Bucket Hydraulic Cylinder for Mini Excavator

A bucket hydraulic cylinder for a mini excavator is a critical component that powers the movement of the bucket, enabling precise digging, lifting, and dumping of materials. Attached to the dipper arm, this cylinder uses pressurized hydraulic fluid to generate linear force, controlling the bucket’s tilt, curl, and angle during excavation tasks. Typically smaller than boom or arm cylinders, it’s designed for detailed control, allowing operators to maneuver the bucket with accuracy in tight spaces.

A bucket hydraulic cylinder for a mini excavator is a critical component that powers the movement of the bucket, enabling precise digging, lifting, and dumping of materials. Attached to the dipper arm, this cylinder uses pressurized hydraulic fluid to generate linear force, controlling the bucket’s tilt, curl, and angle during excavation tasks. Typically smaller than boom or arm cylinders, it’s designed for detailed control, allowing operators to maneuver the bucket with accuracy in tight spaces.

These hydraulic bucket cylinders are double-acting, with a piston and rod assembly that extends and retracts to grip, scoop, or release materials like dirt or gravel. Constructed from durable steel with high-quality seals, they withstand heavy loads and harsh conditions.

Mini Excavator Bucket Hydraulic Cylinder Specifications

| Product Name: | Mini Excavator Bucket Hydraulic Cylinder |

| Function: | Control the action of the bucket. |

| Bore Diameter: | 50mm-105mm |

| Rod diameter: | 25mm-70mm |

| Stroke: | ≤1000 mm |

| Maximum pressure MPa: | 29.4MPa |

| Thrust Force: | 255KN |

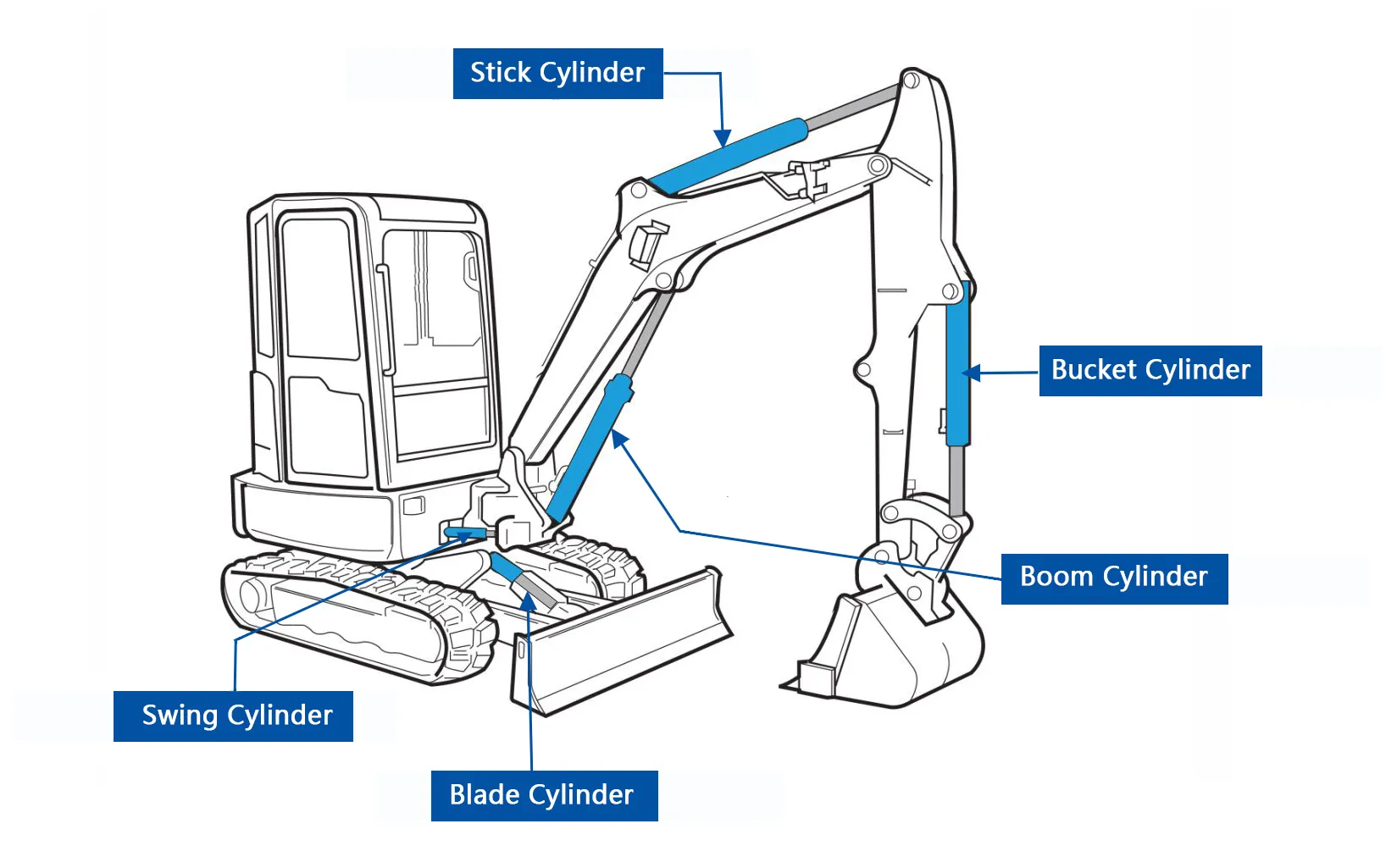

Mini Excavator Hydraulic Cylinder Types

Mini Excavator Bucket Hydraulic Cylinder Features

- Double-Acting Mechanism

The bucket hydraulic cylinder is double-acting, allowing hydraulic fluid to power both extension and retraction of the piston. This provides precise control over bucket movements, enabling smooth curling, tilting, and dumping of materials during excavation tasks in tight spaces. - High-Strength Steel Construction

Constructed from high-strength steel, the hydraulic bucket cylinder withstands heavy loads and harsh working conditions. Its robust build ensures durability, resisting wear from constant digging and exposure to abrasive materials like gravel or sand, extending the component’s operational lifespan. - Precision-Sealed Piston

The excavator hydraulic cylinder features a precision-sealed piston to prevent hydraulic fluid leaks. High-quality seals, such as polyurethane or rubber, maintain pressure integrity, ensuring consistent force output and reliable bucket control, even under high-pressure operations or frequent use. - Compact Design

Designed for mini excavators, the hydraulic bucket cylinder is compact yet powerful, fitting into tight spaces without sacrificing performance. Its smaller size allows for precise movements, making it ideal for detailed excavation work in confined or urban environments. - Corrosion-Resistant Coating

The excavator hydraulic cylinders are coated with corrosion-resistant materials, such as chrome or specialized paints, to protect against rust and environmental damage. This feature ensures longevity, especially in wet or humid conditions, reducing maintenance costs and downtime for repairs. - Precision Control

Bucket hydraulic cylinders offer precise control over the bucket’s movements, including curling, tilting, and dumping. This precision is essential for tasks requiring accuracy, such as trenching, grading, and material placement in confined or delicate areas.

Mini Excavator Hydraulic Bucket Cylinder Applications

- Construction Industry

In construction, mini excavator hydraulic bucket cylinders are essential for tasks such as digging foundations, trenching, and material handling. Their precision and durability allow operators to perform earthmoving and excavation tasks efficiently, even in tight spaces. - Landscaping and Gardening

These bucket hydraulic cylinders play a crucial role in landscaping projects, enabling mini excavators to dig holes, remove tree stumps, and prepare soil. Their compact design and precise movement make them ideal for reshaping terrain or creating garden features. - Agriculture and Farming

In agriculture, bucket cylinders help with tasks like digging irrigation channels, clearing debris, and handling soil or manure. Their ability to operate in rugged conditions makes them indispensable for farm maintenance and land preparation. - Demolition and Recycling

Hydraulic bucket cylinders are used in demolition to break apart structures and remove debris. In recycling operations, they help sort and load materials with precision, ensuring efficient handling of waste for processing or disposal. - Utility and Infrastructure Maintenance

These mini excavator hydraulic cylinders are vital for utility projects, such as laying pipes, repairing water lines, and digging trenches for cables. Their durability and accuracy allow operators to work efficiently without damaging surrounding infrastructure or utilities. - Forestry and Logging

In forestry applications, mini excavators equipped with hydraulic cylinders are used for clearing land, removing tree roots, and loading logs. Their ability to handle tough environments ensures effective operation in dense and rugged terrains.

Additional information

| Edited by | Yjx |

|---|