CMN-NMRV Worm Gear Reducers/Worm Gearbox

CMN-NMRV worm gear reducers use a worm (a screw-like gear) that meshes with a worm wheel (a circular gear). The rotational motion of the worm is converted into a slower rotational motion of the worm wheel, providing a high reduction ratio. CMN-NMRV worm gearboxes are commonly used in industrial applications that require high reduction ratios, high torque output, and compact design. They are often found in machinery, conveyors, and other power transmission systems.

CMN-NMRV worm gear reducers use a worm (a screw-like gear) that meshes with a worm wheel (a circular gear). The rotational motion of the worm is converted into a slower rotational motion of the worm wheel, providing a high reduction ratio. CMN-NMRV worm gearboxes are commonly used in industrial applications that require high reduction ratios, high torque output, and compact design. They are often found in machinery, conveyors, and other power transmission systems.

CMN-NMRV Worm Gearbox Model & Marker

| CMN-NMRV-063-30-VS-F1(FA)-AS-80B5-0.75kW-B3 | |||

| CMN-NMRV | Worm geared motor | ||

| CMN-NRV | Worm reduction unit | ||

| 063 | Center distance | ||

| 30 | Reduction ratio | ||

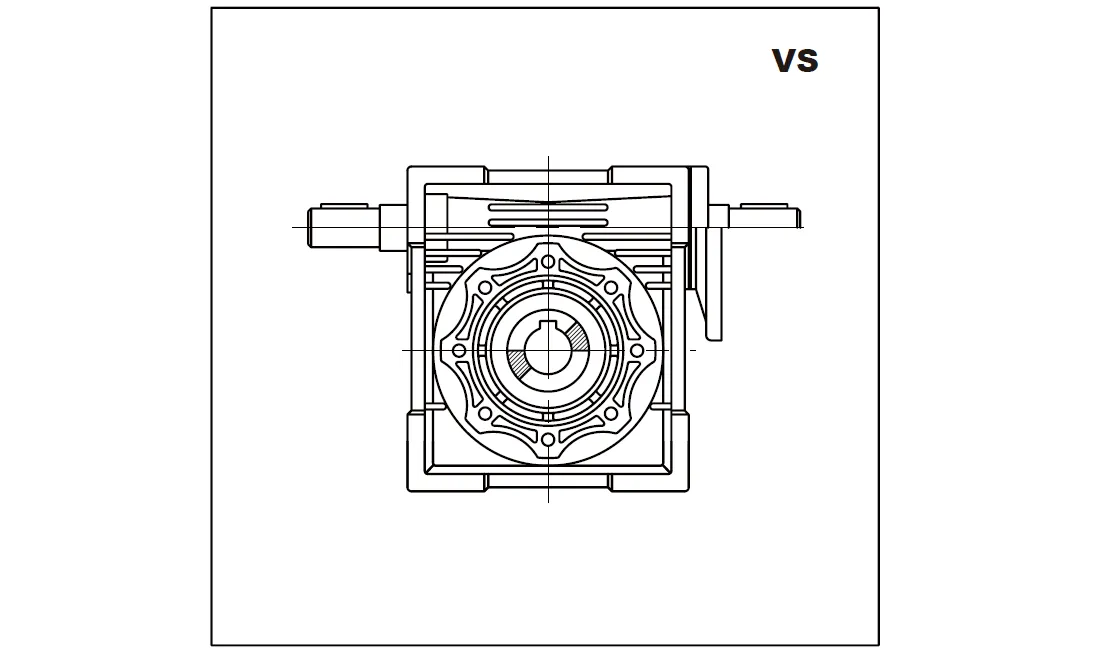

| VS | Double input shaft | F1(FA) | Output flange |

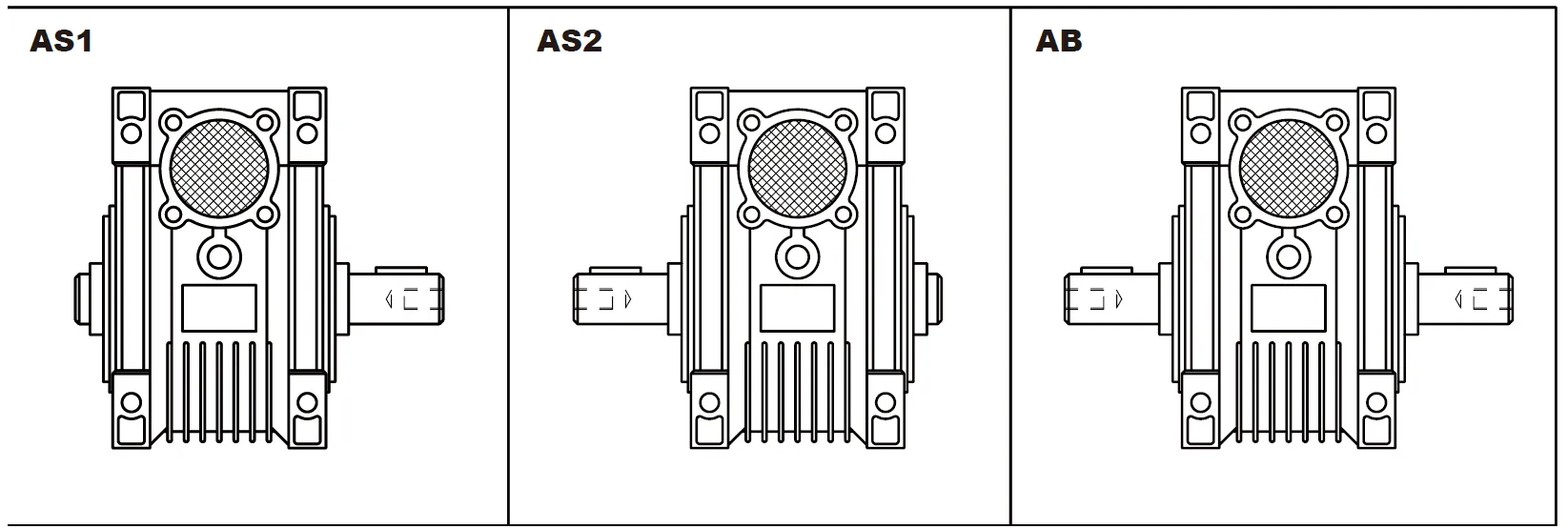

| AS | Single output shaft | AB | Double output shaft |

| PAM | Fitted for motor coupling | 80B5 | Motor size & mounting position |

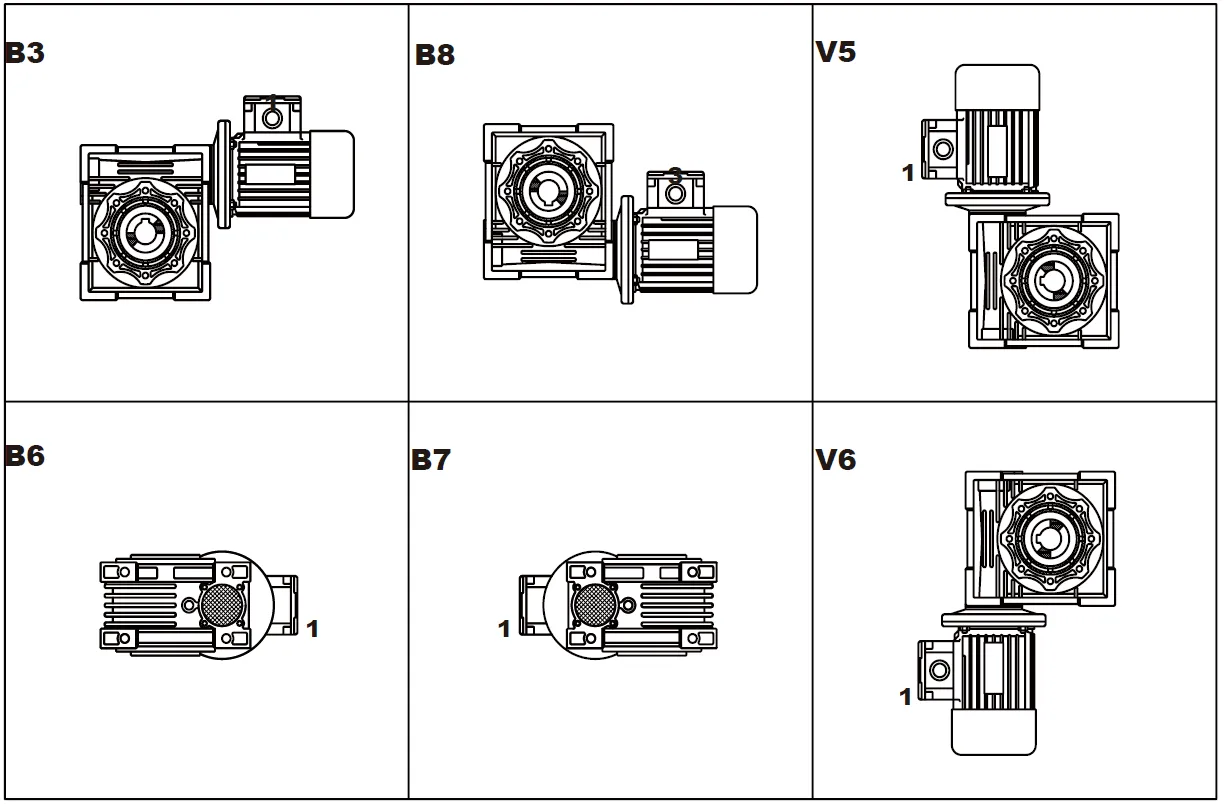

| 0.75kW | Power of electric motor | B3 | Mounting position |

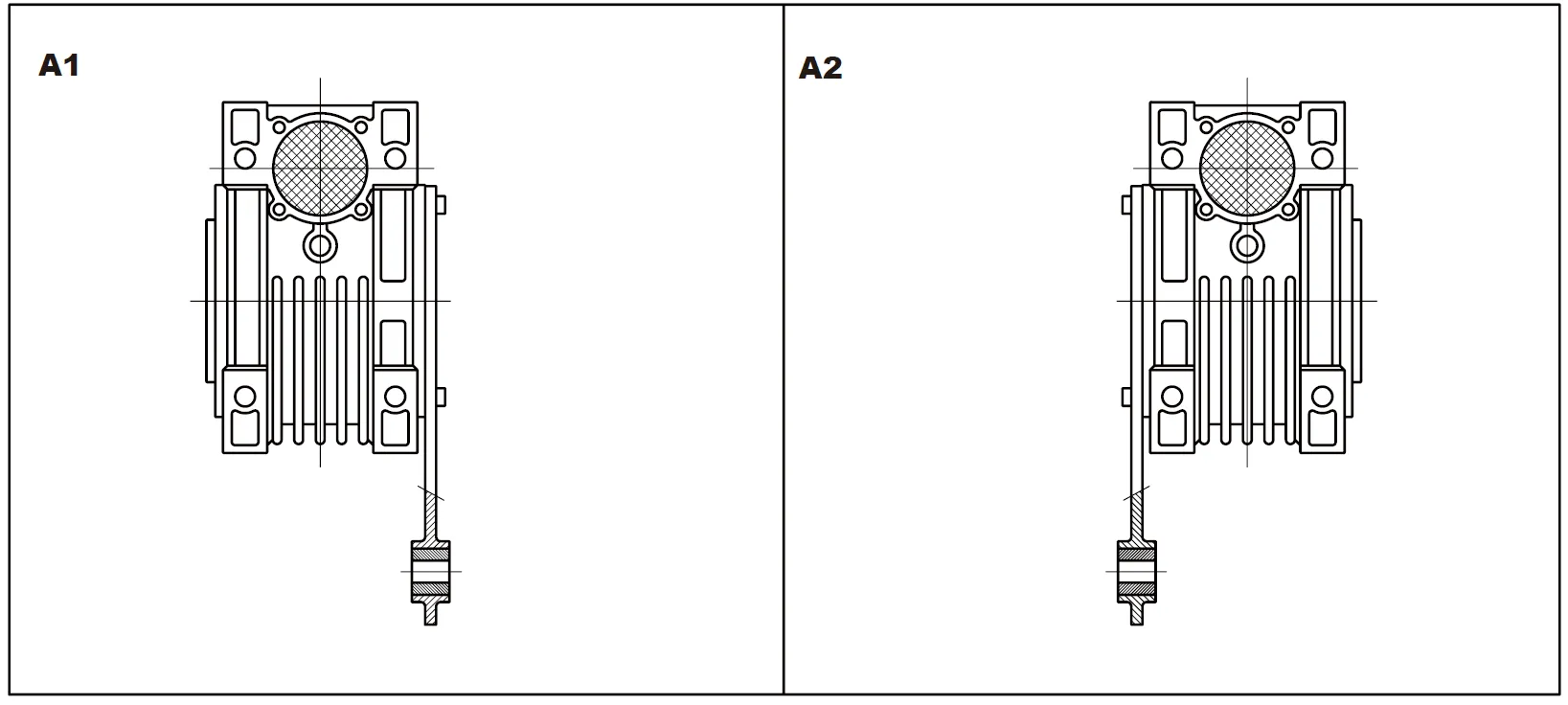

Mounting Position

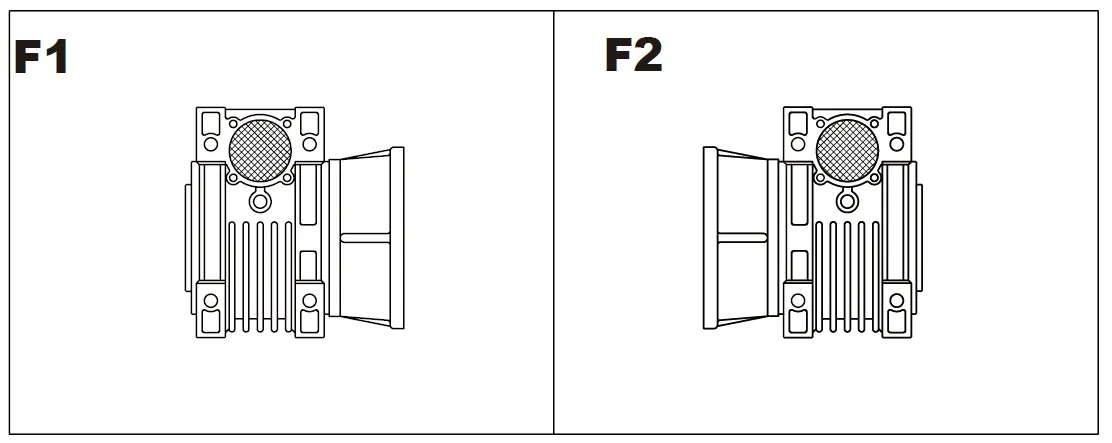

Flange F-FL

Position of Terminal Box

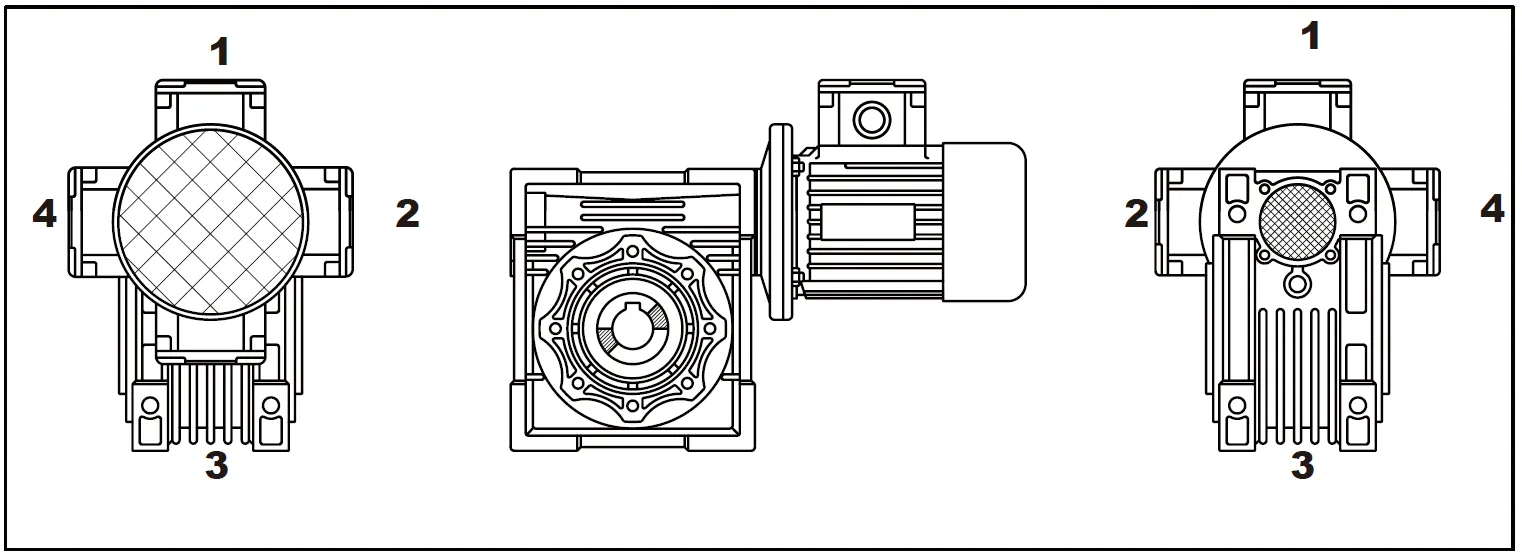

Position of Output Shaft

Double Extension Worm Shaft

Position of Torque Arm

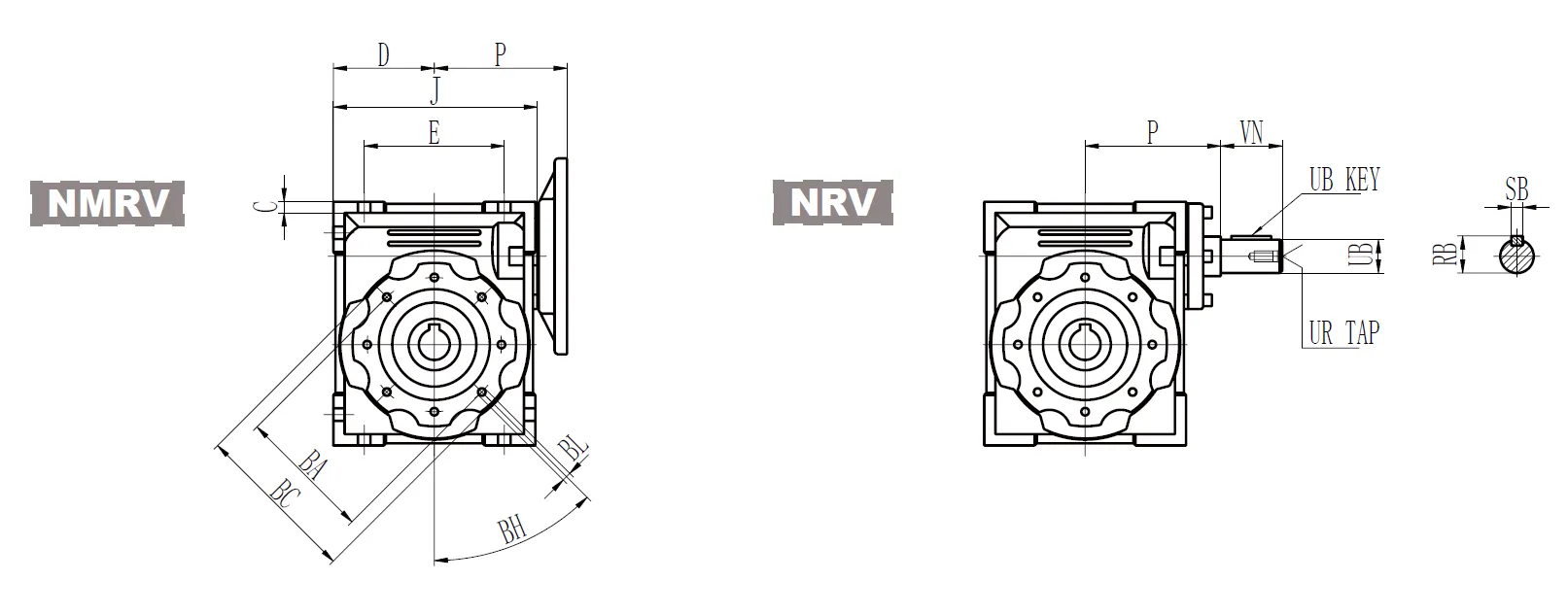

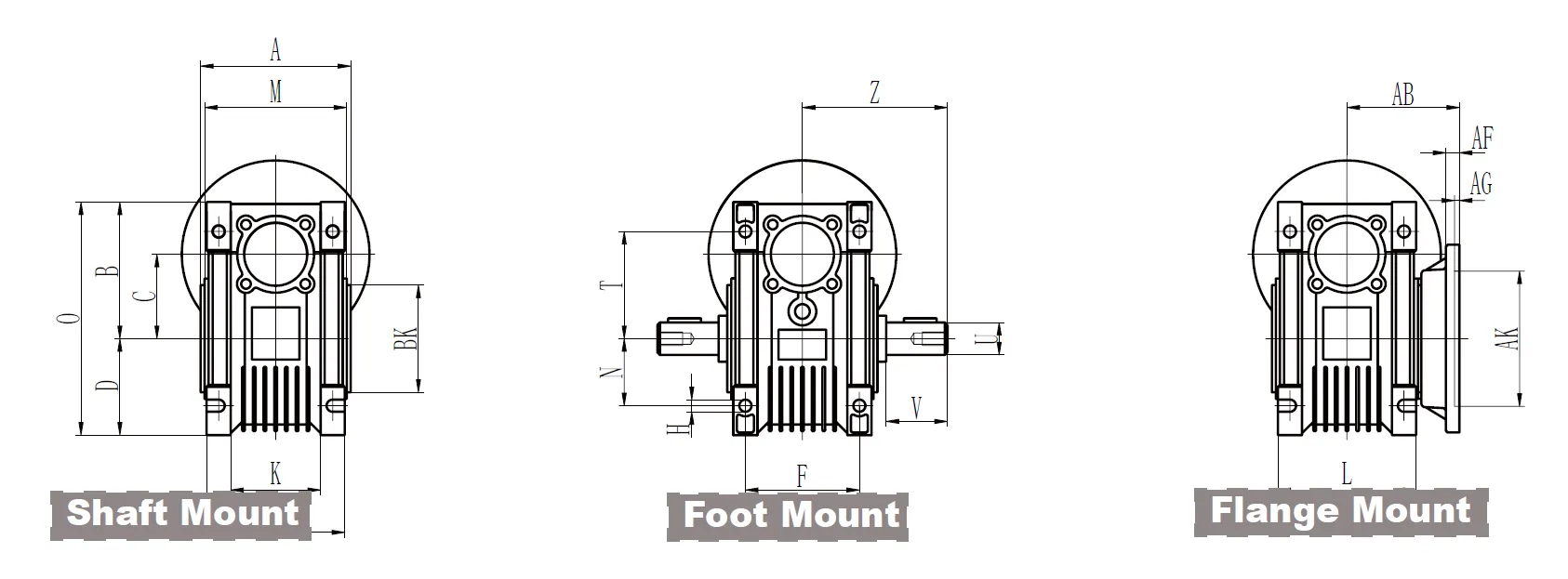

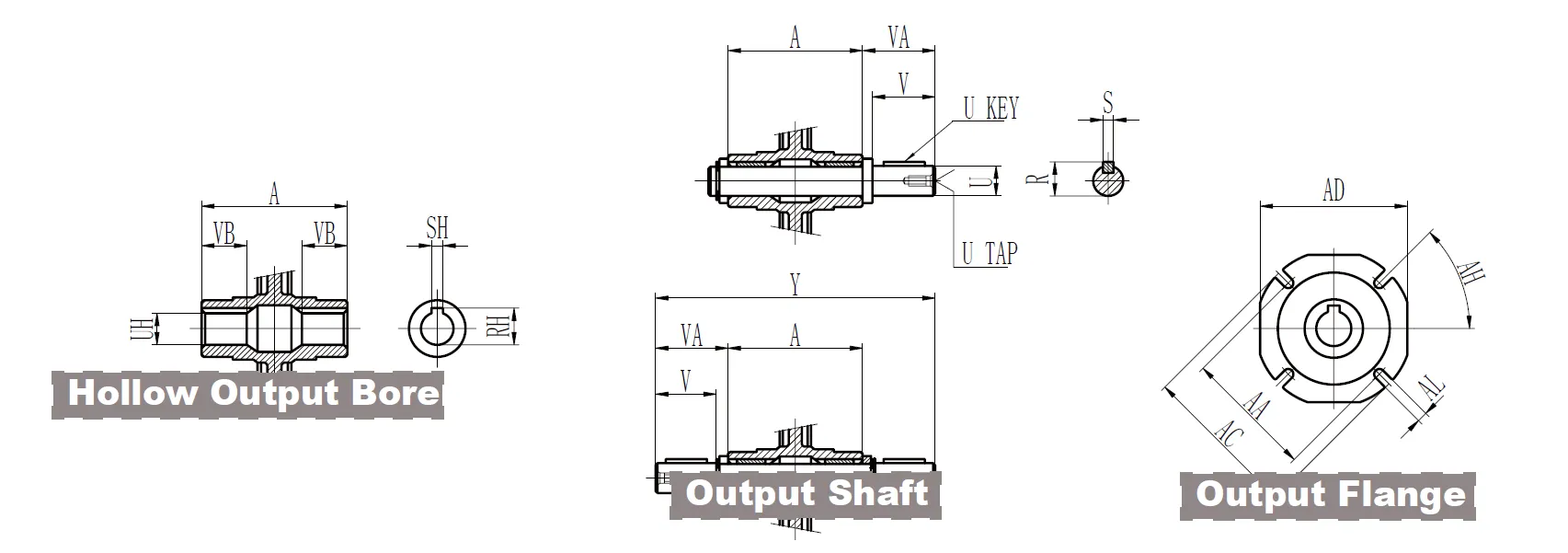

CMN-NMRV Worm Gear Reducer Dimensions

CMN-NMRV Inch Series

| Hollow Output Bore | 030 | 040 | 050 | 063 | 075 | 090 | 110 | 130 | |

| RH | 0.71 | 0.84 | 1.12 | 1.24 | 1.37 | 1.52 | 1.8 | 1.93 | |

| SH | 0.188 | 0.188 | 0.25 | 0.25 | 0.25 | 0.313 | 0.375 | 0.375 | |

| UH | 0.625+0.001 0 | 0.75+0.001 0 | 1+0.001 0 | 1.125+0.001 0 | 1.25+0.001 0 | 1.375+0.001 0 | 1.625+0.001 0 | 1.750 | |

| VB | 0.83 | 1.14 | 1.28 | 1.42 | 1.56 | 1.77 | 1.97 | 2.24 | |

| Output Shaft | 030 | 040 | 050 | 063 | 075 | 090 | 110 | 130 | |

| R | 0.7 | 0.83 | 1.11 | 1.23 | 1.36 | 1.51 | 1.79 | 1.92 | |

| S | 0.188 | 0.188 | 0.25 | 0.25 | 0.25 | 0.313 | 0.375 | 0.375 | |

| U | 0.6250 -0.0005 | 0.750 -0.0005 | 10 -0.0005 | 0 -0.0005 | 1.250 -0.0005 | 1.3750 -0.0005 | 1.6250 -0.0005 | 1.750 -0.0005 | |

| U KEY | 0.1875x1.125 | 0.1875x1.5 | 0.25x1.5 | 0.25x1.875 | 0.25x2.25 | 0.3125x2.5 | 0.375x2.75 | 0.375x2.75 | |

| UT | 1/4-20 | 1/4-20 | 3/8-16 | 3/8-16 | 1/2-13 | 1/2-13 | 5/8-11 | 5/8-11 | |

| V | 1.57 | 1.97 | 1.97 | 2.36 | 2.76 | 3.15 | 3.54 | 3.54 | |

| VA | 1.67 | 2.09 | 2.11 | 2.5 | 2.89 | 3.33 | 3.72 | 3.74 | |

| Y | 5.82 | 7.25 | 7.84 | 9.41 | 10.5 | 12.17 | 13.54 | 14.17 | |

| CMN-NMRV | 030 | 040 | 050 | 063 | 075 | 090 | 110 | 130 |

| A | 2.48 | 3.07 | 3.62 | 4.41 | 4.72 | 5.51 | 6.1 | 6.69 |

| B | 2.24 | 2.81 | 3.31 | 4.02 | 4.69 | 5.31 | 6.59 | 7.38 |

| BA | 2.56 | 2.95 | 3.35 | 3.74 | 4.53 | 5.12 | 6.5 | 8.46 |

| BC | 2.95 | 3.43 | 3.94 | 4.33 | 5.51 | 6.3 | 7.87 | 9.84 |

| BH | 90 ° | 45 ° | 45 ° | 45 ° | 45 ° | 45 ° | 45° | 45 ° |

| BK | 2.165 0 -0.0018 | 2.362 0 -0.0018 | 2.756 0 -0.0018 | 3.15 0 -0.0021 | 3.74 0 -0.0021 | 4.331 0 -0.0021 | 5.118 0 -0.0025 | 7.087 0 -0.0025 |

| BL | M6x11 | M6x10 | M8x10 | M8x14 | M8x14 | M10x18 | M10x18 | M12x21 |

| C | 1.18 | 1.57 | 1.97 | 2.48 | 2.95 | 3.54 | 4.33 | 5.12 |

| D | 1.57 | 1.97 | 2.36 | 2.83 | 3.39 | 4.06 | 5.02 | 5.81 |

| E | 2.13 | 2.76 | 3.15 | 3.94 | 4.72 | 5.51 | 6.69 | 7.87 |

| F | 1.73 | 2.36 | 2.76 | 3.35 | 3.54 | 3.94 | 4.53 | 4.72 |

| G | 0.22 | 0.26 | 0.28 | 0.31 | 0.39 | 0.43 | 0.57 | 0.61 |

| H | 0.26 | 0.26 | 0.33 | 0.33 | 0.45 | 0.51 | 0.55 | 0.63 |

| J | 3.15 | 3.98 | 4.76 | 5.75 | 6.85 | 8.19 | 9.94 | 11.52 |

| K | 1.26 | 1.69 | 1.93 | 2.64 | 2.83 | 2.91 | - | - |

| L | 2.2 | 2.8 | 3.35 | 4.06 | 4.41 | 5.12 | 5.67 | 6.1 |

| M | 2.28 | 2.87 | 3.43 | 4.17 | 4.49 | 5.28 | 5.83 | 6.38 |

| N | 1.06 | 1.38 | 1.57 | 1.97 | 2.36 | 2.76 | 3.35 | 3.94 |

| O | 3.82 | 4.78 | 5.67 | 6.85 | 8.07 | 9.37 | 11.61 | 13.19 |

| P | 2.64 | 3.15 | 3.54 | 4.13 | 4.96 | 5.63 | 6.81 | 7.6 |

| Q | 0.83 | 2.36 | 2.91 | 3.54 | 4.13 | 4.92 | 5.59 | 6.38 |

| T | 1.73 | 2.17 | 2.52 | 3.15 | 3.66 | 4.02 | 4.92 | 5.51 |

| Z | 2.91 | 3.63 | 3.92 | 4.71 | 5.25 | 6.09 | 6.77 | 7.09 |

| Output Flange | AA | AB | AC | AD | AF | AG | AH | AK | AL | ||

| 030 | FA | 2.68 | 2.15 | 3.15 | 2.76 | 0.24 | 0.16 | 45° | 1.969 | +0.0015 0 | 0.26 |

| 040 | FA | 2.95 | 2.64 | 4.33 | 3.74 | 0.28 | 0.16 | 45° | 2.362 | +0.0018 | 0.35 |

| 0 | |||||||||||

| FB | 2.95 | 3.82 | 4.33 | 3.74 | 0.28 | 0.16 | 45° | 2.362 | +0.0018 0 | 0.35 | |

| FC | 4.53 | 3.15 | 5.51 | - | 0.35 | 0.2 | 45° | 3.74 | +0.0021 0 | 0.37 | |

| FD | 3.94 | 2.28 | 4.72 | - | 0.47 | 0.2 | 45° | 3.15 | +0.0018 | 0.35 | |

| 0 | |||||||||||

| 050 | FA | 3.35 | 3.54 | 4.92 | 4.33 | 0.35 | 0.2 | 45° | 2.756 | +0.0018 | 0.43 |

| 0 | |||||||||||

| FB | 3.35 | 4.72 | 4.92 | 4.33 | 0.35 | 0.2 | 45° | 2.756 | +0.0018 0 | 0.43 | |

| FC | 5.12 | 3.5 | 6.3 | - | 0.39 | 0.2 | 45° | 4.331 | +0.0021 0 | 0.37 | |

| FD | 4.53 | 2.83 | 5.51 | - | 0.57 | 0.2 | 45° | 3.543 | +0.0021 | 0.43 | |

| 0 | |||||||||||

| 063 | FA | 4.13 | 3.23 | 7.09 | 5.59 | 0.39 | 0.24 | 45° | 4.528 | +0.0021 | 0.43 |

| 0 | |||||||||||

| FB | 5.91 | 4.41 | 7.09 | 5.59 | 0.39 | 0.24 | 45° | 4.528 | +0.0021 | 0.43 | |

| 0 | |||||||||||

| FC | 6.5 | 3.86 | 7.87 | - | 0.39 | 0.2 | 45° | 5.118 | +0.0025 0 | 0.43 | |

| FD | 6.5 | 4.21 | 7.87 | - | 0.39 | 0.2 | 45° | 5.118 | +0.0025 | 0.43 | |

| 0 | |||||||||||

| FE | 5.12 | 3.17 | 6.3 | - | 0.65 | 0.2 | 45° | 4.331 | +0.0021 | 0.43 | |

| 0 | |||||||||||

| 075 | FA | 6.5 | 4.37 | 7.87 | 6.69 | 0.51 | 0.24 | 45° | 5.118 | +0.0025 | 0.55 |

| 0 | |||||||||||

| FB | 5.12 | 3.54 | 6.3 | - | 0.51 | 0.24 | 45° | 4.331 | +0.0021 | 0.55 | |

| 0 | |||||||||||

| 090 | FA | 6.89 | 4.37 | 8.27 | 8.27 | 0.51 | 0.24 | 45° | 5.984 | +0.0025 | 0.55 |

| 0 | |||||||||||

| FB | 8.46 | 4.8 | 9.84 | - | 0.71 | 0.24 | 45° | 7.087 | +0.0025 0 | 0.55 | |

| FC | 6.5 | 4.33 | 7.87 | - | 0.67 | 0.24 | 45° | 5.118 | +0.0025 0 | 0.43 | |

| FD | 6.89 | 5.94 | 8.27 | - | 0.51 | 0.24 | 45° | 5.984 | +0.0025 | 0.55 | |

| 0 | |||||||||||

| 110 | FA | 9.06 | 5.16 | 11.02 | 10.24 | 0.59 | 0.24 | 45° | 6.693 | +0.0025 | 0.55 |

| 0 | |||||||||||

| FB | 9.06 | 7.09 | 11.02 | 10.24 | 0.59 | 0.24 | 45° | 6.693 | +0.0025 | 0.55 | |

| 0 | |||||||||||

| 130 | FA | 10.04 | 5.51 | 12.6 | 11.42 | 0.59 | 0.24 | 22.5° | 7.087 | +0.0025 0 | 0.63 |

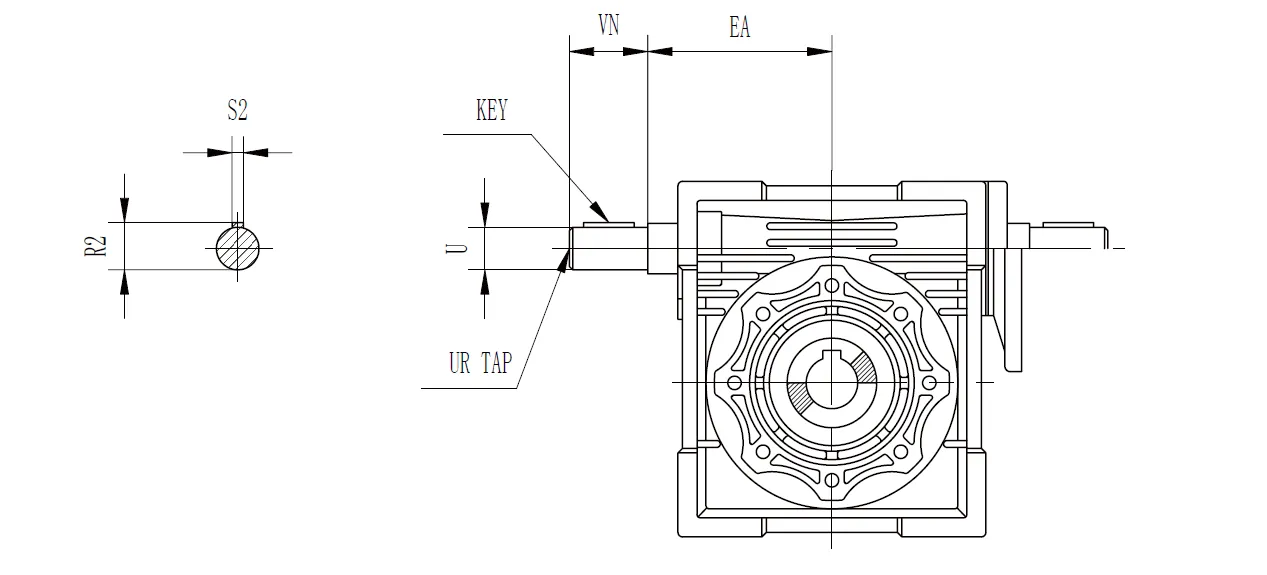

| Input Shaft | 030 | 040 | 050 | 063 | 075 | 090 | 110 | 130 | |

| SB | 0.094 | 0.125 | 0.188 | 0.188 | 0.188 | 0.188 | 0.25 | 0.25 | |

| RB | 0.42 | 0.55 | 0.7 | 0.83 | 0.96 | 0.96 | 1.24 | 1.36 | |

| UB | 0.3750 -0.0005 | 0.50 -0.0005 | 0.6250 -0.0005 | 0.750 -0.0005 | 0.8750 -0.0005 | 0.8750 -0.0005 | 1.1250 -0.0005 | 1.250 -0.0005 | |

| UB KEY | 0.094x0.875 | 0.125x0.875 | 0.1875x1.125 | 0.1875x1.5 | 0.1875x1.875 | 0.1875x1.875 | 0.25x2.25 | 0.25x2.5 | |

| UR | - | 1/4-20 | 1/4-20 | 1/4-20 | 1/4-20 | 1/4-20 | 3/8-16 | 1/2-13 | |

| VN | 1.18 | 1.18 | 1.58 | 1.97 | 2.36 | 2.36 | 2.76 | 3.15 | |

High Speed Extension Shaft Dimensions

| CMN-NMRV | EA | U | VN | UR | S2 | R2 | KEY | |

| Length | Square | |||||||

| 030 | 1.772 | 0.3750 -0.0005 | 1.18 | - | 0.093 | 0.42 | 0.875 | 0.094 |

| 040 | 2.087 | 0.50 -0.0005 | 1.18 | 1/4-20 | 0.13 | 0.55 | 0.875 | 0.125 |

| 050 | 2.52 | 0.6250 -0.0005 | 1.58 | 1/4-20 | 0.19 | 0.7 | 1.125 | 0.188 |

| 063 | 2.953 | 0.750 -0.0005 | 1.97 | 1/4-20 | 0.19 | 0.83 | 1.5 | 0.188 |

| 075 | 3.543 | 0.8750 -0.0005 | 2.36 | 1/4-20 | 0.19 | 0.96 | 1.875 | 0.188 |

| 090 | 4.252 | 0.8750 -0.0005 | 2.36 | 1/4-20 | 0.19 | 0.96 | 1.875 | 0.188 |

| 110 | 5.315 | 1.1250 -0.0005 | 2.76 | 3/8-16 | 0.25 | 1.24 | 2.25 | 0.25 |

| 130 | 6.102 | 1.250 -0.0005 | 3.15 | 1/2-13 | 0.25 | 1.36 | 2.5 | 0.25 |

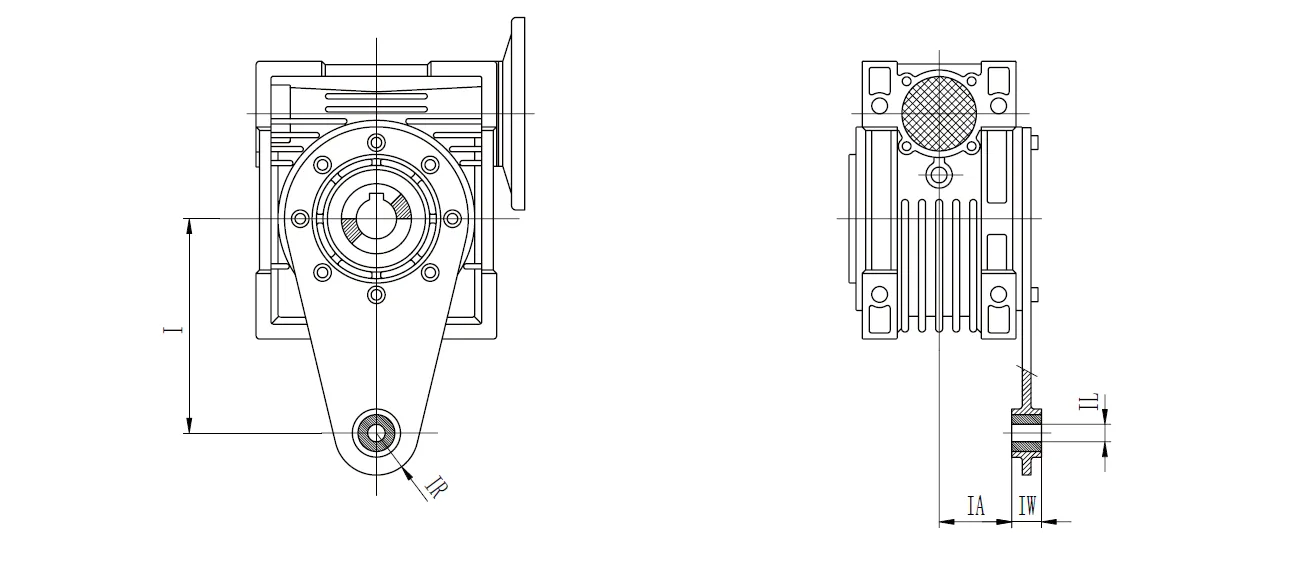

Torque Arm Dimensions

| I | IA | IL | IR | IW | |

| 025 | 2.76 | 0.69 | 0.31 | 0.59 | 0.55 |

| 030 | 3.35 | 0.94 | 0.31 | 0.59 | 0.55 |

| 040 | 3.94 | 1.24 | 0.39 | 0.71 | 0.55 |

| 050 | 3.94 | 1.52 | 0.39 | 0.71 | 0.55 |

| 063 | 5.91 | 1.93 | 0.39 | 0.71 | 0.55 |

| 075 | 7.87 | 1.87 | 0.79 | 1.18 | 0.98 |

| 090 | 7.87 | 2.26 | 0.79 | 1.18 | 0.98 |

| 110 | 9.84 | 2.44 | 0.98 | 1.38 | 1.18 |

| 130 | 9.84 | 2.72 | 0.98 | 1.38 | 1.18 |

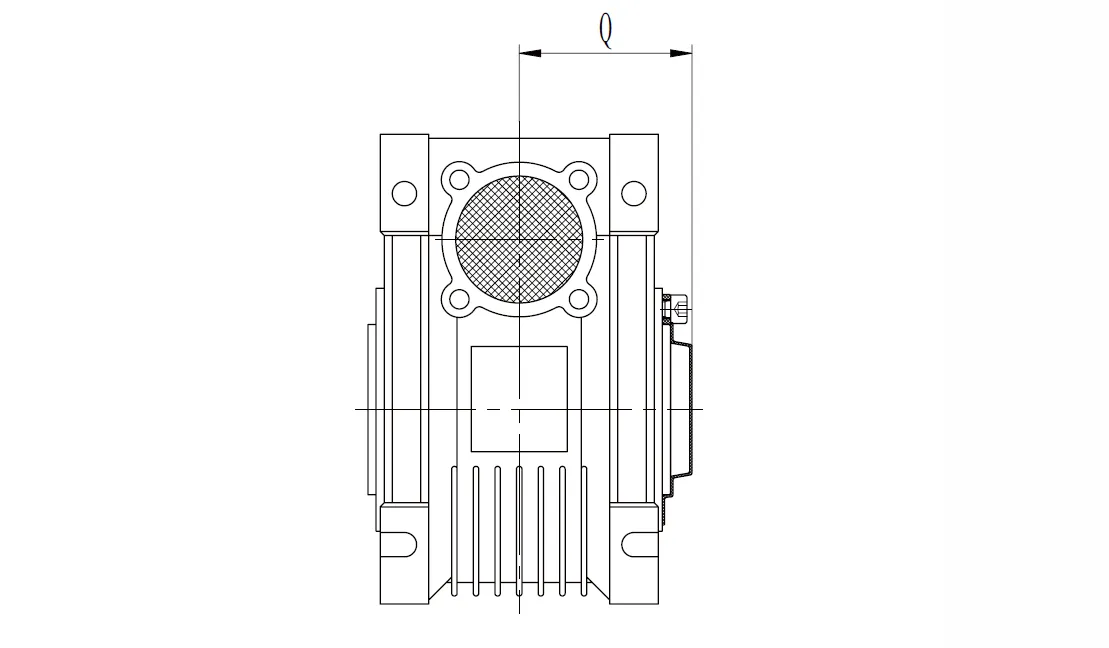

Protective Cover Dimensions

| CMN-NMRV | Q |

| 030 | 1.65 |

| 040 | 1.97 |

| 050 | 2.28 |

| 063 | 2.72 |

| 075 | 2.91 |

| 090 | 3.39 |

| 110 | 3.7 |

| 130 | 4.02 |

NEMA Flange Availability

| CMN-NMRV | NEMA Flange | Input Bore Diameter | Available Ratios | |||||||||||

| 5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 | 60 | 80 | 100 | |||

| 030 | 48C | 0.5 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |

| 040 | 56C | 0.625 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| 050 | 56C | 0.625 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| 063 | 56C | 0.625 | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| 140TC | 0.875 | ● | ● | ● | ● | ● | ● | ● | ||||||

| 075 | 56C | 0.625 | ● | ● | ● | ● | ||||||||

| 140TC | 0.875 | ● | ● | ● | ● | ● | ● | |||||||

| 180TC | 1.125 | ● | ● | ● | ||||||||||

| 090 | 56C | 0.625 | ● | ● | ||||||||||

| 140TC | 0.875 | ● | ● | ● | ● | ● | ||||||||

| 180TC | 1.125 | ● | ● | ● | ● | ● | ● | ● | ||||||

| 110 | 140TC | 0.875 | ● | ● | ● | ● | ||||||||

| 180TC | 1.125 | ● | ● | ● | ● | ● | ● | |||||||

| 210TC | 1.375 | ● | ● | ● | ● | |||||||||

| 130 | 140TC | 0.875 | ● | ● | ||||||||||

| 180TC | 1.125 | ● | ● | ● | ● | ● | ||||||||

| 210TC | 1.375 | ● | ● | ● | ● | ● | ● | ● | ||||||

CMN-NMRV Worm Gear Reducer Advantages

- High Reduction Ratios

CMN-NMRV worm gear reducers provide exceptionally high reduction ratios in a single stage, making them ideal for applications requiring significant speed reduction. This capability eliminates the need for additional stages, simplifying the design and reducing system complexity. - Compact and Lightweight Design

Their compact structure and lightweight aluminum alloy housing make them suitable for applications with limited space. The small form factor ensures easy installation and integration into systems while maintaining high performance and durability, even under demanding conditions. - High Torque Output

These worm drive gearboxes are capable of delivering high torque, essential for powering heavy-duty machinery. This feature ensures reliable performance in industrial applications, including conveyors, mixers, and other systems requiring substantial force for operation. - Smooth and Quiet Operation

Due to their unique design, CMN-NMRV worm gear reducers operate with minimal noise and vibration. This makes them suitable for noise-sensitive environments, such as food processing plants, laboratories, or residential areas where quiet operation is critical. - Durable and Corrosion-Resistant Housing

The use of high-quality aluminum alloy or cast iron housing ensures excellent resistance to wear, corrosion, and environmental conditions. This durability allows the worm reducer gearboxes to maintain long-term efficiency, even in harsh industrial or outdoor settings. - Versatility and Customization Options

CMN-NMRV worm gear speed reducers are available in various configurations, sizes, and mounting options, allowing them to be tailored to specific applications. Their adaptability makes them a preferred choice for diverse industries, from automotive to manufacturing and beyond.

CMN-NMRV Worm Drive Gearbox Applications

- Conveyor Systems

CMN-NMRV worm drive gearboxes are widely used in conveyor systems for material handling. Their high torque and smooth operation ensure precise and efficient movement of goods in industries like logistics, manufacturing, and food processing, even under heavy loads. - Packaging Machinery

These worm gearboxes are essential in packaging equipment, where compact size and precision are critical. They help drive components like belts, rollers, and sealing mechanisms, ensuring reliable and high-speed operation in automated packaging lines. - Industrial Mixers and Agitators

In industries such as chemical, pharmaceutical, and food production, CMN-NMRV industrial worm gearboxes power mixers and agitators. Their ability to deliver high torque and handle variable speeds ensures consistent mixing, even in applications requiring high viscosity materials. - Cranes and Hoists

The heavy duty worm drive gearboxes are used extensively in cranes and hoists due to their robust torque capabilities and reliability. They allow smooth lifting and lowering of heavy materials, making them suitable for construction, shipping, and warehousing industries. - Automated Gates and Barriers

In security and access control systems, CMN-NMRV worm reduction gearboxes are used to power automated gates, barriers, and turnstiles. Their compact design, quiet operation, and precision make them ideal for residential, commercial, and industrial settings. - Agricultural Machinery

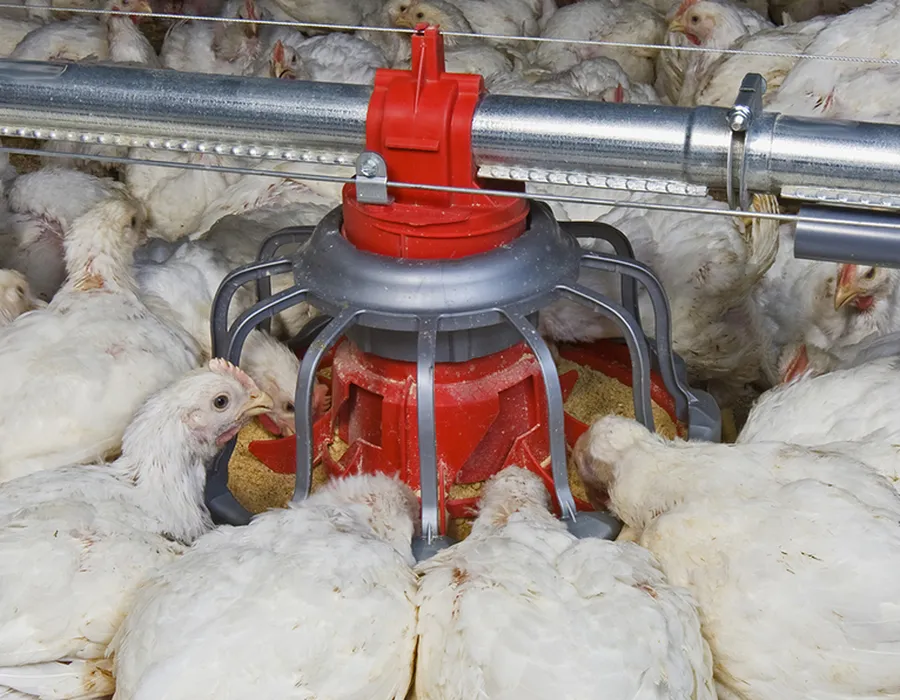

These worm gear reducer gearboxes play a vital role in agricultural equipment such as poultry feeding equipment and irrigation systems. Their efficient power transmission and durability ensure reliable operation in demanding outdoor environments, boosting productivity in the agricultural sector.

|  |

| Worm Gearbox for Mining and Construction | Worm Gearbox for Food Conveyor Systems |

|  |

| Worm Gearbox for Agricultural Machinery | Worm Gearbox for Lifting and Hoisting Equipment |

Additional information

| Edited by | Yjx |

|---|