CMN-NMRV-VS Worm Gear Reducers/Worm Gearbox

The CMN-NMRV-VS dual input shaft worm gear reducers are advanced mechanical devices designed for efficient power transmission in various industrial applications. These reducers are a specialized variation of the standard CMN-NMRV worm gearboxes, featuring dual input shafts for enhanced flexibility and adaptability. The double input shafts allow integration with multiple power sources or motors, making them ideal for systems requiring synchronized or combined motor operation.

The CMN-NMRV-VS dual input shaft worm gear reducers are advanced mechanical devices designed for efficient power transmission in various industrial applications. These reducers are a specialized variation of the standard CMN-NMRV worm gearboxes, featuring dual input shafts for enhanced flexibility and adaptability. The double input shafts allow integration with multiple power sources or motors, making them ideal for systems requiring synchronized or combined motor operation.

Built with a compact and modular design, these worm gearboxes are lightweight, durable, and easy to install. They utilize a worm gear mechanism that ensures high torque output, smooth motion control, and excellent speed reduction capabilities. Additionally, the reducers are made from high-quality materials like aluminum alloy for corrosion resistance and superior heat dissipation. Their wide range of ratios and configurations makes them suitable for industries such as automation, conveyor systems, packaging machinery, and robotics.

CMN-NMRV-VS Worm Gear Reducer Specifications

Type | Worm Gear Speed Reducer/ Worm Gearbox |

Model | CMN-NMRV-VS 25/30/40/50/63/75/90/110/130/150 |

Ratio | 7.5,10,15,20,25,30,40,50,60,80,100 |

Color | Blue(RAL5010)/Silver grey (K9149) Or On Customer Request |

Material | Housing: Aluminum alloy(size 25~90) / Cast iron(size 110~185) |

Worm wheel: Aluminum Bronze or Tin Bronze | |

Worm shaft: 20CrMn Tin | |

Output Shaft: Steel-45# | |

Packing | Carton, Wooden Case,Wooden pallet |

Warranty | 1 Year |

Input Power | 0.09kw,0.18kw,1.1kw,1.5kw,2.2kw,3kw,4kw,5.5kw,7.5kw,11kw,15kw and so on |

Usages | Industrial Machine: Food Stuff, Ceramics, Packing, Chemical, Dyeing, Wood working, Glass |

IEC Flange | IEC standard flange or on customer request |

Lubricant | Synthetic oil or worm gear oil |

CMN-NMRV-VS Worm Gearbox Model & Marker

| CMN-NMRV-063-30-VS-F1(FA)-AS-80B5-0.75kW-B3 | |||

| CMN-NMRV | Worm geared motor | ||

| CMN-NRV | Worm reduction unit | ||

| 063 | Center distance | ||

| 30 | Reduction ratio | ||

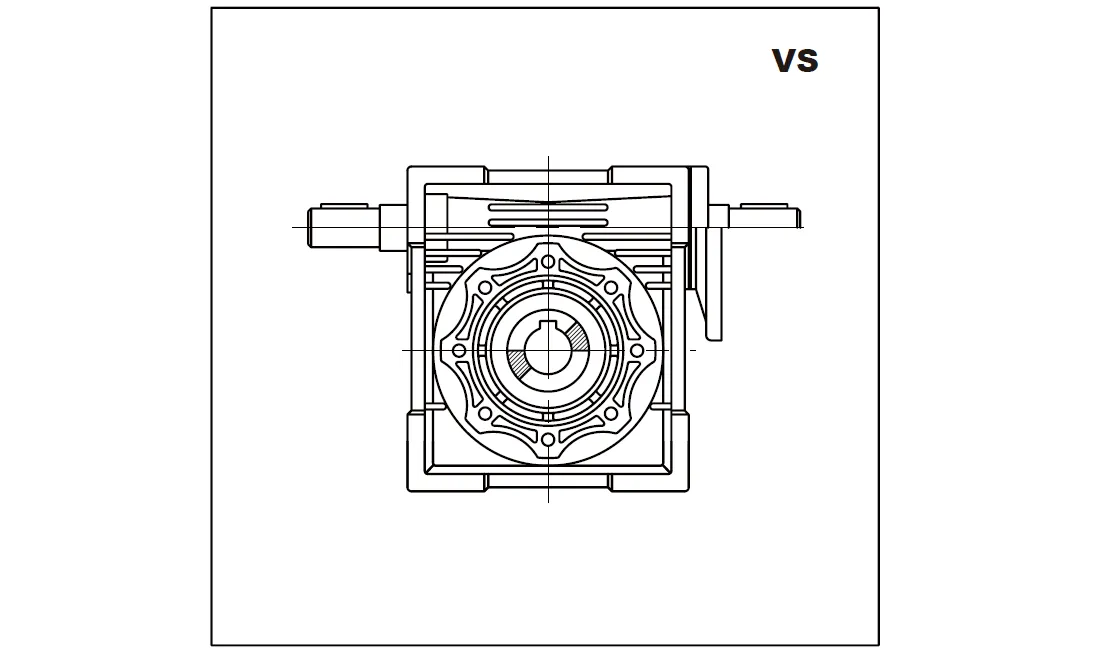

| VS | Double input shaft | F1(FA) | Output flange |

| AS | Single output shaft | AB | Double output shaft |

| PAM | Fitted for motor coupling | 80B5 | Motor size & mounting position |

| 0.75kW | Power of electric motor | B3 | Mounting position |

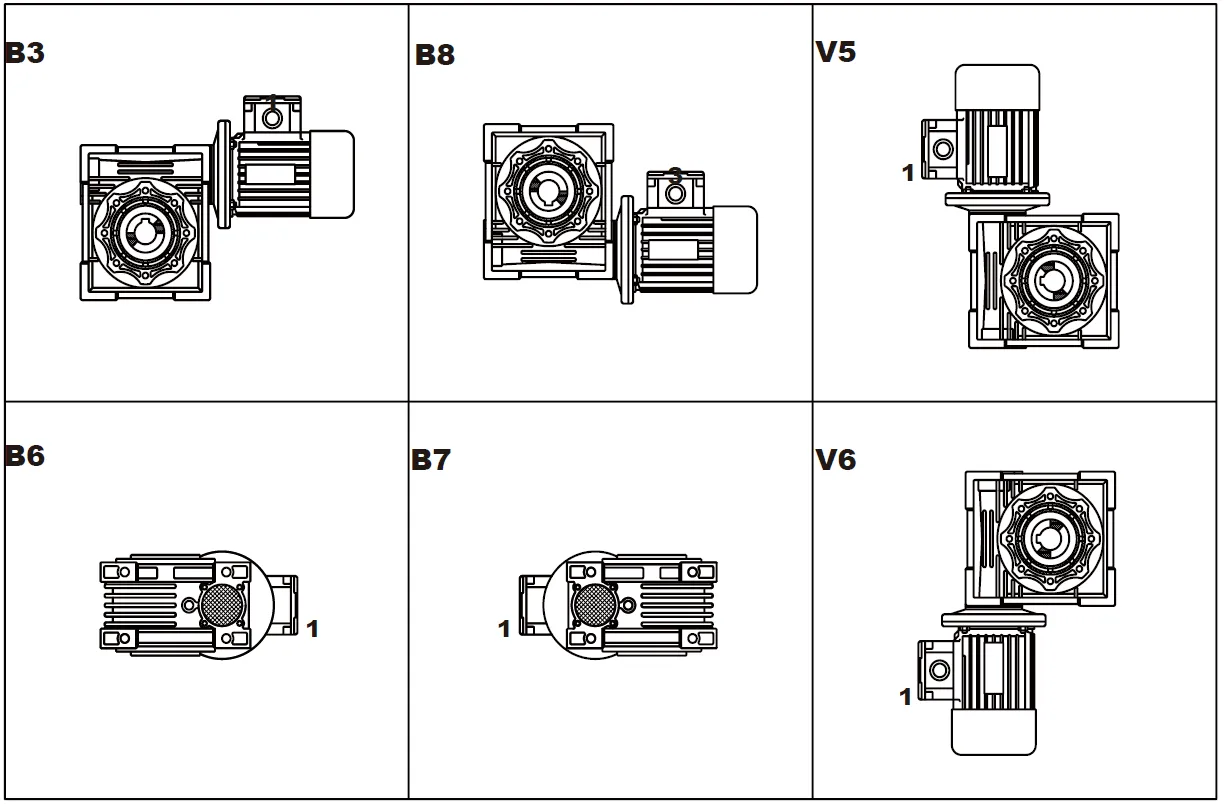

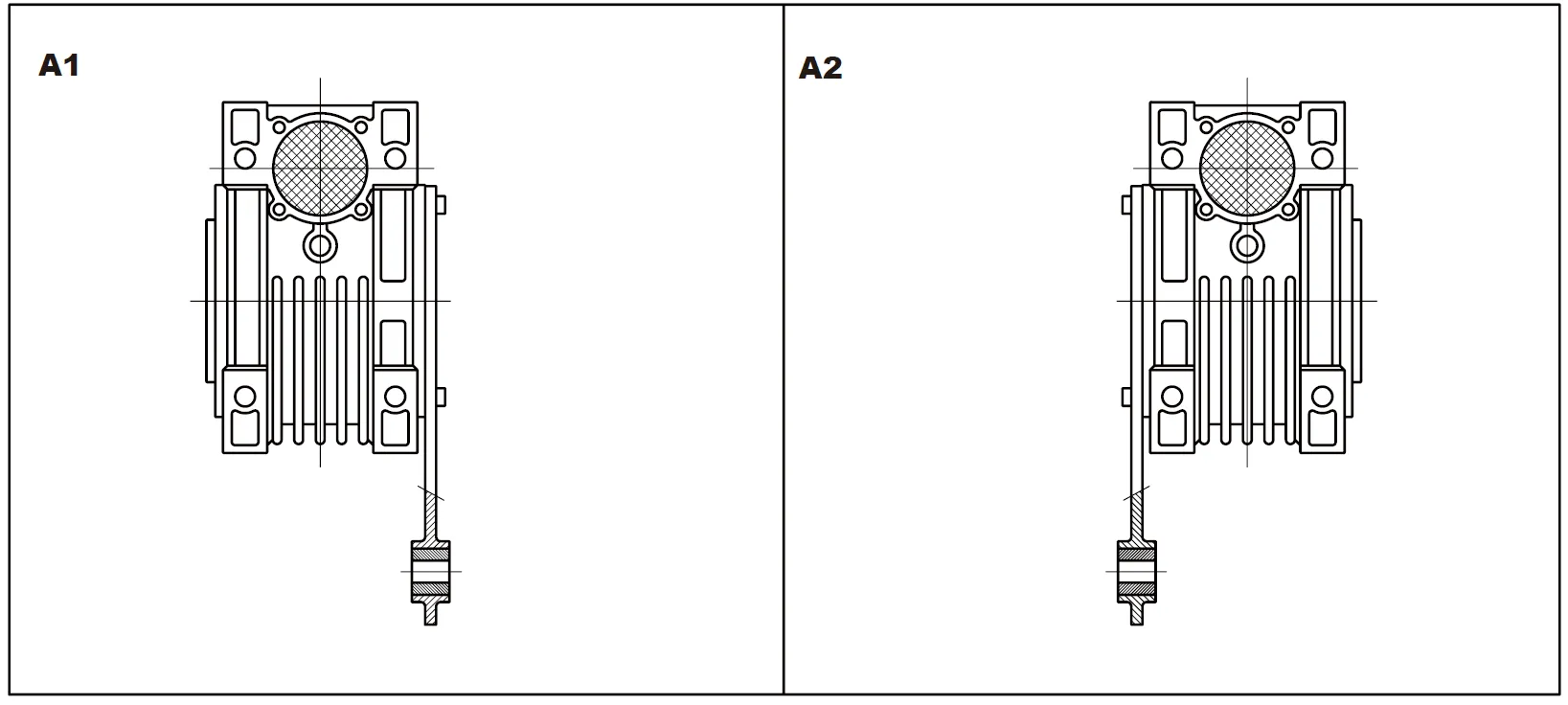

Mounting Position

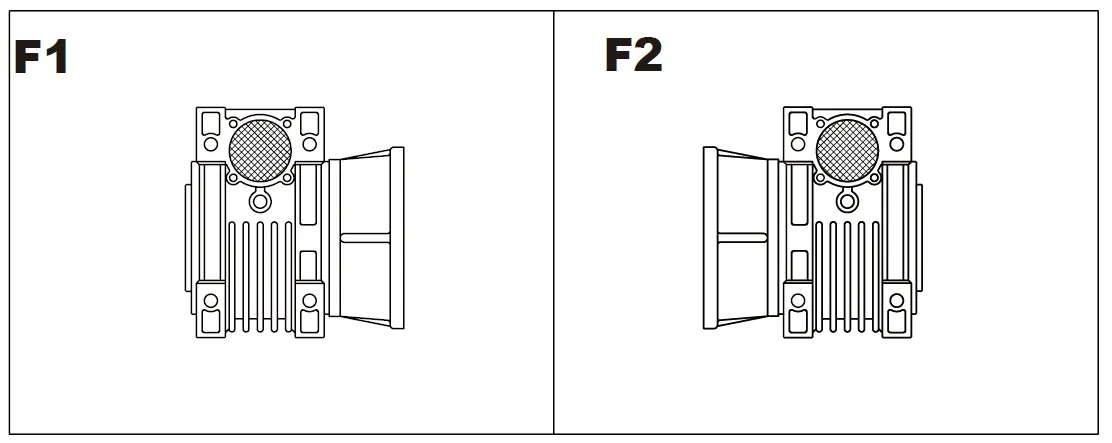

Flange F-FL

Position of Terminal Box

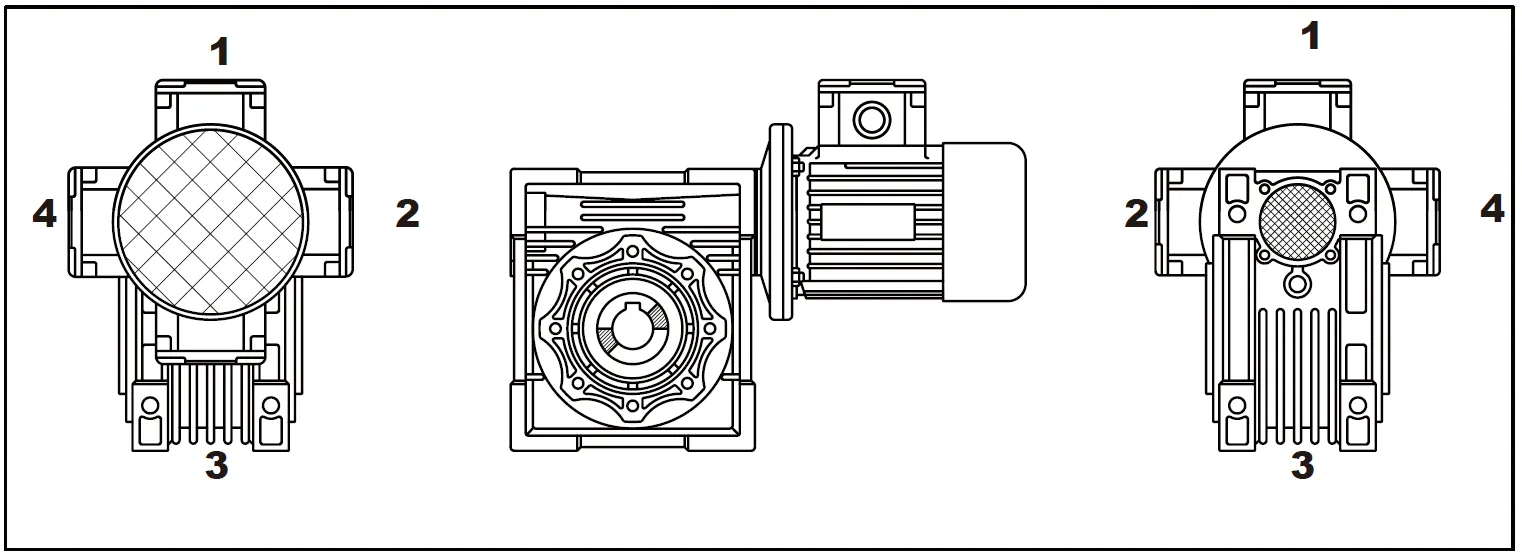

Position of Output Shaft

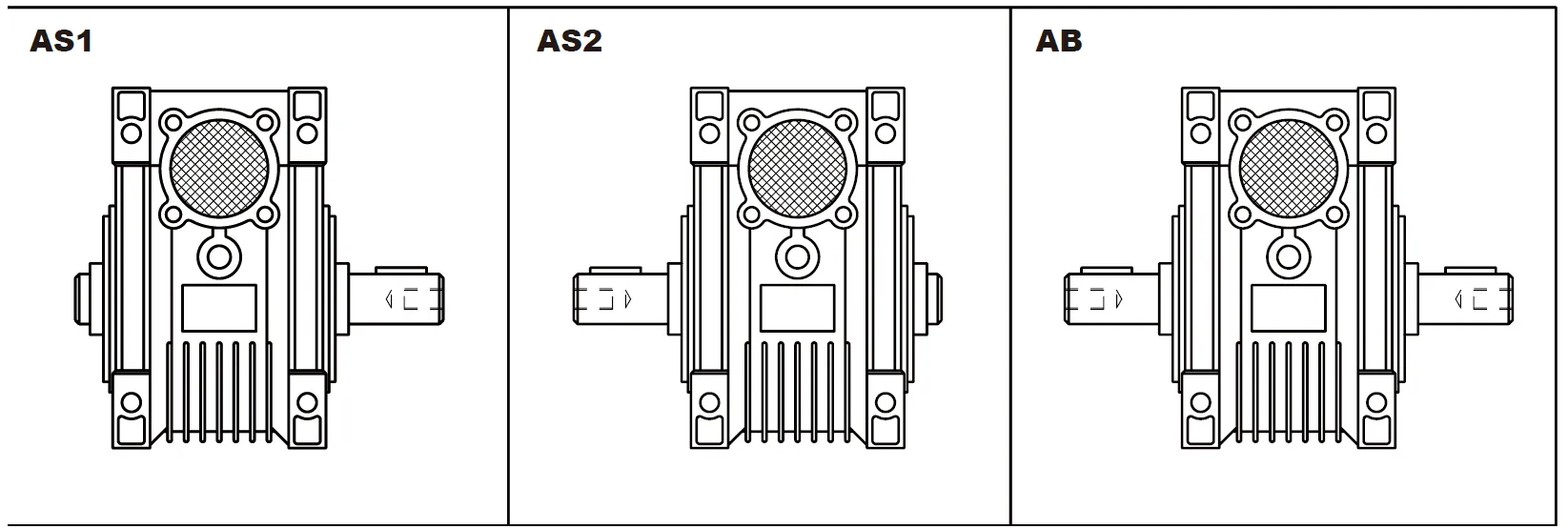

Double Extension Worm Shaft

Position of Torque Arm

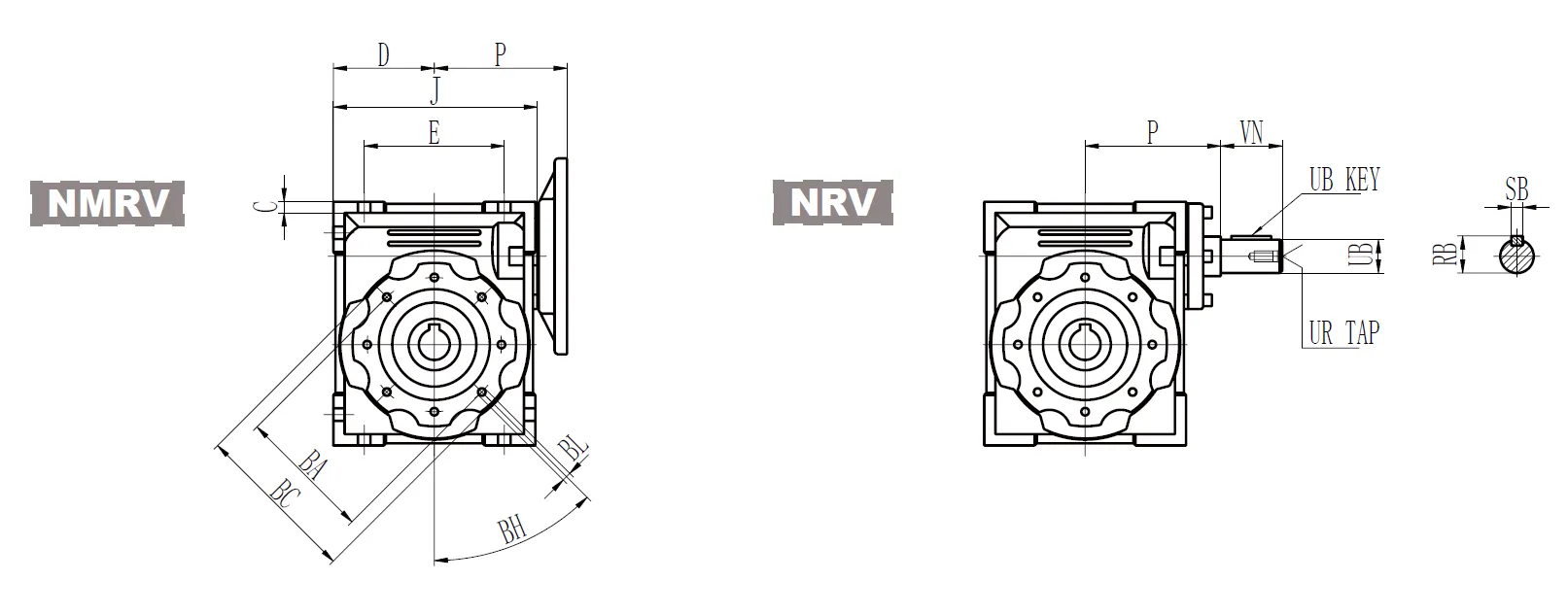

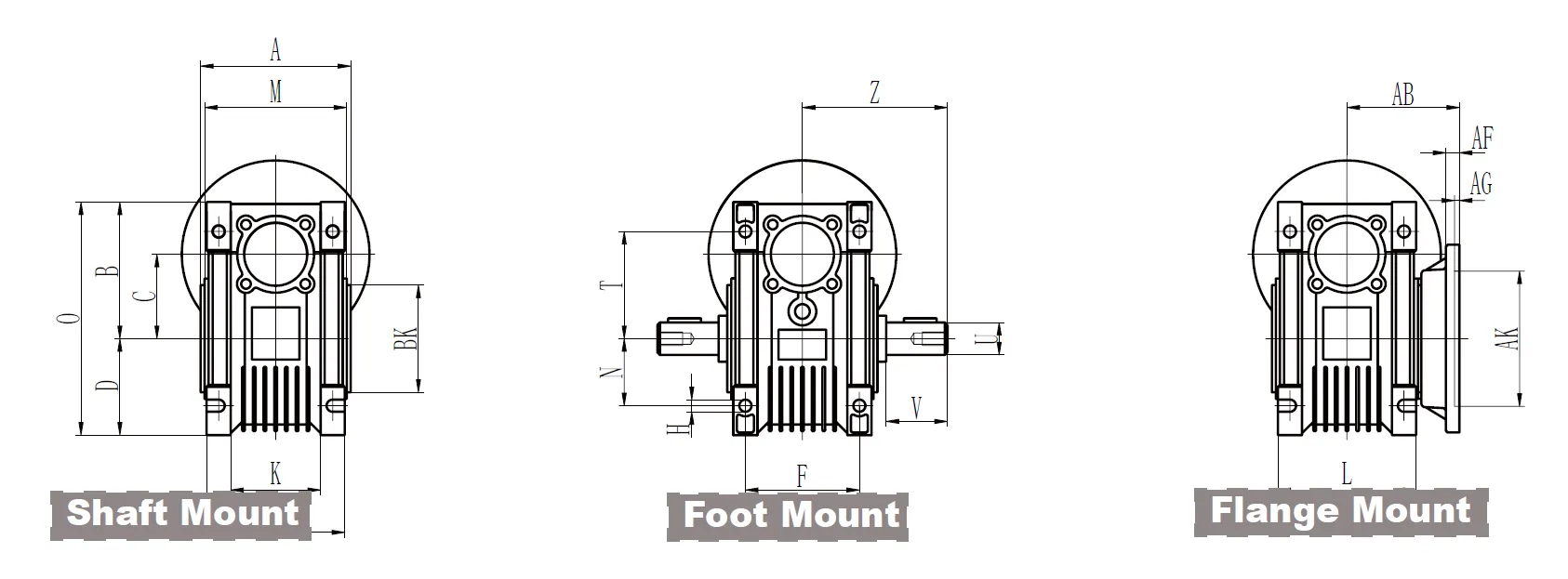

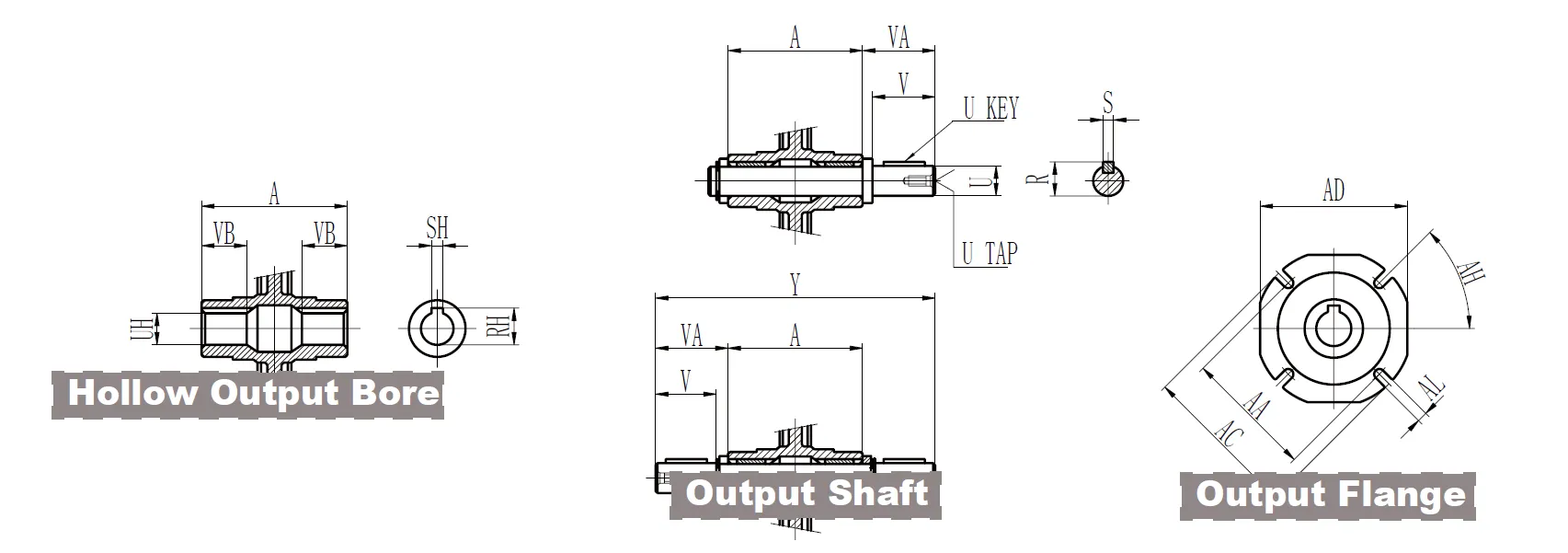

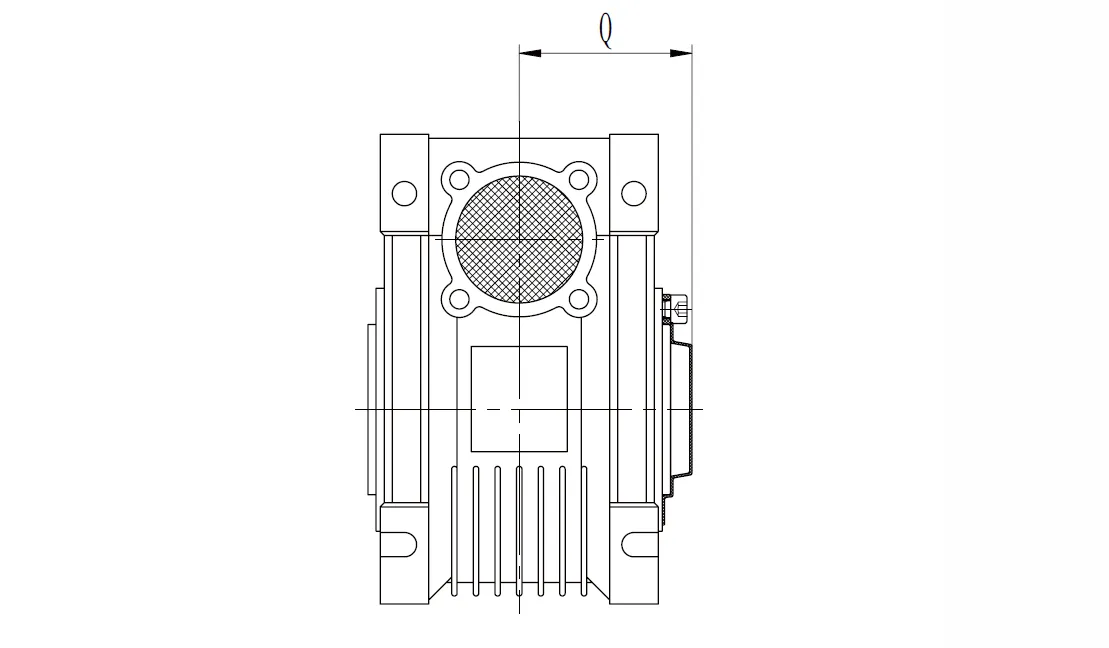

CMN-NMRV-VS Worm Gear Reducer Dimensions

CMN-NMRV-VS Inch Series

| Hollow Output Bore | 030 | 040 | 050 | 063 | 075 | 090 | 110 | 130 | |

| RH | 0.71 | 0.84 | 1.12 | 1.24 | 1.37 | 1.52 | 1.8 | 1.93 | |

| SH | 0.188 | 0.188 | 0.25 | 0.25 | 0.25 | 0.313 | 0.375 | 0.375 | |

| UH | 0.625+0.001 0 | 0.75+0.001 0 | 1+0.001 0 | 1.125+0.001 0 | 1.25+0.001 0 | 1.375+0.001 0 | 1.625+0.001 0 | 1.750 | |

| VB | 0.83 | 1.14 | 1.28 | 1.42 | 1.56 | 1.77 | 1.97 | 2.24 | |

| Output Shaft | 030 | 040 | 050 | 063 | 075 | 090 | 110 | 130 | |

| R | 0.7 | 0.83 | 1.11 | 1.23 | 1.36 | 1.51 | 1.79 | 1.92 | |

| S | 0.188 | 0.188 | 0.25 | 0.25 | 0.25 | 0.313 | 0.375 | 0.375 | |

| U | 0.6250 -0.0005 | 0.750 -0.0005 | 10 -0.0005 | 0 -0.0005 | 1.250 -0.0005 | 1.3750 -0.0005 | 1.6250 -0.0005 | 1.750 -0.0005 | |

| U KEY | 0.1875x1.125 | 0.1875x1.5 | 0.25x1.5 | 0.25x1.875 | 0.25x2.25 | 0.3125x2.5 | 0.375x2.75 | 0.375x2.75 | |

| UT | 1/4-20 | 1/4-20 | 3/8-16 | 3/8-16 | 1/2-13 | 1/2-13 | 5/8-11 | 5/8-11 | |

| V | 1.57 | 1.97 | 1.97 | 2.36 | 2.76 | 3.15 | 3.54 | 3.54 | |

| VA | 1.67 | 2.09 | 2.11 | 2.5 | 2.89 | 3.33 | 3.72 | 3.74 | |

| Y | 5.82 | 7.25 | 7.84 | 9.41 | 10.5 | 12.17 | 13.54 | 14.17 | |

| CMN-NMRV-VS | 030 | 040 | 050 | 063 | 075 | 090 | 110 | 130 |

| A | 2.48 | 3.07 | 3.62 | 4.41 | 4.72 | 5.51 | 6.1 | 6.69 |

| B | 2.24 | 2.81 | 3.31 | 4.02 | 4.69 | 5.31 | 6.59 | 7.38 |

| BA | 2.56 | 2.95 | 3.35 | 3.74 | 4.53 | 5.12 | 6.5 | 8.46 |

| BC | 2.95 | 3.43 | 3.94 | 4.33 | 5.51 | 6.3 | 7.87 | 9.84 |

| BH | 90 ° | 45 ° | 45 ° | 45 ° | 45 ° | 45 ° | 45° | 45 ° |

| BK | 2.165 0 -0.0018 | 2.362 0 -0.0018 | 2.756 0 -0.0018 | 3.15 0 -0.0021 | 3.74 0 -0.0021 | 4.331 0 -0.0021 | 5.118 0 -0.0025 | 7.087 0 -0.0025 |

| BL | M6x11 | M6x10 | M8x10 | M8x14 | M8x14 | M10x18 | M10x18 | M12x21 |

| C | 1.18 | 1.57 | 1.97 | 2.48 | 2.95 | 3.54 | 4.33 | 5.12 |

| D | 1.57 | 1.97 | 2.36 | 2.83 | 3.39 | 4.06 | 5.02 | 5.81 |

| E | 2.13 | 2.76 | 3.15 | 3.94 | 4.72 | 5.51 | 6.69 | 7.87 |

| F | 1.73 | 2.36 | 2.76 | 3.35 | 3.54 | 3.94 | 4.53 | 4.72 |

| G | 0.22 | 0.26 | 0.28 | 0.31 | 0.39 | 0.43 | 0.57 | 0.61 |

| H | 0.26 | 0.26 | 0.33 | 0.33 | 0.45 | 0.51 | 0.55 | 0.63 |

| J | 3.15 | 3.98 | 4.76 | 5.75 | 6.85 | 8.19 | 9.94 | 11.52 |

| K | 1.26 | 1.69 | 1.93 | 2.64 | 2.83 | 2.91 | - | - |

| L | 2.2 | 2.8 | 3.35 | 4.06 | 4.41 | 5.12 | 5.67 | 6.1 |

| M | 2.28 | 2.87 | 3.43 | 4.17 | 4.49 | 5.28 | 5.83 | 6.38 |

| N | 1.06 | 1.38 | 1.57 | 1.97 | 2.36 | 2.76 | 3.35 | 3.94 |

| O | 3.82 | 4.78 | 5.67 | 6.85 | 8.07 | 9.37 | 11.61 | 13.19 |

| P | 2.64 | 3.15 | 3.54 | 4.13 | 4.96 | 5.63 | 6.81 | 7.6 |

| Q | 0.83 | 2.36 | 2.91 | 3.54 | 4.13 | 4.92 | 5.59 | 6.38 |

| T | 1.73 | 2.17 | 2.52 | 3.15 | 3.66 | 4.02 | 4.92 | 5.51 |

| Z | 2.91 | 3.63 | 3.92 | 4.71 | 5.25 | 6.09 | 6.77 | 7.09 |

| Output Flange | AA | AB | AC | AD | AF | AG | AH | AK | AL | ||

| 030 | FA | 2.68 | 2.15 | 3.15 | 2.76 | 0.24 | 0.16 | 45° | 1.969 | +0.0015 0 | 0.26 |

| 040 | FA | 2.95 | 2.64 | 4.33 | 3.74 | 0.28 | 0.16 | 45° | 2.362 | +0.0018 | 0.35 |

| 0 | |||||||||||

| FB | 2.95 | 3.82 | 4.33 | 3.74 | 0.28 | 0.16 | 45° | 2.362 | +0.0018 0 | 0.35 | |

| FC | 4.53 | 3.15 | 5.51 | - | 0.35 | 0.2 | 45° | 3.74 | +0.0021 0 | 0.37 | |

| FD | 3.94 | 2.28 | 4.72 | - | 0.47 | 0.2 | 45° | 3.15 | +0.0018 | 0.35 | |

| 0 | |||||||||||

| 050 | FA | 3.35 | 3.54 | 4.92 | 4.33 | 0.35 | 0.2 | 45° | 2.756 | +0.0018 | 0.43 |

| 0 | |||||||||||

| FB | 3.35 | 4.72 | 4.92 | 4.33 | 0.35 | 0.2 | 45° | 2.756 | +0.0018 0 | 0.43 | |

| FC | 5.12 | 3.5 | 6.3 | - | 0.39 | 0.2 | 45° | 4.331 | +0.0021 0 | 0.37 | |

| FD | 4.53 | 2.83 | 5.51 | - | 0.57 | 0.2 | 45° | 3.543 | +0.0021 | 0.43 | |

| 0 | |||||||||||

| 063 | FA | 4.13 | 3.23 | 7.09 | 5.59 | 0.39 | 0.24 | 45° | 4.528 | +0.0021 | 0.43 |

| 0 | |||||||||||

| FB | 5.91 | 4.41 | 7.09 | 5.59 | 0.39 | 0.24 | 45° | 4.528 | +0.0021 | 0.43 | |

| 0 | |||||||||||

| FC | 6.5 | 3.86 | 7.87 | - | 0.39 | 0.2 | 45° | 5.118 | +0.0025 0 | 0.43 | |

| FD | 6.5 | 4.21 | 7.87 | - | 0.39 | 0.2 | 45° | 5.118 | +0.0025 | 0.43 | |

| 0 | |||||||||||

| FE | 5.12 | 3.17 | 6.3 | - | 0.65 | 0.2 | 45° | 4.331 | +0.0021 | 0.43 | |

| 0 | |||||||||||

| 075 | FA | 6.5 | 4.37 | 7.87 | 6.69 | 0.51 | 0.24 | 45° | 5.118 | +0.0025 | 0.55 |

| 0 | |||||||||||

| FB | 5.12 | 3.54 | 6.3 | - | 0.51 | 0.24 | 45° | 4.331 | +0.0021 | 0.55 | |

| 0 | |||||||||||

| 090 | FA | 6.89 | 4.37 | 8.27 | 8.27 | 0.51 | 0.24 | 45° | 5.984 | +0.0025 | 0.55 |

| 0 | |||||||||||

| FB | 8.46 | 4.8 | 9.84 | - | 0.71 | 0.24 | 45° | 7.087 | +0.0025 0 | 0.55 | |

| FC | 6.5 | 4.33 | 7.87 | - | 0.67 | 0.24 | 45° | 5.118 | +0.0025 0 | 0.43 | |

| FD | 6.89 | 5.94 | 8.27 | - | 0.51 | 0.24 | 45° | 5.984 | +0.0025 | 0.55 | |

| 0 | |||||||||||

| 110 | FA | 9.06 | 5.16 | 11.02 | 10.24 | 0.59 | 0.24 | 45° | 6.693 | +0.0025 | 0.55 |

| 0 | |||||||||||

| FB | 9.06 | 7.09 | 11.02 | 10.24 | 0.59 | 0.24 | 45° | 6.693 | +0.0025 | 0.55 | |

| 0 | |||||||||||

| 130 | FA | 10.04 | 5.51 | 12.6 | 11.42 | 0.59 | 0.24 | 22.5° | 7.087 | +0.0025 0 | 0.63 |

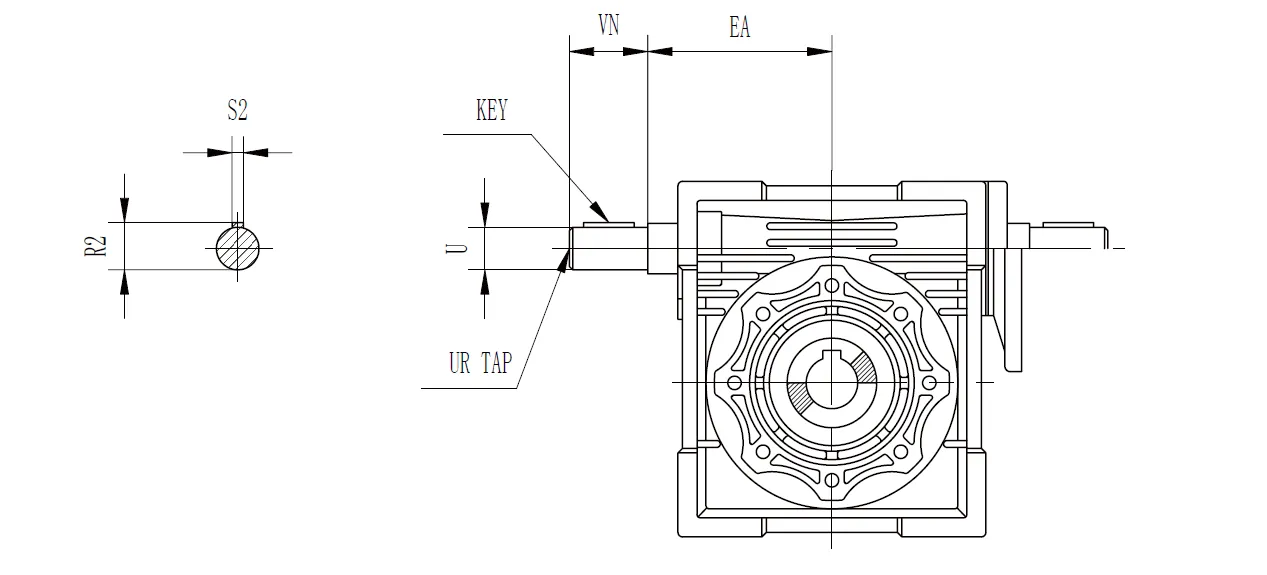

| Input Shaft | 030 | 040 | 050 | 063 | 075 | 090 | 110 | 130 | |

| SB | 0.094 | 0.125 | 0.188 | 0.188 | 0.188 | 0.188 | 0.25 | 0.25 | |

| RB | 0.42 | 0.55 | 0.7 | 0.83 | 0.96 | 0.96 | 1.24 | 1.36 | |

| UB | 0.3750 -0.0005 | 0.50 -0.0005 | 0.6250 -0.0005 | 0.750 -0.0005 | 0.8750 -0.0005 | 0.8750 -0.0005 | 1.1250 -0.0005 | 1.250 -0.0005 | |

| UB KEY | 0.094x0.875 | 0.125x0.875 | 0.1875x1.125 | 0.1875x1.5 | 0.1875x1.875 | 0.1875x1.875 | 0.25x2.25 | 0.25x2.5 | |

| UR | - | 1/4-20 | 1/4-20 | 1/4-20 | 1/4-20 | 1/4-20 | 3/8-16 | 1/2-13 | |

| VN | 1.18 | 1.18 | 1.58 | 1.97 | 2.36 | 2.36 | 2.76 | 3.15 | |

High Speed Extension Shaft Dimensions

| CMN-NMRV-VS | EA | U | VN | UR | S2 | R2 | KEY | |

| Length | Square | |||||||

| 030 | 1.772 | 0.3750 -0.0005 | 1.18 | - | 0.093 | 0.42 | 0.875 | 0.094 |

| 040 | 2.087 | 0.50 -0.0005 | 1.18 | 1/4-20 | 0.13 | 0.55 | 0.875 | 0.125 |

| 050 | 2.52 | 0.6250 -0.0005 | 1.58 | 1/4-20 | 0.19 | 0.7 | 1.125 | 0.188 |

| 063 | 2.953 | 0.750 -0.0005 | 1.97 | 1/4-20 | 0.19 | 0.83 | 1.5 | 0.188 |

| 075 | 3.543 | 0.8750 -0.0005 | 2.36 | 1/4-20 | 0.19 | 0.96 | 1.875 | 0.188 |

| 090 | 4.252 | 0.8750 -0.0005 | 2.36 | 1/4-20 | 0.19 | 0.96 | 1.875 | 0.188 |

| 110 | 5.315 | 1.1250 -0.0005 | 2.76 | 3/8-16 | 0.25 | 1.24 | 2.25 | 0.25 |

| 130 | 6.102 | 1.250 -0.0005 | 3.15 | 1/2-13 | 0.25 | 1.36 | 2.5 | 0.25 |

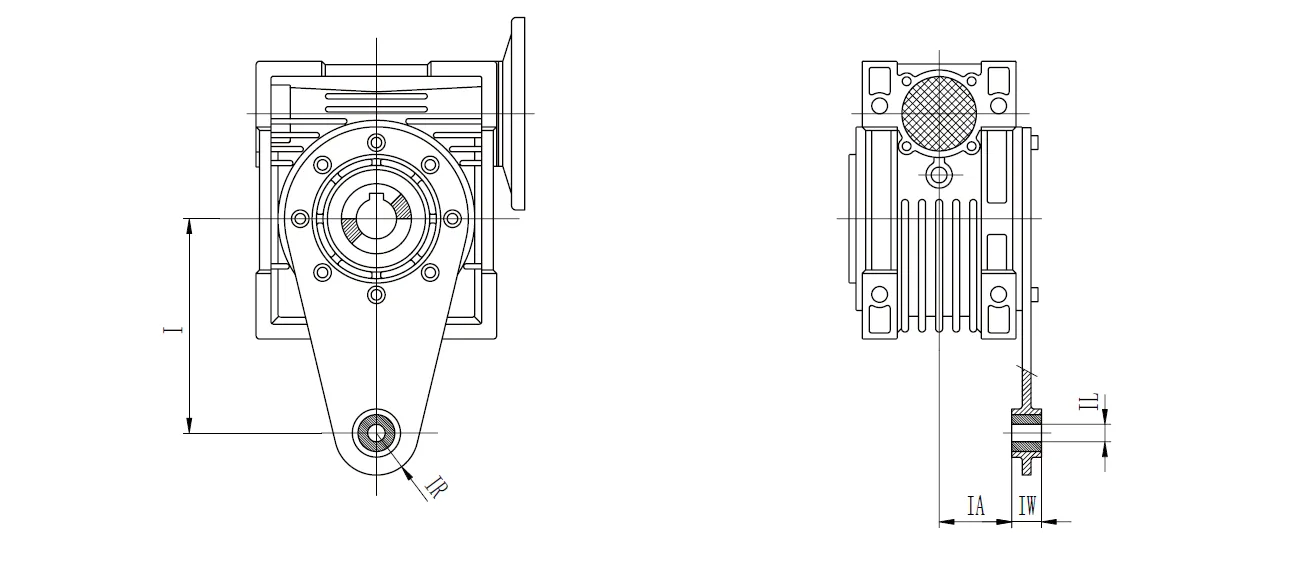

Torque Arm Dimensions

| CMN-NMRV-VS | I | IA | IL | IR | IW |

| 025 | 2.76 | 0.69 | 0.31 | 0.59 | 0.55 |

| 030 | 3.35 | 0.94 | 0.31 | 0.59 | 0.55 |

| 040 | 3.94 | 1.24 | 0.39 | 0.71 | 0.55 |

| 050 | 3.94 | 1.52 | 0.39 | 0.71 | 0.55 |

| 063 | 5.91 | 1.93 | 0.39 | 0.71 | 0.55 |

| 075 | 7.87 | 1.87 | 0.79 | 1.18 | 0.98 |

| 090 | 7.87 | 2.26 | 0.79 | 1.18 | 0.98 |

| 110 | 9.84 | 2.44 | 0.98 | 1.38 | 1.18 |

| 130 | 9.84 | 2.72 | 0.98 | 1.38 | 1.18 |

Protective Cover Dimensions

| CMN-NMRV-VS | Q |

| 030 | 1.65 |

| 040 | 1.97 |

| 050 | 2.28 |

| 063 | 2.72 |

| 075 | 2.91 |

| 090 | 3.39 |

| 110 | 3.7 |

| 130 | 4.02 |

NEMA Flange Availability

| CMN-NMRV-VS | NEMA Flange | Input Bore Diameter | Available Ratios | |||||||||||

| 5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 | 60 | 80 | 100 | |||

| 030 | 48C | 0.5 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |

| 040 | 56C | 0.625 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| 050 | 56C | 0.625 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| 063 | 56C | 0.625 | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| 140TC | 0.875 | ● | ● | ● | ● | ● | ● | ● | ||||||

| 075 | 56C | 0.625 | ● | ● | ● | ● | ||||||||

| 140TC | 0.875 | ● | ● | ● | ● | ● | ● | |||||||

| 180TC | 1.125 | ● | ● | ● | ||||||||||

| 090 | 56C | 0.625 | ● | ● | ||||||||||

| 140TC | 0.875 | ● | ● | ● | ● | ● | ||||||||

| 180TC | 1.125 | ● | ● | ● | ● | ● | ● | ● | ||||||

| 110 | 140TC | 0.875 | ● | ● | ● | ● | ||||||||

| 180TC | 1.125 | ● | ● | ● | ● | ● | ● | |||||||

| 210TC | 1.375 | ● | ● | ● | ● | |||||||||

| 130 | 140TC | 0.875 | ● | ● | ||||||||||

| 180TC | 1.125 | ● | ● | ● | ● | ● | ||||||||

| 210TC | 1.375 | ● | ● | ● | ● | ● | ● | ● | ||||||

CMN-NMRV-VS Dual Input Worm Gearbox with Motor

- Dual Input Flexibility

The CMN-NMRV-VS worm gear gearbox offers dual input shafts, allowing two motors or power sources to operate simultaneously or alternately. This flexibility enhances operational efficiency and provides redundancy, ensuring continuous operation even if one motor fails or requires maintenance. - Compact and Lightweight Design

Designed with a space-saving structure, the worm drive gearbox is compact and lightweight, making it easy to integrate into systems with limited space. Its aluminum alloy housing ensures durability and corrosion resistance while maintaining a low overall weight for easy handling and installation. - High Torque and Smooth Operation

The worm gear system delivers exceptional torque output while maintaining smooth and stable operation. This makes it ideal for applications requiring precise motion control, such as automated machinery, robotics, and conveyor systems, ensuring consistent performance under varying loads. - Versatile Speed Reduction Options

The worm reducer gearbox offers a wide range of gear ratios, enabling precise speed reduction to suit diverse industrial requirements. This adaptability allows users to optimize performance for specific tasks, improving efficiency and extending the lifespan of connected equipment. - Low Noise and Vibration Levels

The worm gear mechanism is designed to minimize noise and vibration during operation. This makes the worm gear reducer well-suited for applications where quiet performance is crucial, such as medical equipment, packaging machines, and other noise-sensitive environments. - High Performance and Longevity

With efficient heat dissipation properties due to its aluminum alloy construction, the worm gear speed reducer operates reliably even under demanding conditions. Better thermal management reduces wear and tear, prolonging the service life of the gearbox and associated components, lowering maintenance costs over time.

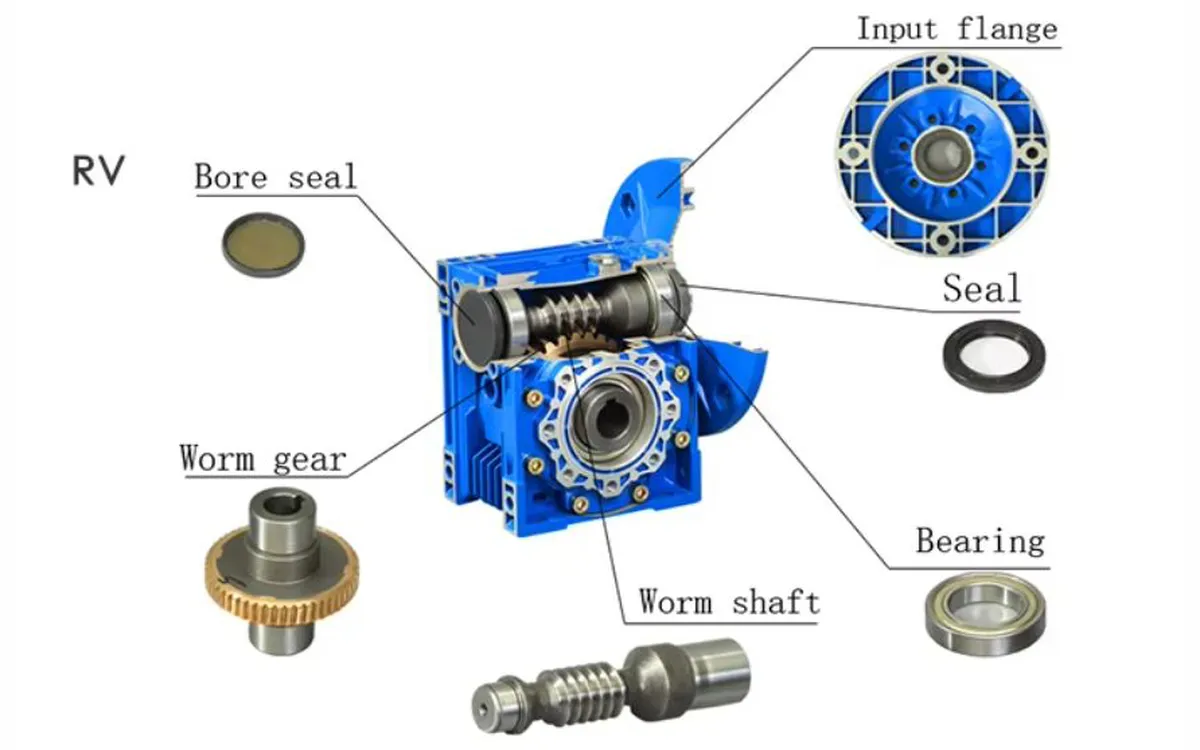

Dual Input Worm Gear Reducer Parts

- Dual Input Shafts

The dual input shafts allow the gearbox to connect to two separate power sources. This design is ideal for applications requiring synchronized motor operations or redundancy to ensure seamless functionality during equipment maintenance or unexpected motor failures. - Worm Gear and Worm Shaft

The worm gear and shaft form the core mechanism of the reducer, enabling efficient torque transmission and speed reduction. Their precise design ensures smooth and consistent motion, minimizing energy losses and providing high performance under various load conditions. - Aluminum Alloy Housing

The housing is made from high-strength aluminum alloy, offering excellent corrosion resistance and thermal conductivity. This lightweight yet durable construction ensures the gearbox's protection from environmental factors and facilitates heat dissipation for extended operational life. - Output Shaft

The output shaft transfers the reduced speed and increased torque to the connected machinery. It is engineered to handle high loads and maintain alignment, ensuring reliable power transmission and optimal performance for a wide range of industrial applications. - Bearing Assemblies

High-quality bearings are integrated into the gearbox to reduce friction and support the rotating components. These bearings enhance the gearbox's efficiency, reduce wear and tear, and ensure smooth operation even under continuous or heavy-duty conditions. - Sealing System

The sealing system prevents the ingress of contaminants such as dust, dirt, and moisture, protecting the internal components. This ensures long-lasting performance and minimizes the risk of damage or failure, particularly in harsh working environments.

CMN-NMRV-VS Worm Drive Gearbox Applications

- Conveyor Systems

The CMN-NMRV-VS worm gearbox is widely used in conveyor systems for material handling. Its precise speed reduction and high torque output ensure smooth and efficient operation, making it ideal for industries like logistics, manufacturing, and mining where reliable motion control is critical. - Packaging Machinery

This worm reducer gearbox is a perfect fit for packaging machinery, offering consistent performance and quiet operation. The dual input shafts allow integration with multiple motors, ensuring flexibility and efficiency in operations such as filling, sealing, and labeling in food, pharmaceutical, and consumer goods industries. - Robotics and Automation

In robotics and automated systems, the CMN-NMRV-VS worm wheel gearbox provides precise motion control and compact design, which are essential for space-saving applications. Its low noise and vibration levels make it ideal for high-precision robotic arms and automated assembly lines. - Agricultural Equipment

The worm drive gearbox is employed in agricultural machinery, such as seeders, harvesters, and irrigation systems. Its robust design and ability to handle high loads make it suitable for demanding outdoor conditions, ensuring reliable performance even in harsh environments. - Lifting and Hoisting Systems

With its high torque capacity and compact build, the worm gear reducer is ideal for lifting and hoisting applications. It ensures smooth and controlled movement of loads in cranes, elevators, and winches, offering safety and precision in vertical motion tasks. - Renewable Energy Systems

The CMN-NMRV-VS worm reduction gearbox is also utilized in renewable energy applications, such as solar trackers and small wind turbines. Its efficient speed reduction and durable design ensure optimal performance and longevity in systems designed to operate in varying environmental conditions.

Additional information

| Edited by | Yjx |

|---|