Brass Bevel Gears Ratio 1:1 Straight-Tooth System

A brass bevel gear ratio 1:1 straight-tooth system refers to a mechanical arrangement involving two bevel gears made of brass with an equal number of teeth, creating a 1:1 gear ratio. Bevel gears are conical in shape and are typically used to transmit motion between shafts that are at an angle to each other, most commonly at 90 degrees. In this specific system, the straight-tooth design means that the teeth are cut in a linear fashion, rather than being curved or helical.

A brass bevel gear ratio 1:1 straight-tooth system refers to a mechanical arrangement involving two bevel gears made of brass with an equal number of teeth, creating a 1:1 gear ratio. Bevel gears are conical in shape and are typically used to transmit motion between shafts that are at an angle to each other, most commonly at 90 degrees. In this specific system, the straight-tooth design means that the teeth are cut in a linear fashion, rather than being curved or helical.

This type of gear setup ensures equal speed and torque transfer between the gears without altering the rotational speed. Brass is chosen as the material for its excellent wear resistance, corrosion resistance, and ability to operate quietly in various industrial and mechanical applications.

Brass Bevel Gear Ratio 1:1

|  |

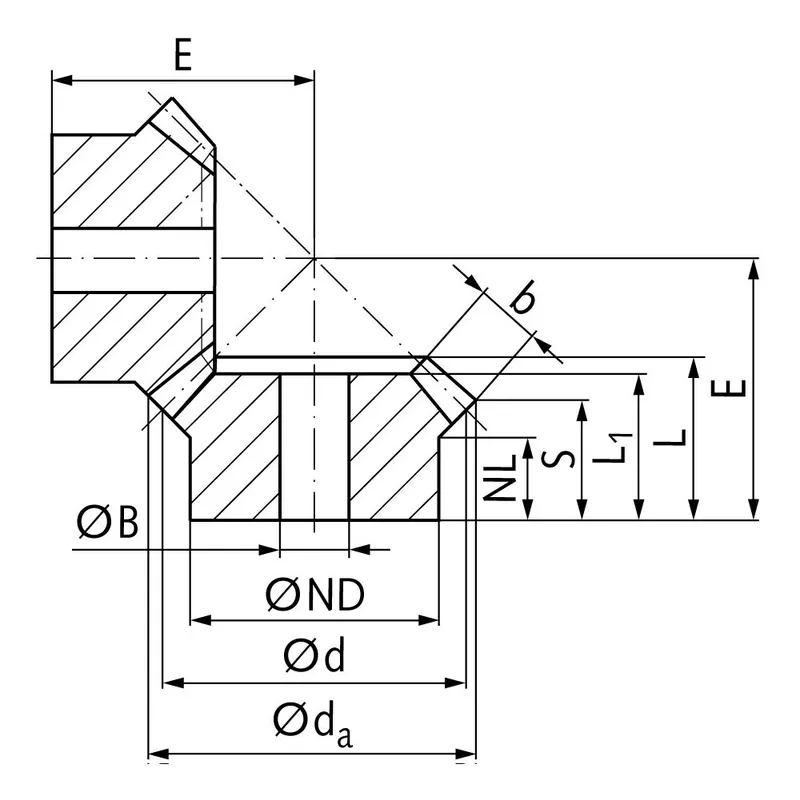

| Module | Number of teeth | da | d | ND | NL | L1 | L | S | b | BH7 | E | Torque* | Weight |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | Ncm | g | ||

| 0,5 | 15 | 8,2 | 7,5 | 6 | 5 | 6,3 | 7,3 | 6,1 | 2 | 3 | 9,5 | 0,9 | 1 |

| 0,5 | 20 | 10,7 | 10 | 8 | 4 | 7 | 7 | 5 | 3 | 4 | 9,7 | 1,9 | 1 |

| 0,5 | 24 | 12,7 | 12 | 8 | 4 | 6,4 | 7 | 5 | 3 | 4 | 10,7 | 3,0 | 3 |

| 0,5 | 30 | 15,7 | 15 | 10 | 4 | 7,5 | 8,5 | 6,6 | 3 | 4 | 13,7 | 5,3 | 4 |

| 0,5 | 36 | 18,7 | 18 | 12 | 5 | 9 | 10,1 | 8 | 3 | 4 | 16,7 | 8,2 | 10 |

| 0,5 | 40 | 20,7 | 20 | 12 | 5 | 8,5 | 9,5 | 7,5 | 3 | 4 | 17,1 | 10,6 | 10 |

| 0,5 | 50 | 25,7 | 25 | 14 | 5 | 8,5 | 9,5 | 7,5 | 3 | 4 | 19,6 | 18,0 | 16 |

| 1 | 12 | 13,0 | 12 | 8 | 5 | 8,5 | 9,6 | 7,7 | 3 | 5 | 13,2 | 5,0 | 3 |

| 1 | 16 | 17,4 | 16 | 12 | 5 | 9 | 10,3 | 7,8 | 4 | 5 | 15,1 | 6,0 | 9 |

| 1 | 20 | 21,4 | 20 | 15 | 5 | 9 | 10,4 | 7,8 | 4 | 5 | 17,1 | 13,0 | 15 |

| 1 | 25 | 26,4 | 25 | 16 | 6,7 | 11,5 | 13 | 9,7 | 5 | 5 | 21,5 | 26,0 | 26 |

| 1 | 30 | 31,4 | 30 | 16 | 7 | 11,5 | 13,1 | 9,7 | 5 | 5 | 24,0 | 40,0 | 33 |

| 1 | 36 | 37,4 | 36 | 16 | 7 | 11,5 | 13 | 9,6 | 5 | 5 | 26,9 | 62,0 | 43 |

| 1 | 40 | 41,4 | 40 | 16 | 8 | 12,5 | 14 | 10,6 | 5 | 5 | 29,9 | 79,0 | 53 |

| 1 | 50 | 51,4 | 50 | 16 | 8 | 12,5 | 14 | 10,6 | 5 | 6 | 34,9 | 130,0 | 76 |

| 1 | 60 | 61,4 | 60 | 16 | 8 | 12,5 | 14,1 | 10,6 | 5 | 6 | 39,9 | 197,0 | 110 |

Brass Straight Bevel Gear Design Features

- Straight-Tooth Configuration

Brass straight bevel gears feature teeth cut parallel to the pitch cone’s generators, resembling conical spur gears. This design ensures straightforward manufacturing and cost-effectiveness, ideal for low-speed applications, but abrupt tooth engagement can generate noise and stress at higher speeds. - 1:1 Gear Ratio

These brass bevel gears often have a 1:1 ratio, meaning both gears have an equal number of teeth. This maintains identical rotational speeds between intersecting shafts, typically at 90 degrees, ensuring consistent motion transfer without speed or torque alteration in applications like hand tools. - Brass Material Properties

Typically made from brass alloy Ms58, these brass bevel gears offer excellent corrosion resistance and machinability. Brass provides moderate strength and durability, suitable for light to medium loads, while its low friction reduces wear, enhancing longevity in less demanding mechanical systems. - 90-Degree Shaft Intersection

Designed for shafts intersecting at 90 degrees, these bevel gears enable efficient power transmission in compact setups. Precise alignment is critical to prevent excessive wear or vibration, making them suitable for applications requiring angular motion transfer, such as differential systems. - Compact and Lightweight Design

The conical shape and brass composition result in a compact, lightweight gear system. This reduces inertia, making them ideal for applications where space and weight are constraints, like in small machinery or precision instruments requiring smooth operation. - Low-Speed Application Suitability

Best suited for speeds below 1000 rpm, straight bevel gears avoid excessive noise and stress due to their non-gradual tooth engagement. They are commonly used in hand drills or simple mechanical devices where high-speed performance is not required.

Brass Bevel Gear Purpose and Applications

- Hand Tools and Drills

Brass bevel gears are widely used in hand tools like drills and screwdrivers. Their 1:1 ratio and straight-tooth design ensure precise 90-degree power transmission, enabling compact, lightweight mechanisms for manual operation in low-speed, low-torque applications. - Automotive Differentials

In automotive systems, brass bevel gears are employed in differential assemblies. Their ability to transfer motion at right angles ensures smooth torque distribution to wheels, particularly in vintage or small-scale vehicles, where corrosion resistance and ease of machining are beneficial. - Small Machinery

These gears are integral in small machinery, such as textile or printing equipment. The straight-tooth design and brass’s durability suit low-speed operations, providing reliable angular motion transfer in compact setups where maintenance and corrosion resistance are priorities. - Marine Equipment

Brass bevel gears are used in marine applications, like winches or steering systems. Their corrosion resistance to saltwater environments ensures longevity, while the straight-tooth system supports low-speed, high-precision tasks, maintaining efficiency in harsh conditions without frequent maintenance. - Clock and Watch Mechanisms

In clocks and watches, brass bevel gears enable precise angular motion for timekeeping components. Their compact size and machinability allow intricate designs, ensuring smooth, low-friction operation critical for maintaining accuracy in small-scale, low-speed mechanical systems. - Pumps and Valves

Brass bevel gears are utilized in pump and valve systems for fluid control. Their ability to handle 90-degree motion transfer in compact, corrosion-resistant setups makes them ideal for low-speed applications in water or chemical processing, ensuring reliable performance.

|  |

| Bevel Gear for Power Tools | Bevel Gear for Automotive Differentials |

|  |

| Bevel Gear for Robotics | Bevel Gear for Marine Industry |

Brass Bevel Gears vs. Steel Bevel Gears

Brass and steel bevel gears differ significantly in terms of material properties, performance, and application suitability. These differences stem from the distinct characteristics of brass and steel, influencing their mechanical behavior and durability in various environments.

- Material Composition and Strength

Brass bevel gears are made from a copper-zinc alloy, which is softer compared to steel. This softness contributes to lower tensile strength, making them less suitable for high-load applications. Steel bevel gears, on the other hand, are made from iron-carbon alloys, providing superior strength and hardness, which allow them to withstand heavy loads and high torque without deformation. - Corrosion Resistance and Environmental Suitability

Brass bevel gears have excellent corrosion resistance, especially in moist, salty, or chemically aggressive environments. This makes them ideal for marine, chemical, and outdoor applications. Steel bevel gears, unless treated with coatings or made from stainless steel, are more prone to rust and corrosion, limiting their use in corrosive environments. - Wear and Longevity

Brass gears exhibit self-lubricating properties, which reduce friction and wear during operation. However, their softer nature makes them wear out faster under continuous heavy loads. Steel gears, due to their hardness, are more resistant to wear and are better suited for high-stress, long-term applications. - Noise and Vibration Levels

Brass bevel gears operate more quietly compared to steel gears, as brass naturally dampens vibrations. Steel gears tend to generate more noise during operation, especially in high-speed systems, due to their rigid and dense structure. - Cost and Manufacturing Complexity

Brass bevel gears are typically more expensive due to the cost of raw materials and their machining ease. Steel gears, while generally cheaper in material cost, may require additional heat treatment or coatings, increasing overall production complexity. - Application Fields

Brass gears are preferred in precision instruments, marine equipment, and low-load systems where smooth operation and corrosion resistance are critical. Steel gears dominate heavy-duty applications such as automotive, industrial machinery, and aerospace, where strength and durability are paramount.

|  |

| Brass Bevel Gears | Steel Bevel Gears |