Blade Hydraulic Cylinder for Mini Excavator

The blade hydraulic cylinder, also known as the dozer hydraulic cylinder, is a critical component of a mini excavator’s hydraulic system, responsible for controlling the movement of the dozer blade. This blade, mounted at the front of the excavator, is used for pushing materials like dirt, sand, or gravel and stabilizing the machine on uneven terrain. The hydraulic blade cylinder operates by converting pressurized hydraulic fluid into linear motion, extending or retracting to raise and lower the blade with precision.

The blade hydraulic cylinder, also known as the dozer hydraulic cylinder, is a critical component of a mini excavator’s hydraulic system, responsible for controlling the movement of the dozer blade. This blade, mounted at the front of the excavator, is used for pushing materials like dirt, sand, or gravel and stabilizing the machine on uneven terrain. The hydraulic blade cylinder operates by converting pressurized hydraulic fluid into linear motion, extending or retracting to raise and lower the blade with precision. Typically double-acting, it allows controlled movement in both directions.

Mini Excavator Blade Hydraulic Cylinder Specifications

| Product Name: | Mini Excavator Blade Hydraulic Cylinder |

| Function: | Control the action of the bulldozer. |

| Bore Diameter: | 50mm-140mm |

| Rod diameter: | 25mm-80mm |

| Stroke: | ≤250mm |

| Maximum pressure MPa: | 29.4MPa |

| Thrust Force: | 453KN |

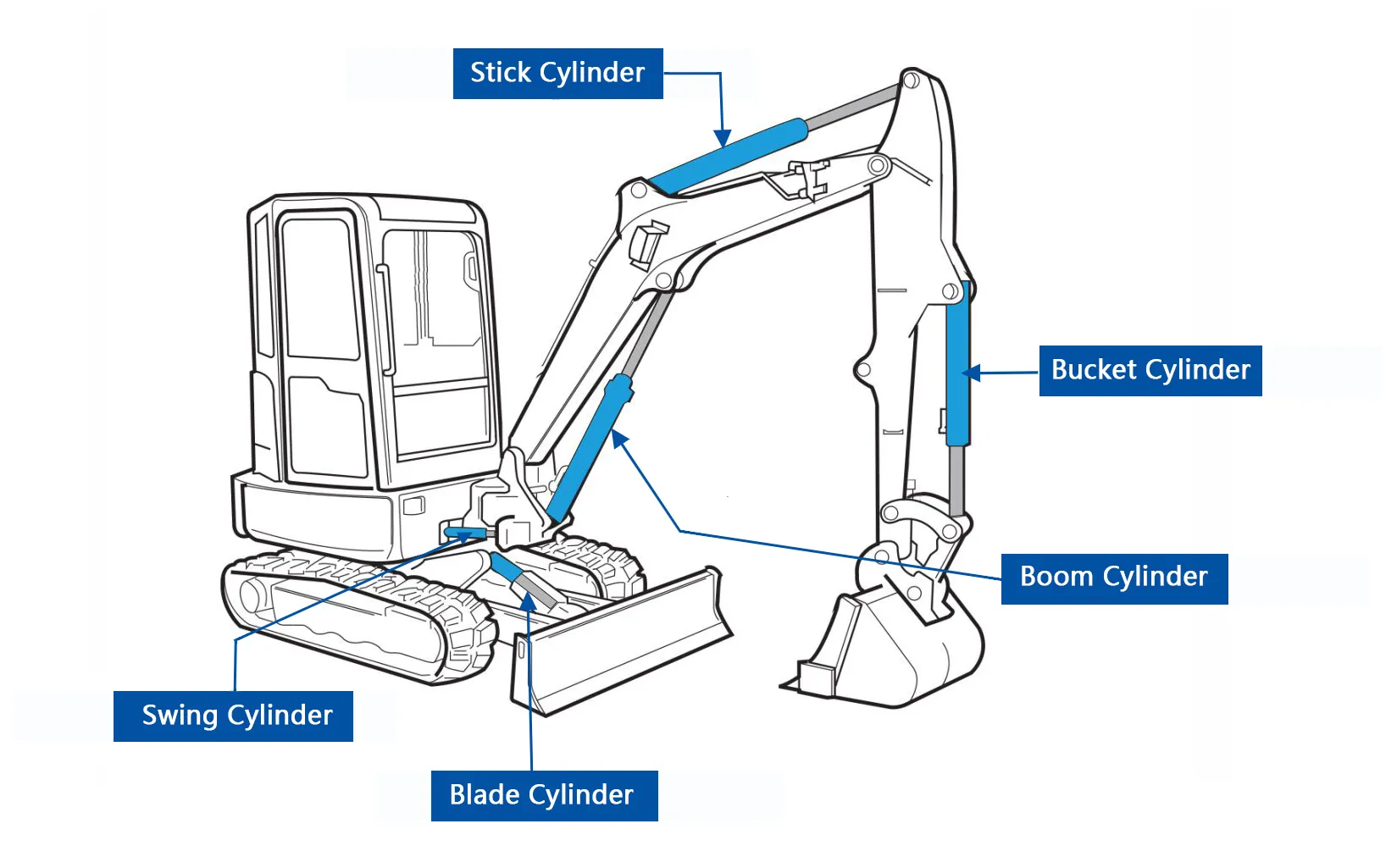

Mini Excavator Hydraulic Cylinder Types

- Stick Hydraulic Cylinder

The stick hydraulic cylinder, also called the arm or dipper hydraulic cylinder, controls the movement of the excavator's stick, the articulated arm extending from the boom. It facilitates precise digging motions by extending and retracting, using pressurized hydraulic fluid to deliver powerful linear force. Typically double-acting, it ensures controlled extension and retraction for tasks like trenching or grading. - Boom Hydraulic Cylinder

The boom hydraulic cylinder powers the primary lifting and lowering of the excavator’s boom, the main structural arm. It handles heavy loads, enabling vertical and horizontal reach for digging or lifting. Double-acting designs provide robust control, with high-pressure fluid driving the piston. Requiring routine checks to maintain performance and avoid downtime on construction sites. - Bucket Hydraulic Cylinder

The bucket hydraulic cylinder controls the curling and uncurling of the excavator’s bucket, essential for scooping and dumping materials like soil or gravel. It delivers precise, high-force movements for efficient digging. Double-acting, it uses hydraulic fluid to extend and retract. Proper maintenance, including seal inspections, ensures reliability during intensive tasks like landscaping or foundation work. - Swing Hydraulic Cylinder

The swing hydraulic cylinder enables the lateral rotation of the excavator’s upper structure, allowing the cab and arm to pivot left or right. This facilitates precise positioning during digging or material handling. It operates with hydraulic fluid driving a piston, often in a compact design for mini excavators. Regular lubrication and seal checks are vital to maintain smooth, responsive swinging in confined spaces like urban job sites. - Blade Hydraulic Cylinder

The blade hydraulic cylinder, or dozer hydraulic cylinder, controls the dozer blade’s up-and-down movement for pushing materials and stabilizing the excavator. It uses hydraulic fluid for precise linear motion, typically in a double-acting setup. Routine maintenance ensures durability for tasks like grading or backfilling in construction.

Mini Excavator Blade Hydraulic Cylinder Advantages

- Precise Blade Control

The blade hydraulic cylinder provides exceptional precision in blade movement, enabling operators to adjust the blade's height and angle accurately. This precision is essential for tasks like grading, leveling, and material spreading. - Enhanced Machine Stability

By controlling the dozer blade, the hydraulic cylinder helps stabilize the excavator during digging operations. Lowering the blade to the ground reduces machine wobbling, ensuring safety and improved efficiency on uneven terrain. - Increased Versatility

The hydraulic blade cylinder allows the blade to perform multiple functions, such as backfilling, trenching, or site preparation. Its ability to angle and tilt enhances the excavator's adaptability for various tasks and job sites. - Durability in Tough Conditions

Blade hydraulic cylinders are designed to withstand high pressure and harsh environments. Built with robust materials and seals, they resist wear and tear, ensuring reliable performance in demanding construction and landscaping work. - Time and Labor Efficiency

With precise and powerful control, the blade cylinder enables quicker execution of tasks like leveling or pushing debris. This reduces manual labor and operational time, increasing productivity on job sites. - Reduced Operator Fatigue

The hydraulic system minimizes the physical effort required to manipulate the blade. Operators can control heavy loads and make fine adjustments effortlessly, leading to increased comfort and reduced strain during long work hours.

Choose the Right Hydraulic Blade Cylinder for Mini Excavator

- Compatibility with Excavator Model

Ensure the hydraulic blade cylinder is specifically designed for your mini excavator model. Proper compatibility ensures seamless integration, optimal performance, and avoids potential issues with installation, alignment, or hydraulic fluid flow. - Cylinder Size and Stroke Length

Choose a mini excavator hydraulic cylinder with the correct bore size, rod diameter, and stroke length to match your blade's required range of motion. An incorrect size can limit functionality or cause inefficiencies during operation. - Pressure Capacity and Load Handling

Select an excavator hydraulic cylinder capable of handling the hydraulic pressure and loads your tasks demand. A higher pressure capacity ensures durability and reliable performance, even in heavy-duty applications like grading or backfilling. - Material and Build Quality

Opt for blade hydraulic cylinders made from robust materials such as high-strength steel. High-quality construction ensures resistance to wear, corrosion, and extreme conditions, prolonging the cylinder’s lifespan and reducing maintenance costs. - Seal and Leak Prevention Systems

Ensure the hydraulic cylinder for excavator has advanced sealing systems to prevent hydraulic fluid leaks. Reliable seals maintain consistent performance, reduce downtime, and prevent contamination that could lead to system failure or costly repairs.

|

|

Additional information

| Edited by | Yjx |

|---|