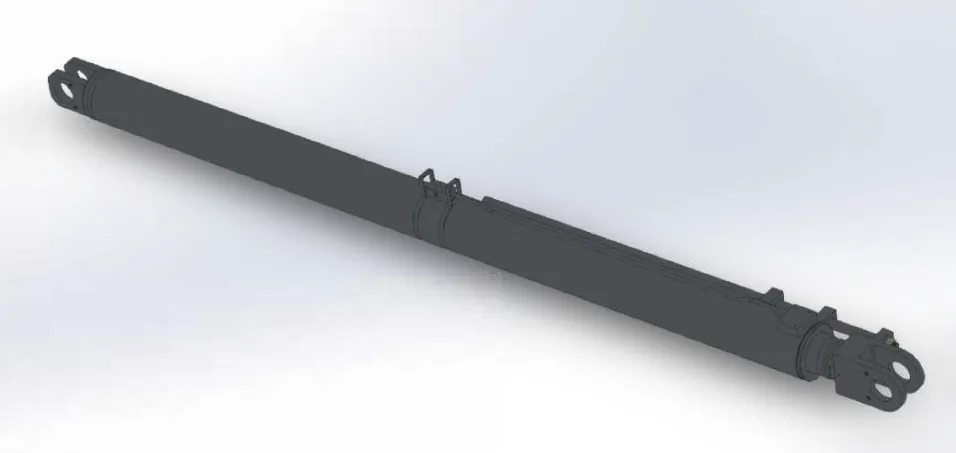

Arm Anti Tilt Hydraulic Cylinder for Truss Arm Crawler Crane

The arm anti-tilt hydraulic cylinder for a truss arm crawler crane is a specialized hydraulic component designed to maintain stability and precision during crane operations. It plays a critical role in controlling and preventing the tilting of the crane’s arm (or boom) when handling heavy loads or operating on uneven terrain. This cylinder ensures that the truss arm remains aligned by compensating for tilt forces caused by load weight, wind, or other external factors.

The arm anti-tilt hydraulic cylinder for a truss arm crawler crane is a specialized hydraulic component designed to maintain stability and precision during crane operations. It plays a critical role in controlling and preventing the tilting of the crane's arm (or boom) when handling heavy loads or operating on uneven terrain. This cylinder ensures that the truss arm remains aligned by compensating for tilt forces caused by load weight, wind, or other external factors.

The hydraulic arm anti-tilt cylinder operates by using pressurized hydraulic fluid to generate force, which adjusts the arm's position dynamically. It is built to withstand extreme loads and environmental conditions, ensuring durability and safety. Typically, this cylinder features high-strength materials, advanced seals to prevent fluid leakage, and precise control mechanisms. By maintaining proper balance, it not only enhances operational efficiency but also minimizes the risk of accidents or structural damage to the crane.

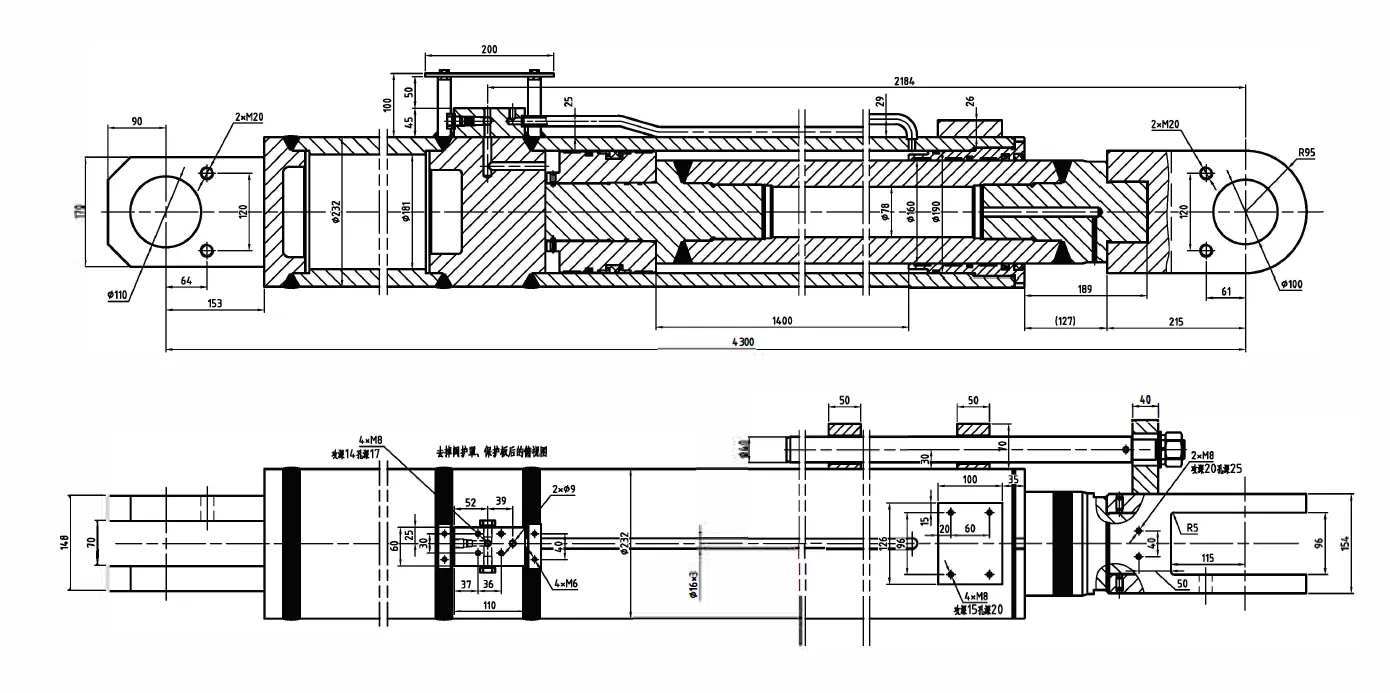

Arm Anti Tilt Hydraulic Cylinder Dimensions

|

|

|

|

| Hydraulic Arm Anti Tilt Cylinder | ||||||

| Cylinder model | Specifications | Working pressure | Maximum withstand pressure | Trip | Installation distance | Weight |

| CMNYY11112019 | Φ190xΦ160x1400 | 31.5MPa | 40MPa | 1400 | 4300 | 820kg |

| Product Name: | Arm Anti Backtilt Hydraulic Cylinder |

| Function: | Control the movement of the arm frame. |

| Cylinder diameter: | 100mm-320mm |

| Rod diameter: | 85mm-220mm |

| Travel: | 1200mm-3550mm |

| Maximum pressure: | 31.5MPa |

| Maximum thrust: | 2533KN |

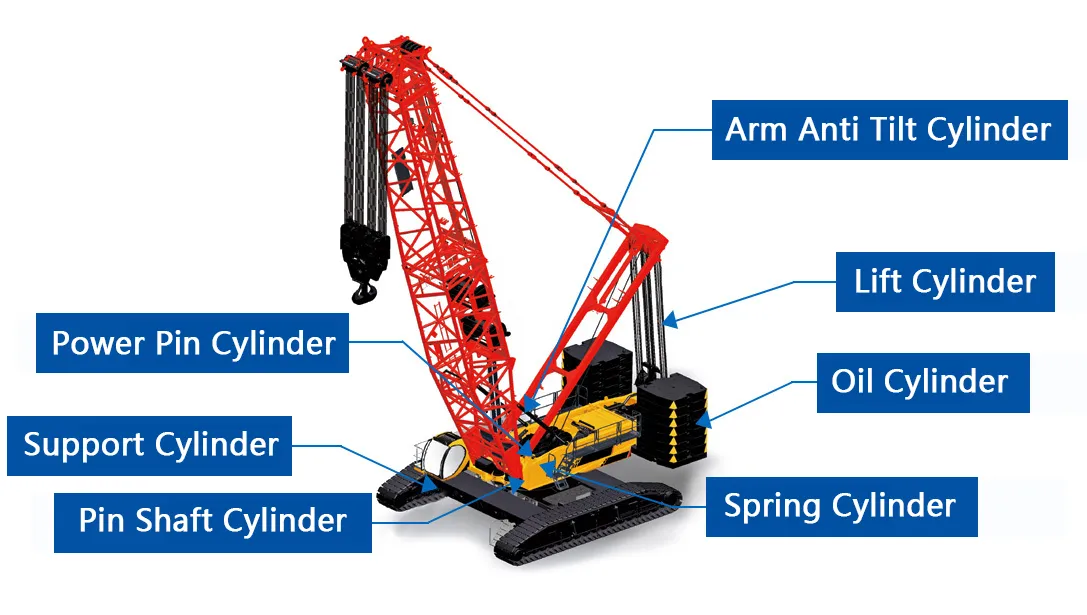

Truss Arm Crawler Crane Hydraulic Cylinder Types

- Support Hydraulic Cylinders

Support hydraulic cylinders are used to provide stability to the truss arm crawler crane during operation. These cylinders distribute the weight of the crane evenly, ensuring it remains steady on uneven or loose terrain. They are built to handle heavy loads and are critical for maintaining operational safety by preventing tilting or tipping while the crane is stationary or in use. - Lift Hydraulic Cylinders

Lift hydraulic cylinders are responsible for raising and lowering the crane’s truss arm or boom. These high-pressure cylinders generate immense force to move heavy loads vertically with precision. They allow operators to adjust the boom’s position dynamically, ensuring smooth lifting operations while providing the strength needed for heavy-duty applications such as construction and industrial tasks. - Pin Shaft Hydraulic Cylinders

Pin shaft hydraulic cylinders connect pivotal components of the crane and provide controlled movement between them. They enable rotational or angular adjustments of the truss arm or boom. By facilitating smooth articulation, these cylinders improve flexibility and operational efficiency. They are designed for durability and can withstand repetitive motion under extreme stress conditions. - Spring Hydraulic Cylinders

Spring hydraulic cylinders incorporate spring mechanisms within their design, offering an additional layer of control. These cylinders are commonly used in damping or shock-absorbing applications to reduce mechanical stress. They help maintain the crane’s structural integrity when operating under dynamic conditions or in environments where sudden load shifts may occur. Their design ensures smoother operation and longer equipment life. - Power Pin Hydraulic Cylinders

Power pin hydraulic cylinders are designed to lock and secure key components of the crane during operation. They provide the necessary force to engage or disengage locking pins, ensuring the crane’s components are held firmly in place. These cylinders enhance safety by preventing unintended movements or misalignments when the crane is handling heavy loads or undergoing adjustments. - Arm Anti-Tilt Hydraulic Cylinders

Arm anti-tilt hydraulic cylinders are critical for maintaining the truss arm’s balance during operation. These cylinders counteract forces that could tilt the arm, such as uneven loads or external environmental factors like wind. By dynamically adjusting the arm’s position, they ensure precision, stability, and safety, reducing the risk of accidents or mechanical failure.

Truss Arm Crawler Crane Arm Anti Tilt Hydraulic Cylinder Benefits

- Enhanced Stability During Operations

The arm anti-tilt hydraulic cylinder ensures that the truss arm remains balanced and stable, even when handling heavy or uneven loads. This reduces the risk of tipping and improves operational safety in challenging conditions. - Improved Load Handling Precision

By dynamically counteracting tilt forces, this hydraulic cylinder allows for more precise positioning of the crane’s arm. Operators can handle loads with greater accuracy, enhancing efficiency in construction or industrial tasks where precision is critical. - Increased Safety in Adverse Conditions

The anti-tilt hydraulic cylinder prevents the arm from losing alignment due to external factors such as wind, vibrations, or uneven ground. This minimizes the risk of accidents and ensures safe operations under adverse conditions. - Reduced Structural Stress on the Crane

By maintaining balance and preventing excessive tilting, the cylinder reduces strain on the crane’s truss arm and other structural components. This prolongs the lifespan of the equipment and reduces maintenance costs over time. - Adaptability to Dynamic Load Changes

The cylinder is designed to respond quickly to changes in load distribution, ensuring the arm stays aligned in real-time. This adaptability is crucial when handling varying weights or shifting loads during lifting operations. - Enhanced Overall Efficiency

With the arm anti-tilt hydraulic cylinder maintaining stability and precision, operators can work more efficiently without frequent adjustments. This improves productivity by reducing downtime and ensuring smoother, uninterrupted crane operations.

Custom Hydraulic Cylinder for Truss Arm Crawler Crane

- Rod Diameter

The rod diameter is a critical specification in custom hydraulic cylinders, as it determines the cylinder’s ability to handle tension and compression forces. A larger rod diameter provides greater strength and resistance to bending, ensuring reliable performance under heavy loads. The diameter is often customized based on the crane's weight capacity and operational requirements, enhancing durability and safety. - Bore Diameter

The bore diameter affects the volume of hydraulic fluid the cylinder can hold and the force it can generate. A larger bore diameter increases the cylinder’s thrust capacity, making it suitable for high-pressure applications. Customizing the bore diameter allows the cylinder to meet the specific lifting and stability needs of the truss arm crawler crane, ensuring optimal performance. - Working Pressure

The working pressure is the maximum hydraulic pressure the cylinder can safely operate under. Customizing the working pressure ensures that the cylinder matches the crane's hydraulic system and workload demands. High-pressure cylinders are essential for heavy-duty applications, enabling the crane to lift and maneuver massive loads with precision and efficiency. - Installation Distance

The installation distance refers to the length between the mounting points of the hydraulic cylinder when fully retracted. Customizing this distance ensures proper integration with the truss arm crawler crane’s design. It enables the cylinder to fit seamlessly into the crane, providing optimal movement and preventing misalignment during operation. - Stroke Length

The stroke length defines the distance the cylinder rod can extend and retract, directly affecting the range of motion of the truss arm. Customizing the stroke length allows the cylinder to meet specific operational requirements, such as lifting heights or arm adjustments. An optimized stroke length ensures smooth, efficient movement and maximum flexibility during crane operations. - Thrust Force

Thrust force is determined by the cylinder's bore diameter, rod diameter, and working pressure. Customizing the thrust force ensures the hydraulic cylinder can generate the necessary power to lift and stabilize heavy loads. Properly designed thrust force prevents overloading and ensures safe, precise handling of materials, making it crucial for demanding crane applications.

|

|

Additional information

| Edited by | Yjx |

|---|