Belt Conveyor for Mining Industry

A belt conveyor for the mining industry is a continuous material handling system designed to transport bulk materials, such as ores, coal, and aggregates, over long distances or varying terrains. It consists of a continuous loop of durable rubber or fabric belt, driven by pulleys and supported by rollers, capable of handling high volumes and harsh conditions.

Mining Belt Conveyor for Sale

Types of Belt Conveyor in Mining

-

Universal Belt Conveyor

The universal belt conveyor is a versatile system used in various mining applications. It is designed for general material handling, capable of transporting materials horizontally or at slight inclines. Its adaptability makes it suitable for transporting bulk materials like coal, ore, or gravel, and it can be customized to meet specific operational requirements, including different belt widths and load capacities. -

Fixed Belt Conveyor

A fixed belt conveyor is a permanent installation primarily used in large-scale mining operations. It is designed to handle high volumes of material over long distances. This conveyor is highly durable and ideal for continuous operation in harsh conditions, such as surface mining. Its rigid framework ensures stability, and it is often installed to connect different processing stages or transport materials to stockpiles. -

High Angle Edge Conveyor

The high angle edge conveyor is specially designed for handling materials at steep inclines, often reaching angles up to 90 degrees. It uses sidewalls and cleats to prevent material spillage during transport. This system is ideal for maximizing space efficiency in mining operations with limited room. It is commonly used to transfer materials from underground to surface levels or in vertical transport systems. -

Mobile Belt Conveyor

The mobile belt conveyor is a portable system designed for easy relocation within mining sites. It is equipped with wheels or tracks, allowing it to be moved as operations shift. This conveyor is highly flexible, suitable for temporary material handling tasks, and often used in open-pit mining for transferring materials to trucks or processing equipment. Its mobility reduces setup time and enhances operational efficiency. -

Screw Conveyor

A screw conveyor is a specialized system used for transporting fine or powdered materials in mining, such as sand, cement, or crushed ore. It operates by rotating a helical screw blade within a tube, moving materials in a controlled manner. This conveyor is ideal for handling materials in confined spaces or under specific conditions, such as moisture-sensitive or abrasive substances. It is often used in processing plants or underground mining.

Mobile Belt Conveyor for Mining Industry

Fixed Belt Conveyor for Mining Industry

Why Choose CMN’s Mining Belt Conveyor?

As a professional belt conveyor manufacturer and supplier, CMN is dedicated to delivering high-quality, high-performance belt conveyor solutions tailored to meet the unique demands of the mining industry. Our commitment to excellence is backed by cutting-edge production equipment and a team of experienced technical experts, ensuring that every belt conveyor we produce meets international standards and exceeds customer expectations.

Our product line is comprehensive, covering a wide range of conveyors designed for various mining applications. From rubber belt conveyors for mining, ideal for bulk material handling, to rolling belt conveyors engineered for continuous, large-scale material transport, we have the right solutions for every need. We also offer advanced mobile belt conveyors with wheels, providing unmatched flexibility and ease of movement for mining operations that require frequent relocation.

At CMN, we understand the specific challenges faced by the mining industry, such as harsh operating environments, heavy loads, and the need for reliable systems to minimize downtime. That’s why our belt conveyors are designed with durability, efficiency, and versatility in mind. Whether it’s for open-pit mining, underground operations, or material transport between processing plants, our equipment is built to perform in the most demanding scenarios.

Choosing CMN means partnering with a trusted belt conveyor supplier that prioritizes quality, innovation, and customer satisfaction to optimize your mining operations and material handling efficiency.

Belt Conveyor Design and Structure

Mining belt conveyors are engineered to handle the rigors of transporting heavy and abrasive materials over long distances. The design and construction of these conveyors are critical to their efficiency and durability.

(1) Framework

The conveyor structure typically consists of a series of metal frames or trusses that support the entire system. These frames are designed to withstand heavy loads and are usually made from robust materials like steel to provide stability and durability.

(2) Belt

The conveyor belt itself is a continuous loop made from materials such as rubber, fabric, or metal, depending on the specific application. For mining, belts are often reinforced with steel cords or synthetic fibers to enhance their strength and resistance to wear and tear.

(3) Pulleys

Key components at both ends of the conveyor. The head pulley drives the belt, while the tail pulley maintains tension. Pulleys may have specialized surfaces to improve grip and reduce slippage.

(4) Idlers and Rollers

Support the belt along its length. Idlers are strategically placed to prevent sagging and ensure smooth movement. They can be flat or trough-shaped to support the belt and the material being transported.

(5) Drive System

Typically includes electric motors and gearboxes. The drive system must be powerful enough to move the belt and its load over long distances, and it often includes features like variable speed controls to adjust the belt speed as needed.

(6) Controls and Safety Features

Modern conveyors are equipped with advanced control systems to monitor and manage their operation. Safety features such as emergency stop buttons, guards, and sensors help prevent accidents and ensure safe operation.

Application of Belt Conveyor

- Overburden Removal in Surface Mining

Mining belt conveyors are essential tools for removing overburden, which includes soil and rocks covering valuable minerals. These conveyors efficiently transport this material away from mining sites, ensuring smooth excavation processes and preparing the site for ore extraction. - Ore Transport in Surface Mining

Belt conveyors play a critical role in transporting raw ore from mining sites to processing plants or stockpiles. This streamlined material handling system improves operational efficiency by reducing time and labor costs associated with ore movement. - In-Pit Crushing and Conveying (IPCC) in Surface Mining

Conveyors are a key part of IPCC systems, where material is crushed in-pit and transported via conveyor belts. This system minimizes the reliance on truck haulage, reducing fuel consumption, operational costs, and environmental impact. - Material Haulage in Underground Mining

In underground mining, belt conveyors are used to transport extracted materials, such as ore or coal, from deep within the mine to the surface. This ensures a continuous and efficient material flow, even in challenging underground conditions. - Ore Handling in Underground Mining

Conveyors are vital for moving ore to crushers or processing stations located underground. Their reliability and efficiency are crucial for maintaining uninterrupted operations and ensuring the timely processing of extracted materials. - Waste Transport in Underground Mining

Mining operations generate significant waste materials, which must be transported to designated areas. Belt conveyors provide an efficient solution for waste disposal, ensuring proper site management and reducing environmental hazards.

Belt Conveyor Parts

- Conveyor Idler

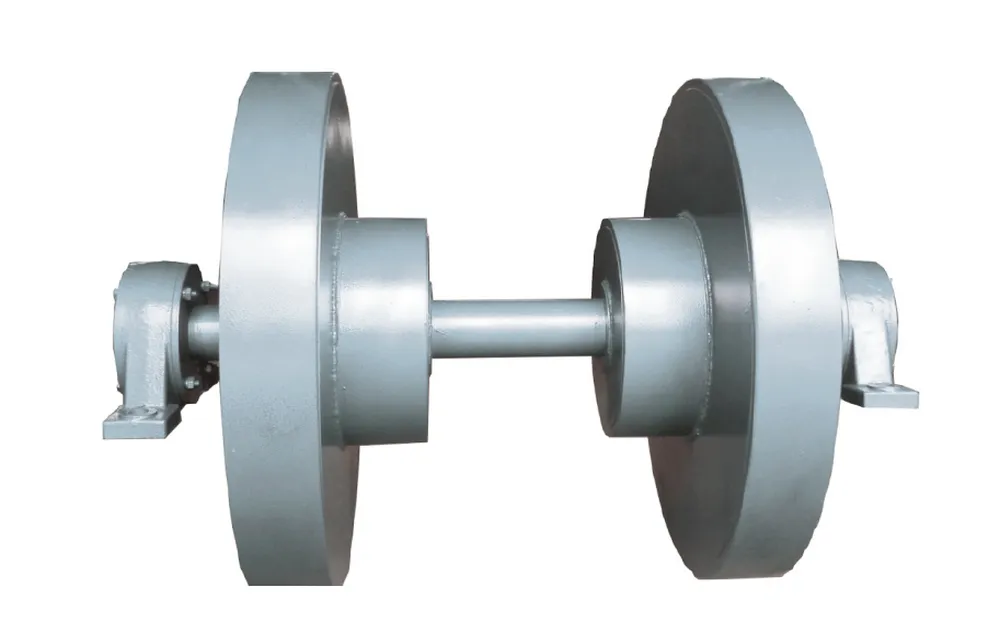

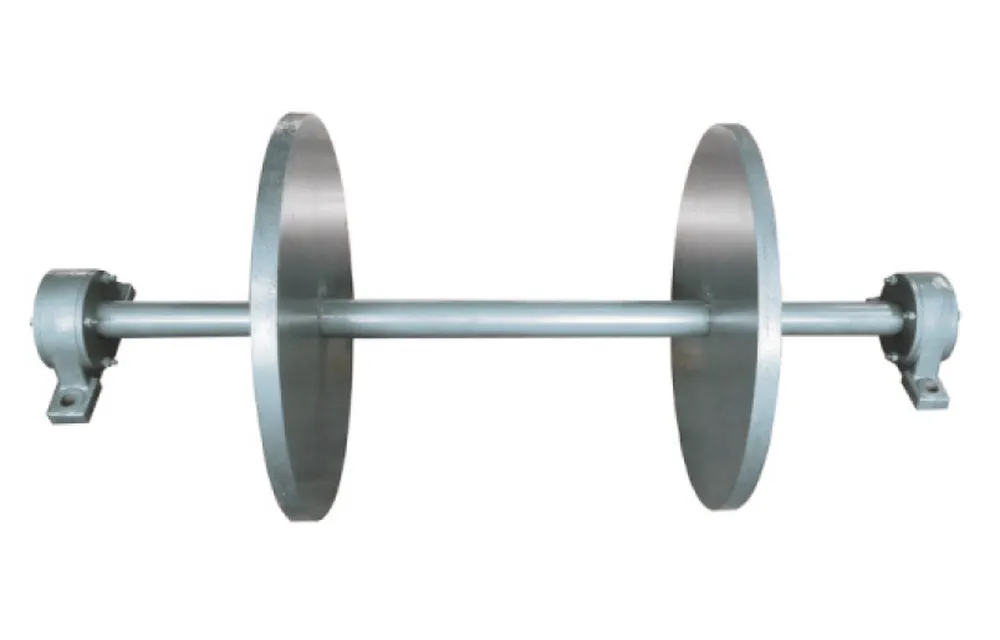

Conveyor idlers are cylindrical rollers supporting the belt and load in a mining conveyor system. Positioned along the frame, they reduce friction, ensuring smooth belt movement. Available in types like troughing or flat, they withstand heavy loads and harsh conditions, enhancing belt stability and longevity in ore or coal transport. - Conveyor Pulley

Conveyor pulleys are critical components driving or redirecting the belt. Drive pulleys, powered by motors, propel the belt, while tail or bend pulleys guide it. Constructed from durable steel, they ensure reliable operation under high tension, handling heavy mining materials like aggregates with minimal slippage or wear. - Conveyor Belt Roller

Conveyor belt rollers support the belt and material load, reducing sagging and friction. Mounted on frames, they facilitate smooth transport of ores or coal. Heavy-duty designs resist abrasion and impact, ensuring consistent performance in rugged mining environments, with options for sealed bearings to prevent dust ingress.

- Conveyor Belt Cleaner

Conveyor belt cleaners remove residual material from the belt surface, preventing carryback that causes spillage or damage. Primary and secondary scrapers, made of polyurethane or tungsten, ensure clean operation. In mining, they reduce maintenance and improve efficiency by keeping belts free of sticky or abrasive materials.

Conveyor Transfer Chute

Conveyor transfer chutes guide materials from one conveyor to another or onto stockpiles, minimizing spillage and dust. Lined with wear-resistant materials like ceramic, they handle abrasive ores efficiently. Proper design reduces belt wear and material degradation, ensuring smooth flow in high-volume mining operations.

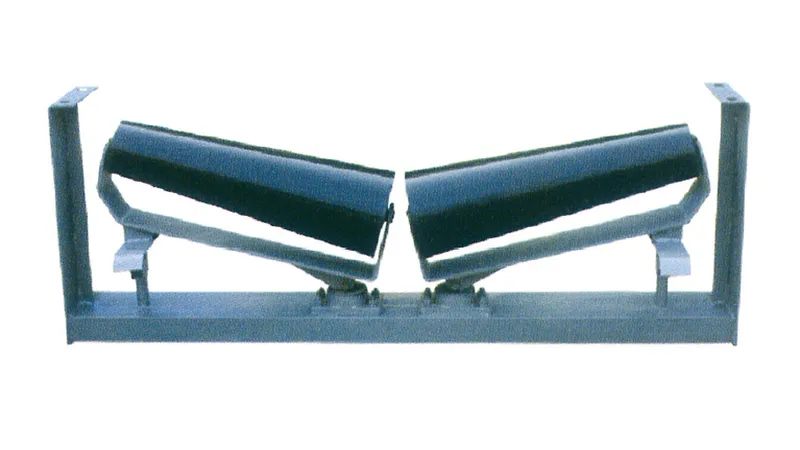

Conveyor Idler Bracket

Conveyor idler brackets are steel frames securing idlers to the conveyor structure, ensuring proper alignment and stability. Designed for heavy-duty mining use, they resist corrosion and vibration, supporting consistent belt tracking. Easy-to-install designs reduce maintenance time, enhancing reliability in transporting bulk materials like coal or ore.

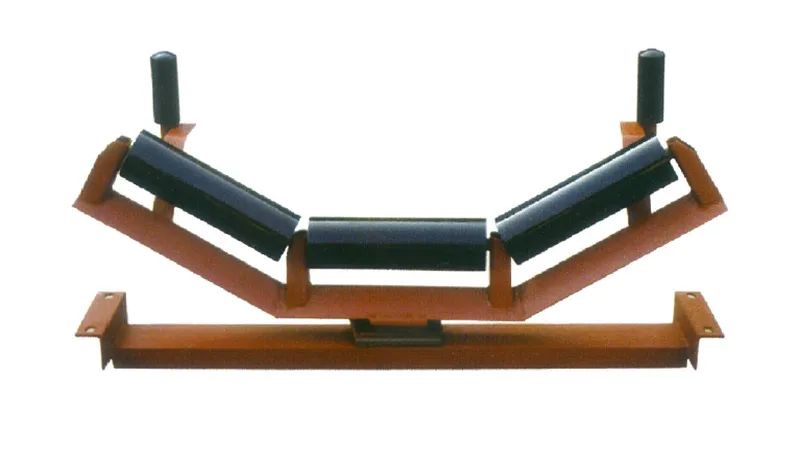

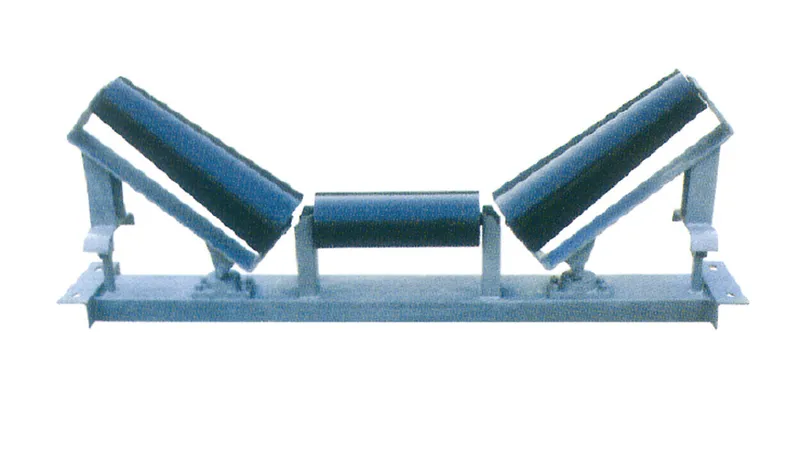

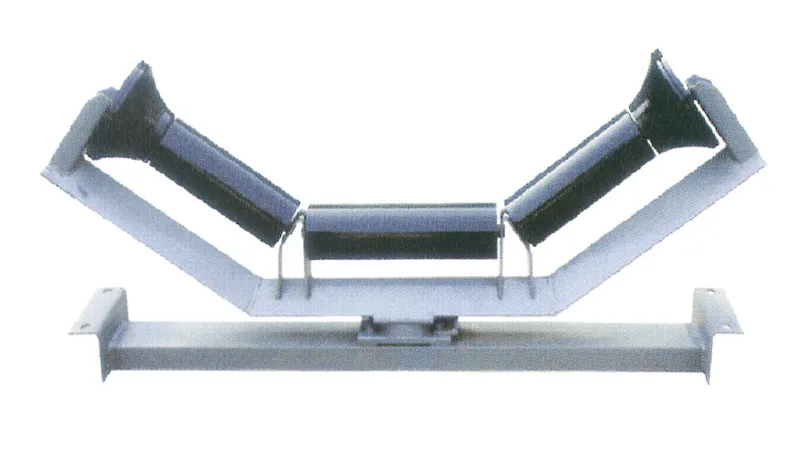

Trough Self-Aligning Idler

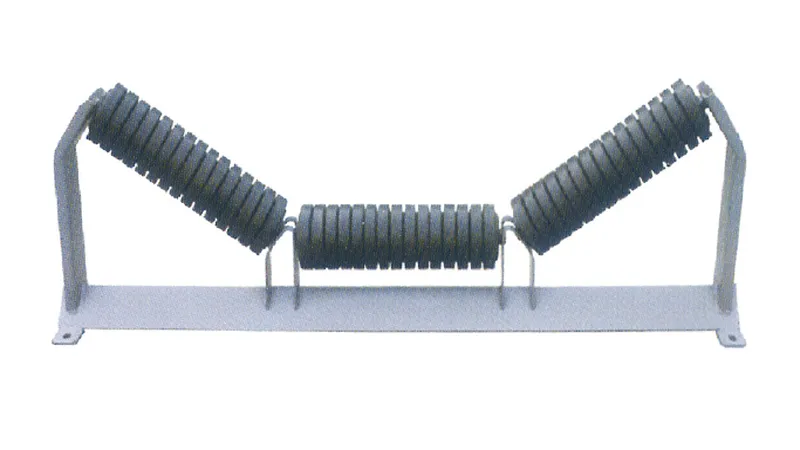

Impact Idler

Lower Friction Self-Aligning Idler

Taper Self-Aligning Idler

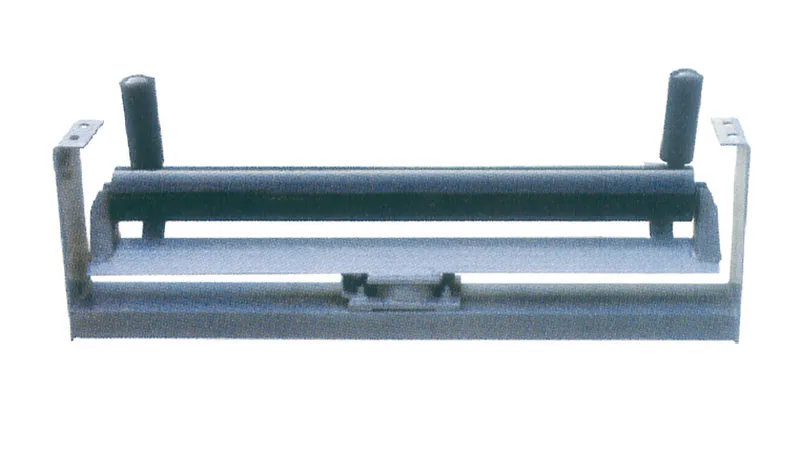

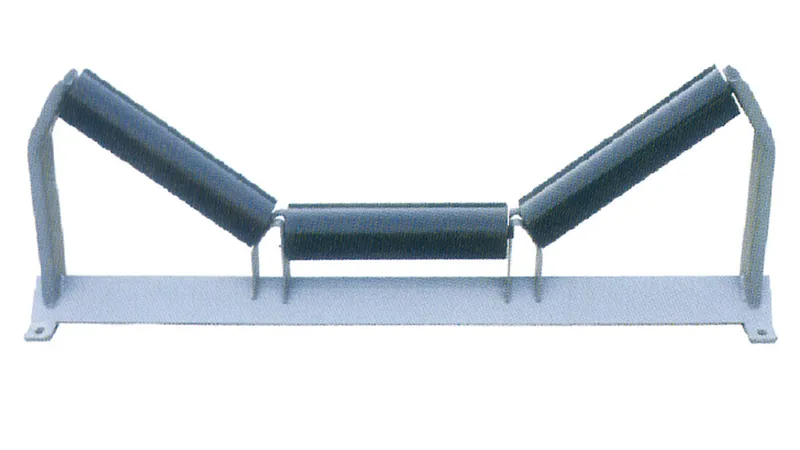

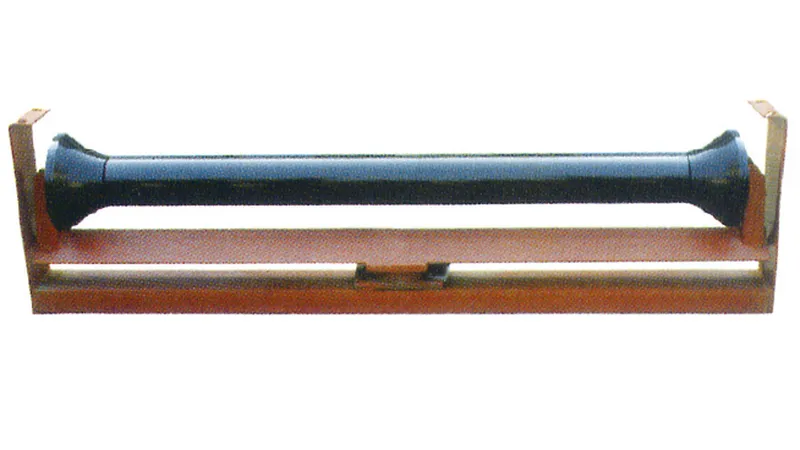

Lower Parallel Idler

Lower Taper Self-Aligning Idler

Upper Parallel Idler

Impact Self-Aligning Idler

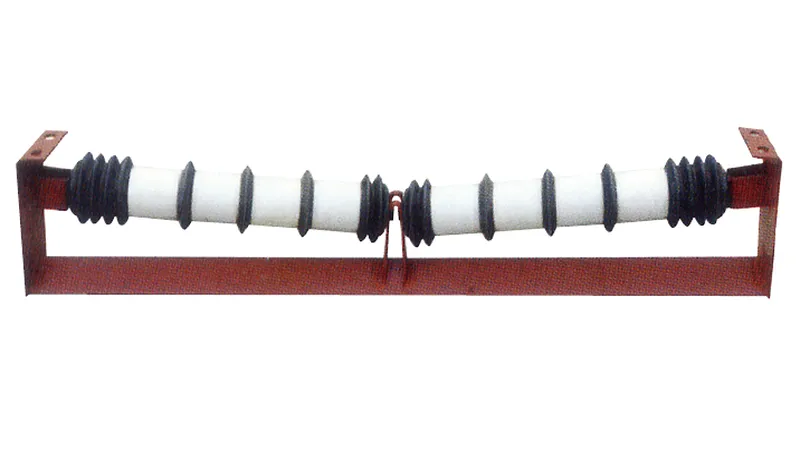

Trough Idler

Lower Impact Self-Aligning Idler

Upper Friction Flat Self-Aligning Idler

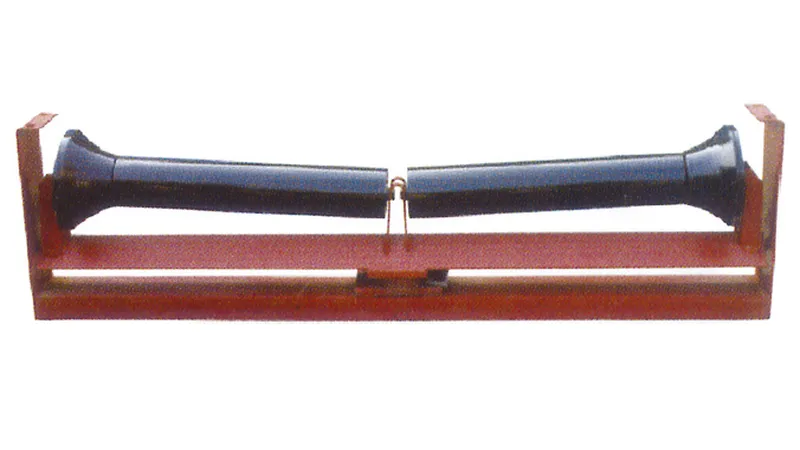

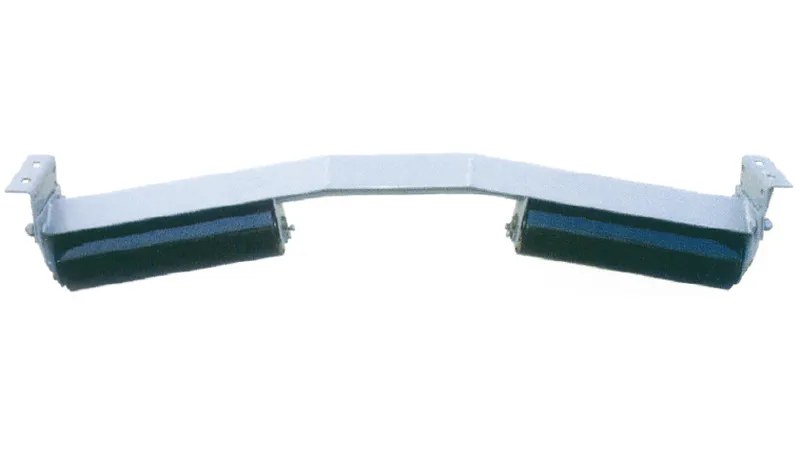

Inverted V-Shaped Idler

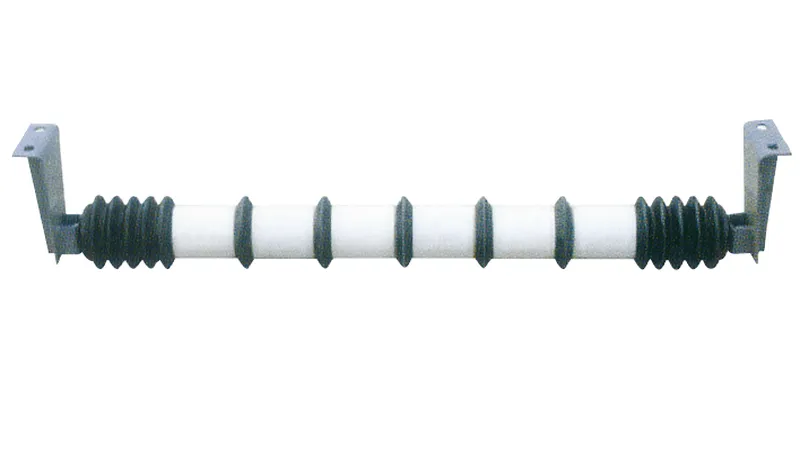

Paralle Comb Idler

Screw Idler

V-Shaped Comb Idler

V Type Idler

Belt Conveyor Pulleys

Belt Conveyor Rollers

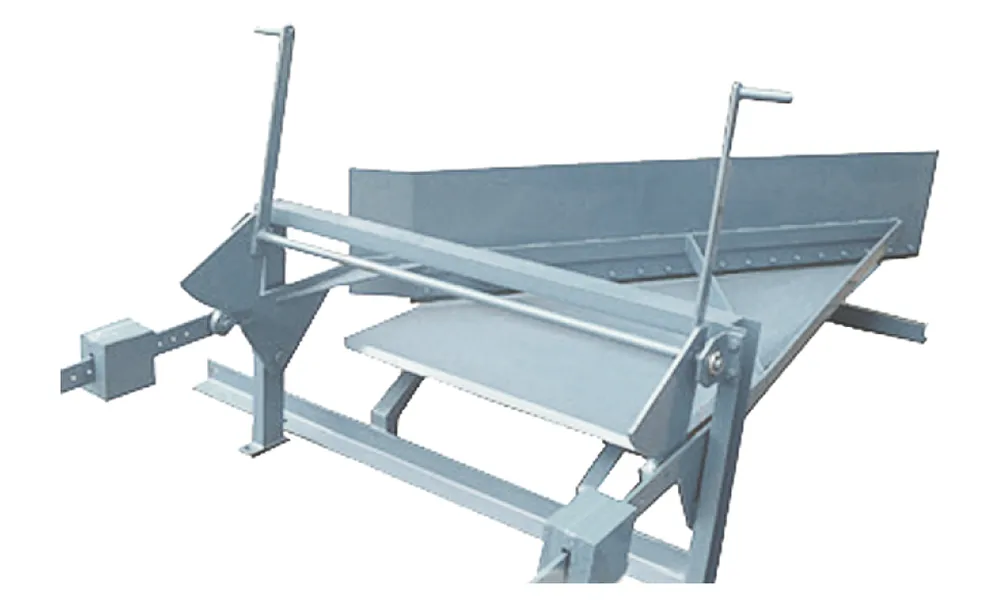

Tripper Car

Tripper Car

Nonloaded Cleaner

Manual Plow Unloader

Alloy Rubber Cleaner (P Type)

Alloy Rubber Cleaner (H Type)

Diversion Pressure Wheel

Diversion Roller

ZL Type Elastic Pin Tooth Coupling

Backstop

Vertical Take-Up

Screw Take-Up