Brass Bevel Gears Ratio 3:1 Straight-Tooth System

The brass bevel gears ratio 3:1 straight-tooth system refers to a pair of gears designed for transmitting rotational motion between shafts at an angle, typically 90 degrees, using a 3:1 gear ratio. These gears are made of durable brass, known for its strength, corrosion resistance, and smooth machining properties. Bevel gears have a conical shape, and in a straight-tooth system, the teeth are cut along the cone’s surface in a straight-line pattern. This configuration is commonly used in applications requiring torque amplification or speed reduction, such as in hand drills, automotive differentials, and small machinery.

The brass bevel gears ratio 3:1 straight-tooth system refers to a pair of gears designed for transmitting rotational motion between shafts at an angle, typically 90 degrees, using a 3:1 gear ratio. These gears are made of durable brass, known for its strength, corrosion resistance, and smooth machining properties, making it ideal for precision mechanical applications. Bevel gears have a conical shape, and in a straight-tooth system, the teeth are cut along the cone's surface in a straight-line pattern. The 3:1 ratio indicates that for every three rotations of the larger gear, the smaller gear completes one rotation. This configuration is commonly used in applications requiring torque amplification or speed reduction, such as in hand drills, automotive differentials, and small machinery.

Brass Bevel Gear Ratio 3:1

|  |

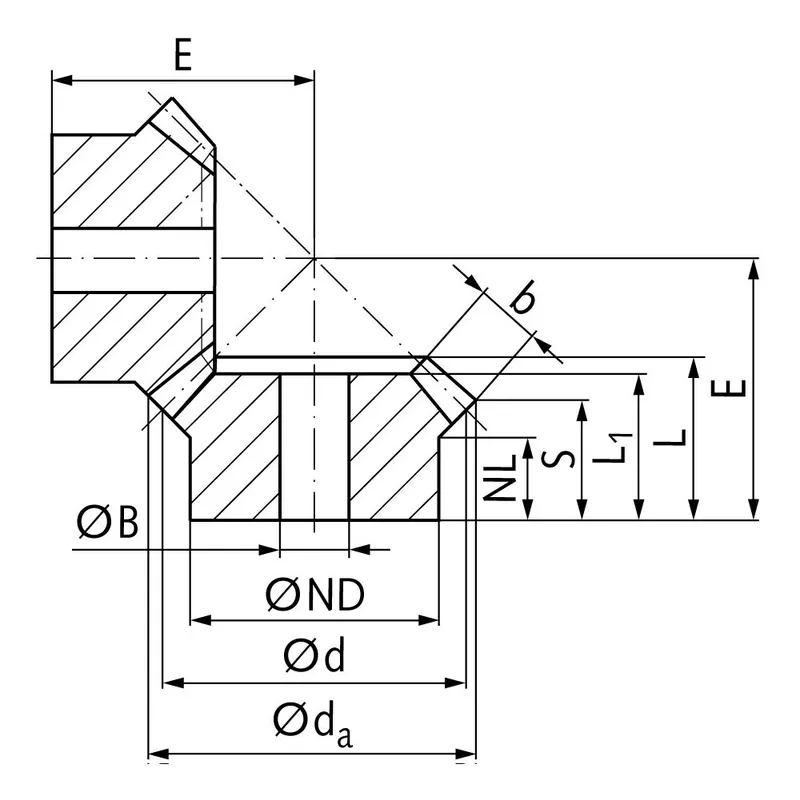

| Module | Number of teeth | da | d | ND | NL | L1 | L | S | b | BH7 | E | Torque* | Weight |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | Ncm | g | ||

| 0,5 | 15 | 8,8 | 7,5 | 6 | 3,7 | 6,5 | 7 | 4,3 | 3 | 3 | 15,3 | 1,5 | 1 |

| 0,5 | 45 | 22,7 | 22,5 | 12 | 5 | 7,5 | 8,4 | 7,5 | 3 | 4 | 11,0 | 4,5 | 11 |

| 1 | 15 | 17,7 | 15 | 13 | 5 | 10 | 11,1 | 6,5 | 5 | 5 | 28,5 | 11,0 | 10 |

| 1 | 45 | 45,4 | 45 | 16 | 8 | 12,5 | 14,7 | 13,2 | 5 | 6 | 20,2 | 33,0 | 68 |

Brass Straight Bevel Gear Features

- Durable Brass Construction

Brass straight bevel gears are made from high-quality brass, providing excellent durability and resistance to corrosion. This makes them suitable for long-term use in environments exposed to moisture, chemical exposure, or varying temperatures, ensuring reliable performance over extended periods. - Straight-Tooth Design

The straight-tooth design ensures smooth and efficient power transmission between intersecting shafts. This configuration reduces friction and heat generation, offering quieter operation while maintaining high precision and stability during rotational motion, especially in low to moderate-speed applications. - High Torque Capacity

These gears are capable of handling significant torque loads due to their robust construction. This feature makes them ideal for heavy-duty applications requiring reliable torque transfer, such as mechanical drive systems in industrial machinery and automotive assemblies. - Compact and Lightweight

Brass bevel gears are both compact and lightweight, ensuring they do not add unnecessary bulk to mechanical systems. This feature is particularly beneficial in applications requiring space efficiency, such as robotics, precision instruments, and compact mechanical assemblies. - Resistance to Wear and Tear

The brass material provides excellent resistance to wear and tear, reducing the need for frequent maintenance or replacement. This characteristic ensures long-lasting performance, even in systems that operate continuously under load or in challenging conditions. - Versatile Application Range

Brass straight bevel gears are versatile, suitable for a wide range of applications, including automotive systems, industrial machines, and power tools. Their adaptability to various mechanical setups makes them a preferred choice in both commercial and specialized engineering projects.

Brass Bevel Gear Uses

- Automotive Industry

Brass bevel gears are widely used in automotive systems, particularly in differentials and transmission setups. They enable smooth torque transfer and directional changes between drive shafts, ensuring efficient power delivery to the wheels for improved performance, stability, and fuel efficiency in vehicles. - Industrial Machinery

In industrial machinery, bevel gears provide reliable motion and torque transmission in mechanical systems like conveyors and cutting tools. Their durability and resistance to wear make them ideal for heavy-duty equipment operating continuously under high stress in demanding environments. - Aerospace Industry

Aerospace applications use brass bevel gears for precise motion control in navigation systems, actuators, and gearboxes. Their lightweight properties and resistance to corrosion make them suitable for high-performance environments where weight reduction and reliability are critical for optimal aircraft functionality. - Robotics and Automation

Brass bevel gears are essential in robotics and automation systems, providing precise movement in robotic arms, joints, and drive systems. Their compact size and smooth operation allow for accurate positioning and control in robots used for manufacturing, healthcare, and research applications. - Power Tools and Equipment

These gears are commonly found in power tools like drills, grinders, and saws, where they enable torque transfer between angled shafts. Their ability to handle high loads and provide consistent performance makes them indispensable in tools used for construction and maintenance. - Marine Industry

In the marine industry, bevel gears are used in propulsion systems, steering mechanisms, and winches. Their resistance to corrosion from saltwater and moisture ensures they perform reliably in harsh marine environments, contributing to the smooth operation of ships and boats.

|  |

| Bevel Gear for Automotive Industry | Bevel Gear for Robotics Industry |

|  |

| Bevel Gear for Aerospace Industry | Bevel Gear for Marine Industry |

Brass Bevel Gear Maintenance Tips

- Regular Cleaning

Clean the brass bevel gears periodically to remove dirt, debris, and grease buildup. Use a soft brush and a mild cleaning solvent to prevent contamination from affecting gear performance. Keeping the gears clean ensures smooth operation and reduces wear over time. - Proper Lubrication

Apply suitable lubricants regularly to minimize friction and prevent excessive wear between the gear teeth. Use high-quality grease or oil recommended for brass gears, ensuring proper coverage on all contact surfaces to maintain efficiency and extend the gear's lifespan. - Inspect for Wear and Damage

Conduct routine visual inspections to check for signs of wear, cracks, or chipped teeth. Identifying and addressing damage early prevents further deterioration and avoids unexpected mechanical failures that could disrupt operations or lead to costly repairs. - Monitor Alignment and Fit

Ensure the gears are properly aligned and securely fitted within the mechanical system. Misalignment can lead to uneven wear or slipping, reducing efficiency. Adjust or replace components as needed to maintain optimal gear performance and prevent unnecessary strain on the system. - Prevent Corrosion

Although brass is corrosion-resistant, exposure to harsh chemicals or moisture over time can still cause degradation. Protect the gears by storing them in a dry environment when not in use and applying protective coatings if operating in corrosive conditions.

Additional information

| Edited by | Yjx |

|---|