Forklift Hydraulic Cylinders

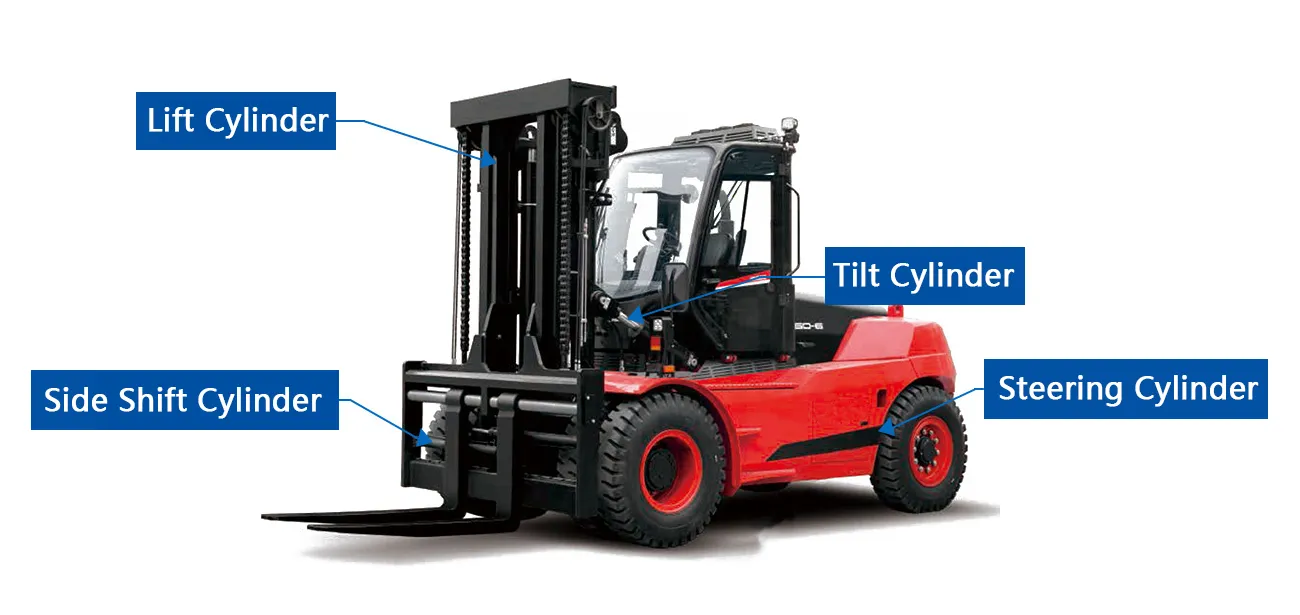

Forklift hydraulic cylinders are critical components of a forklift’s hydraulic system, responsible for generating the force required to lift, lower, tilt, or move loads. These cylinders use pressurized hydraulic fluid to transfer energy, converting it into mechanical motion. Commonly found in the mast, tilt, or steering systems, they ensure precise control, high load capacity, and efficient operation, making them essential for material handling in industrial settings.

Forklift Hydraulic Cylinder Types

Forklift hydraulic cylinders are essential components that power the lifting, tilting, and moving mechanisms of forklifts. There are several types, each designed for specific applications:

- Small Tonnage Forklift Hydraulic Cylinders: These are compact cylinders used in light-duty forklifts, ideal for applications requiring less lifting capacity. They provide precise control and efficient performance for handling lighter loads in smaller spaces.

- Large Tonnage Forklift Hydraulic Cylinders: Built for heavy-duty forklifts, these cylinders can handle substantial weights and are used in industrial and construction environments. They are robust, durable, and designed to lift and maneuver heavy loads efficiently.

- Warehouse Storage Forklift Hydraulic Cylinders: These cylinders are specialized for forklifts used in warehouses, where vertical lifting and stacking are crucial. They ensure smooth operation and precise positioning, allowing for efficient storage and retrieval of goods.

- Pallet Stacker Truck Hydraulic Cylinders: Found in pallet stackers, these cylinders are tailored for low-lift applications, such as stacking and transporting pallets. They are compact yet powerful, offering excellent maneuverability in tight warehouse spaces.

- Forward Moving Forklift Hydraulic Cylinders: These cylinders enable forward motion and tilting, crucial for forklifts that require extended reach or load dumping. They are designed for strength and stability, ensuring safe operation during forward movement tasks.

Small Tonnage Forklift Hydraulic Cylinders

Large Tonnage Forklift Hydraulic Cylinders

Warehouse Storage Forklift Hydraulic Cylinders

Pallet Stacker Truck Hydraulic Cylinders

Forward Moving Forklift Hydraulic Cylinders

Hydraulic Cylinder for Forklift

- Lift Hydraulic Cylinders: These forklift hydraulic lift cylinders are responsible for raising and lowering the forklift’s mast, allowing it to lift and stack loads at various heights. They play a crucial role in vertical load handling and are built to withstand high pressures.

- Tilt Hydraulic Cylinders: These forklift hydraulic tilt cylinders allow the forklift mast to tilt forward or backward. This tilting action ensures safe handling of loads by stabilizing them during transport and enabling easier placement or retrieval.

- Steering Hydraulic Cylinders: These forklift hydraulic steering cylinders control the directional movement of the forklift by assisting in steering. They provide smooth and precise maneuverability, especially in tight spaces.

Together, these hydraulic cylinders ensure the forklift operates efficiently, safely, and reliably, making them indispensable for material handling tasks.

Forklift Hydraulic Cylinder Parts

- Cylinder Barrel

The cylinder barrel is the main housing where hydraulic fluid is pressurized. It contains the piston and ensures smooth movement. Made from durable materials, it withstands high pressures and prevents leakage or deformation during operation. - Piston

The piston is a critical internal component that separates the hydraulic fluid chambers inside the barrel. It transfers hydraulic pressure into mechanical force, enabling the cylinder to push, pull, or lift loads effectively. - Piston Rod

The piston rod extends from the cylinder and connects to the load or other machinery parts. It transmits the force generated by the piston and is designed to handle heavy stresses and bending forces. - Seals

Hydraulic cylinder seals prevent fluid leakage and maintain pressure within the cylinder. They also protect the internal components from contaminants like dirt or debris, ensuring the cylinder operates efficiently and lasts longer. - End Caps (Head and Base)

End caps are located at both ends of the cylinder barrel. They enclose the cylinder, maintain hydraulic pressure, and house seals or bushings for added protection and stability during cylinder operation. - Hydraulic Ports

These are entry and exit points for hydraulic fluid. The ports allow the fluid to flow in and out of the cylinder, enabling the creation of pressure that drives the piston’s movement.

Forklift Hydraulic Cylinder Diagram

How Does the Forklift Hydraulic Lift Cylinder Work

The forklift hydraulic lift cylinder is a pivotal component responsible for raising and lowering the forklift’s mast to handle loads efficiently. Operating within a hydraulic system, it converts pressurized hydraulic fluid into linear mechanical force, enabling precise vertical movement of heavy loads in warehouses and industrial settings.

The lift cylinder is typically a double-acting hydraulic cylinder, consisting of a steel barrel, a piston, a piston rod, seals, and hydraulic ports. The process begins when the forklift operator engages the lift control, signaling the hydraulic pump to draw fluid from a reservoir and pressurize it. This pressurized fluid is directed through hoses to the cylinder’s base port, entering the chamber below the piston. As the fluid fills this chamber, it exerts force on the piston, pushing it upward. The piston rod, attached to the piston, extends and raises the forklift’s mast, which is connected to the forks carrying the load.

To lower the load, the operator adjusts the control valve, allowing fluid to exit the cylinder’s base chamber and return to the reservoir. Gravity assists the descent, while fluid may enter the rod-side chamber through a second port to control the retraction speed, ensuring smooth and safe lowering. Seals around the piston and rod prevent fluid leaks, maintaining system efficiency. The cylinder’s robust construction withstands high pressures and repetitive cycles, ensuring reliability. By precisely translating hydraulic energy into motion, the lift cylinder enables forklifts to lift loads weighing thousands of pounds with ease and accuracy, optimizing material handling operations.

Custom Hydraulic Cylinder for Forklifts

As a leading forklift hydraulic cylinder manufacturer and supplier, we provide a comprehensive range of high-quality forklift hydraulic cylinder products designed to meet the needs of various forklift models. Our forklift hydraulic cylinder replacements are compatible with top forklift brands, including Caterpillar forklift hydraulic cylinders, Clark forklift hydraulic cylinders, Hyster forklift hydraulic cylinders, Komatsu forklift hydraulic cylinders, Toyota forklift hydraulic cylinders, Nissan forklift hydraulic cylinders, Yale forklift hydraulic cylinders, etc. Each hydraulic cylinder is engineered for perfect compatibility, delivering superior performance, durability, and reliability. Contact us today for a personalized quotation!

Applications of Forklift Hydraulic Cylinders

- Warehouse Material Handling

Forklift hydraulic cylinders enable precise lifting and stacking of pallets in warehouses. They power the mast to elevate heavy goods to high shelves, optimizing storage space and streamlining inventory management for efficient logistics operations. - Construction Site Operations

In construction, hydraulic cylinders lift and position heavy materials like steel beams or concrete blocks. Their robust design ensures reliable performance under rugged conditions, facilitating safe and efficient material transport across uneven terrain. - Manufacturing and Assembly Lines

Hydraulic cylinders in forklifts support manufacturing by moving raw materials and finished products. They enable precise positioning for assembly processes, ensuring smooth workflow and reducing manual handling in high-volume production environments. - Shipping and Logistics

Forklift cylinders are critical in loading and unloading cargo from trucks and containers. They provide the force needed to handle heavy shipments, ensuring quick turnaround times and efficient operations in ports and distribution centers. - Container Handling

Forklift hydraulic cylinders are widely used in ports and shipping yards for handling large containers. They ensure the safe lifting, tilting, and stacking of containers, accommodating the heavy-duty requirements of cargo transportation and storage. - Agricultural Product Handling

In agriculture, forklift cylinders lift and transport heavy produce like crates of fruit or grain sacks. Their durability ensures reliable operation in dusty or outdoor environments, aiding efficient handling during harvest or storage processes.

Warehouse Material Handling

Container Handling

Construction Industry

Agricultural Industry

Our Customer Reviews

—–United Kingdom Customer

—–Australian Customer

“These forklift hydraulic cylinders are robust and reliable. We operate in a high-demand logistics facility, and they’ve consistently performed well without failure. Maintenance is straightforward, saving us time and costs. The build quality is impressive, and the durability ensures long-term use even in a high-pressure environment. The CMN Transmission’s cylinders operate smoothly, minimizing downtime in our operations. The support team is highly responsive and provides thorough guidance whenever required.”

—–German Customer

—– Italian Customer

—–Canadian Customer

—– United States Customer