Aluminum Gear Racks

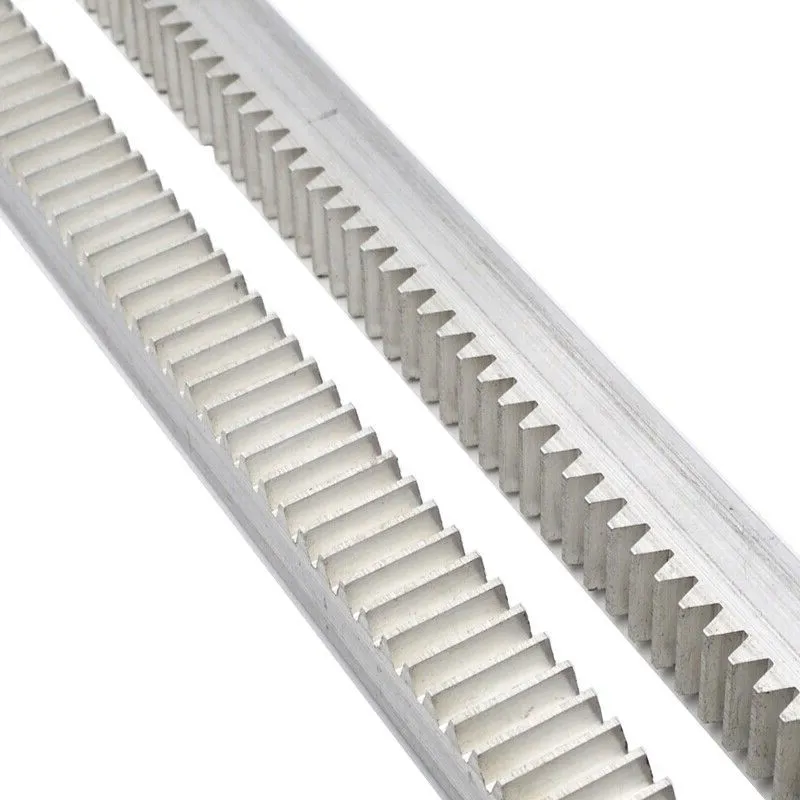

Aluminum gear racks are mechanical components designed to convert rotational motion into linear motion or vice versa, commonly used in machinery and automation systems. They consist of a straight bar or rail with evenly spaced teeth along its length, designed to mesh with a rotating spur gear. The aluminum construction provides a lightweight yet durable solution, offering excellent resistance to corrosion and wear, making it ideal for various industrial and outdoor applications.

Aluminum gear racks are mechanical components designed to convert rotational motion into linear motion or vice versa, commonly used in machinery and automation systems. They consist of a straight bar or rail with evenly spaced teeth along its length, designed to mesh with a rotating spur gear. The aluminum construction provides a lightweight yet durable solution, offering excellent resistance to corrosion and wear, making it ideal for various industrial and outdoor applications.

These aluminum spur gear racks are favored for their high strength-to-weight ratio and are often used in systems requiring precision, such as CNC machines, robotics, and conveyor systems. Aluminum spur gear racks are also easy to machine and install, and their smooth operation ensures minimal friction and noise. They are available in various sizes, tooth configurations, and lengths to meet specific application requirements.

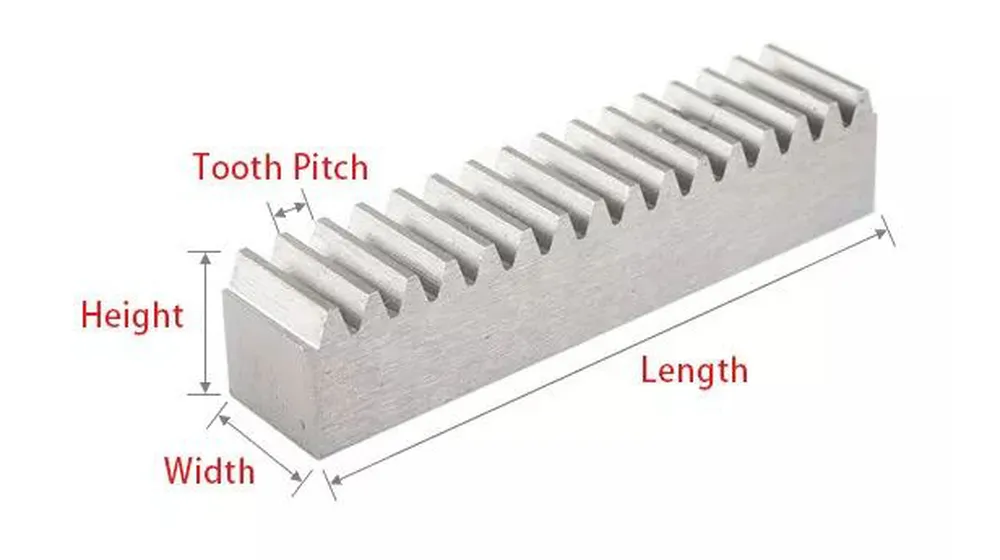

Aluminum Gear Rack Dimensions

| Model | Width | Height | Tooth Pitch | Tooth Depth |

| 1 Mod,10x10x1 Meter | 10 | 10 | 3.14 | 2.25 |

| 1 Mod,10x12x1 Meter | 10 | 12 | 3.14 | 2.25 |

| 1 Mod,10x15x1 Meter | 10 | 15 | 3.14 | 2.25 |

| 1 Mod,12x12x1 Meter | 12 | 12 | 3.14 | 2.25 |

| 1 Mod,15x15x1 Meter | 15 | 15 | 3.14 | 2.25 |

| 1 Mod,20x20x1 Meter | 20 | 20 | 3.14 | 2.25 |

| 1.5 Mod,15x15x1 Meter | 15 | 15 | 4.71 | 3.375 |

| 1.5 Mod,16x16x1 Meter | 16 | 16 | 4.71 | 3.375 |

| 1.5 Mod,15x20x1 Meter | 15 | 20 | 4.71 | 3.375 |

| 1.5 Mod,20x20x1 Meter | 15 | 20 | 4.71 | 3.375 |

| 2 Mod,20x20x1 Meter | 20 | 20 | 6.28 | 4.5 |

| 2 Mod,20x25x1 Meter | 20 | 25 | 6.28 | 4.5 |

| 2 Mod,25x25x1 Meter | 25 | 25 | 6.28 | 4.5 |

Aluminum Spur Gear Rack Design Features

1. Lightweight Construction

Aluminum spur gear racks are known for their lightweight properties, making them easy to handle and install. The reduced weight minimizes the overall load on machinery, improving efficiency and reducing energy consumption without compromising structural integrity or performance.

2. Corrosion Resistance

Aluminum's natural resistance to corrosion ensures the gear rack remains durable in challenging environments, such as exposure to moisture or chemicals. This feature makes it ideal for outdoor applications or industries requiring high hygiene standards, like food processing or medical equipment.

3. Precision Teeth Profiles

The teeth on aluminum spur gear racks are engineered with high precision to ensure smooth meshing with spur gears. This precision reduces friction, enhances accuracy, and ensures consistent performance in systems requiring exact motion control, such as robotics or automation.

4. Customizable Lengths and Sizes

Aluminum spur gear racks are available in various lengths, widths, and tooth configurations. This allows them to be tailored for specific applications, whether for compact machines or large-scale systems, making them highly versatile in industrial use.

5. High Strength-to-Weight Ratio

Despite being lightweight, aluminum gear racks offer excellent strength and rigidity. They can handle considerable loads and stresses while maintaining their structural integrity, making them suitable for heavy-duty applications without adding unnecessary bulk to the system.

6. Low Noise Operation

The smooth surface finish and precise manufacturing of aluminum spur gear racks help reduce noise during operation. This feature is particularly important in environments where reduced sound levels are critical, such as laboratories, offices, or residential automation systems.

Applications of Aluminum Gear Racks

- CNC Machinery

Aluminum gear racks are widely used in CNC machines to enable precise linear motion. Their lightweight yet durable construction ensures smooth and accurate movements, which are critical for cutting, milling, and engraving tasks requiring high precision and efficiency. - Robotics and Automation

In robotics, aluminum gear racks facilitate the controlled movement of robotic arms and platforms. Their precision teeth profiles ensure smooth operation and consistent motion control, making them essential for tasks like assembly, welding, or material handling in automated systems. - Conveyor Systems

Aluminum gear racks are used in conveyor systems to move items along production lines. Their corrosion resistance ensures durability in industrial settings, while their lightweight nature reduces energy consumption, enhancing the efficiency of material transport in factories or warehouses. - Aerospace Applications

Due to their high strength-to-weight ratio, aluminum gear racks are ideal for aerospace applications. They are used in mechanisms requiring linear motion, such as landing gear systems or cargo handling equipment, where weight reduction is critical for performance and fuel efficiency. - Medical Equipment

In medical devices like imaging machines or surgical equipment, spur gear racks provide precise and reliable linear motion. Their corrosion resistance and smooth operation ensure long-lasting performance in sterile environments, where hygiene and operational accuracy are essential. - Renewable Energy Systems

Aluminum gear racks are employed in solar tracking systems to adjust the position of solar panels for optimal sunlight exposure. Their lightweight design and corrosion resistance make them suitable for outdoor use, enhancing the efficiency and durability of solar energy installations.

|  |

| Gear Rack for CNC Machine Tool | Gear Rack for Automation and Robotics |

|  |

| Gear Rack for Medical Equipment | Gear Rack for Aerospace Systems |

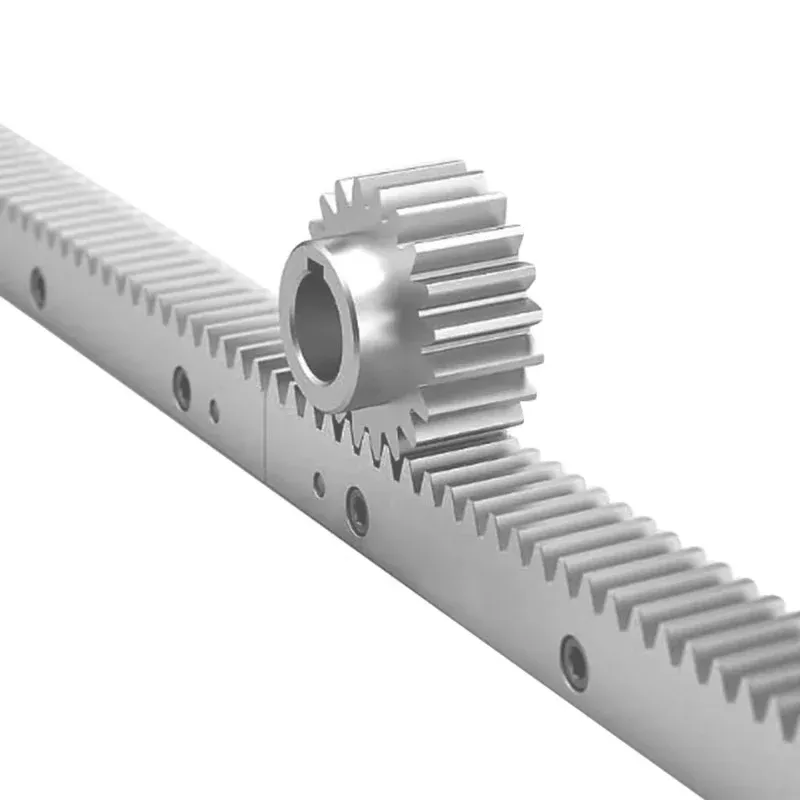

Aluminum Spur Gear Rack and Pinion

The aluminum spur gear rack and pinion system is a mechanical assembly designed to convert rotational motion into linear motion or vice versa, widely used in various industries for precision and efficiency. The system consists of two primary components: the gear rack, which is a straight bar with evenly spaced teeth along its length, and the pinion, a round gear that meshes with the rack. When the pinion rotates, it moves the rack in a straight line, or, conversely, when the rack moves, it rotates the pinion.

The use of aluminum in the rack provides several advantages, such as a lightweight design, excellent corrosion resistance, and high strength-to-weight ratio. These features make aluminum spur gear racks and pinions ideal for applications where weight reduction and durability are critical, such as in aerospace, robotics, and CNC machinery. The precision manufacturing of aluminum gear racks ensures accurate tooth profiles, which enable smooth engagement with the pinion. This guarantees minimal backlash and consistent motion, making the system suitable for high-precision tasks.

Furthermore, the aluminum spur gear rack and pinion system is highly customizable. It is available in various lengths, tooth sizes, and module configurations to meet specific application requirements. The aluminum construction also reduces noise and friction during operation, contributing to a quieter and more efficient system. Whether used for industrial automation, medical equipment, or renewable energy systems, this system offers a reliable and efficient solution for linear motion control.

Additional information

| Edited by | Yjx |

|---|