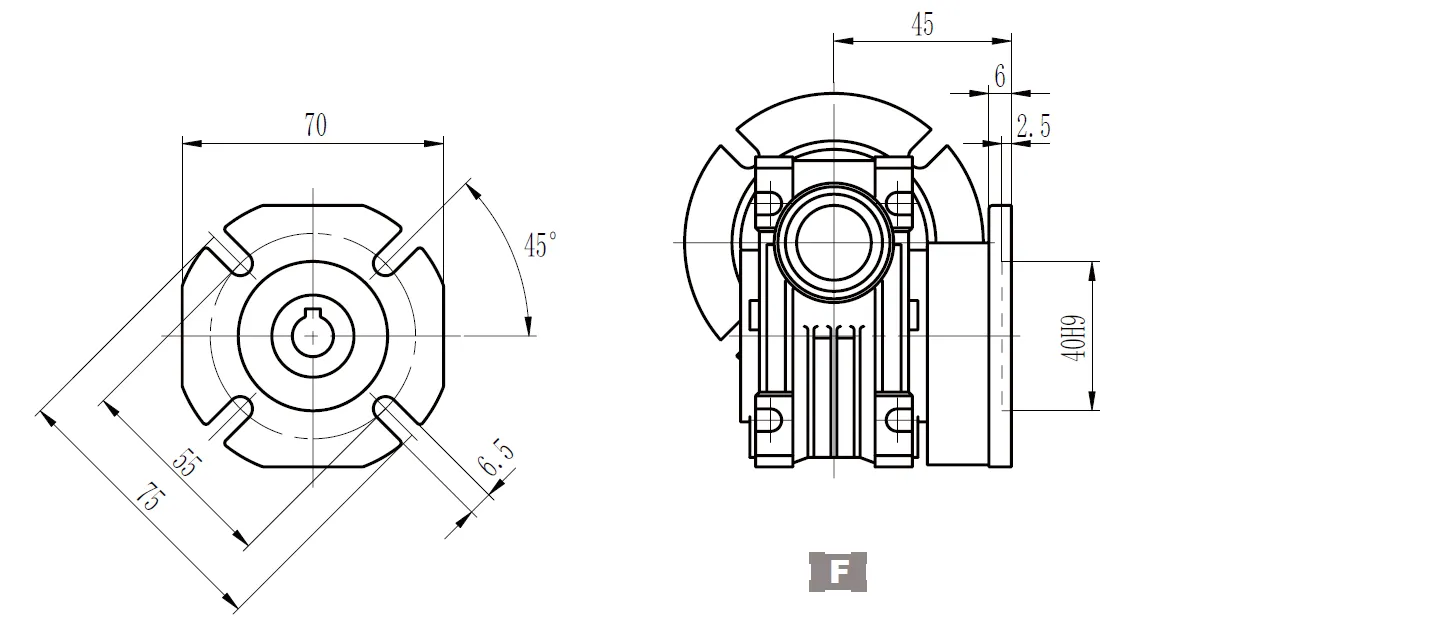

Flange F-FL

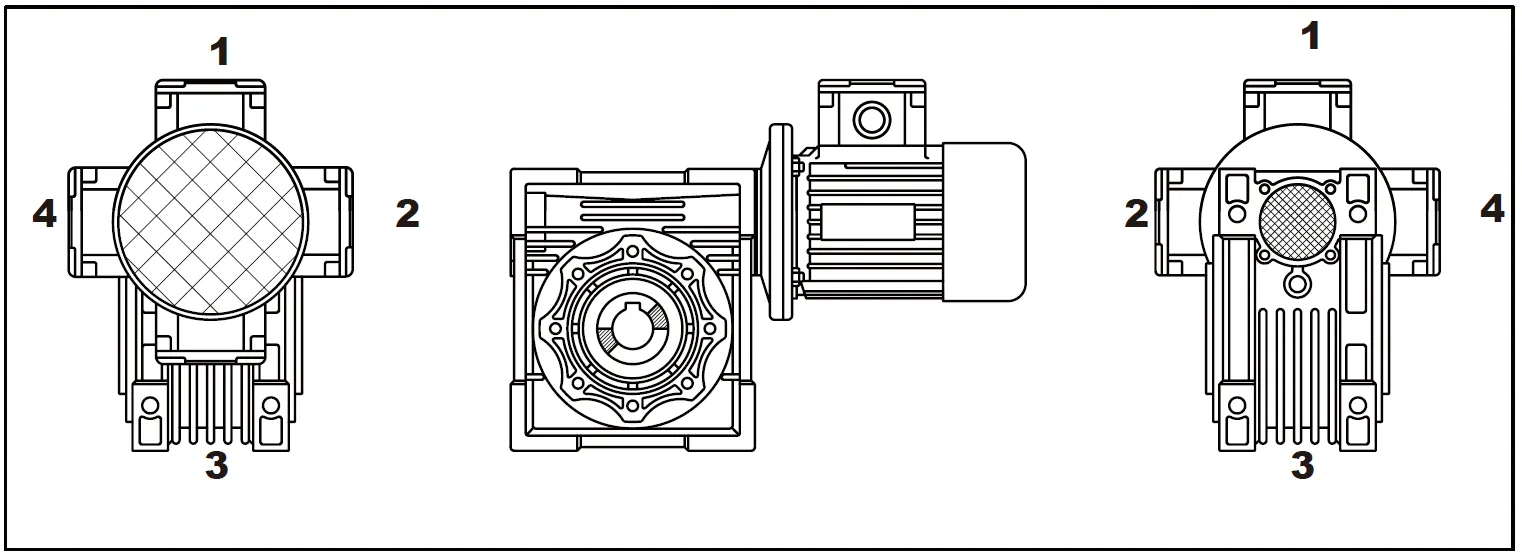

Position of Terminal Box

Position of Output Shaft

Double Extension Worm Shaft

Position of Torque Arm

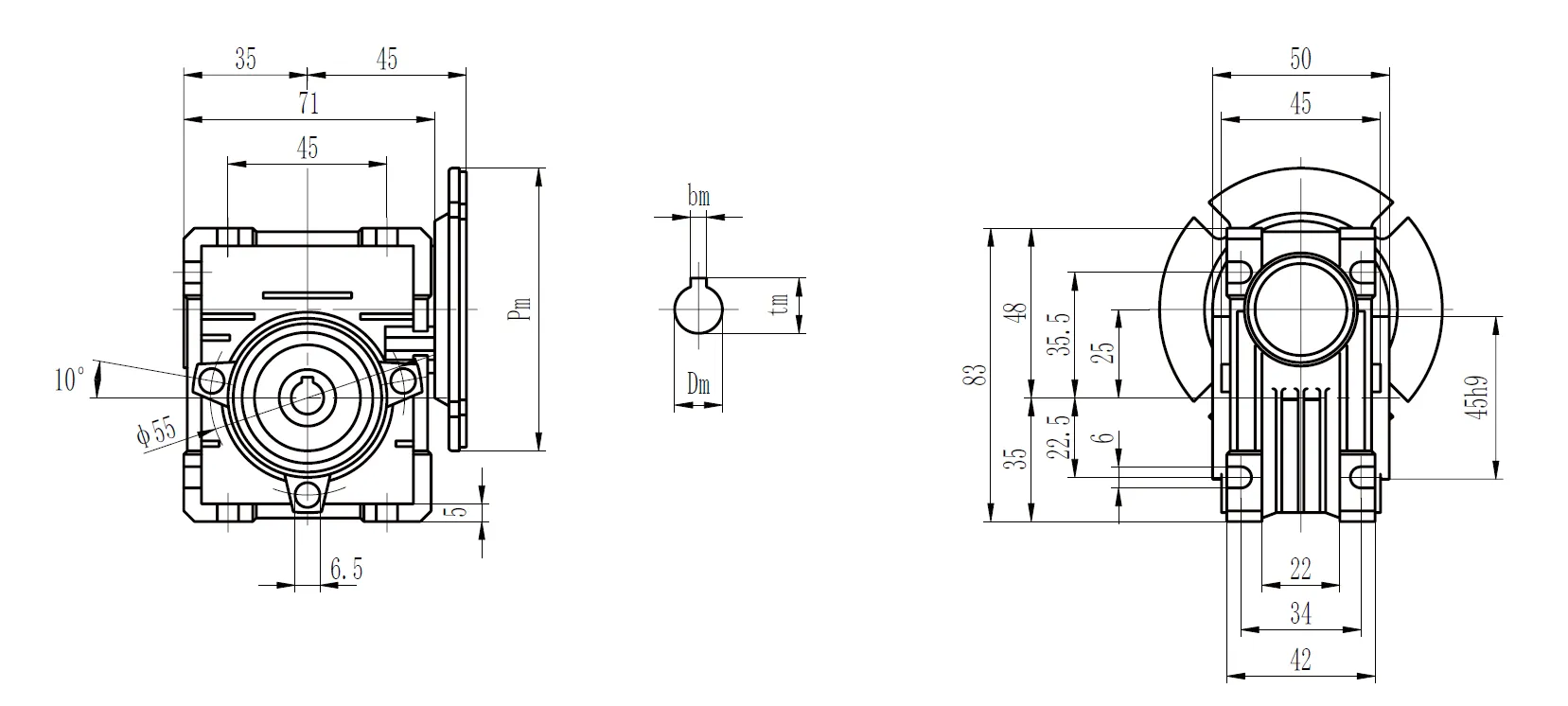

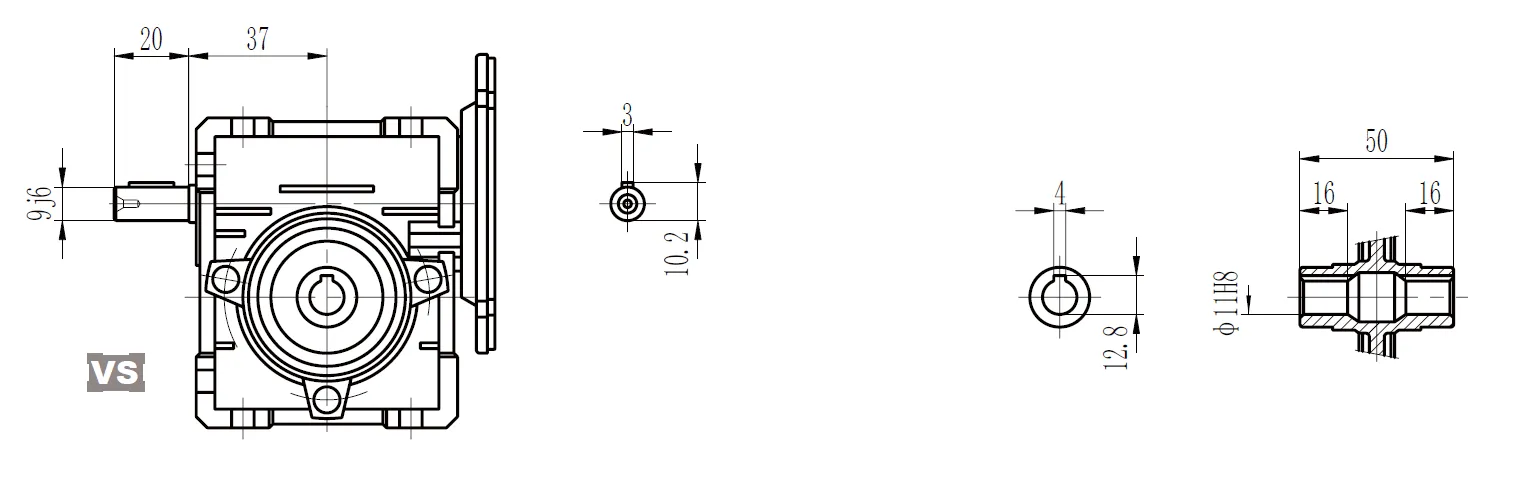

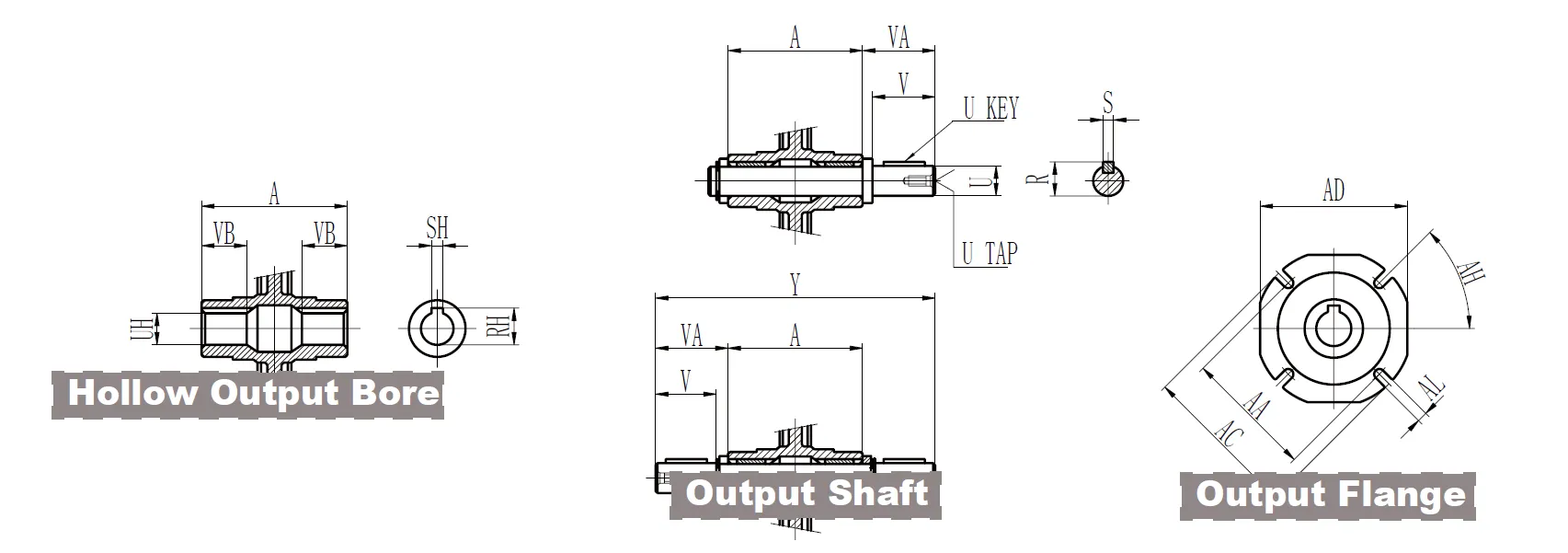

CMN-NMRV025 Worm Gear Reducer Dimensions

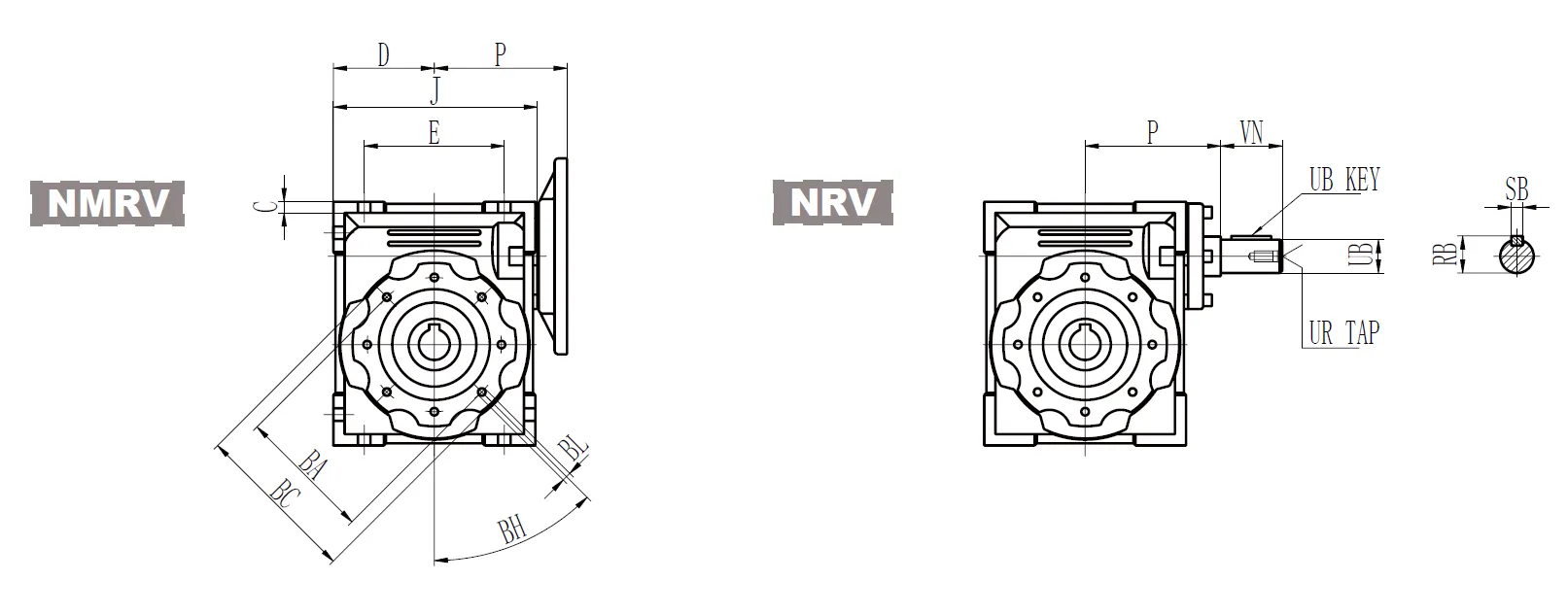

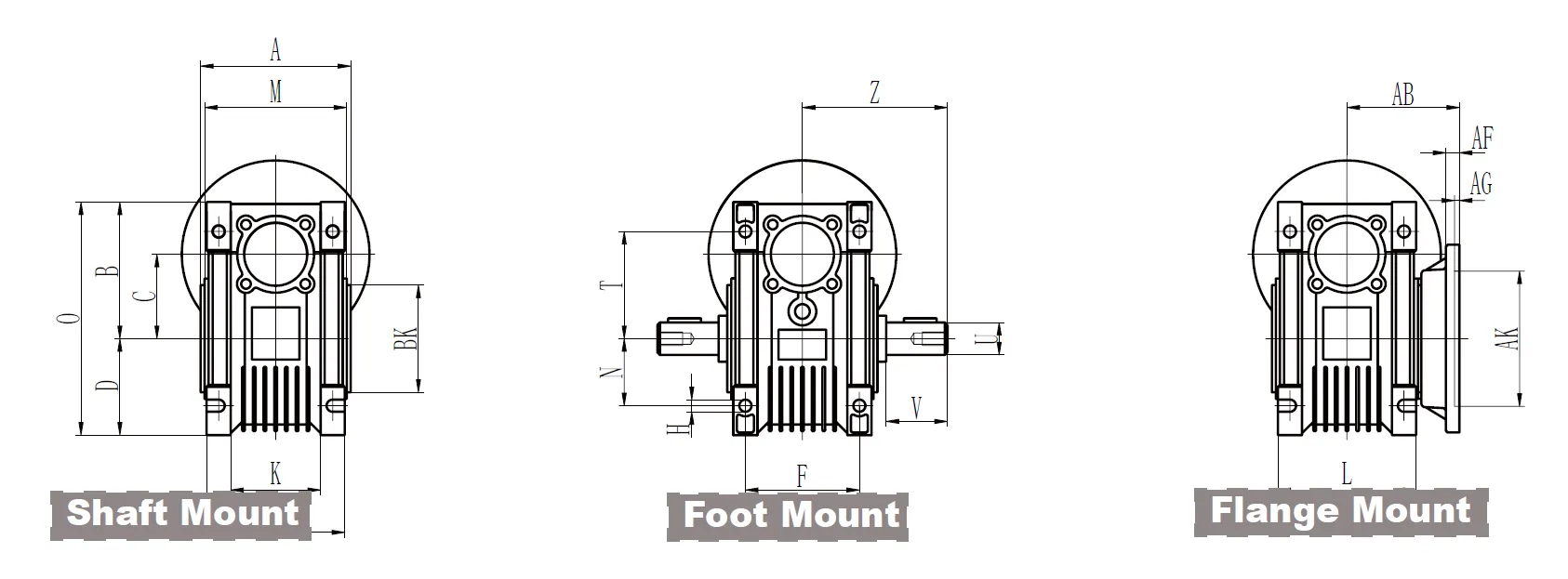

CMN-NMRV Worm Gear Reducer Dimensions

CMN-NMRV Inch Series

| Hollow Output Bore | 030 | 040 | 050 | 063 | 075 | 090 | 110 | 130 | |

| RH | 0.71 | 0.84 | 1.12 | 1.24 | 1.37 | 1.52 | 1.8 | 1.93 | |

| SH | 0.188 | 0.188 | 0.25 | 0.25 | 0.25 | 0.313 | 0.375 | 0.375 | |

| UH | 0.625+0.001 0 | 0.75+0.001 0 | 1+0.001 0 | 1.125+0.001 0 | 1.25+0.001 0 | 1.375+0.001 0 | 1.625+0.001 0 | 1.750 | |

| VB | 0.83 | 1.14 | 1.28 | 1.42 | 1.56 | 1.77 | 1.97 | 2.24 | |

| Output Shaft | 030 | 040 | 050 | 063 | 075 | 090 | 110 | 130 | |

| R | 0.7 | 0.83 | 1.11 | 1.23 | 1.36 | 1.51 | 1.79 | 1.92 | |

| S | 0.188 | 0.188 | 0.25 | 0.25 | 0.25 | 0.313 | 0.375 | 0.375 | |

| U | 0.6250 -0.0005 | 0.750 -0.0005 | 10 -0.0005 | 0 -0.0005 | 1.250 -0.0005 | 1.3750 -0.0005 | 1.6250 -0.0005 | 1.750 -0.0005 | |

| U KEY | 0.1875x1.125 | 0.1875x1.5 | 0.25x1.5 | 0.25x1.875 | 0.25x2.25 | 0.3125x2.5 | 0.375x2.75 | 0.375x2.75 | |

| UT | 1/4-20 | 1/4-20 | 3/8-16 | 3/8-16 | 1/2-13 | 1/2-13 | 5/8-11 | 5/8-11 | |

| V | 1.57 | 1.97 | 1.97 | 2.36 | 2.76 | 3.15 | 3.54 | 3.54 | |

| VA | 1.67 | 2.09 | 2.11 | 2.5 | 2.89 | 3.33 | 3.72 | 3.74 | |

| Y | 5.82 | 7.25 | 7.84 | 9.41 | 10.5 | 12.17 | 13.54 | 14.17 | |

| CMN-NMRV | 030 | 040 | 050 | 063 | 075 | 090 | 110 | 130 |

| A | 2.48 | 3.07 | 3.62 | 4.41 | 4.72 | 5.51 | 6.1 | 6.69 |

| B | 2.24 | 2.81 | 3.31 | 4.02 | 4.69 | 5.31 | 6.59 | 7.38 |

| BA | 2.56 | 2.95 | 3.35 | 3.74 | 4.53 | 5.12 | 6.5 | 8.46 |

| BC | 2.95 | 3.43 | 3.94 | 4.33 | 5.51 | 6.3 | 7.87 | 9.84 |

| BH | 90 ° | 45 ° | 45 ° | 45 ° | 45 ° | 45 ° | 45° | 45 ° |

| BK | 2.165 0 -0.0018 | 2.362 0 -0.0018 | 2.756 0 -0.0018 | 3.15 0 -0.0021 | 3.74 0 -0.0021 | 4.331 0 -0.0021 | 5.118 0 -0.0025 | 7.087 0 -0.0025 |

| BL | M6x11 | M6x10 | M8x10 | M8x14 | M8x14 | M10x18 | M10x18 | M12x21 |

| C | 1.18 | 1.57 | 1.97 | 2.48 | 2.95 | 3.54 | 4.33 | 5.12 |

| D | 1.57 | 1.97 | 2.36 | 2.83 | 3.39 | 4.06 | 5.02 | 5.81 |

| E | 2.13 | 2.76 | 3.15 | 3.94 | 4.72 | 5.51 | 6.69 | 7.87 |

| F | 1.73 | 2.36 | 2.76 | 3.35 | 3.54 | 3.94 | 4.53 | 4.72 |

| G | 0.22 | 0.26 | 0.28 | 0.31 | 0.39 | 0.43 | 0.57 | 0.61 |

| H | 0.26 | 0.26 | 0.33 | 0.33 | 0.45 | 0.51 | 0.55 | 0.63 |

| J | 3.15 | 3.98 | 4.76 | 5.75 | 6.85 | 8.19 | 9.94 | 11.52 |

| K | 1.26 | 1.69 | 1.93 | 2.64 | 2.83 | 2.91 | - | - |

| L | 2.2 | 2.8 | 3.35 | 4.06 | 4.41 | 5.12 | 5.67 | 6.1 |

| M | 2.28 | 2.87 | 3.43 | 4.17 | 4.49 | 5.28 | 5.83 | 6.38 |

| N | 1.06 | 1.38 | 1.57 | 1.97 | 2.36 | 2.76 | 3.35 | 3.94 |

| O | 3.82 | 4.78 | 5.67 | 6.85 | 8.07 | 9.37 | 11.61 | 13.19 |

| P | 2.64 | 3.15 | 3.54 | 4.13 | 4.96 | 5.63 | 6.81 | 7.6 |

| Q | 0.83 | 2.36 | 2.91 | 3.54 | 4.13 | 4.92 | 5.59 | 6.38 |

| T | 1.73 | 2.17 | 2.52 | 3.15 | 3.66 | 4.02 | 4.92 | 5.51 |

| Z | 2.91 | 3.63 | 3.92 | 4.71 | 5.25 | 6.09 | 6.77 | 7.09 |

| Output Flange | AA | AB | AC | AD | AF | AG | AH | AK | AL | ||

| 030 | FA | 2.68 | 2.15 | 3.15 | 2.76 | 0.24 | 0.16 | 45° | 1.969 | +0.0015 0 | 0.26 |

| 040 | FA | 2.95 | 2.64 | 4.33 | 3.74 | 0.28 | 0.16 | 45° | 2.362 | +0.0018 | 0.35 |

| 0 | |||||||||||

| FB | 2.95 | 3.82 | 4.33 | 3.74 | 0.28 | 0.16 | 45° | 2.362 | +0.0018 0 | 0.35 | |

| FC | 4.53 | 3.15 | 5.51 | - | 0.35 | 0.2 | 45° | 3.74 | +0.0021 0 | 0.37 | |

| FD | 3.94 | 2.28 | 4.72 | - | 0.47 | 0.2 | 45° | 3.15 | +0.0018 | 0.35 | |

| 0 | |||||||||||

| 050 | FA | 3.35 | 3.54 | 4.92 | 4.33 | 0.35 | 0.2 | 45° | 2.756 | +0.0018 | 0.43 |

| 0 | |||||||||||

| FB | 3.35 | 4.72 | 4.92 | 4.33 | 0.35 | 0.2 | 45° | 2.756 | +0.0018 0 | 0.43 | |

| FC | 5.12 | 3.5 | 6.3 | - | 0.39 | 0.2 | 45° | 4.331 | +0.0021 0 | 0.37 | |

| FD | 4.53 | 2.83 | 5.51 | - | 0.57 | 0.2 | 45° | 3.543 | +0.0021 | 0.43 | |

| 0 | |||||||||||

| 063 | FA | 4.13 | 3.23 | 7.09 | 5.59 | 0.39 | 0.24 | 45° | 4.528 | +0.0021 | 0.43 |

| 0 | |||||||||||

| FB | 5.91 | 4.41 | 7.09 | 5.59 | 0.39 | 0.24 | 45° | 4.528 | +0.0021 | 0.43 | |

| 0 | |||||||||||

| FC | 6.5 | 3.86 | 7.87 | - | 0.39 | 0.2 | 45° | 5.118 | +0.0025 0 | 0.43 | |

| FD | 6.5 | 4.21 | 7.87 | - | 0.39 | 0.2 | 45° | 5.118 | +0.0025 | 0.43 | |

| 0 | |||||||||||

| FE | 5.12 | 3.17 | 6.3 | - | 0.65 | 0.2 | 45° | 4.331 | +0.0021 | 0.43 | |

| 0 | |||||||||||

| 075 | FA | 6.5 | 4.37 | 7.87 | 6.69 | 0.51 | 0.24 | 45° | 5.118 | +0.0025 | 0.55 |

| 0 | |||||||||||

| FB | 5.12 | 3.54 | 6.3 | - | 0.51 | 0.24 | 45° | 4.331 | +0.0021 | 0.55 | |

| 0 | |||||||||||

| 090 | FA | 6.89 | 4.37 | 8.27 | 8.27 | 0.51 | 0.24 | 45° | 5.984 | +0.0025 | 0.55 |

| 0 | |||||||||||

| FB | 8.46 | 4.8 | 9.84 | - | 0.71 | 0.24 | 45° | 7.087 | +0.0025 0 | 0.55 | |

| FC | 6.5 | 4.33 | 7.87 | - | 0.67 | 0.24 | 45° | 5.118 | +0.0025 0 | 0.43 | |

| FD | 6.89 | 5.94 | 8.27 | - | 0.51 | 0.24 | 45° | 5.984 | +0.0025 | 0.55 | |

| 0 | |||||||||||

| 110 | FA | 9.06 | 5.16 | 11.02 | 10.24 | 0.59 | 0.24 | 45° | 6.693 | +0.0025 | 0.55 |

| 0 | |||||||||||

| FB | 9.06 | 7.09 | 11.02 | 10.24 | 0.59 | 0.24 | 45° | 6.693 | +0.0025 | 0.55 | |

| 0 | |||||||||||

| 130 | FA | 10.04 | 5.51 | 12.6 | 11.42 | 0.59 | 0.24 | 22.5° | 7.087 | +0.0025 0 | 0.63 |

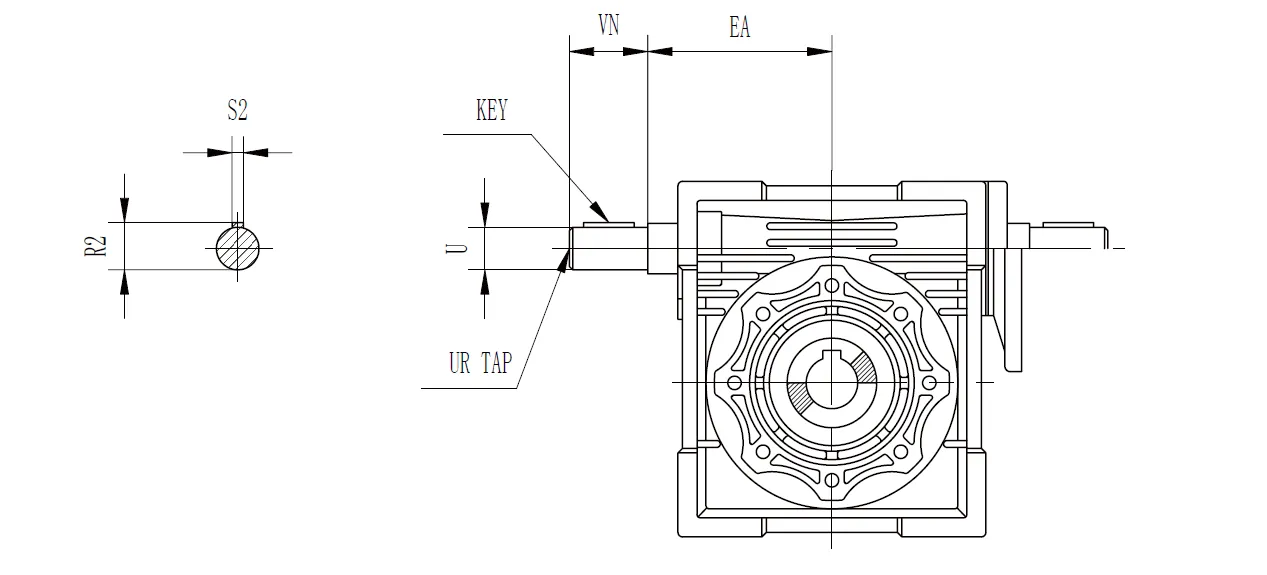

| Input Shaft | 030 | 040 | 050 | 063 | 075 | 090 | 110 | 130 | |

| SB | 0.094 | 0.125 | 0.188 | 0.188 | 0.188 | 0.188 | 0.25 | 0.25 | |

| RB | 0.42 | 0.55 | 0.7 | 0.83 | 0.96 | 0.96 | 1.24 | 1.36 | |

| UB | 0.3750 -0.0005 | 0.50 -0.0005 | 0.6250 -0.0005 | 0.750 -0.0005 | 0.8750 -0.0005 | 0.8750 -0.0005 | 1.1250 -0.0005 | 1.250 -0.0005 | |

| UB KEY | 0.094x0.875 | 0.125x0.875 | 0.1875x1.125 | 0.1875x1.5 | 0.1875x1.875 | 0.1875x1.875 | 0.25x2.25 | 0.25x2.5 | |

| UR | - | 1/4-20 | 1/4-20 | 1/4-20 | 1/4-20 | 1/4-20 | 3/8-16 | 1/2-13 | |

| VN | 1.18 | 1.18 | 1.58 | 1.97 | 2.36 | 2.36 | 2.76 | 3.15 | |

High Speed Extension Shaft Dimensions

| CMN-NMRV | EA | U | VN | UR | S2 | R2 | KEY | |

| Length | Square | |||||||

| 030 | 1.772 | 0.3750 -0.0005 | 1.18 | - | 0.093 | 0.42 | 0.875 | 0.094 |

| 040 | 2.087 | 0.50 -0.0005 | 1.18 | 1/4-20 | 0.13 | 0.55 | 0.875 | 0.125 |

| 050 | 2.52 | 0.6250 -0.0005 | 1.58 | 1/4-20 | 0.19 | 0.7 | 1.125 | 0.188 |

| 063 | 2.953 | 0.750 -0.0005 | 1.97 | 1/4-20 | 0.19 | 0.83 | 1.5 | 0.188 |

| 075 | 3.543 | 0.8750 -0.0005 | 2.36 | 1/4-20 | 0.19 | 0.96 | 1.875 | 0.188 |

| 090 | 4.252 | 0.8750 -0.0005 | 2.36 | 1/4-20 | 0.19 | 0.96 | 1.875 | 0.188 |

| 110 | 5.315 | 1.1250 -0.0005 | 2.76 | 3/8-16 | 0.25 | 1.24 | 2.25 | 0.25 |

| 130 | 6.102 | 1.250 -0.0005 | 3.15 | 1/2-13 | 0.25 | 1.36 | 2.5 | 0.25 |

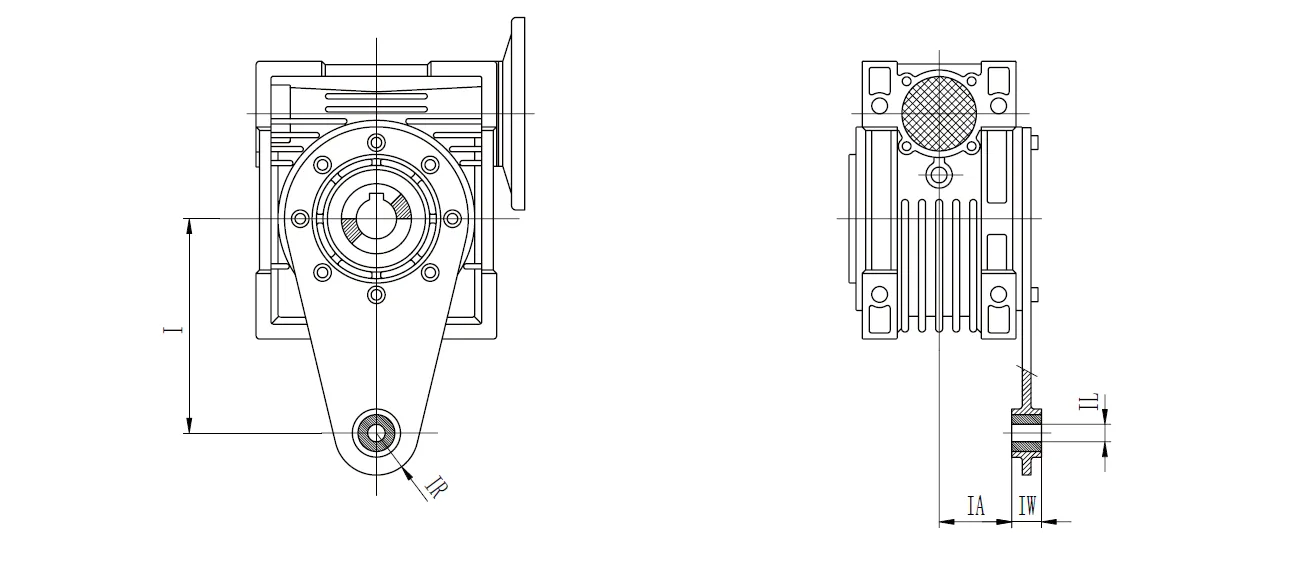

Torque Arm Dimensions

| I | IA | IL | IR | IW | |

| 025 | 2.76 | 0.69 | 0.31 | 0.59 | 0.55 |

| 030 | 3.35 | 0.94 | 0.31 | 0.59 | 0.55 |

| 040 | 3.94 | 1.24 | 0.39 | 0.71 | 0.55 |

| 050 | 3.94 | 1.52 | 0.39 | 0.71 | 0.55 |

| 063 | 5.91 | 1.93 | 0.39 | 0.71 | 0.55 |

| 075 | 7.87 | 1.87 | 0.79 | 1.18 | 0.98 |

| 090 | 7.87 | 2.26 | 0.79 | 1.18 | 0.98 |

| 110 | 9.84 | 2.44 | 0.98 | 1.38 | 1.18 |

| 130 | 9.84 | 2.72 | 0.98 | 1.38 | 1.18 |

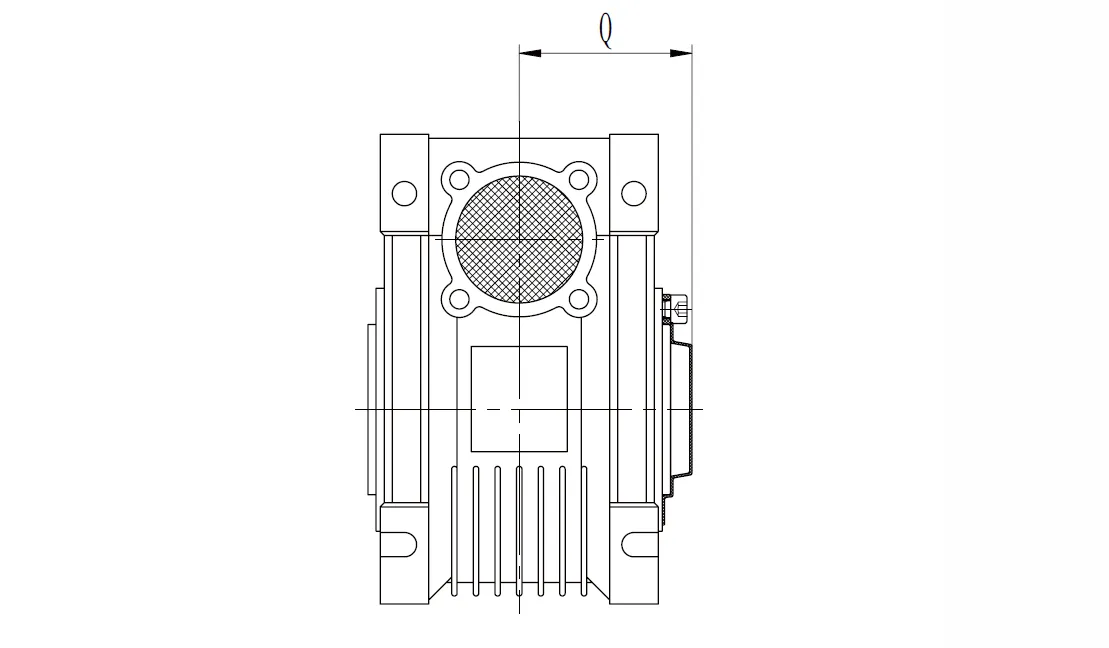

Protective Cover Dimensions

| CMN-NMRV | Q |

| 030 | 1.65 |

| 040 | 1.97 |

| 050 | 2.28 |

| 063 | 2.72 |

| 075 | 2.91 |

| 090 | 3.39 |

| 110 | 3.7 |

| 130 | 4.02 |

NEMA Flange Availability

| CMN-NMRV | NEMA Flange | Input Bore Diameter | Available Ratios | |||||||||||

| 5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 | 60 | 80 | 100 | |||

| 030 | 48C | 0.5 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |

| 040 | 56C | 0.625 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| 050 | 56C | 0.625 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| 063 | 56C | 0.625 | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| 140TC | 0.875 | ● | ● | ● | ● | ● | ● | ● | ||||||

| 075 | 56C | 0.625 | ● | ● | ● | ● | ||||||||

| 140TC | 0.875 | ● | ● | ● | ● | ● | ● | |||||||

| 180TC | 1.125 | ● | ● | ● | ||||||||||

| 090 | 56C | 0.625 | ● | ● | ||||||||||

| 140TC | 0.875 | ● | ● | ● | ● | ● | ||||||||

| 180TC | 1.125 | ● | ● | ● | ● | ● | ● | ● | ||||||

| 110 | 140TC | 0.875 | ● | ● | ● | ● | ||||||||

| 180TC | 1.125 | ● | ● | ● | ● | ● | ● | |||||||

| 210TC | 1.375 | ● | ● | ● | ● | |||||||||

| 130 | 140TC | 0.875 | ● | ● | ||||||||||

| 180TC | 1.125 | ● | ● | ● | ● | ● | ||||||||

| 210TC | 1.375 | ● | ● | ● | ● | ● | ● | ● | ||||||

CMN-NMRV025 Worm Gear Reducer Advantages

1. Compact and Lightweight Design

The CMN-NMRV025 worm drive gearbox features a compact and lightweight aluminum alloy housing, making it easy to install in limited spaces. Its reduced weight does not compromise its durability, allowing it to perform efficiently in demanding industrial applications while being easy to handle and transport.

2. High Efficiency and Torque Output

This worm gear reducer delivers exceptional torque output while ensuring high efficiency. Its worm and worm wheel design provides smooth power transmission, enabling the gearbox to handle heavy loads effectively, making it suitable for applications requiring significant torque.

3. Corrosion-Resistant Construction

Built with high-quality materials and coated for protection, the CMN-NMRV025 worm reducer gearbox resists corrosion and wear. This feature makes it ideal for use in harsh environments, including those with exposure to moisture, chemicals, or extreme temperatures, ensuring a longer lifespan.

4. Low Noise and Vibration

The worm gear reducer operates with minimal noise and vibration, thanks to its precision-engineered worm gear mechanism. This characteristic makes it an excellent choice for environments where quiet operation is essential, such as packaging lines or automated systems.

5. Versatile Mounting Options

The CMN-NMRV025 worm gear gearbox offers flexibility in installation, supporting various mounting positions to adapt to different system requirements. This versatility allows it to integrate seamlessly into a wide range of machinery, ensuring compatibility and ease of use in industrial setups.

6. Wide Range of Gear Ratios

With multiple gear ratio options, the CMN-NMRV025 worm gear speed reducer can be customized to meet diverse speed and torque requirements. This adaptability makes it suitable for a variety of applications, from high-speed operations to tasks requiring precise control and lower speeds.

CMN-NMRV025 Worm Reducer Gearbox Applications

- Food Processing Industry

The CMN-NMRV025 worm gear reducer is widely used in food processing equipment, such as conveyors and mixers, due to its corrosion-resistant aluminum housing and low-noise operation. Its compact design ensures efficient torque transmission, meeting hygiene and space requirements in food production lines. - Textile Manufacturing

In textile machinery, the NMRV025 worm reducer gearbox drives looms, spinning machines, and winding systems. Its high torque output and precise speed reduction ensure smooth operation, while the self-locking feature prevents reverse motion, enhancing safety and reliability in high-speed textile production environments. - Ceramics Production

The NMRV025 worm gear gearbox is ideal for ceramics manufacturing, powering equipment like clay mixers and molding machines. Its durable tin bronze worm wheel and robust construction withstand abrasive environments, delivering consistent performance and reducing maintenance needs in demanding, dust-heavy ceramic processing applications. - Automation and Robotics

This worm gear reducer gearbox supports automation systems and robotic arms by providing precise speed control and high torque in a compact form. Its compatibility with NEMA 23 stepper motors and versatile mounting options make it perfect for precise, repeatable movements in automated assembly lines. - Packaging Machinery

In packaging systems, the NMRV025 worm gear drive gearbox drives conveyor belts, sealing machines, and labeling equipment. Its lightweight design and low maintenance requirements, enabled by synthetic oil lubrication, ensure reliable operation, while its quiet performance suits high-speed packaging lines in various industries. - Material Handling Systems

The NMRV025 worm reduction gearbox is employed in material handling equipment like hoists and automated conveyors. Its self-locking capability enhances safety by preventing load backdriving, and its high reduction ratios provide the torque needed for heavy-duty lifting and transport in logistics and warehousing.

Additional information

| Edited by | Yjx |

|---|