Gear Racks

A gear rack is a type of gear on which gear teeth are cut on one face of a bar. The bar can be square, round or rectangular in cross section and the teeth can be either parallel to the base or set at an angle. They are a simple and common type of element in mechanical drive systems and are always paired with a pinion. Gear rack and pinion are used for lifting mechanisms (vertical movement), horizontal movement, positioning mechanisms, stoppers, and to permit the synchronous rotation of several shafts in general industrial machinery.

Types of Gear Racks for Sale

Spur Gear Rack

Helical Gear Rack

Round Gear Rack

Curved Gear Rack

Gear Rack Material Optional

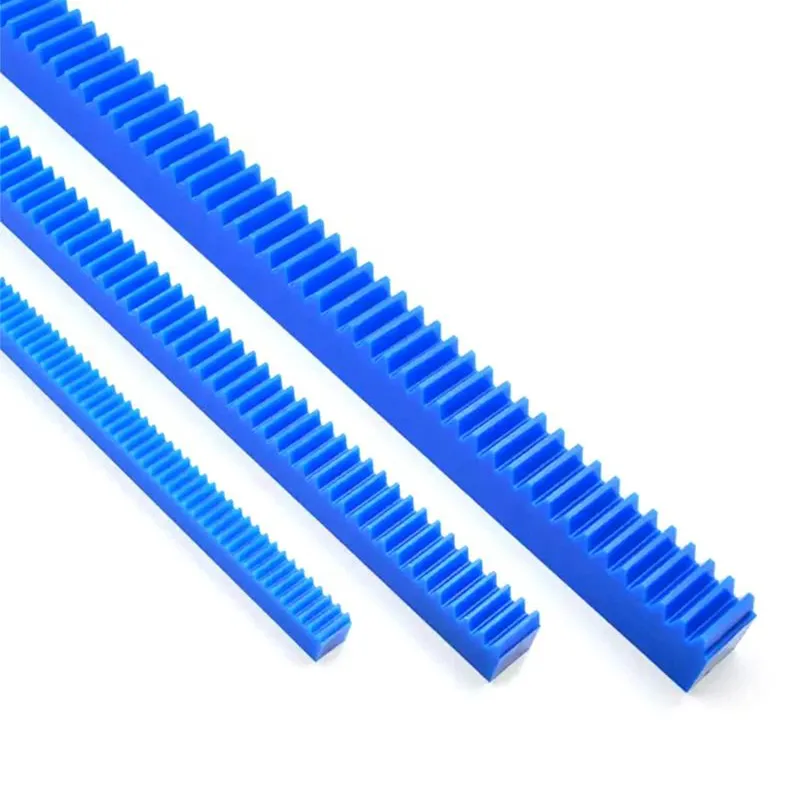

Plastic Gear Rack

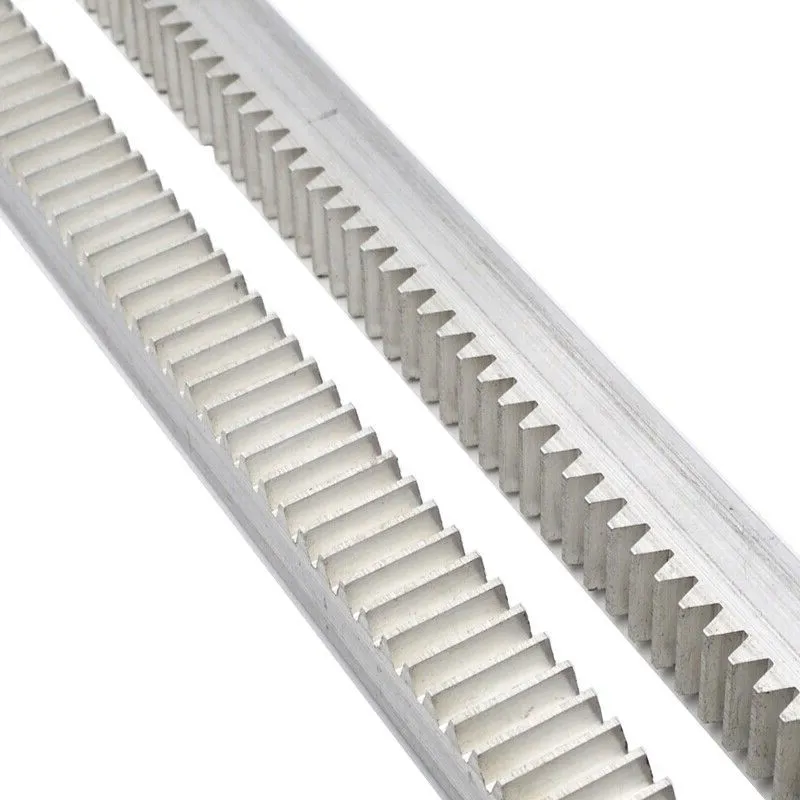

Aluminum Gear Rack

Stainless Steel Gear Rack

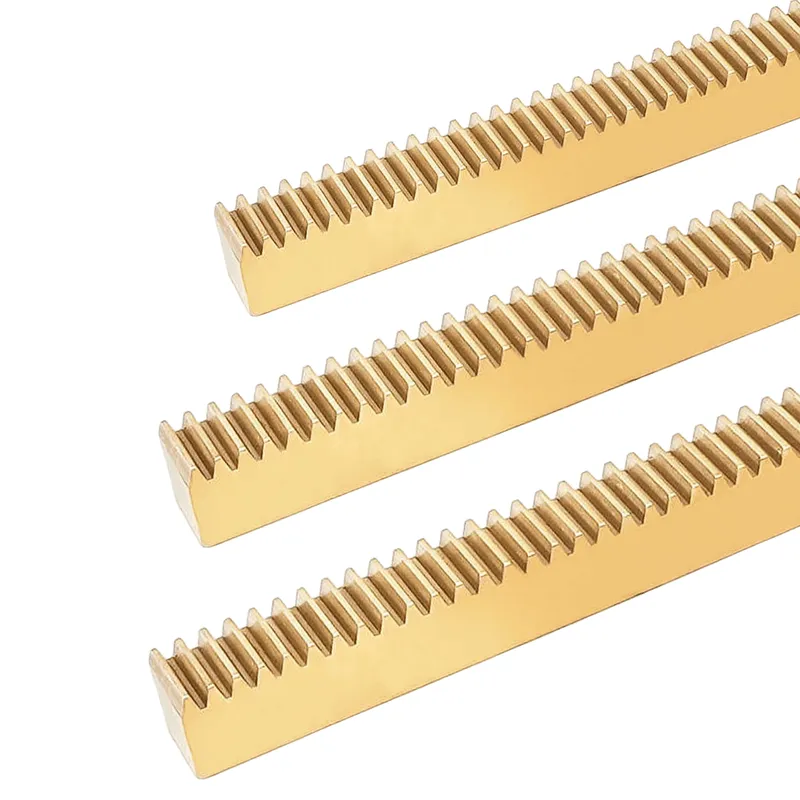

Brass Gear Rack

Steel Gear Rack

Gear Rack for Different Applications

Steel Gear Rack for Sliding Gate

Curved Gear Rack for Open Window Ventilation System

Gear Rack for Construction Hoist

Gear Rack for CNC Machine Tools

What Is a Gear Rack?

CMN Transmission has its own factory to produce gear racks and can provide a variety of different gear racks and pinions. Not only does it have a variety of gear rack inventories, but it can also produce custom gear racks and gears according to customer drawings.

Gear Rack Design Features

(1) High Precision:

Due to the unidirectional motion of the rack, friction loss is small and position control precision is high. The gear teeth on the rack can mesh with the gears in the mechanical device to achieve precise positioning and control.

(2) Large Transmission Power:

The rack can withstand movement with a certain impact load, cooperate with the gear, and transmit power through the gear drive. At the same time, it can also realize movement through its own movement.

(3) Smooth Movement:

The meshing method of the gear rack makes it run smoothly, and the phenomenon of jumping is rarely caused. The change in speed will not affect its performance.

(4) Low Noise:

The surface finish is high, which can effectively reduce noise and ensure quiet operation, which can meet the low noise requirements of machine operation. The gear rack is reliable in operation and has a long service life. It does not require regular maintenance and replacement.

(5) Simple Structure:

The structure of the rack is relatively simple, the process is easy to grasp, and the manufacturing cost is relatively low. At the same time, the shape and size of the rack are relatively stable, which is easy for batch production and processing.

(6) Wide Application:

Gear racks are widely used in various mechanical devices, such as CNC machine tools, lifting equipment, iron and steel metallurgy equipment, numerical control machine tools, laser cutting machines, and other equipment

Gear Rack and Pinion Applications

Automation and Robotics: Gear racks and pinions are essential in automation and robotics for precise linear motion control. They enable robotic arms, conveyors, and automated assembly systems to perform accurate, repetitive tasks efficiently in industrial environments.

CNC Machine Tools: In CNC machine tools, gear racks help achieve precise linear positioning of cutting tools or workpieces. They ensure high accuracy and consistency, vital for producing complex components in industries like aerospace, automotive, and manufacturing.

Automotive Systems: Gear racks are widely used in automotive steering systems, specifically in rack-and-pinion mechanisms. They help convert the rotary motion of the steering wheel into linear motion, offering precise control and responsive handling.

Construction and Heavy Machinery: Construction hoists, cranes, and heavy machinery rely on gear racks for lifting and positioning heavy loads. Their ability to handle high weights with accuracy makes them indispensable in demanding construction environments.

Material Handling: In material handling systems, gear racks are used in conveyors, automated storage, and retrieval systems. They ensure smooth and efficient movement of goods, enhancing productivity in warehouses and distribution centers.

Elevators and Lifts: Gear racks are crucial in elevators and vertical lifts, particularly rack-and-pinion systems. They provide stable, reliable motion for transporting people or materials, ensuring safety and efficiency in vertical applications.

Packaging Machines: In packaging machinery, gear racks ensure precise motion for cutting, sealing, and forming operations. They contribute to high-speed production lines while maintaining accuracy and consistency, essential for packaging quality.

Rail Systems: Gear racks are used in cog railways for climbing steep gradients. They provide traction and stability, enabling trains to safely ascend and descend slopes in mountainous or challenging terrains.

Printing and Textile Machinery: Printing presses and textile machines use gear racks for accurate positioning of components. This ensures precise printing and fabric handling, enhancing production quality and efficiency in these industries.

Aerospace Industry: In aerospace, gear racks and pinions are used in actuators for precise motion control. They are critical for adjusting components like wing flaps, landing gear, and other mechanisms requiring reliability and precision.

Sliding Gates and Automatic Doors: Gear racks are integral to sliding gates and automatic doors, providing smooth and controlled linear motion. They ensure secure operation, durability, and efficiency in residential, commercial, and industrial settings.

Open Window Ventilation Systems: In open window ventilation systems, gear racks enable automatic opening and closing of windows. They ensure smooth and controlled motion, improving energy efficiency and ventilation in residential and commercial buildings.

Automation and Robotics

CNC Machine Tools

Construction Hoist Machinery

Open Window Ventilation Systems

Sliding Gate Openers

Material Handling

Automotive Systems

Elevators and Lifts

Packaging Machines

Why Choose CMN’s Gear Racks?

- High-Quality Materials

CMN’s gear racks are manufactured using premium materials like steel, stainless steel, aluminum, and plastic. This ensures durability, corrosion resistance, and optimal performance across a wide range of industrial and commercial applications. - Precision Engineering

CMN’s gear racks are precisely engineered to deliver accurate and smooth motion. Their advanced manufacturing processes guarantee perfect tooth alignment and minimal backlash, making them ideal for high-precision systems like CNC machines and robotics. - Wide Range of Options

CMN offers a diverse selection of gear racks, including spur, helical, round, and curved designs. Customers can choose from various lengths, sizes, and materials to suit specific requirements and applications. - Customizable Solutions

CMN provides tailored gear rack system solutions to meet unique customer needs. From special coatings and specific dimensions to custom teeth profiles, their team ensures every product fits the intended application perfectly. - Reliable Performance

CMN’s gear racks are built for long-term, dependable performance under demanding conditions. They are tested for high load capacities, wear resistance, and consistent operation, making them trusted by industries worldwide. - Expert Support and Service

CMN offers exceptional customer service, including technical assistance and after-sales support. Their team of experts helps clients select the best gear rack for their application and ensures a seamless purchasing experience.

Custom Gear Racks

As a leading gear rack manufacturer and supplier, we excel in providing premium-quality, custom gear rack solutions designed to meet the unique needs of diverse industries. Our custom gear racks are crafted with precision, using high-grade materials like steel, aluminum, and plastic to ensure durability and performance. Whether you require specific dimensions, teeth profiles, or materials, we deliver tailored solutions that fit your exact application. Contact us today to discuss your specific requirements and receive a personalized quotation for your project!

Our Customer Reviews

–Italian Customer

–American Customer

–Canadian Customer

–British Customer

“The gear rack and pinions we purchased are perfect for our robotic systems. Their precision engineering ensures smooth and accurate movement, which is critical for our operations. Maintenance has been minimal, and the racks show no signs of wear even after extensive use.”

–Korean Customer

“We integrated these gear racks into our construction hoists, and they’ve performed brilliantly. They handle heavy loads with ease and provide consistent motion. The quality is evident, and they’ve significantly improved safety and reliability in our operations. ”

–Australian Customer

–German Customer

–Brazilian Customer

–Russian Customer