Brass Bevel Gears Ratio 2:1 Straight-Tooth System

The brass bevel gears ratio 2:1 straight-tooth system is a mechanical arrangement of bevel gears designed to transmit torque and rotational motion between intersecting shafts, typically at a 90-degree angle. In this system, the gears are made of brass, a durable and corrosion-resistant alloy, which ensures smooth operation and longevity under various conditions. The 2:1 gear ratio means that for every two rotations of the driving gear (the smaller gear), the driven gear (the larger gear) completes one rotation.

The brass bevel gears ratio 2:1 straight-tooth system is a mechanical arrangement of bevel gears designed to transmit torque and rotational motion between intersecting shafts, typically at a 90-degree angle. In this system, the gears are made of brass, a durable and corrosion-resistant alloy, which ensures smooth operation and longevity under various conditions. The 2:1 gear ratio means that for every two rotations of the driving gear (the smaller gear), the driven gear (the larger gear) completes one rotation.

The straight-tooth configuration indicates that the teeth are aligned radially along the gear's face, intersecting at the apex of the bevel. This design is simpler than spiral bevel gears and is ideal for low-speed or low-load applications where precision and cost efficiency are priorities. Commonly used in machinery, robotics, and power transmission systems, this straight bevel gear system offers reliable performance in compact spaces. Its brass construction also reduces friction and noise, making it a preferred choice for applications requiring minimal wear and smooth operation.

Brass Bevel Gear Ratio 2:1

|  |

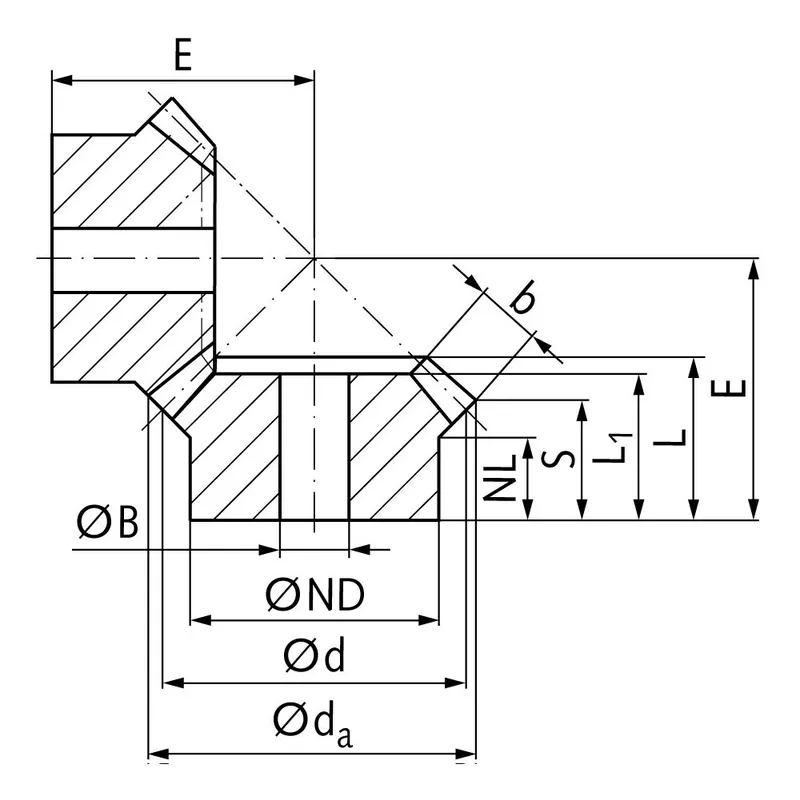

| Module | Number of teeth | da | d | ND | NL | L1 | L | S | b | BH7 | E | Torque* | Weight |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | Ncm | g | ||

| 0,5 | 20 | 11,2 | 10 | 8 | 4 | 7 | 7,5 | 5,0 | 3 | 4 | 14,65 | 2,7 | 2 |

| 0,5 | 40 | 20,3 | 20 | 12 | 5 | 7,5 | 8,4 | 7,1 | 3 | 4 | 11,83 | 5,4 | 8 |

| 1 | 15 | 17,4 | 15 | 12,5 | 4,5 | 9 | 10,1 | 5,8 | 5 | 5 | 20,2 | 9,4 | 9 |

| 1 | 30 | 30,6 | 30 | 16 | 5 | 9 | 10,8 | 8,8 | 5 | 5 | 15,7 | 18,8 | 27 |

| 1 | 20 | 22,4 | 20 | 15 | 5 | 10 | 11,1 | 6,8 | 5 | 5 | 26,2 | 20,6 | 17 |

| 1 | 40 | 40,6 | 40 | 16 | 8 | 12 | 13,8 | 11,7 | 5 | 6 | 21,1 | 41,2 | 50 |

Different Types of Bevel Gears

Straight Bevel Gears

Straight bevel gears are the simplest type of bevel gears, featuring straight teeth that are parallel to the generatrix of the pitch cone. They are used in applications where high speeds and low to medium loads are present. However, straight bevel gears may generate more noise compared to other types of bevel gears due to the sudden engagement of the teeth.

Spiral Bevel Gears

Spiral bevel gears have curved teeth that are oblique to the generatrix of the pitch cone. The spiral angle of the teeth provides a gradual and smooth engagement, resulting in quieter operation and higher load capacity compared to straight bevel gears. Spiral bevel gears are commonly used in automotive differentials and industrial applications that require high speeds and heavy loads.

Hypoid Bevel Gears

Hypoid bevel gears are similar to spiral bevel gears but with a notable difference: the pitch cones of the gears do not intersect. Instead, the axes of the gears are offset, allowing for larger pinion diameters and improved tooth contact. This offset configuration provides several advantages, such as higher torque capacity, reduced noise, and more compact designs. Hypoid gears are frequently used in automotive rear axles and industrial gearboxes.

Zerol Bevel Gears

Zerol bevel gears are a special case of spiral bevel gears, where the spiral angle is zero. This means that the teeth are parallel to the axis of rotation, similar to straight bevel gears. However, unlike straight bevel gears, Zerol bevel gears have a curved tooth profile that allows for smooth and gradual engagement. Zerol bevel gears offer a balance between the benefits of straight and spiral bevel gears, providing improved load capacity and quieter operation compared to straight bevel gears.

Miter Bevel Gears

Miter bevel gears are a specific type of bevel gear where the number of teeth on both gears is equal, and the shaft angle is 90°. This configuration results in a 1:1 gear ratio, making miter gears ideal for applications that require a change in the direction of rotation without altering the speed or torque. Miter gears can have straight, spiral, or Zerol teeth.

|  |  |

| Spiral Bevel Gears | Hypoid Bevel Gears | Miter Bevel Gears |

Brass Straight Bevel Gear Applications

- Industrial Machinery

Brass straight bevel gears are widely used in heavy-duty industrial machinery, such as conveyor systems and packaging equipment. Their ability to provide efficient torque transmission at 90-degree angles ensures smooth operation, durability, and minimal maintenance in rigorous environments where precision is critical. - Automotive Systems

In automotive applications, these gears are employed in differential systems and transmission mechanisms. They enable smooth power transfer between the engine and wheels, ensuring proper torque distribution. Their brass construction minimizes wear and provides long-lasting performance under high-stress conditions. - Robotics and Automation

Robotics systems rely on brass straight bevel gears for precise motion control and compact design. These gears allow robots to achieve accurate rotational movement and power transmission at specific angles, making them ideal for intricate and high-precision automated operations. - Marine Equipment

The high corrosion resistance of brass makes these gears ideal for marine equipment, including winches and propeller systems. Straight bevel gears provide robust torque transfer in damp or saline environments, ensuring reliability in harsh conditions commonly encountered in marine applications. - Aerospace Components

In aerospace technology, brass straight bevel gears are used in actuator systems and flight control mechanisms. Their lightweight yet durable characteristics, combined with smooth torque transmission, make them essential for applications where precision, efficiency, and reliability are paramount. - Power Tools and Handheld Equipment

Power tools such as drills and grinders utilize these gears for efficient torque redirection in compact spaces. The brass material ensures a quieter operation and reduces friction, making the tools more ergonomic and durable for prolonged use in demanding environments.

|  |

| Bevel Gear for Power Tools | Bevel Gear for Marine Industry |

|  |

| Bevel Gear for Robotics | Bevel Gear for Automotive Differentials |

Additional information

| Edited by | Yjx |

|---|