Industrial Vehicle Hydraulic Cylinders

Hydraulic cylinders play a pivotal role in industrial vehicles like truss arm crawler cranes, telescopic crawler cranes, truck cranes, small and large excavators, and rotary drilling rigs. These cylinders are critical components for converting hydraulic energy into mechanical force, enabling precise and powerful movements. They control lifting, lowering, extending, and retracting functions, ensuring stability, efficiency, and safety during heavy-duty operations. Their robust construction accommodates high loads, making them indispensable in construction, mining, and drilling applications.

Industrial Vehicle Hydraulic Cylinder for Sale

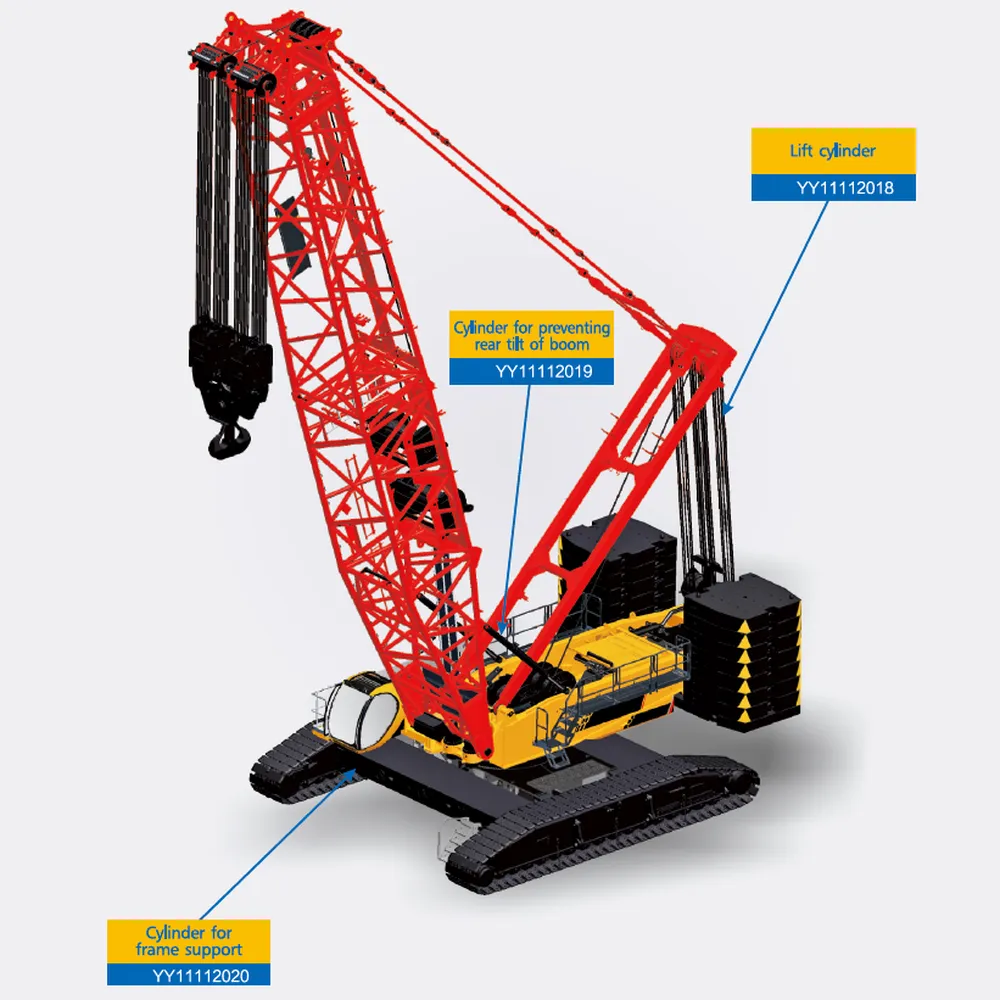

Truss Arm Crawler Crane Hydraulic Cylinders

- Pin Shaft Hydraulic Cylinder

- Spring Hydraulic Cylinder

- Oil Hydraulic Cylinder

- Power Pin Hydraulic Cylinder

- Arm Anti Backtilt Hydraulic Cylinder

- Support Hydraulic Cylinder

- Lift Hydraulic Cylinder

Telescopic Crawler Crane Hydraulic Cylinders

- Luffing Hydraulic Cylinder

Truck Crane Hydraulic Cylinders

- Counterweight Hydraulic Cylinder

- Luffing Hydraulic Cylinder

- Horizontal Hydraulic Cylinder

- Support Leg Hydraulic Cylinder

Small Excavator Hydraulic Cylinders

- Bucket Hydraulic Cylinder

- Boom Hydraulic Cylinder

- Stick Hydraulic Cylinder

- Bulldozing Hydraulic Cylinder

- Rotary Actuator Hydraulic Cylinder

Large Excavator Hydraulic Cylinders

- Bucket Hydraulic Cylinder

- Boom Hydraulic Cylinder

- Stick Hydraulic Cylinder

- Tightening Hydraulic Cylinder

Rotary Drilling Hydraulic Cylinders

- Luffing Hydraulic Cylinder

- Mast Hydraulic Cylinder

- Pressurized Hydraulic Cylinder

Industrial Vehicle Hydraulic Cylinder Types

-

Truss Arm Crawler Crane Hydraulic Cylinders

Truss arm crawler crane hydraulic cylinders provide stability and precise control by powering the movement of the crane’s arm. They ensure efficient lifting and lowering of heavy loads, enabling smooth and safe operations on uneven terrains. -

Telescopic Crawler Crane Hydraulic Cylinders

Telescopic crawler crane hydraulic cylinders support the extension and retraction of the crane’s telescopic boom. These cylinders enhance reach and flexibility, allowing the crane to handle heavy materials at varying heights with exceptional precision and reliability. -

Truck Crane Hydraulic Cylinders

Truck crane hydraulic cylinders facilitate the lifting, positioning, and stabilization of the crane during operation. They are essential for handling heavy loads while maintaining balance, ensuring safety in dynamic environments like construction or urban projects. -

Small Excavator Hydraulic Cylinders

Small excavator hydraulic cylinders control the movement of the bucket, arm, and boom. These cylinders provide the power and precision necessary for tasks like digging, trenching, and grading in confined spaces where maneuverability is critical. -

Large Excavator Hydraulic Cylinders

Large excavator hydraulic cylinders are designed for heavy-duty applications. They deliver immense force to handle tough tasks like breaking rock, moving earth, or demolishing structures, ensuring durability and efficiency for large-scale projects. -

Rotary Drilling Hydraulic Cylinders

Rotary drilling hydraulic cylinders enable precise positioning and forceful operation of the drilling rig. They support vertical and horizontal movements, ensuring accurate drilling in challenging soil or rock conditions for construction and mining purposes.

Hydraulic Cylinder for Crawler Crane

Hydraulic Cylinder for Truck Crane

The Importance of Hydraulic Cylinder for Crane

In cranes such as truss arm crawler cranes, telescopic crawler cranes, and truck cranes, hydraulic cylinders control the movement of the boom, arm, or other structural elements. They allow the crane to adjust its reach and angle, handle varying load capacities, and maintain stability even in challenging environments. For example, telescopic cylinders in telescopic cranes enable the extension and retraction of the boom, allowing the machine to reach greater heights while maintaining compactness when not in use.

Moreover, hydraulic cylinders are designed to handle immense pressure and loads, making them suitable for heavy-duty applications. Their durability ensures a long service life, even under extreme operating conditions. By providing smooth and precise operations, hydraulic cylinders improve the overall efficiency of cranes, reduce downtime, and enhance workplace safety, making them indispensable in industries such as construction, mining, and logistics.

The Role of Hydraulic Cylinder for Excavator

For small excavators, hydraulic cylinders provide the precision and flexibility needed for operations in confined spaces, such as urban construction, landscaping, and trenching. These cylinders enable smooth and accurate movements of the bucket and arm, allowing operators to perform detailed tasks like grading or digging small trenches with ease.

In large excavators, hydraulic cylinders are built to handle heavy-duty applications, such as mining, quarrying, and large-scale construction. These cylinders deliver immense force, enabling the machine to break through tough materials like rock or compacted soil. The boom cylinders lift the arm, the stick cylinders control the extension of the arm, and the bucket cylinders provide the power necessary for scooping or demolishing.

Hydraulic cylinders ensure that excavators operate efficiently and safely, regardless of the size or scope of the project. Their durability, high-pressure tolerance, and smooth performance make them indispensable for ensuring productivity in construction, mining, and earthmoving industries.

Industrial Vehicle Hydraulic Cylinder Parts

(1) Cylinder Barrel

The hydraulic cylinder barrel is the main body housing the piston and hydraulic fluid. Constructed from high-strength steel, it withstands extreme pressures during operation, ensuring structural integrity and reliable performance in industrial vehicles like cranes and excavators under heavy loads.

(2) Piston

The hydraulic cylinder piston divides the cylinder into chambers, converting hydraulic pressure into linear motion. Made from durable materials, it ensures smooth movement and force transmission, critical for precise operations in excavators and cranes during lifting or digging tasks.

(3) Seals

Seals prevent hydraulic fluid leaks and contamination, maintaining system efficiency. High-quality rubber or polyurethane seals ensure a tight fit, enduring high pressures and temperatures, supporting consistent performance in demanding construction environments.

(4) Piston Rod

The hydraulic cylinder piston rod extends from the piston to transfer force outside the cylinder. Crafted from hardened steel, it resists bending and wear, ensuring reliable motion in harsh conditions for vehicles like rotary drills and truck cranes.

(5) End Caps

Hydraulic cylinder end caps seal the cylinder barrel at both ends, guiding the piston rod and containing fluid pressure. Made from robust materials, they ensure structural stability and alignment, vital for smooth operation in cranes and excavators.

(6) Hydraulic Fluid Ports

Hydraulic fluid ports allow fluid entry and exit, enabling pressure transfer to move the piston. Precision-engineered for secure connections, they ensure efficient fluid flow, supporting reliable operation in heavy-duty vehicles like rotary drilling rigs.

Industrial Vehicle Hydraulic Cylinder Applications

- Construction Industry

Hydraulic cylinders in construction vehicles like excavators and cranes enable precise lifting, digging, and material handling. They provide the force needed for heavy-duty tasks, ensuring efficiency and safety on construction sites for buildings, roads, and infrastructure projects. - Mining Industry

In mining, hydraulic cylinders power large excavators and drilling rigs for extracting minerals. Their robust design handles extreme forces, enabling deep excavation and material transport in harsh environments, ensuring reliable performance in demanding mining operations. - Forestry Industry

Hydraulic cylinders in forestry equipment, such as log loaders and feller bunchers, facilitate tree cutting and handling. They deliver precise control and power for lifting heavy logs, ensuring efficient operations in rugged forest terrains with consistent reliability. - Agricultural Industry

Agricultural vehicles like tractors and harvesters use hydraulic cylinders for tasks like plowing and lifting. They provide smooth, powerful movements, enhancing productivity in planting, harvesting, and material handling across large-scale farming operations with precision. - Waste Management Industry

Hydraulic cylinders in waste management vehicles, such as garbage trucks and compactors, enable efficient material compression and handling. Their durability ensures reliable operation under high-pressure conditions, supporting effective waste collection and processing in urban environments. - Marine Industry

In marine applications, hydraulic cylinders power cranes and winches on ships and docks. They provide the strength for lifting heavy cargo, ensuring stable and precise movements in challenging marine environments, supporting port and offshore operations. - Oil and Gas Industry

Hydraulic cylinders in rotary drilling rigs and service vehicles drive drilling and equipment positioning in oil and gas exploration. They deliver high torque and stability, ensuring accurate and efficient operations in deep drilling under extreme conditions.

Hydraulic Cylinder for Excavator

Hydraulic Cylinder for Crane

Hydraulic Cylinder for Rotary Drilling

Hydraulic Cylinder for Grapple Bucket

Hydraulic Cylinder for Dump Trailer

Hydraulic Cylinder for Log Splitter

Choose the Right Hydraulic Cylinder for Crane

-

Rod Diameter

The rod diameter is a critical factor in selecting a hydraulic cylinder for a crane as it determines the cylinder’s strength and stability. A thicker rod can withstand higher loads and resist bending during heavy-duty operations. -

Bore Diameter

The bore diameter impacts the hydraulic cylinder’s power and force generation. A larger bore diameter allows for greater hydraulic fluid volume, enabling the cylinder to produce higher lifting and pushing forces for crane applications. -

Working Pressure

Working pressure defines the maximum hydraulic pressure the cylinder can handle. It is essential to select a cylinder with a pressure rating that matches or exceeds the operating pressure of the crane’s hydraulic system to ensure safety.

-

Installation Distance

The installation distance refers to the mounting space required for the hydraulic cylinder. Choosing a cylinder with the correct installation length ensures proper fitment and alignment with the crane’s structural components, preventing mechanical stress or misalignment. -

Stroke Length

The stroke length determines the maximum range of movement the hydraulic cylinder can achieve. For cranes, selecting an appropriate stroke length ensures the boom or arm can extend and retract as required for operational tasks. -

Thrust Force

Thrust force is the cylinder’s ability to push or pull loads, which depends on bore diameter and working pressure. Selecting a cylinder with sufficient thrust force ensures the crane can lift and maneuver heavy loads safely and efficiently.

Custom Hydraulic Cylinders

As a leading industrial vehicle hydraulic cylinder manufacturer and supplier, we are dedicated to providing premium-quality, custom solutions designed to meet the unique requirements of various industrial vehicles. Our hydraulic cylinders are expertly engineered for seamless integration with diverse vehicle models, ensuring superior performance, exceptional durability, and reliability under the most demanding conditions. Utilizing advanced manufacturing processes and high-grade materials, we deliver products that guarantee precise functionality, smooth operation, and extended service life. Whether for construction, mining, agriculture, or logistics, our tailored hydraulic cylinder solutions are built to excel. Contact us today to discuss your specific needs and receive a personalized quotation!

Our Customer Reviews

—–Italian Customer

—–German Customer

—–Australian Customerr

“These excavator hydraulic cylinders exceeded our expectations. We’ve used them in tough construction environments, and their performance has been flawless. The durability and smooth operation have noticeably improved our productivity, and the customer support team was incredibly responsive and helpful.”

—–American Customer

—–British Customer

—–Brazilian Customer

—–Korean Customer

—–Canadian Customer

—–Russian Customer