Garbage Truck Hydraulic Cylinders

Garbage truck hydraulic cylinders play a pivotal role in the functionality of sanitation machinery by providing the immense force required for lifting, compacting, and unloading waste. These cylinders convert hydraulic energy into mechanical motion, enabling the efficient operation of components such as the lifting arms, compactor plates, and tailgates. Their robust construction ensures durability and reliability, making them essential for handling heavy loads and improving waste management efficiency.

Garbage Truck Hydraulic Cylinders for Sale

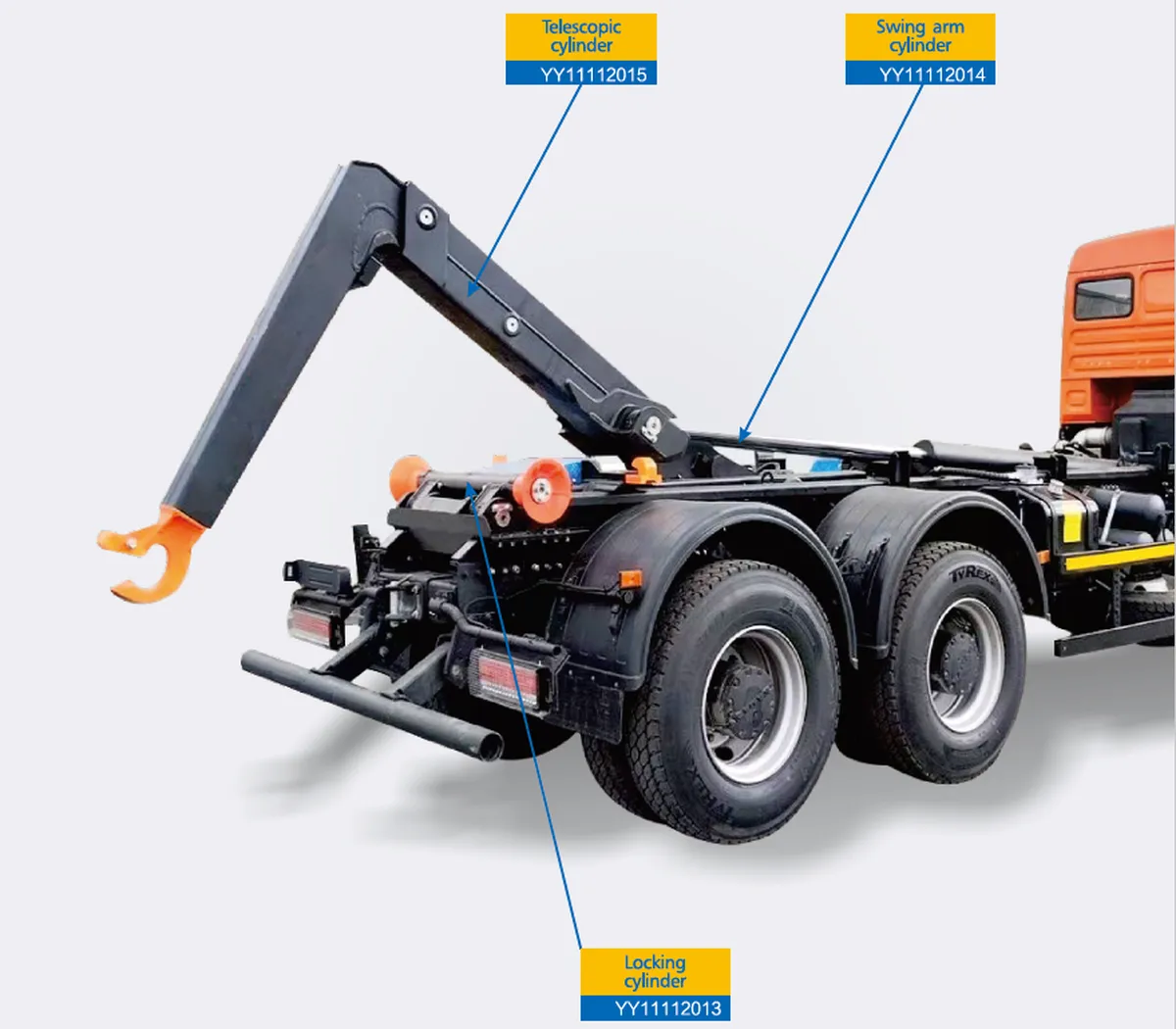

Hook Arm Lift Garbage Truck Hydraulic Cylinders

- Locking Hydraulic Cylinders

- Swing Arm Hydraulic Cylinders

- Telescopic Hydraulic Cylinders

Garbage Crane Grab Bucket Hydraulic Cylinders

- Grab Bucket Hydraulic Cylinders

Garbage Truck Hydraulic Cylinder Types

- Locking Hydraulic Cylinders

Locking hydraulic cylinders are designed to securely hold loads in place during waste collection and transportation. They prevent unintended movement by locking the piston rod in a fixed position. This type of cylinder is critical for safety, especially when garbage trucks are stationary but still handling heavy loads. Their reliability ensures stable operation even under high-pressure conditions. - Swing Arm Hydraulic Cylinders

Swing arm hydraulic cylinders are specifically designed to control the swinging motion of arms used for lifting and dumping waste bins. These cylinders provide precise movements, ensuring efficiency during waste collection. They are highly durable to withstand repeated use and the stresses of lifting heavy bins. Their smooth operation helps minimize wear and tear in the machinery. - Telescopic Hydraulic Cylinders

Telescopic hydraulic cylinders have a multi-stage design that provides an extended reach while maintaining a compact size when retracted. They are primarily used for ejecting or tipping large loads from garbage trucks. The telescopic mechanism allows for maximum stroke length, making them ideal for high-capacity vehicles. Their sturdy construction ensures they perform effectively even with frequent operations.

Hydraulic Cylinder for Hook Lift Garbage Truck

Hydraulic cylinders are the backbone of hook lift garbage trucks, enabling efficient and reliable waste collection. These trucks rely on hydraulic cylinders to power the hook arm mechanism, which lifts and secures large waste containers for transport and disposal. The cylinders convert hydraulic fluid pressure into linear motion, providing the force needed to handle heavy containers, often weighing several tons, with precision and control. This capability ensures seamless loading and unloading, critical for maintaining tight schedules in municipal waste management.

The hook arm lift system depends on robust hydraulic cylinders to execute smooth, controlled movements. These cylinders are designed to withstand high pressures and repetitive cycles, enduring the harsh conditions of waste handling, including exposure to debris, moisture, and temperature fluctuations. Their durability minimizes downtime, ensuring trucks remain operational and cost-effective. Additionally, hydraulic cylinders allow for precise positioning of the hook arm, enabling operators to align and secure containers accurately, reducing the risk of accidents or damage.

Regular maintenance of hydraulic cylinders, such as checking seals, fluid levels, and connections, is vital to prevent leaks and ensure optimal performance. Advanced designs may incorporate features like corrosion-resistant coatings or self-lubricating components to extend service life. By providing the power and reliability needed for heavy-duty tasks, hydraulic cylinders enhance the efficiency of hook arm lift garbage trucks, supporting cleaner communities and sustainable waste management.

Garbage Truck Hydraulic Cylinder Components

(1) Cylinder Barrel

The hydraulic cylinder barrel is a robust tube housing the piston and hydraulic fluid. It withstands high internal pressures during garbage truck operations. Constructed from durable steel, it ensures structural integrity for compaction and lifting tasks in harsh sanitation environments.

(2) Piston

The hydraulic cylinder piston is a vital moving component inside the cylinder barrel that separates the hydraulic fluid chambers. It transfers the hydraulic force to the piston rod, enabling the cylinder to perform its lifting or pushing functions. The piston must be precisely machined to ensure a tight seal and efficient operation.

(3) Piston Rod

The hydraulic cylinder piston rod extends externally from the cylinder and connects to the garbage truck’s mechanical components, such as the hook arm or compactor. It transfers the force generated by the piston to perform lifting or movement tasks. The rod is made from high-strength materials to resist bending, corrosion, and wear.

(4) Seals and O-Rings

Hydraulic cylinder seals and O-rings are crucial for maintaining the hydraulic system’s fluid containment and pressure. They prevent leaks and contamination inside the cylinder, ensuring optimal performance and longevity. High-quality seals also reduce wear and tear on moving parts.

(5) End Caps

Hydraulic cylinder end caps are mounted on both ends of the cylinder barrel to secure the internal components and provide mounting points for the cylinder. They are designed to handle the high-pressure environment and maintain structural integrity during heavy-duty operations.

(5) Hydraulic Ports

Hydraulic ports allow the entry and exit of hydraulic fluid into the cylinder, enabling the movement of the piston. Properly designed ports ensure efficient fluid flow, minimizing energy loss and enhancing the cylinder’s overall performance during waste handling tasks.

Garbage Truck Hydraulic Cylinder Applications

-

Waste Collection and Transportation

Hydraulic cylinders are extensively used in garbage trucks for lifting and compacting waste materials. They enable efficient movement of bins and containers, making waste collection faster and more reliable. Their robust design ensures smooth operation even with heavy and irregularly shaped loads, enhancing overall productivity in waste management. -

Compaction Mechanisms

Garbage trucks rely on hydraulic cylinders for compacting waste inside the truck’s storage compartment. The cylinders provide the force required to compress large volumes of waste into smaller, denser forms. This process increases the truck’s load capacity, reducing the frequency of trips to disposal sites and improving operational efficiency. -

Hook Lift Systems

Hook lift garbage trucks use hydraulic cylinders to lift and secure heavy containers onto the truck bed. The cylinders provide the strength and precision needed to handle large containers, ensuring safe and efficient operations. Their reliability is essential for managing diverse waste collection needs across urban and industrial areas. -

Rear-Loader Garbage Trucks

In rear-loader garbage trucks, hydraulic cylinders operate the lifting and tipping mechanisms for waste bins. They enable smooth and controlled movements, ensuring proper handling of bins without causing damage. These systems are crucial for residential and commercial waste collection tasks. -

Side-Loader Garbage Trucks

Side-loader garbage trucks use hydraulic cylinders to power the automated arms that lift and empty bins into the truck. These cylinders allow for precise and repetitive operations, making the trucks ideal for high-efficiency, single-operator waste collection routes. -

Landfill Operations

Hydraulic cylinders are also used in landfill operations, where specialized garbage trucks unload compacted waste. Cylinders operate the tipping mechanisms that eject waste from the truck, ensuring effective and consistent unloading. Their durability is essential for handling harsh landfill environments.

Hydraulic Cylinder for Hook Lift Trucks

Hydraulic Cylinder for Waste Collection

Hydraulic Cylinder for Rear-Loader Garbage Trucks

Hydraulic Cylinder for Side-Loader Garbage Trucks

Select a Hydraulic Cylinder for Garbage Truck

-

Bore Diameter

The bore diameter determines the cylinder’s force output, as it influences the internal pressure and hydraulic power. A larger bore diameter provides greater lifting or compressing force, essential for handling heavy waste loads. Selecting the right bore size ensures efficient operation without overloading the hydraulic system or compromising performance. -

Rod Diameter

The rod diameter affects the cylinder’s ability to handle mechanical stress and resist bending during operation. A properly sized rod ensures durability and stability under high-pressure conditions. Choosing the correct rod diameter prevents premature wear, enhances reliability, and guarantees smooth operation when lifting or compacting waste materials. -

Installation Distance

The installation distance refers to the space between the mounting points of the hydraulic cylinder. It must match the garbage truck’s design to ensure proper alignment and functionality. Incorrect installation distances can cause misalignment, reduced efficiency, and mechanical strain, leading to potential operational failures.

- Working Pressure

The hydraulic cylinder working pressure indicates the maximum hydraulic force the cylinder can safely handle. It must align with the garbage truck’s hydraulic system specifications. Choosing a cylinder with the correct pressure rating ensures optimal performance, prevents leaks, and avoids damage to other components. - Stroke Length

The hydraulic cylinder stroke length determines the cylinder’s range of motion, influencing how far it can extend or retract. The stroke length must match the specific operational requirements of the garbage truck, such as lifting arms or compaction plates. A properly sized stroke ensures smooth and precise movements. - Seal and Material

The quality of hydraulic cylinder seals and construction materials determines the cylinder’s durability and resistance to wear, corrosion, and high temperatures. Selecting cylinders with high-grade seals and materials ensures longevity, reduces maintenance needs, and enhances performance in demanding waste-handling environments.

Custom Hydraulic Cylinders for Your Needs

As a leading garbage truck hydraulic cylinder manufacturer and supplier, we are committed to delivering premium-quality, custom solutions tailored to the specific requirements of various garbage trucks. Our hydraulic cylinders are meticulously engineered to ensure seamless compatibility, offering optimal performance, exceptional durability, and unmatched reliability even under the most demanding conditions. Utilizing advanced manufacturing techniques and high-grade materials, we guarantee precision functionality and long service life. Contact us today for custom hydraulic cylinder solutions and receive a personalized quotation tailored to your unique needs!

Our Customer Reviews

—–American Customer

—–Italian Customer

—–Korean Customer

—–German Customer

—–British Customer

—–Canadian Customer

—–Australian Customer

—–Brazilian Customer

—–Russian Customer